Method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas

A technology of tricalcium phosphate and low calorific value, which is applied in the field of tricalcium phosphate and calcium phosphate, and can solve the problems of high cost of feed grade tricalcium phosphate and insufficient environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

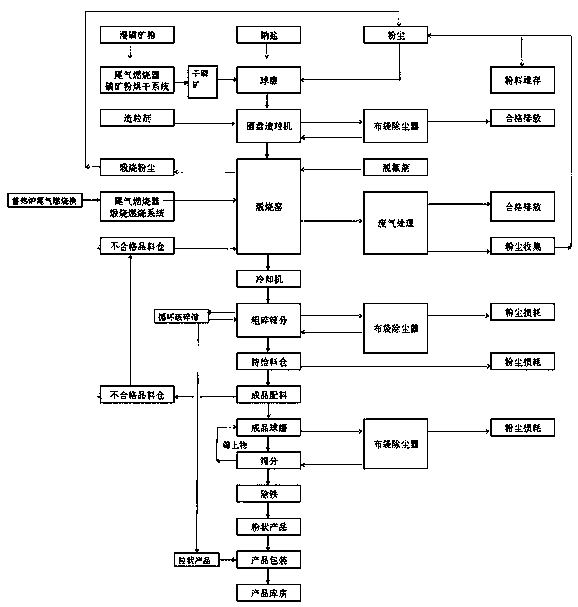

Image

Examples

Embodiment Construction

[0039] A certain company adopts the method for producing feed grade tricalcium phosphate by utilizing low calorific value tail gas provided by the invention, and the main steps are as follows:

[0040] (1) Drying of phosphate rock powder

[0041] Send the wet phosphate rock powder into the dryer so that the moisture content after drying can meet the process requirements; among them, in the phosphate rock powder drying process, the drying kiln uses low calorific value tail gas to burn, and the drying temperature is 150 ° C to 1000 ° C. Drying method: downstream or countercurrent; after drying, the moisture content of phosphate rock powder is controlled to ≤5%; the drying and combustion device is a low calorific value tail gas combustion device, and the combustion temperature is 600 ° C ~ 1200 ° C; the quality of the effective combustion components in the low calorific value tail gas A score of 95%;

[0042] The composition of described wet phosphate rock powder is calculated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com