Patents

Literature

156results about How to "Reduce quality fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wide heavy standard high strength ship plate steel and technique for producing the same

InactiveCN101418417AIncrease productivitySimple production processTemperature control deviceMetal rolling arrangementsHeating timeHeating furnace

The invention relates to high-strength steel and a process for producing the same. The components of high-strength ship plate steel by width-thickness specification are as follows: 0.04 to 0.16 percent of C, 1.20 to 1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.10 to 0.30 percent of Si, less than or equal to 0.40 percent of Ni, 0.020 to 0.060 percent of Alt, 0.02 to 0.05 percent of Nb, less than or equal to 0.02 percent of Ti, less than or equal to 0.012 percent of N, and the balance being Fe. The temperature in a smelting and heating furnace is between 1180 and 1220 DEG C, and the heating time is between 3.0 and 4.0 hours; the starting temperature for rough rolling is between 1080 and 1120 DEG C, and the rough rolling is performed for 4 to 6 times; the starting temperature for finish rolling is between 800 and 900 DEG C, and the finish rolling is performed for 4 to 9 times, and the finishing temperature is between 800 and 830 DEG C; and the starting water spray cooling temperature for cold control is between 780 and 820 DEG C, and the finishing water spray cooling temperature is between 600 and 720 DEG C. The invention has the advantages of simple process, high production efficiency, stable product performance, and mall quality fluctuation.

Owner:NANJING IRON & STEEL CO LTD

Steel for large-thickness hardening and tampering ocean platform and production method thereof

InactiveCN101709432AReasonable design of chemical compositionIncreasing the thicknessHeat treatment process controlSheet steelChemical composition

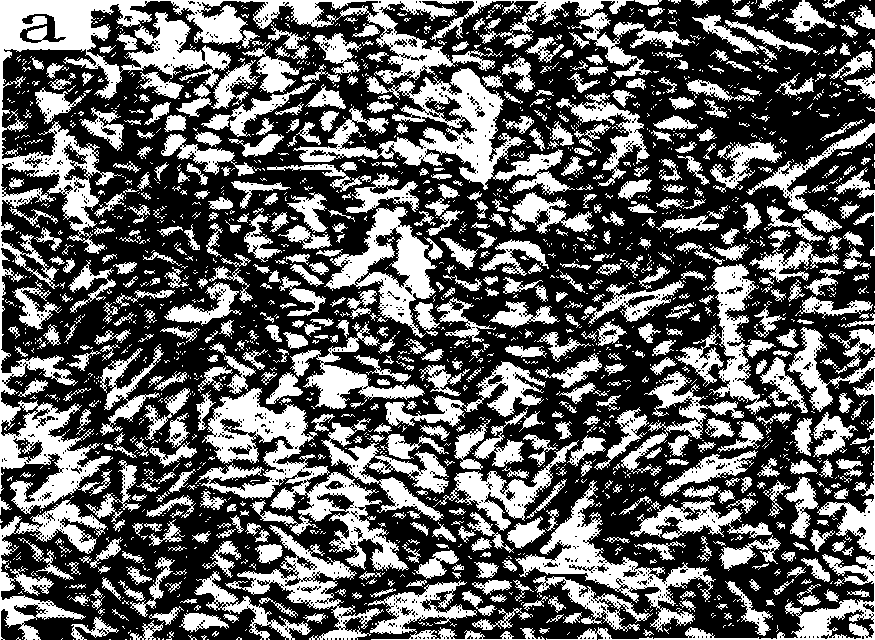

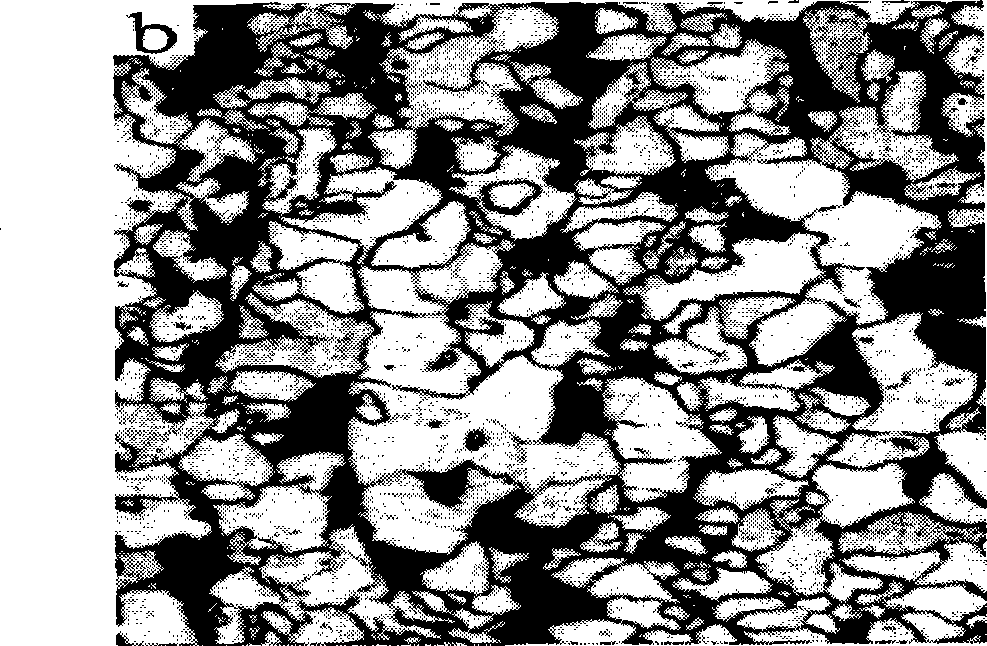

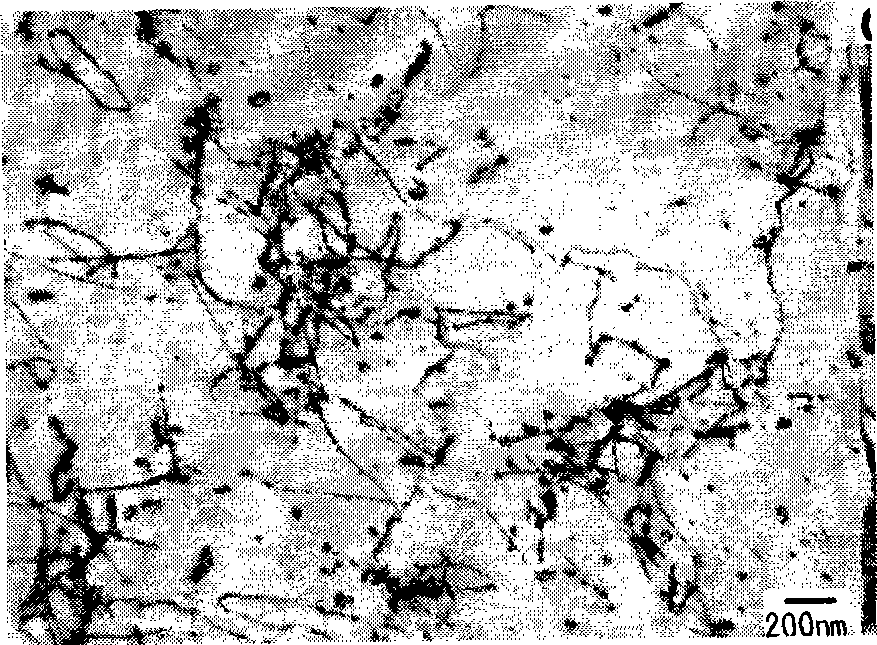

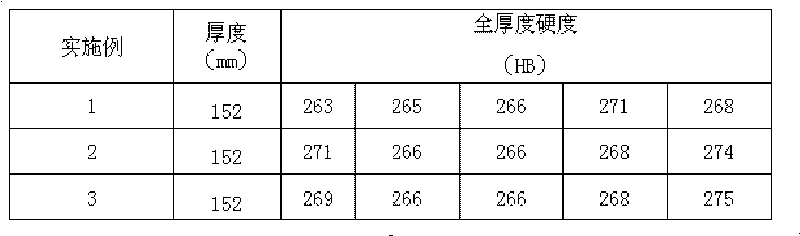

The invention discloses steel for a large-thickness hardening and tampering ocean platform, comprising the following components: 0.16 to 0.18 wt% of C, 0.15 to 0.35 wt% of Si, 1.10 to 1.15 wt% of Mn, no more than 0.015 wt% of P, no more than 0.005 wt% of S, 1.30 to 1.40 wt% of Ni, 1.20 to 1.30 wt% of Cr, 0.05 to 0.10 wt% of Cu, 0.45 to 0.55 wt% of Mo, 0.03 to 0.04 wt% of Nb, 0.020 to 0.025 wt% of Ti, 0.05 to 0.06 wt% of V, 0.02 to 0.04 wt% of Al, 0.0014 to 0.0023 wt% of B and balance of Fe and inevitable impurities. The production method comprises the steps of smelting, casting, heating, rolling, hardening, tempering and cutting to obtain a final product steel plate. The produced steel plate has reasonable design of the chemical components, low cost, large thickness (reaching 152mm), high strength, favorable impact toughness and favorable welding performance, and passes the factory certifications of DNV and CCS Classification Societies. The production process of the steel plate is simple and easy to operate, and the performance of each batch of steel is stable.

Owner:WUYANG IRON & STEEL +1

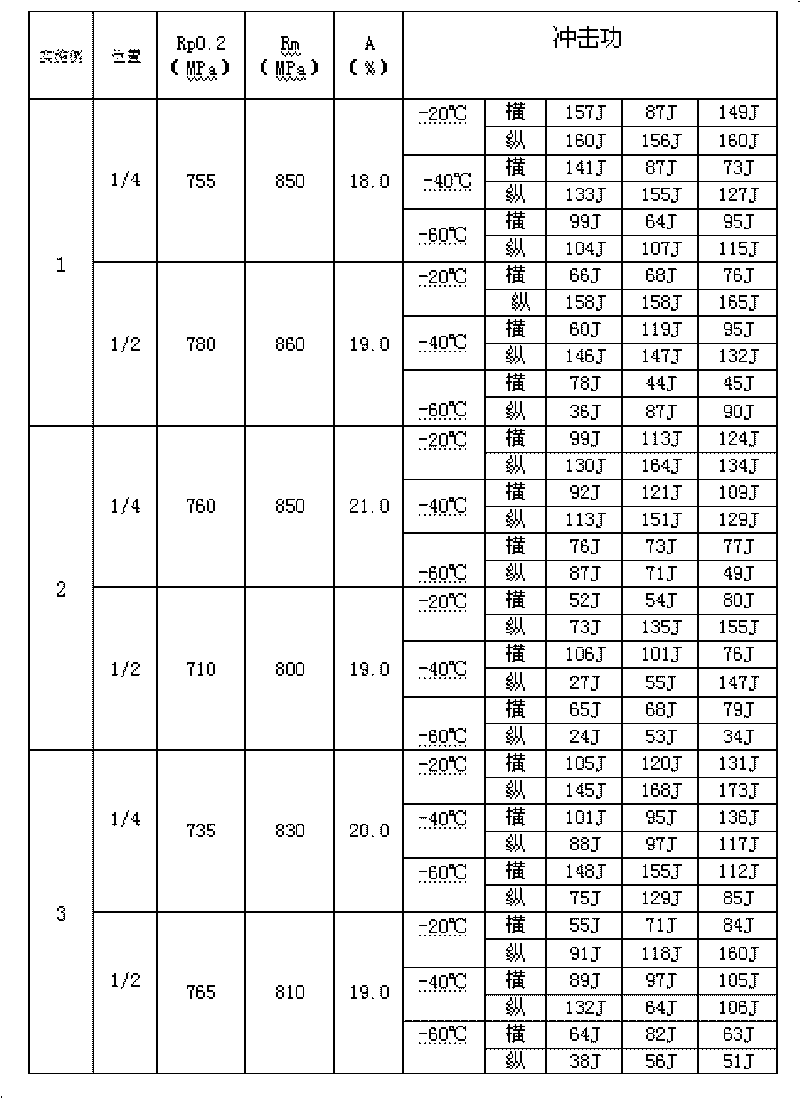

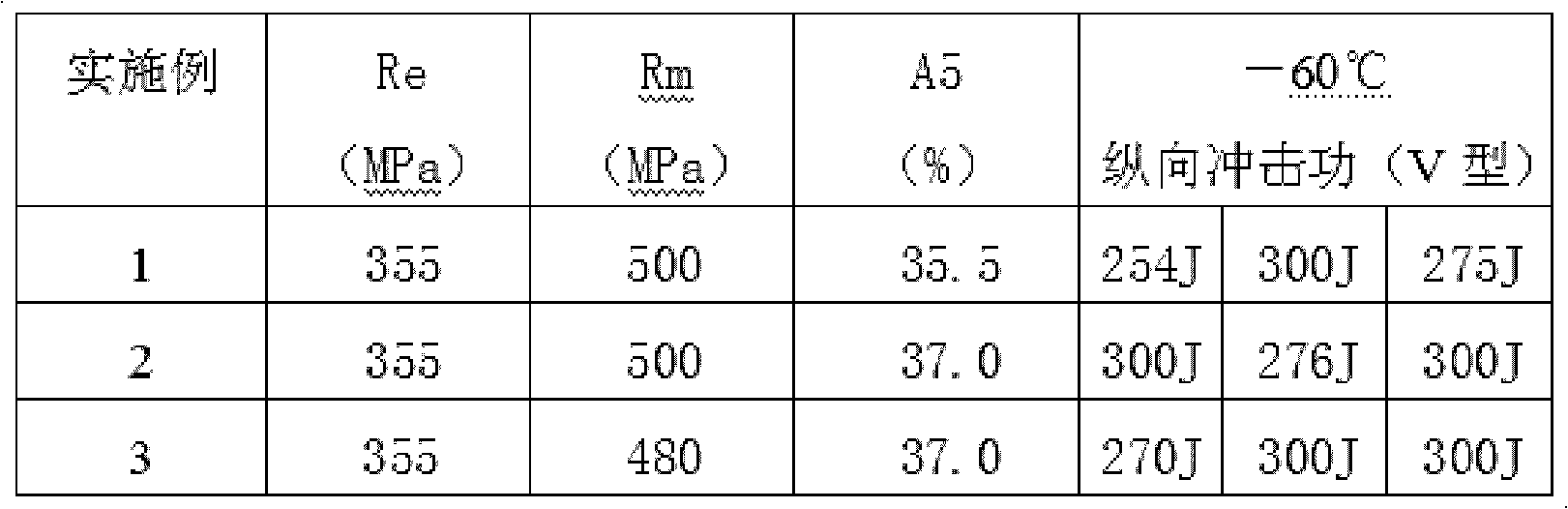

Low-temperature high-toughness ship plate steel and production method thereof

InactiveCN101876033AIncreasing the thicknessHigh strengthTemperature control deviceProcess efficiency improvementChemical compositionSheet steel

The invention discloses a low-temperature high-toughness ship plate steel which comprises the following components in percentage by mass: at most 0.16% of C, 0.10-0.50% of Si, 0.90-1.60% of Mn, at most 0.025% of P, at most 0.025% of S, at most 0.80% of Ni, at most 0.20% of Cr, at most 0.35% of Cu, at most 0.08% of Mo, at most 0.02% of Ti, and balance of Fe and inevitable impurities. The production method comprises the following steps: electrosmelting, LF external refining, vacuuming with a VD furnace, casting, heating, controlled-rolling, straightening, shot-blasting, quenching, normalizing and cutting to obtain the finished steel plate. The steel plate has the advantages of reasonable design of chemical components, low cost, large thickness (up to 110 mm), high strength (Re>=350 MPa, Rm>=480MPa, A5 / %>=35) and high toughness under low-temperature impact, and the longitudinal impact work at -60 DEG C is greater than or equal to 250 J. The invention has the advantages of simple production technique, stable product performance and small quality fluctuation.

