Method for preparing organic lactone

An organic and lactone technology is applied in the field of catalysis of organic ketone oxidation to prepare organic lactone, can solve the problems of low efficiency, difficult recycling of catalyst, low catalyst activity and selectivity, and achieves simple preparation, good industrial application prospect, The effect of cheap catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

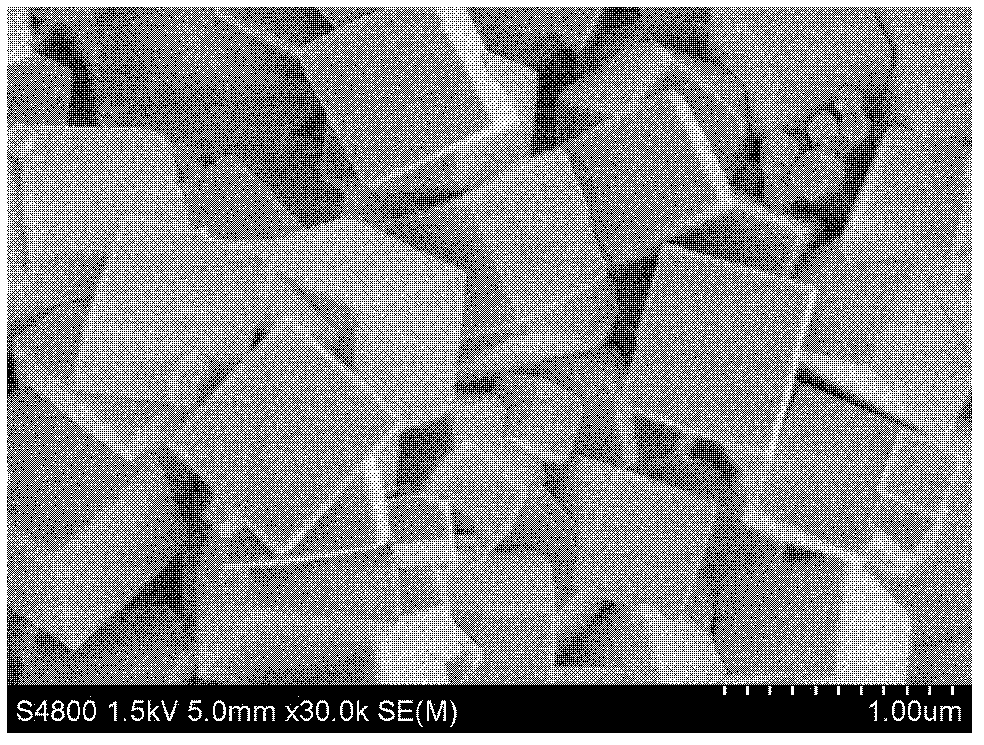

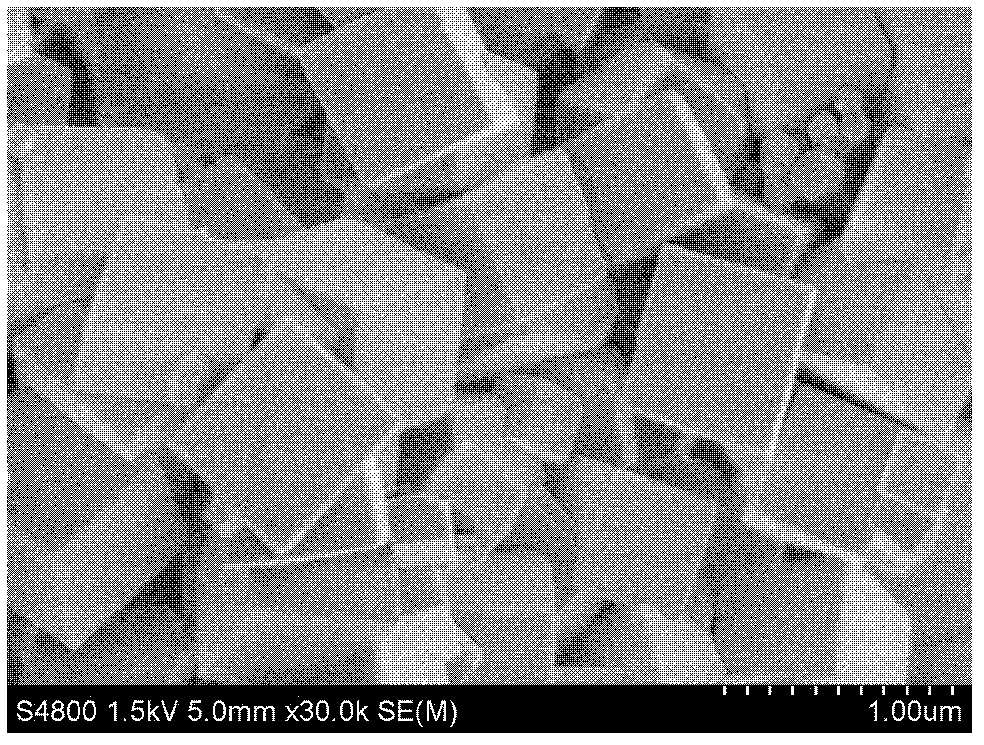

Image

Examples

Embodiment 1

[0033] In the three-necked glass bottle, add successively 0.5 grams of the above-mentioned cubic cobalt tetraoxide catalyst synthesized, 10 grams of cyclopentanone, 10 grams of benzaldehyde and 200 milliliters of carbon tetrachloride, feed oxygen, and the flow rate of oxygen is 100 milliliters / minute, while stirring After reacting at 40° C. for 3 hours, gas chromatography-mass spectrometry analysis results showed that the product was the target product valerolactone, and gas chromatography analysis results showed that the selectivity and yield of valerolactone were 100% and 99%, respectively. After the catalyst was recycled 10 times, the selectivity and yield of valerolactone were still 100% and 99.2%, respectively.

Embodiment 2

[0035] Add 0.2 grams of the above-mentioned cubic cobalt tetroxide catalyst, 10 grams of cyclohexanone, 20 grams of butyraldehyde and 200 milliliters of 1,2-dichloroethane in the three-necked glass bottle successively, and feed oxygen at a flow rate of 200 milliliters / Minutes, after stirring for 1 hour at 80°C, the gas chromatography-mass spectrometry analysis results showed that the product was the target product caprolactone, and the gas chromatography analysis results showed that the selectivity and yield of caprolactone were 100% respectively and 99.5%.

Embodiment 3

[0037] Add 0.8 grams of the above-mentioned cubic cobalt tetroxide catalyst, 10 grams of 2-methylcyclohexanone, 40 grams of p-chlorobenzaldehyde and 200 milliliters of acetonitrile into the three-necked glass bottle successively, and feed oxygen at a flow rate of 400 milliliters / minute , after reacting at 30°C under stirring for 9 hours, the gas chromatography-mass spectrometry analysis results showed that the product was the target product 2-methylcaprolactone, and the gas chromatography analysis results showed that the selectivity of 2-methylcaprolactone and yields are both 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com