Owner:WUYANG IRON & STEEL +1

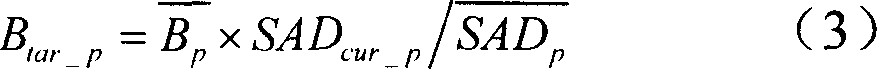

Video compression code ratio control method using uneven distribution of frame target bit number

InactiveCN1909662AQuality improvementGuaranteed stabilityTelevision systemsDigital video signal modificationVideo monitoringVideo quality

The invention relates to a video compression code rate control method which uses non-uniform distribution of frame target bits, wherein it comprises: first, setting the video code buffer; then distributing bit for each GOP; then controlling the frame-jump on present coded P frames; distributing bits for present coded P frames. Said method con support different video compression standards as H.263, MPEG-4 and H.264; the applied video sequence mode is GOP mode; said code mode can be used in video detection and network TV, etc. Compared with traditional method, the invention is easy, with improved video quality and reduced quality fluctuation, while it can confirm the stability of buffer when switching views.

Owner:ZHEJIANG UNIV

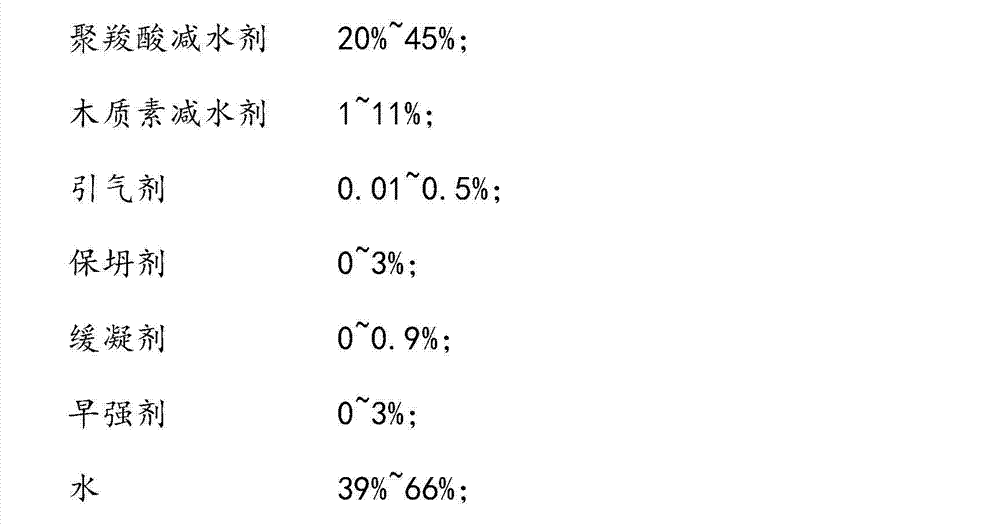

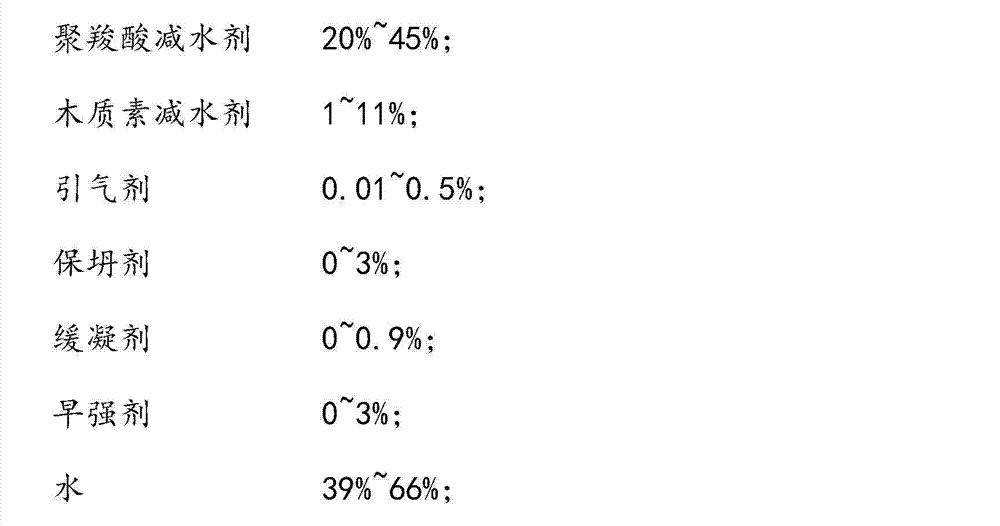

Polycarboxylic acid-lignin composite additive

The invention discloses a polycarboxylic acid-lignin composite additive. The additive is characterized in that: the additive is composed of the components of, by weight: 20-45% of a polycarboxylic acid water reducer, 1-11% of a lignin water reducer, 0.01-0.5% of an air-entraining agent, 0-3% of a slump-retaining agent, 0-0.9% of a retarding agent, 0-3% of an early strength agent, and 39-66% of water. The total amount of the components accounts for 100% by mass. When the contents of the slump-retaining agent and the retarding agent are not 0, the content of the early strength agent is 0. When the content of the early strength agent is not 0, the contents of the slump-retaining agent and the retarding agent are both 0. According to the invention, the polycarboxylic acid water reducer and the lignin water reducer are complexed. Compared with a single polycarboxylic acid water reducer or a single lignin water reducer, under a same concrete water reducing rate, the dosage of the polycarboxylic acid component is reduced, and the cost is reduced. The quality of the concrete is easy to control, and quality fluctuation is reduced. The water reducing rate of the concrete is improved. When the additive is added into concrete, the quality of the concrete is improved.

Owner:上海市建筑构件制品有限公司

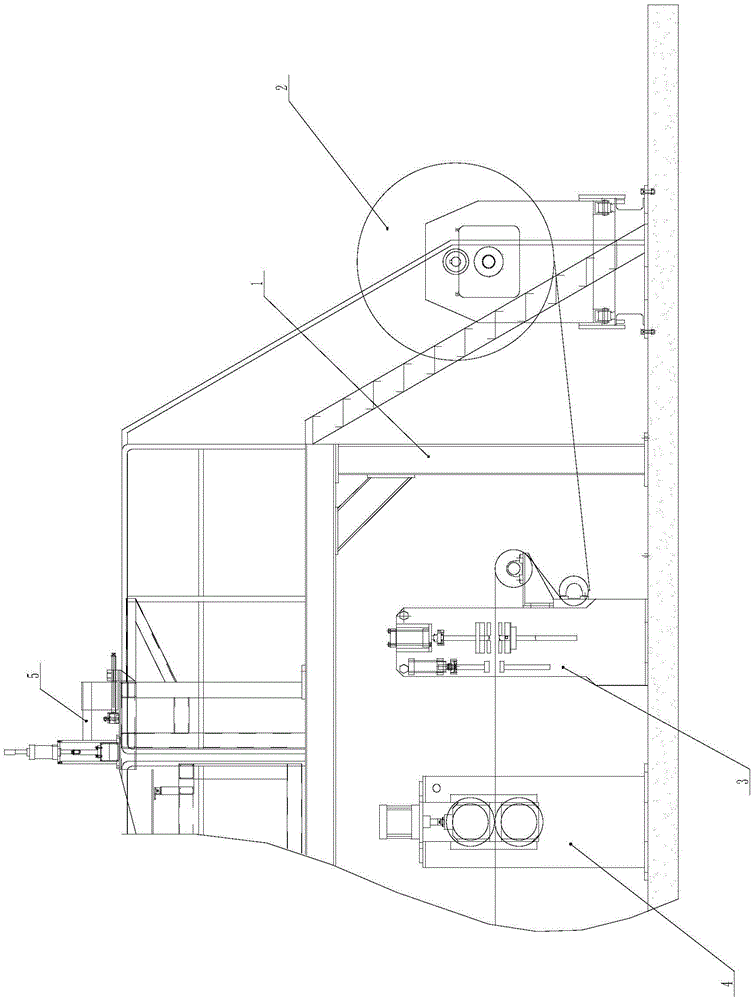

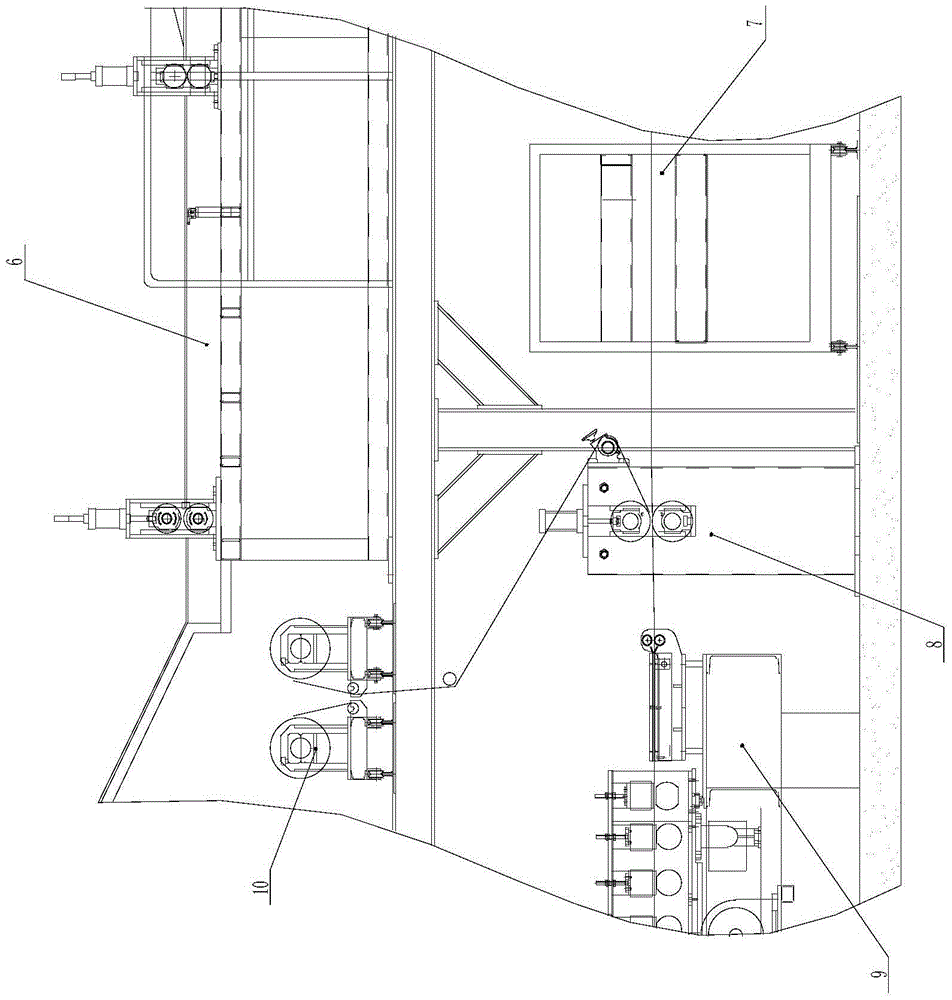

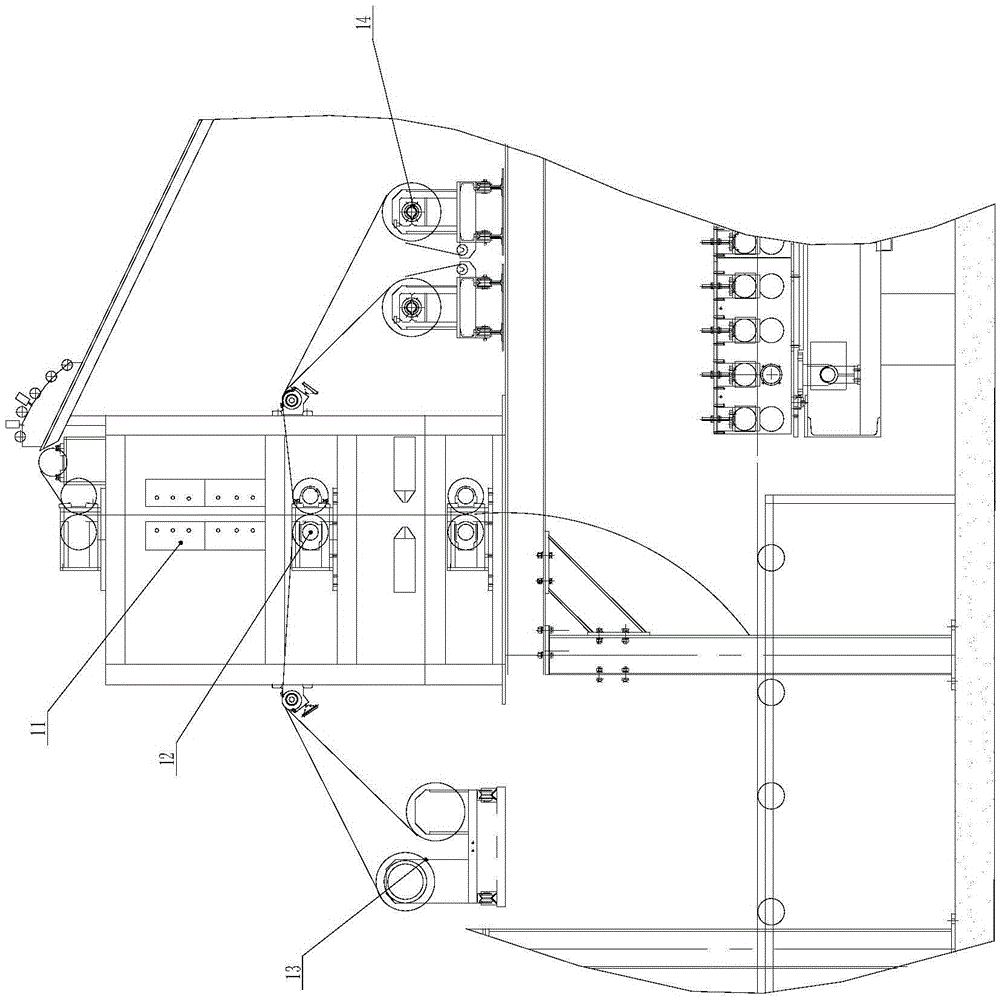

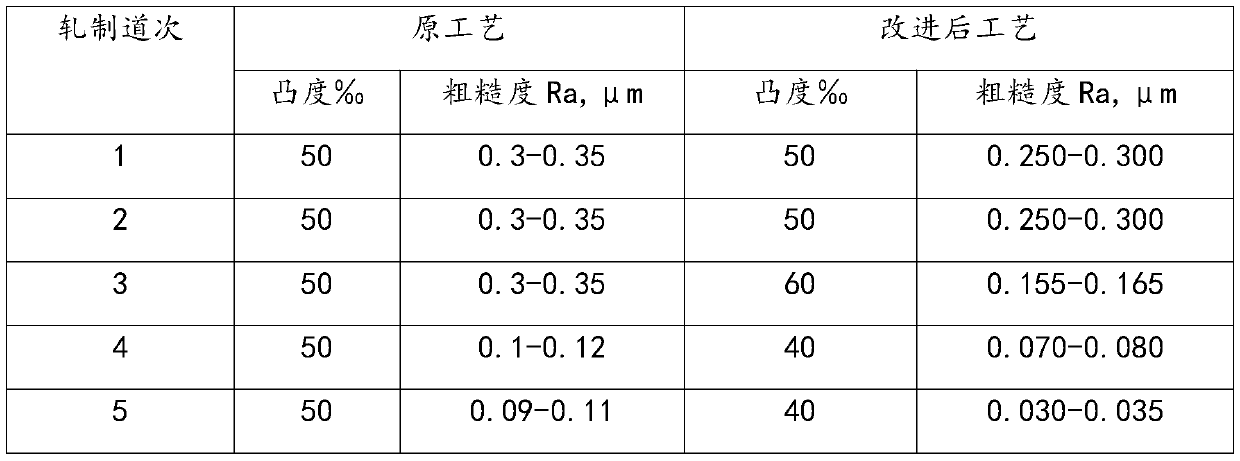

Continuous and automatic production line for aluminum honeycomb composite boards and continuous production process

InactiveCN105538870AFit tightlyReduce manual involvementLamination plant layoutLaminationProduction lineAluminum honeycomb

The invention discloses a continuous and automatic production line for aluminum honeycomb composite boards. The continuous and automatic production line comprises a rack, an aluminum honeycomb core layer forming unit, an upper-layer board forming unit, a lower-layer board forming unit and a composite forming unit. The aluminum honeycomb core layer forming unit achieves automation of splicing, stretching and unfolding aluminum honeycomb core strips into aluminum honeycomb core layers and coating the aluminum honeycomb core layers with polymeric membranes in advance, the upper-layer board forming unit and the lower-layer board forming unit are used for unreeling upper-layer boards and lower-layer boards and coating the upper-layer boards and the lower-layer boards with polymeric membranes in advance respectively, and finally the three layers are compounded on the composite forming unit. The aluminum honeycomb composite boards can be continuously produced through the continuous production line, capacity is improved, the quality of the formed aluminum honeycomb composite boards is consistent, and the thickness is uniform.

Owner:张家港市弘扬机械设备有限公司

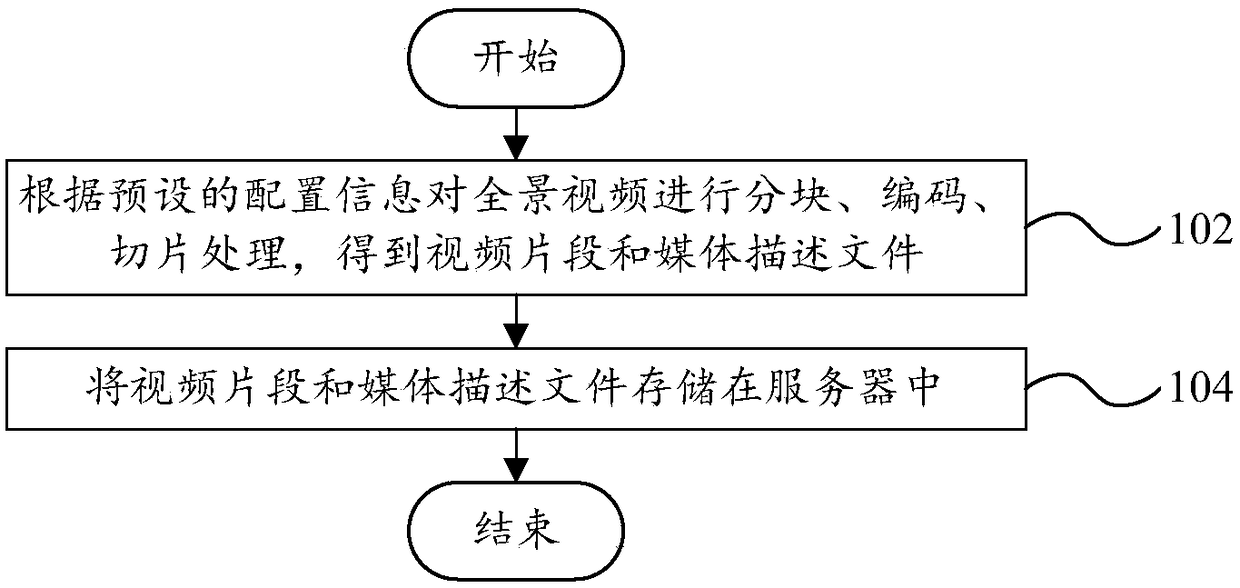

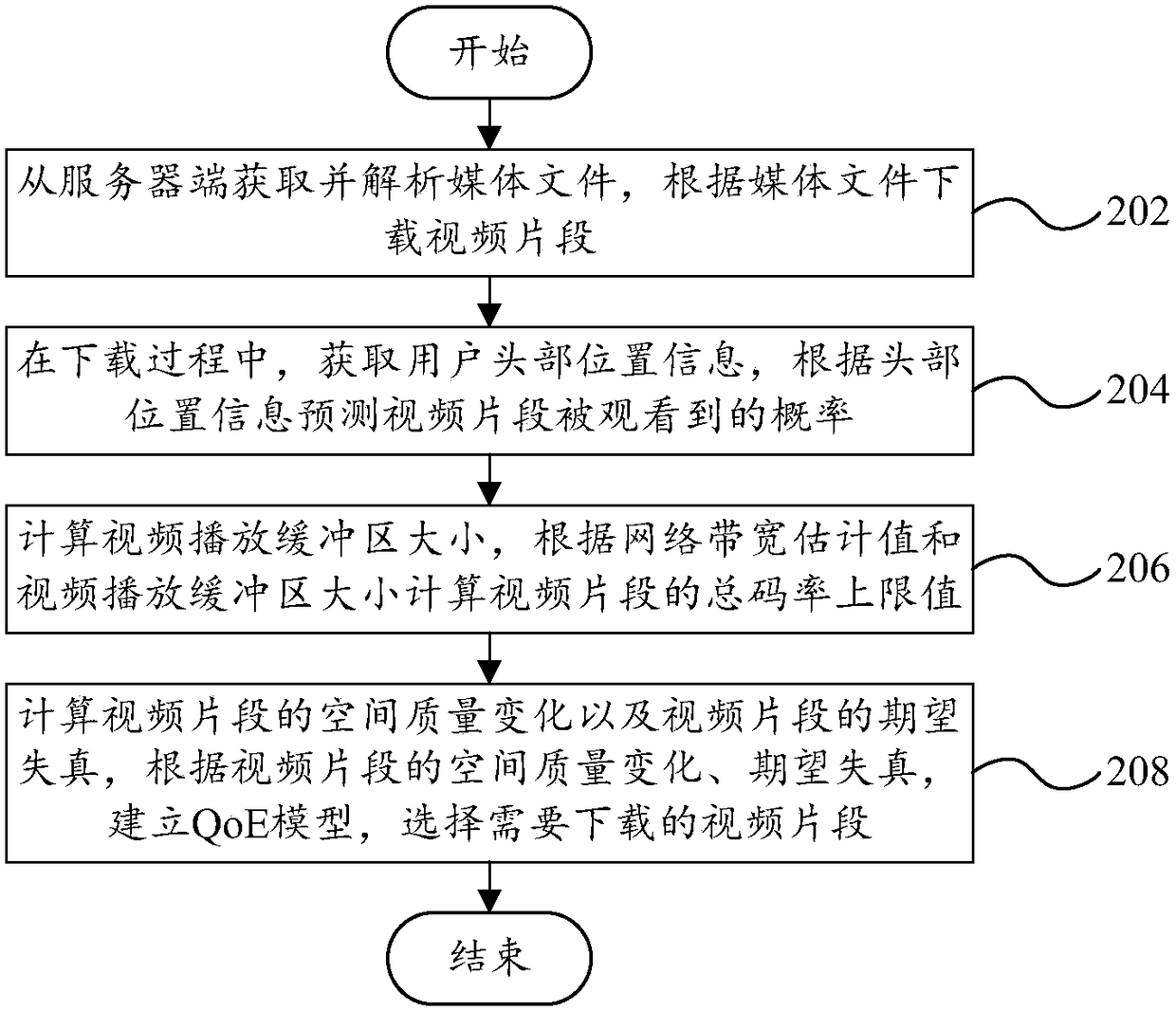

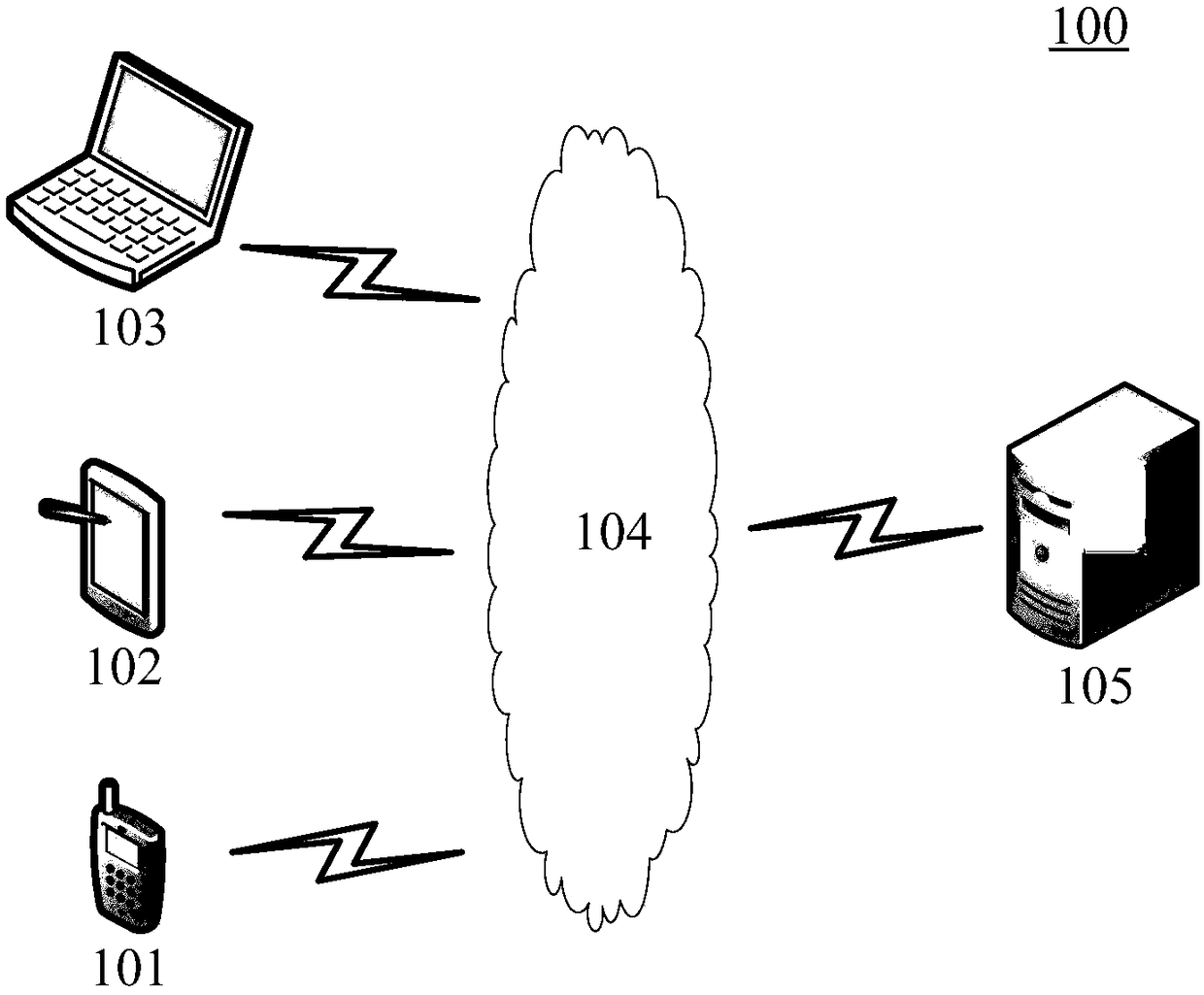

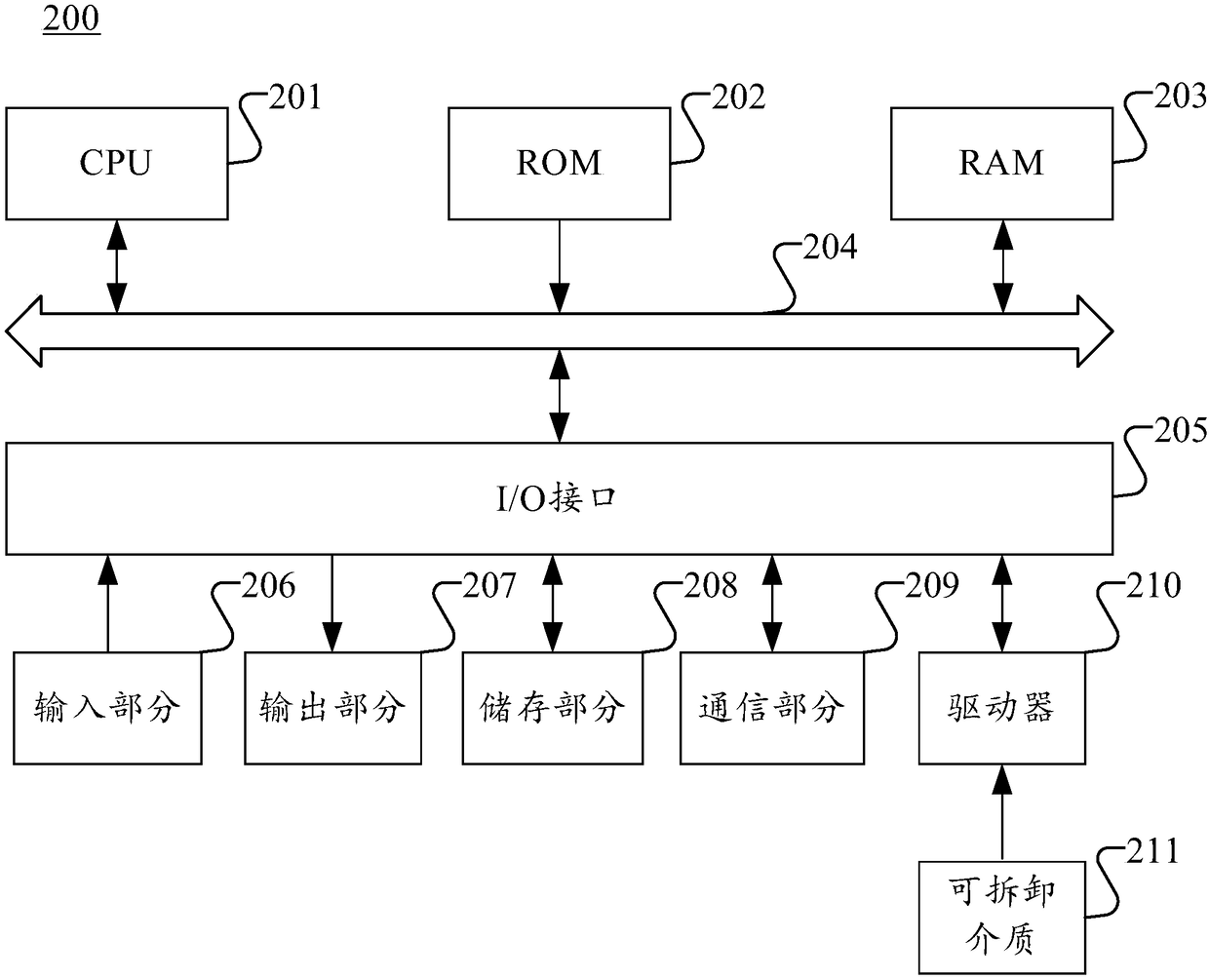

Panoramic video transmission method, transmission device and transmission system

InactiveCN109286855AQuality improvementReduce quality fluctuationsSelective content distributionComputer graphics (images)Video transmission

The invention provides a panoramic video transmission method, a transmission device and a transmission system, wherein the panoramic video transmission method is applied to a client and comprises thesteps of acquiring a media file from a server end and analyzing the file, and downloading video segments according to the media file; in a loading process, acquiring head position information of a user, and predicating viewing probability of the video segments according to the head position information; calculating the size of a video playing buffering area, and calculating a total code rate upperlimit of the video segments according to the estimated network bandwidth and the size of the video playing buffering area; calculating the spatial quality change of the video segments and the expected distortion of the video segments, establishing a QoE model according to the spatial quality change and the expected distortion of the video fragments, and selecting the to-be-downloaded video fragments. The panoramic video transmission method, the transmission device and the transmission system realize technical effects of reducing data volume in panoramic video transmission, improving video quality, reducing spatial quality fluctuation and lags in video playing.

Owner:PEKING UNIV

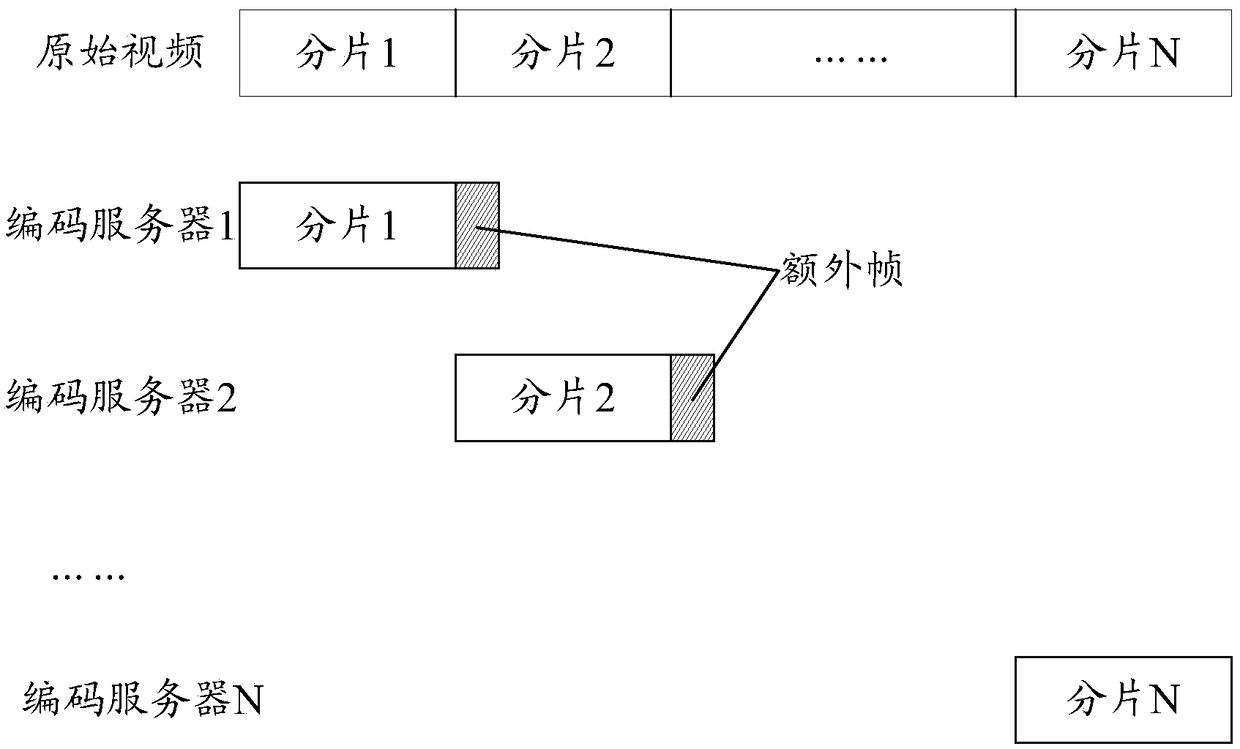

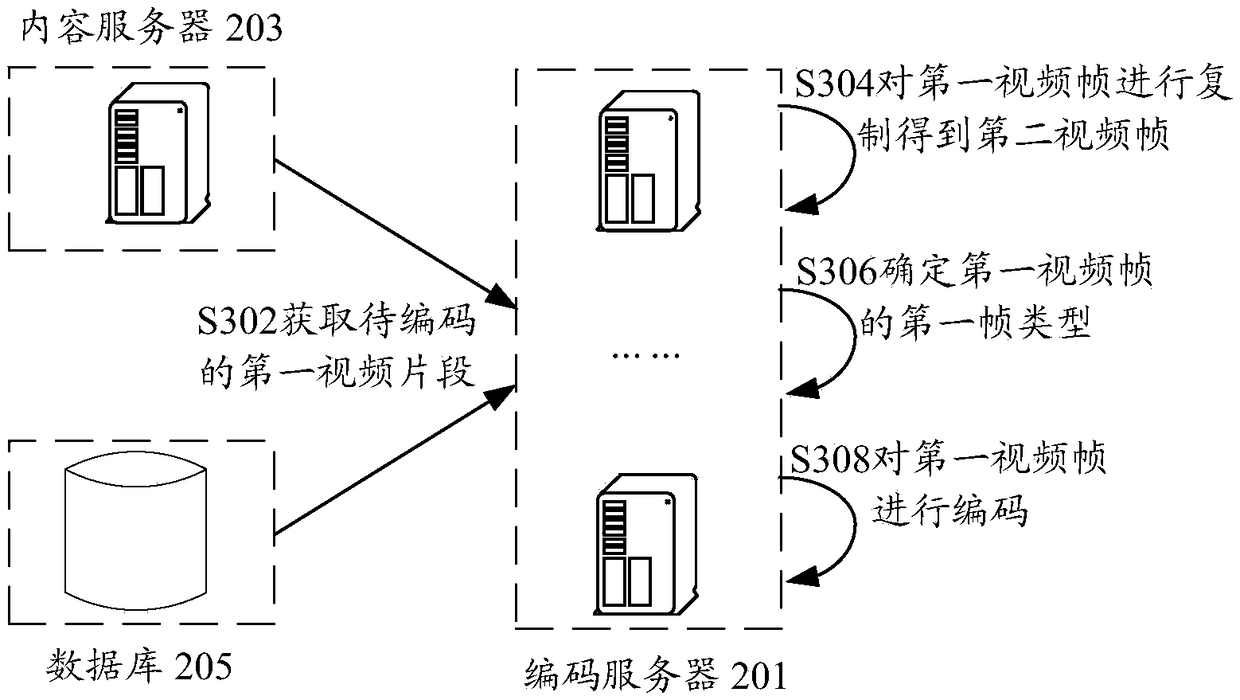

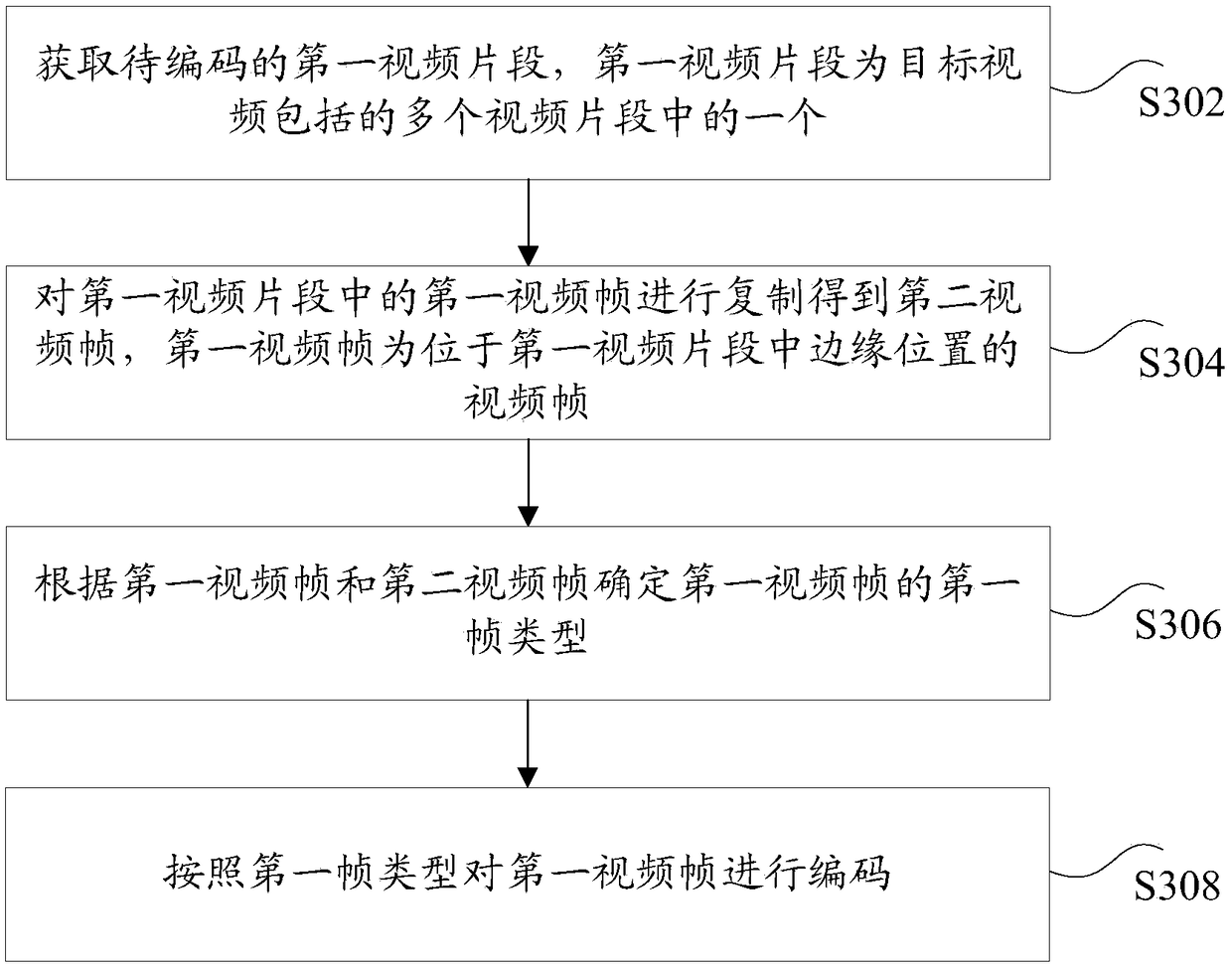

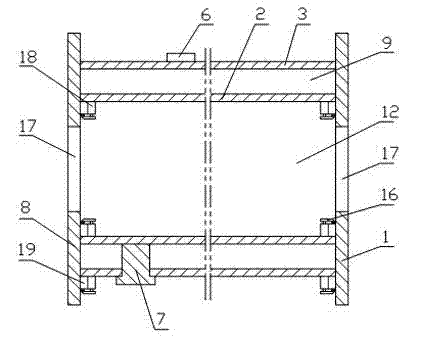

Video coding method and device, storage medium and electronic device

ActiveCN108650510AReduce quality fluctuationsSolve technical issues with loss of coherence in clarityDigital video signal modificationComputer graphics (images)Video image

The invention discloses a video coding method and device, a storage medium and an electronic device. The method comprises the following steps of acquiring a first video clip to be coded, wherein the first video clip is one of a plurality of video clips included in a target video, and each of the video clips is allocated to one corresponding encoder for encoding; copying a first video frame in thefirst video clip to obtain a second video frame, wherein the first video frame is a video frame located at the edge position in the first video clip; determining a first frame type of the first videoframe according to the first video frame and the second video frame; and encoding the first video frame according to the first frame type. According to the video coding method and device, the storagemedium and the electronic device, the technical problem that the definition of a video image loses coherence in the related technology is solved.

Owner:CENT SOUTH UNIV +1

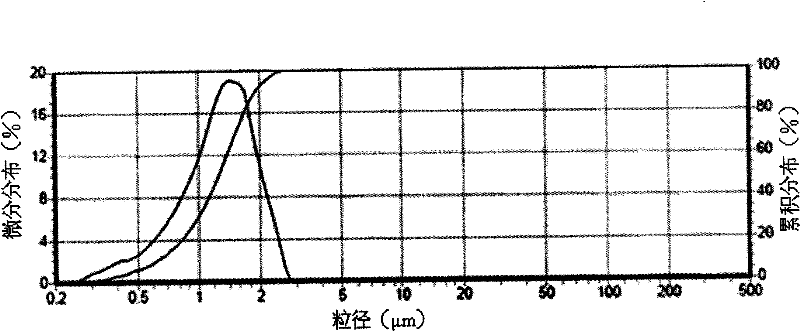

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777BImprove control stabilitySmall median diameterOther chemical processesPolishing compositions with abrasivesCerium oxalateRare earth

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

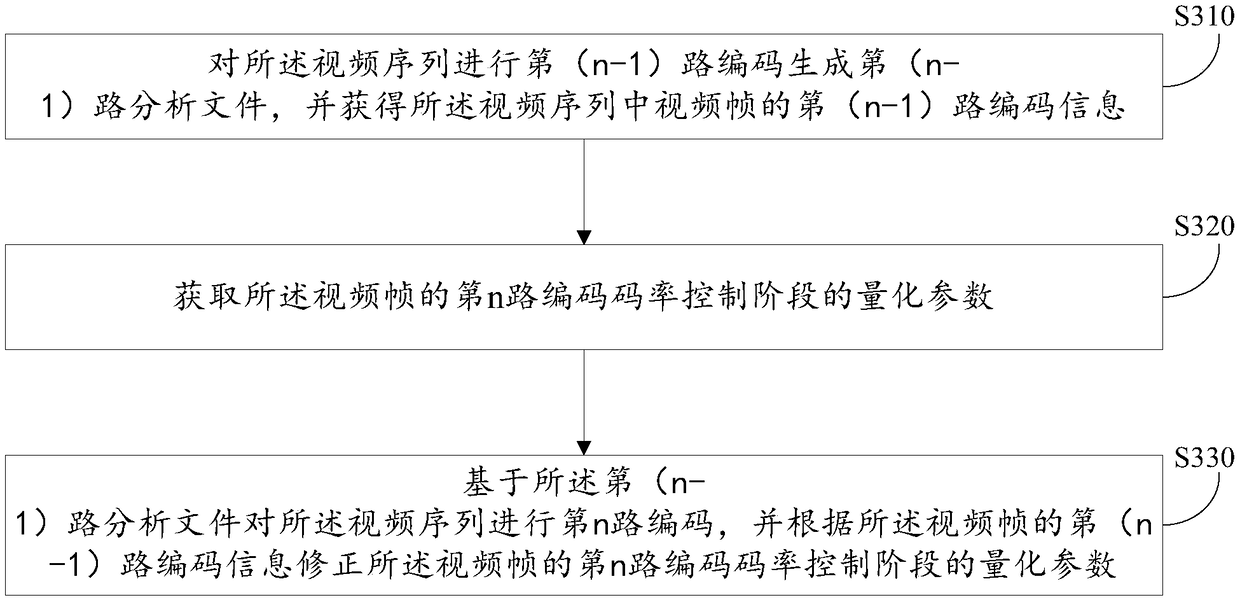

Method and device for video coding, computer readable medium and electronic equipment

ActiveCN108810545AReduce quality fluctuationsImprove visual experienceDigital video signal modificationComputer architectureVideo encoding

The embodiment of the invention provides a method and device for video coding, a computer readable medium and electronic equipment. N-way coding is employed for a video sequence. The method comprisesthe steps of carrying out (n-1)th-way coding on the video sequence to generate an (n-1)th-way analysis file, and obtaining (n-1)th-way coding information of video frames in the video sequence; obtaining quantization parameters of an nth-way coding bit rate control phase of the video frames; and carrying out the nth-way coding on the video sequence based on the (n-1)th-way analysis file, and correcting the quantization parameters of the nth-way coding bit rate control phase of the video frames according to the (n-1)th-way coding information of the video frames, wherein the n is a positive integer greater than or equal to 2. According to the technical scheme provided by the invention, the quantization parameters of the current-way coding bit rate control phase of the video frames in the video sequence can be corrected according to the previous-way coding information, so the quality fluctuation of the video sequence can be reduced.

Owner:CENT SOUTH UNIV +1

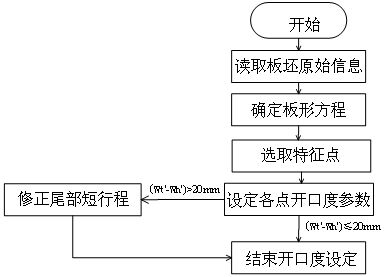

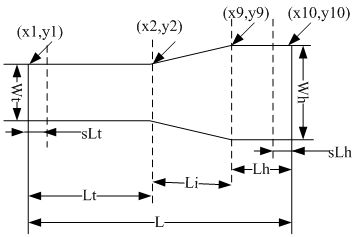

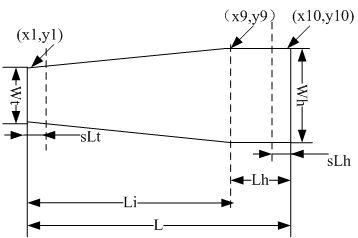

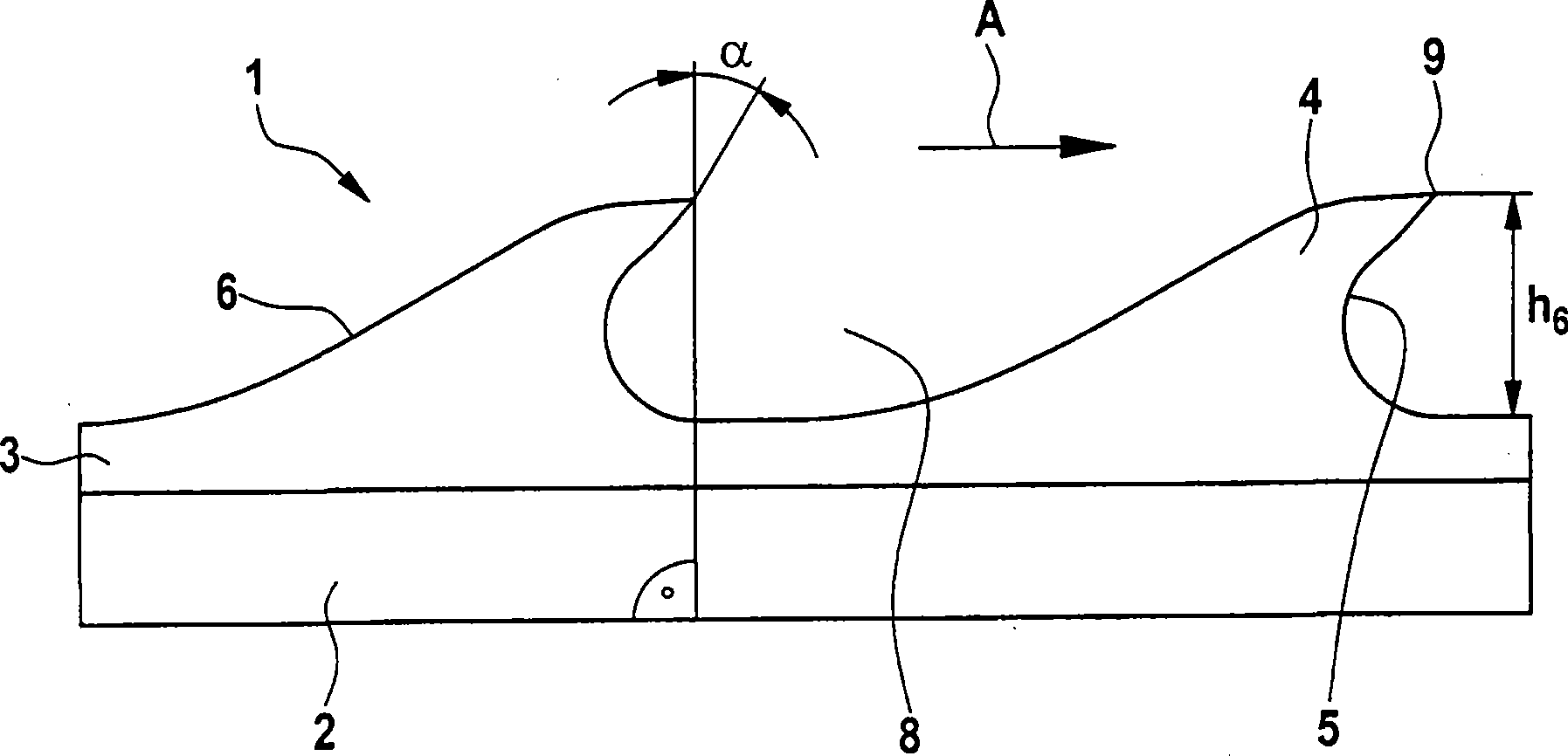

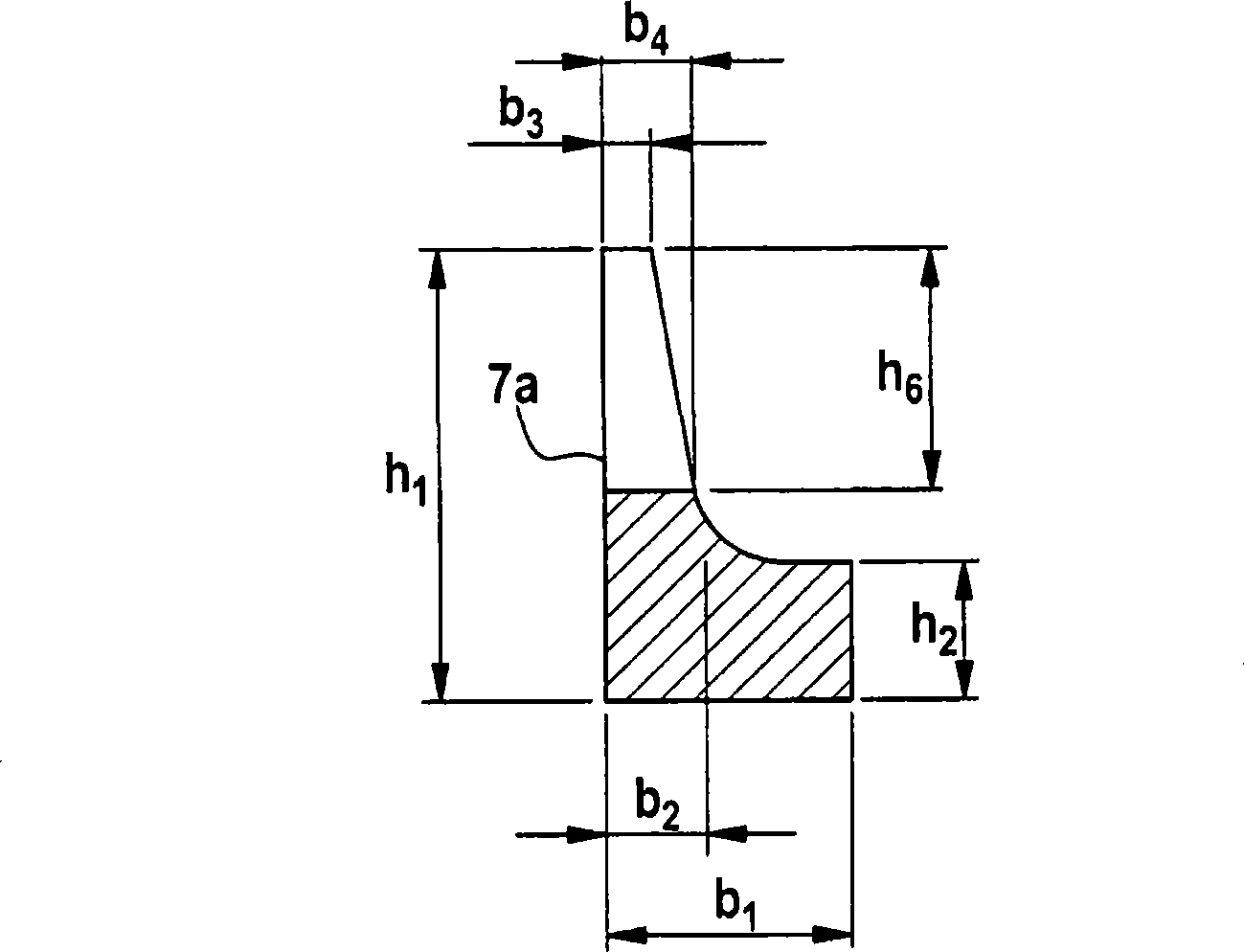

Method for controlling opening degree of rough rolling edger during rolling of tapered slab

ActiveCN102581033AFully automaticFaster turnaroundRoll force/gap control deviceOriginal dataEngineering

The invention relates to the field of hot-rolled band steel production control, in particular to a method for controlling the opening degree of a rough rolling edger during the rolling of a tapered slab. A method for controlling the opening degree of a rough rolling edger during the rolling of a tapered slab includes the following steps: step 1 of dividing a slab into three sections, respectively: a head parallel section, a middle oblique section and an end parallel section, with the width of the head parallel section being larger than that of the end parallel section; step 2 of reading the original data of the slab; step 3 of determining the shape equation of the slab according to the original data of the slab; step 4 of selecting a plurality of characteristic points on the shaft of the slab at equal intervals, and obtaining the coordinates of the characteristic points by calculation; and step 5 of setting various parameters required by this rolling procedure according to the obtained coordinates of the characteristic points of the slab. In the invention, by accurately describing and defining the shape of the tapered slab, and precisely calculating the set values of the opening degree of the edger during the process in which tapered slabs in various shapes pass through the edger, the products rolled from the tapered slabs have no difference with products rolled from normal slabs in terms of quality precision.

Owner:BAOSHAN IRON & STEEL CO LTD

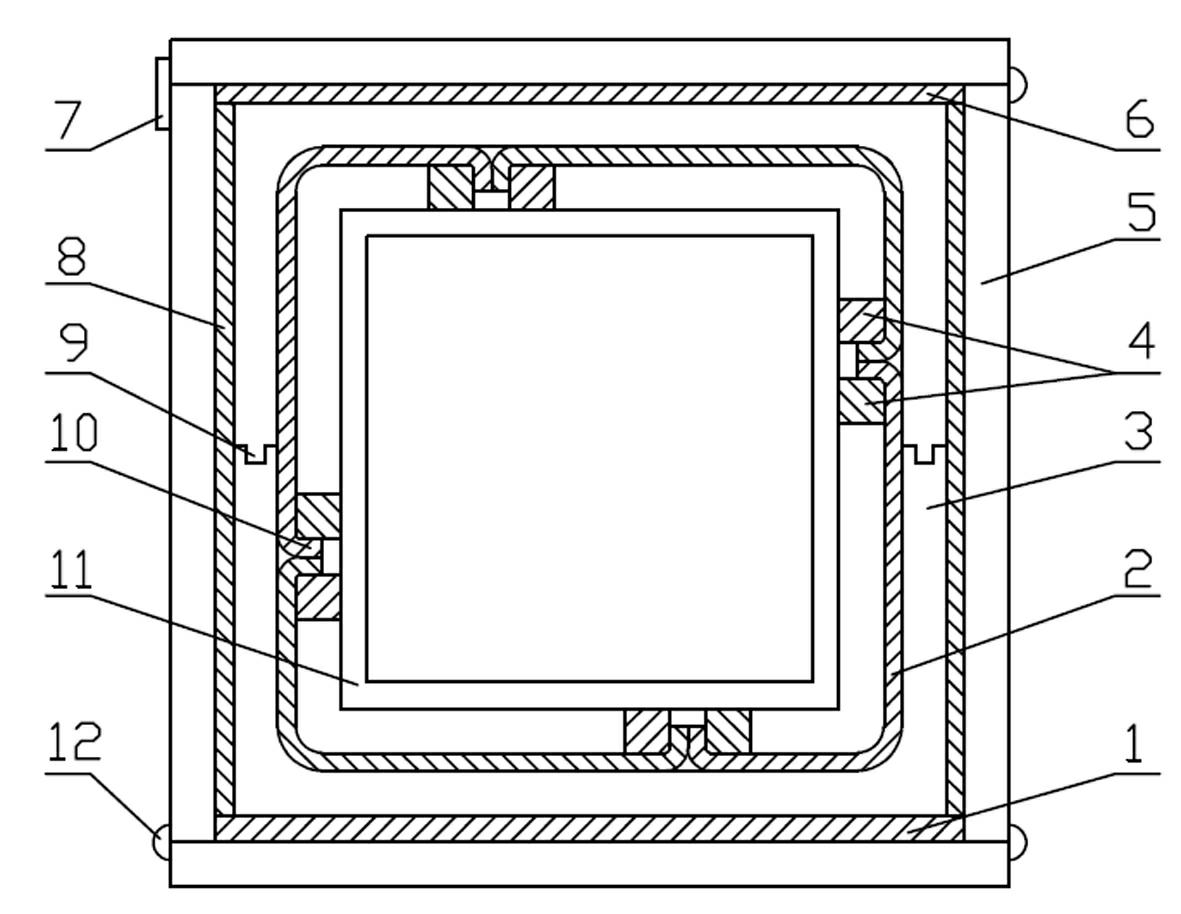

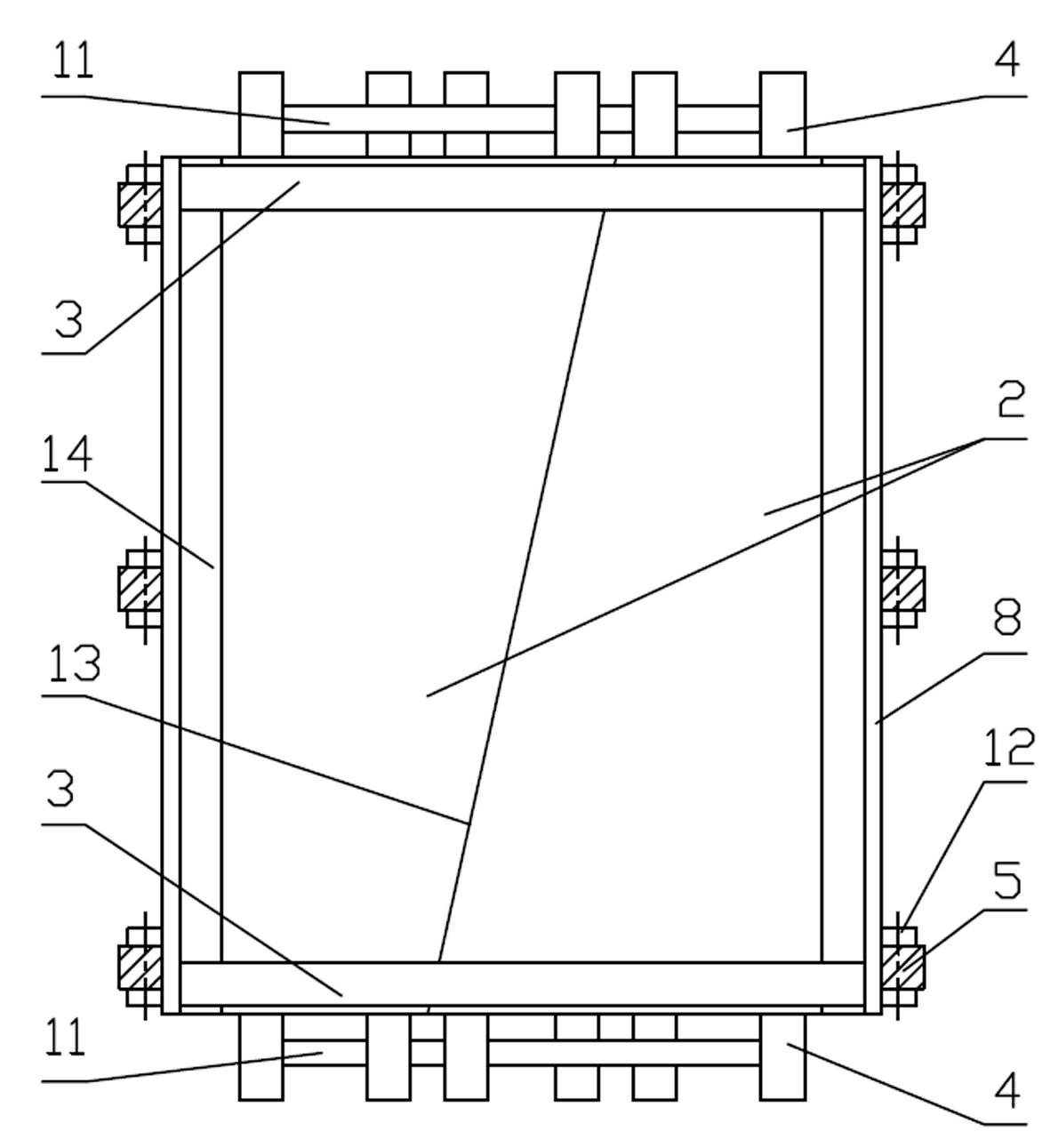

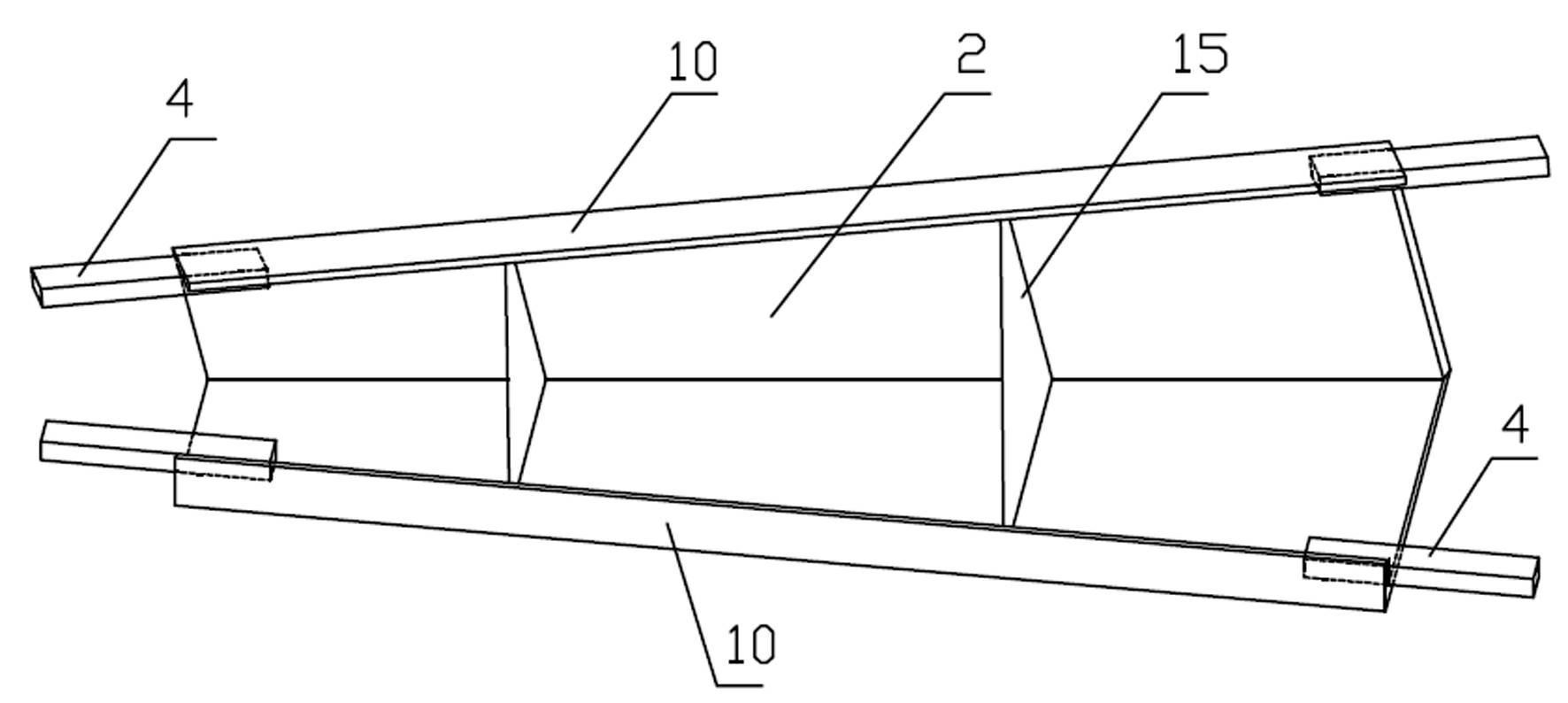

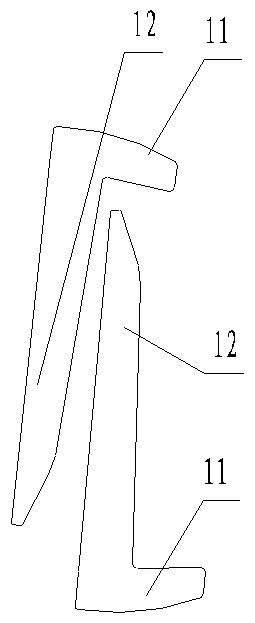

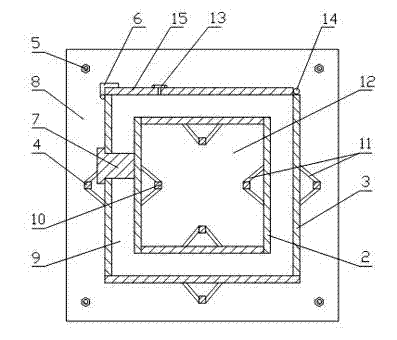

Mould for forming prefabricated exhaust pipeline

ActiveCN102320077AEasy to assembleEasy to disassembleMouldsManufactured materialUltimate tensile strength

The invention discloses a mould for forming a prefabricated exhaust pipeline. The mould comprises an outer template and an inner template. The outer template comprises an outer bottom template and two outer lateral templates matched with the outer bottom template. An outer mould cavity is formed by encircling the outer bottom template and the two outer lateral templates. The inner template is encircled to form a core mould in the outer mould cavity. A forming cavity is formed between the core mould and the outer mould cavity. An end frame is arranged between the outer wall of the core mould at the two ends of the forming cavity and the inner wall of the outer mould cavity. Inner mould support frames are arranged at the two ends of the inner cavity of the core mould. An outer limiting device is arranged on the outer wall of the outer mould cavity. According to the mould disclosed by the invention, the production of a mechanical mould of a thin-wall exhaust pipeline can be realized; the problems of incapability of mechanical production of a prefabricated non-circular thin-wall component in the forming field and the like can be solved; products are formed at one time; the production efficiency is increased; the labour intensity of workers is reduced; the product intensity is high; the quality is good; simultaneously, the quality fluctuation and the raw material waste resulted from manual operation can be reduced.

Owner:韩青

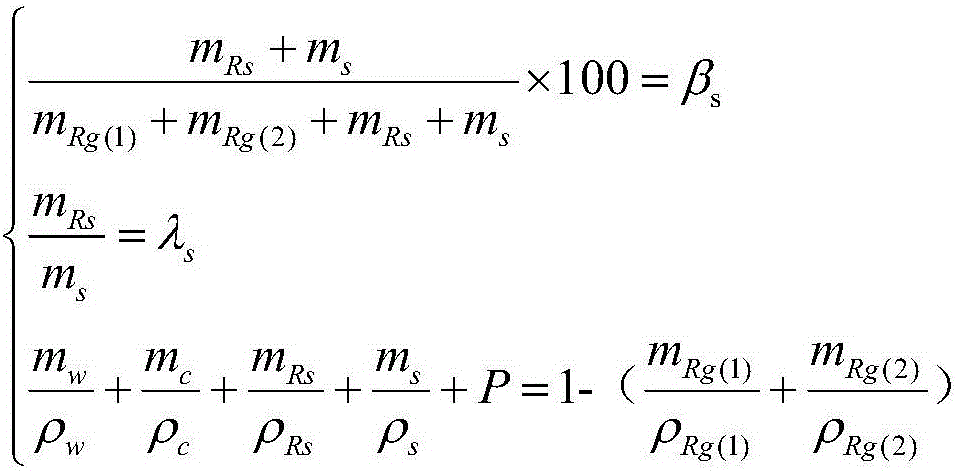

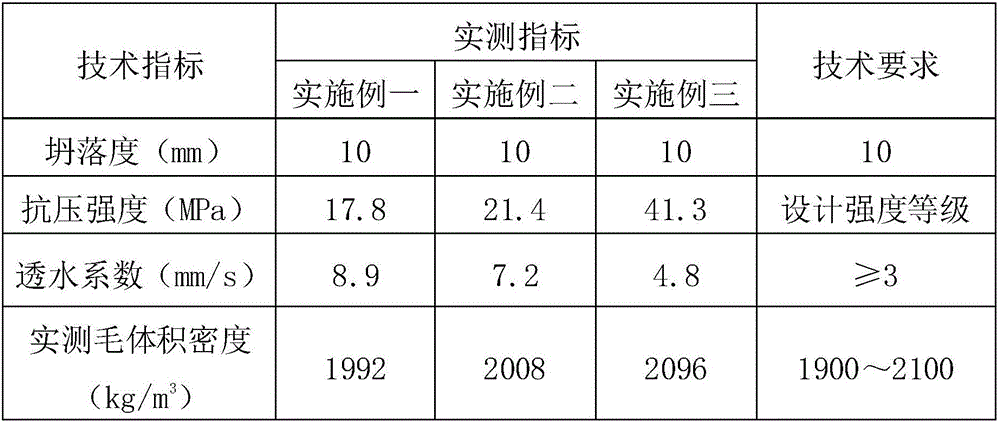

Laboratory mix proportion design method of permeable recycled aggregate concrete

ActiveCN106227976AReduce quality fluctuationsGeometric CADSpecial data processing applicationsVoid ratioCombined method

The invention provides a laboratory mix proportion design method of permeable recycled aggregate concrete. The laboratory mix proportion design method is adaptable to characteristics of more cracks, high water absorption rate and large design mix proportion experimental result volatility of building rubbish recycled aggregates. Compared with a common concrete mix proportion design method, by the aid of an experiment and calculation combined method and a framework volume filling method, double-control indexes design void ratio and compressive strength serve as a main design target, and a recycled coarse-fine aggregate and natural sand serve as design references of a surface dry state and an air drying state respectively. The design method is simple, practical, narrow in fluctuation range, less in cement content, high in recycling degree, economical and environmentally friendly, quality is easily controlled, and addition agents and admixtures are omitted.

Owner:SHANDONG JIAOTONG UNIV

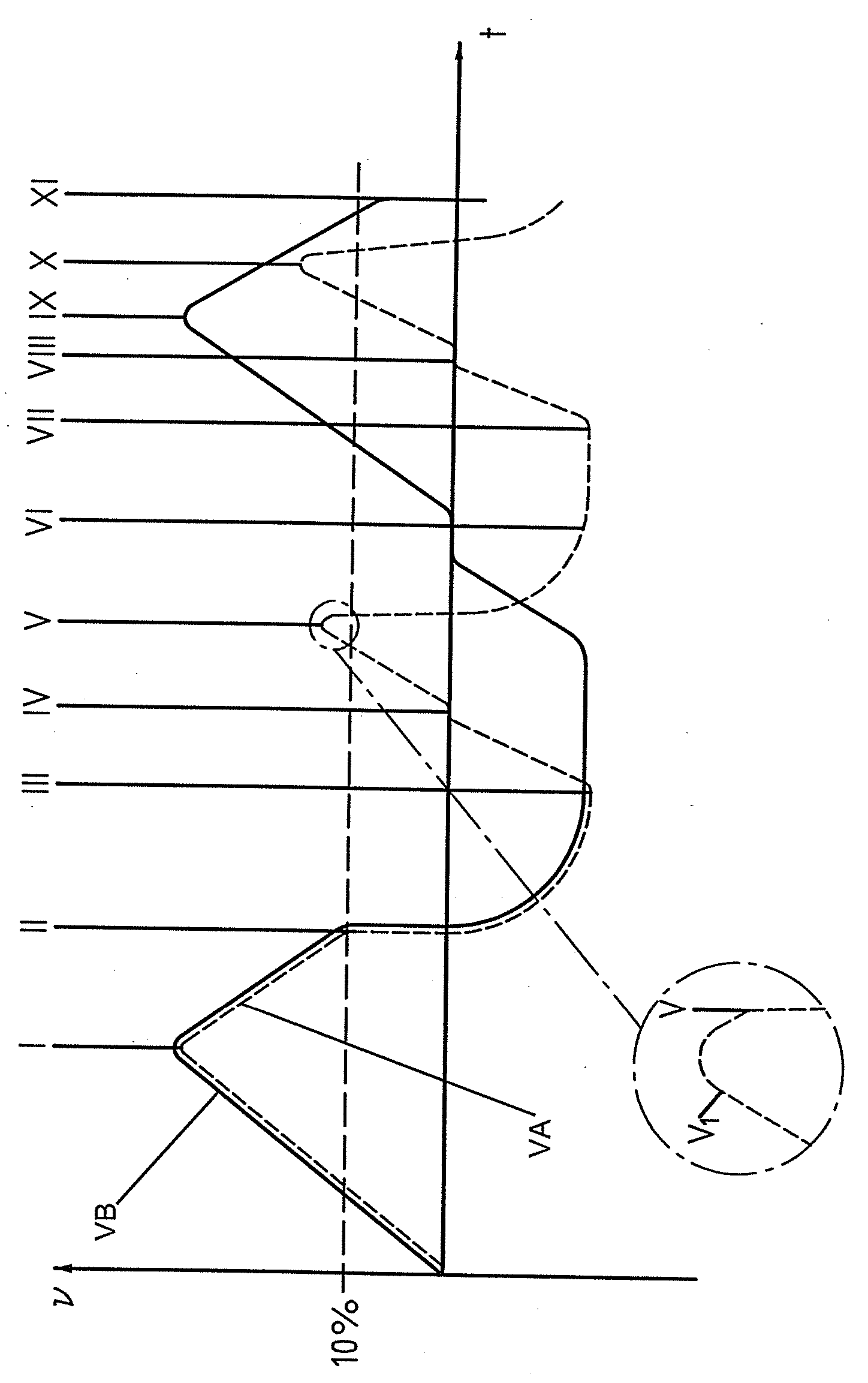

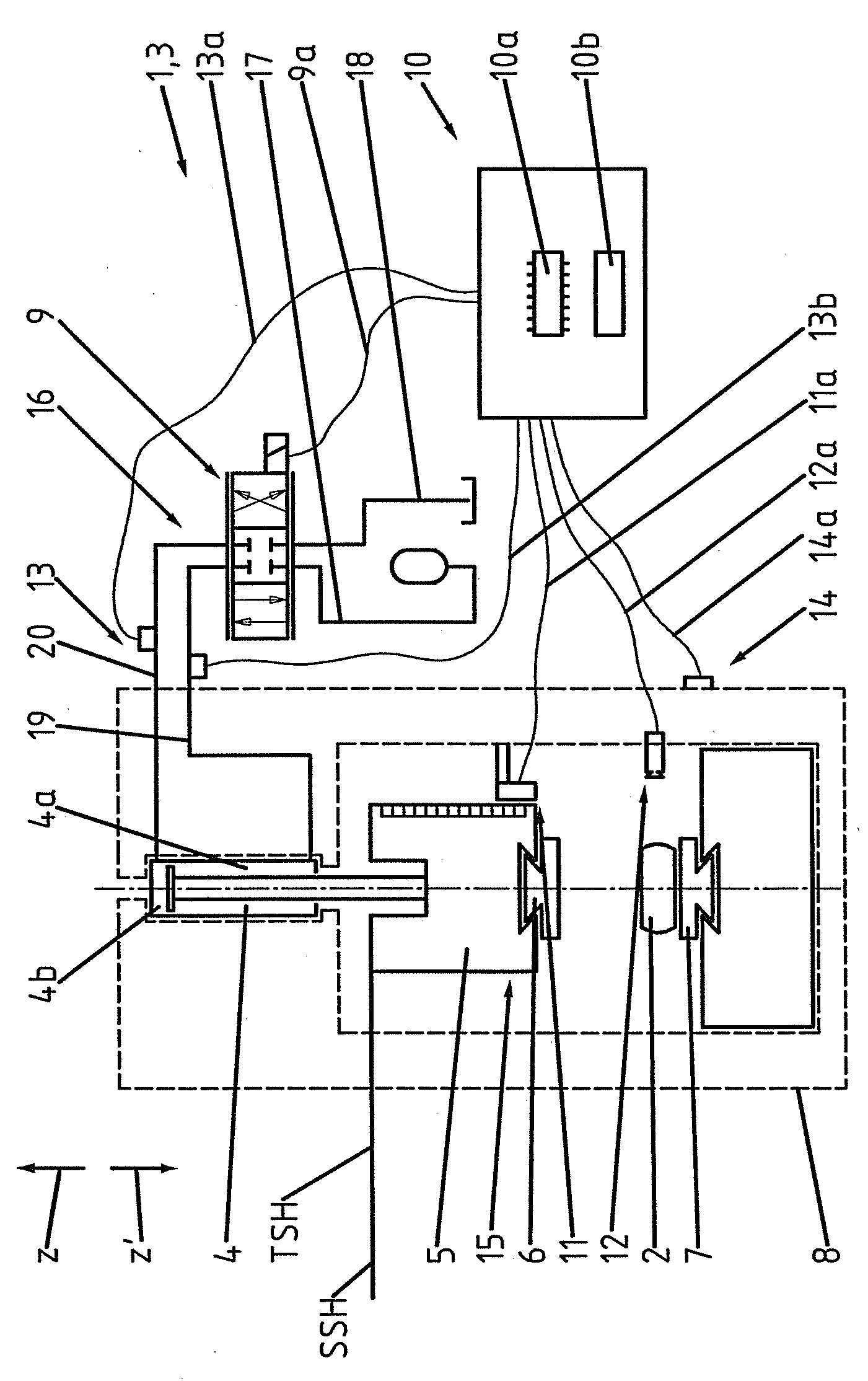

Method for operating forging hammer

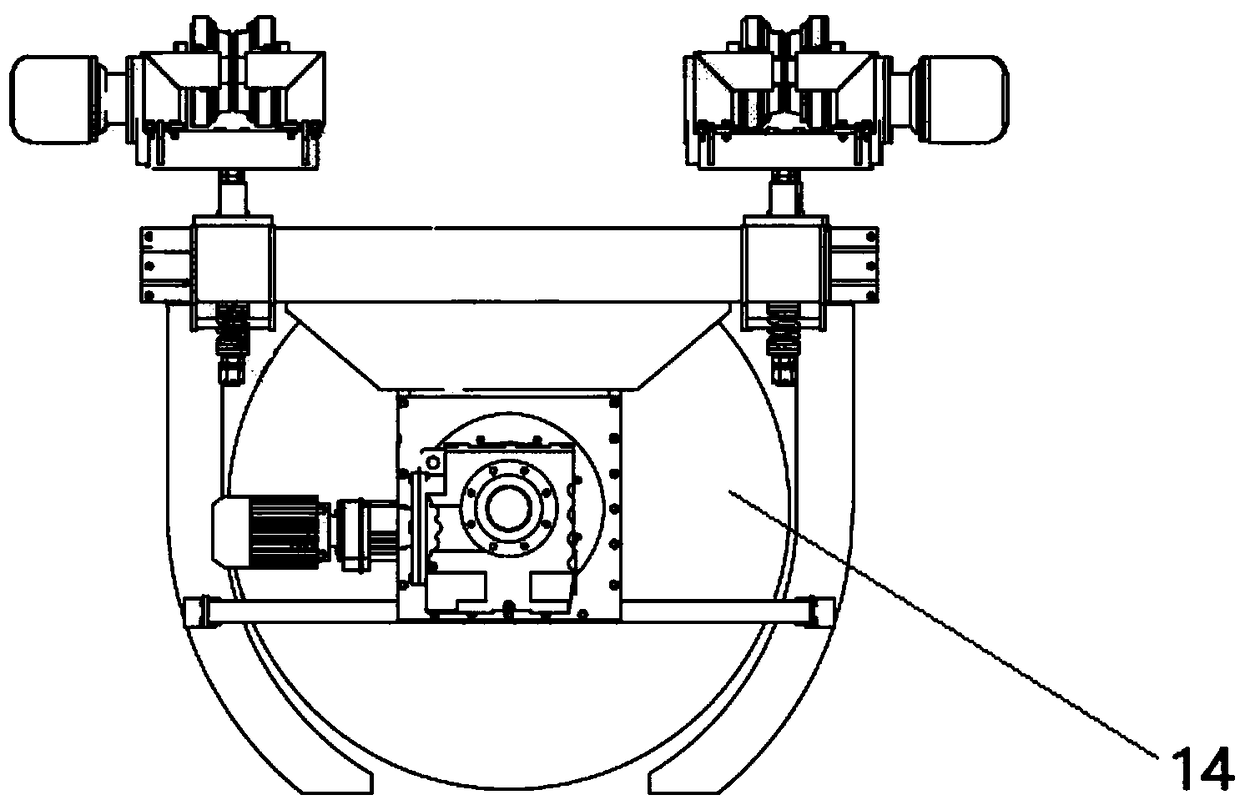

ActiveCN103978139ARealize monitoringImplement fixesHammer drivesForging press detailsHydraulic cylinderControl valves

The invention relates to a method for operating a forging hammer (1). The forging hammer (1) comprises a hydraulic cylinder (4), a hammerhead (5), an upper die (6), a lower die (7), a machine frame (8), at least one control valve (9), an electronic control device (10) and at least one sensing device (11-14), wherein the hammerhead (5) and the upper die (6) form an upper tool (15) moved by the hydraulic cylinder (4).

Owner:SCHULER PRESSEN GMBH & CO KG

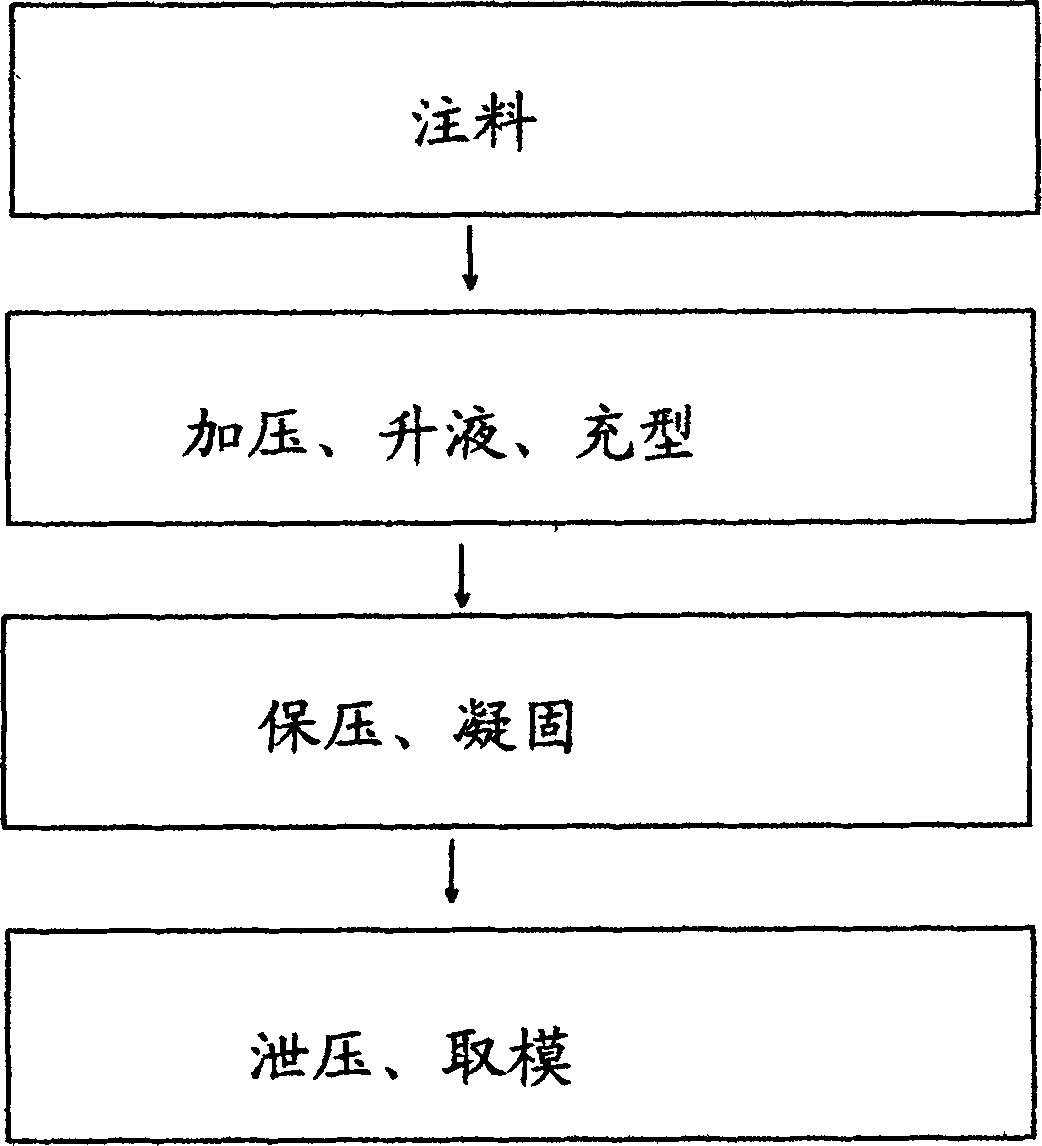

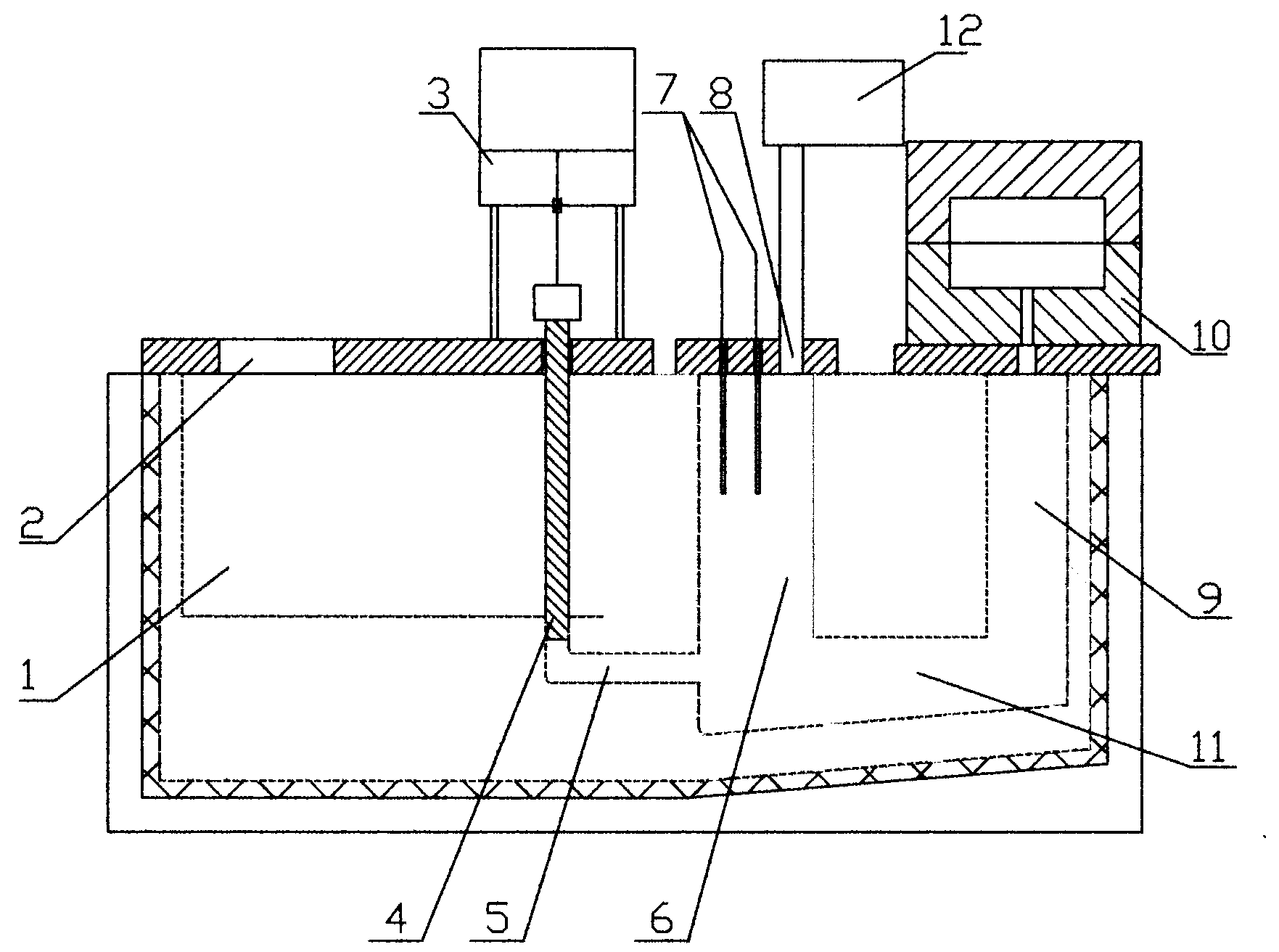

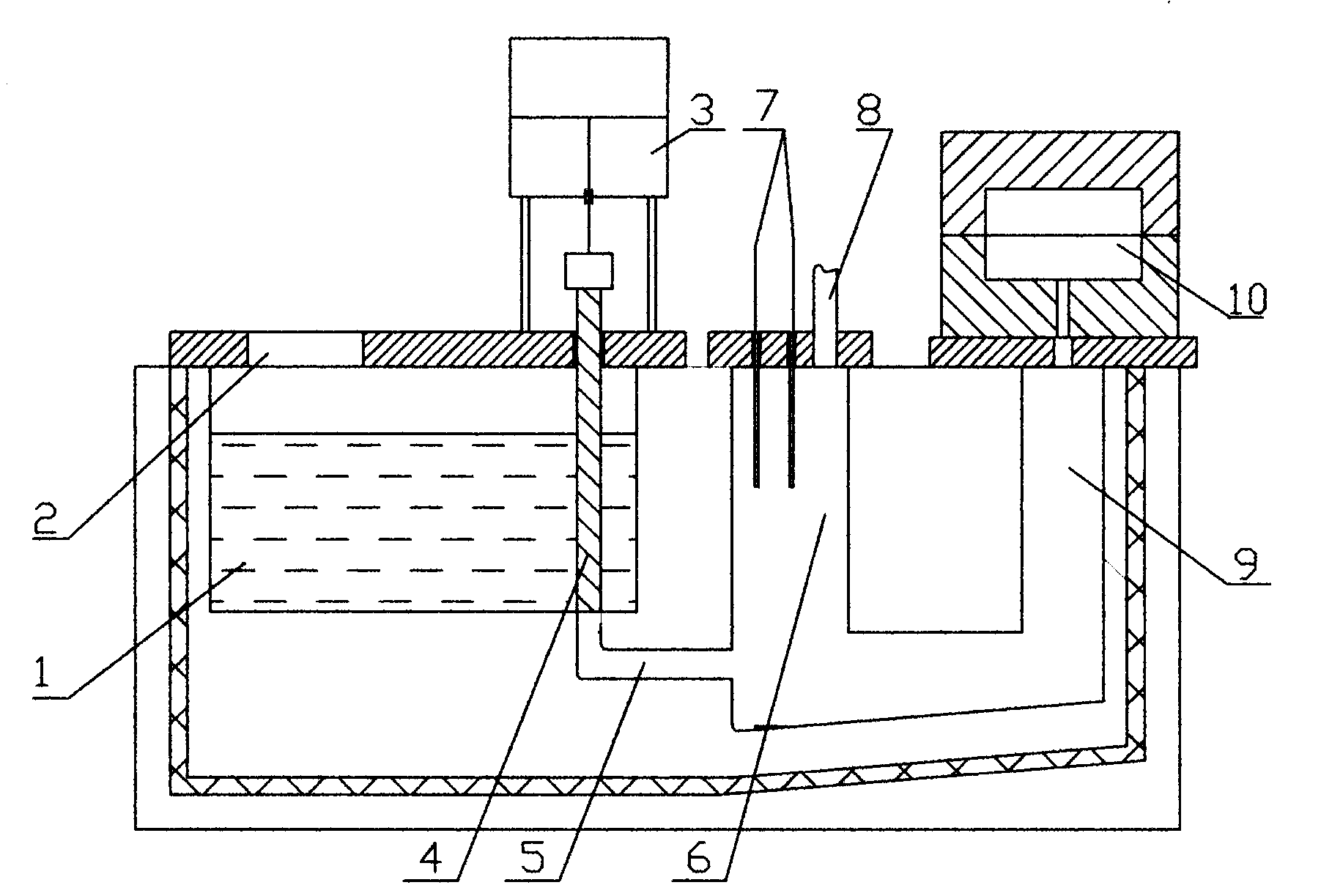

Low-pressure casting method and device thereof

InactiveCN102962430AIncrease productivityRealize continuous productionControl systemDegrees of freedom

The invention relates to the technical field of casting and discloses a low-pressure casting method and a low-pressure casting device. The low-pressure casting method comprises the following steps: feeding, pressurizing, lifting liquid, keeping pressure, solidifying, decompressing and taking a mould. The low-pressure casting device comprises a temperature keeping chamber, a mould, a pressurizing chamber, a liquid lifting chamber, a plug rod, a liquid level pressurizing control system and a liquid level sensor, wherein the plug rod is used for controlling a feeding channel to open and close. The low-pressure casting method and device provided by the invention have the following advantages: the production efficiency is greatly increased; the continuous production is realized; the casting parameter is stable; the metal liquid level at each time of pouring is kept constant, so that the fluctuation of the pressurized pressure is small and athe control system is simplified; the quality of the metal liquid level is stable; and the degree of freedom of the technology is increased.

Owner:GUANGDONG HONGTAI TECH HLDG +1

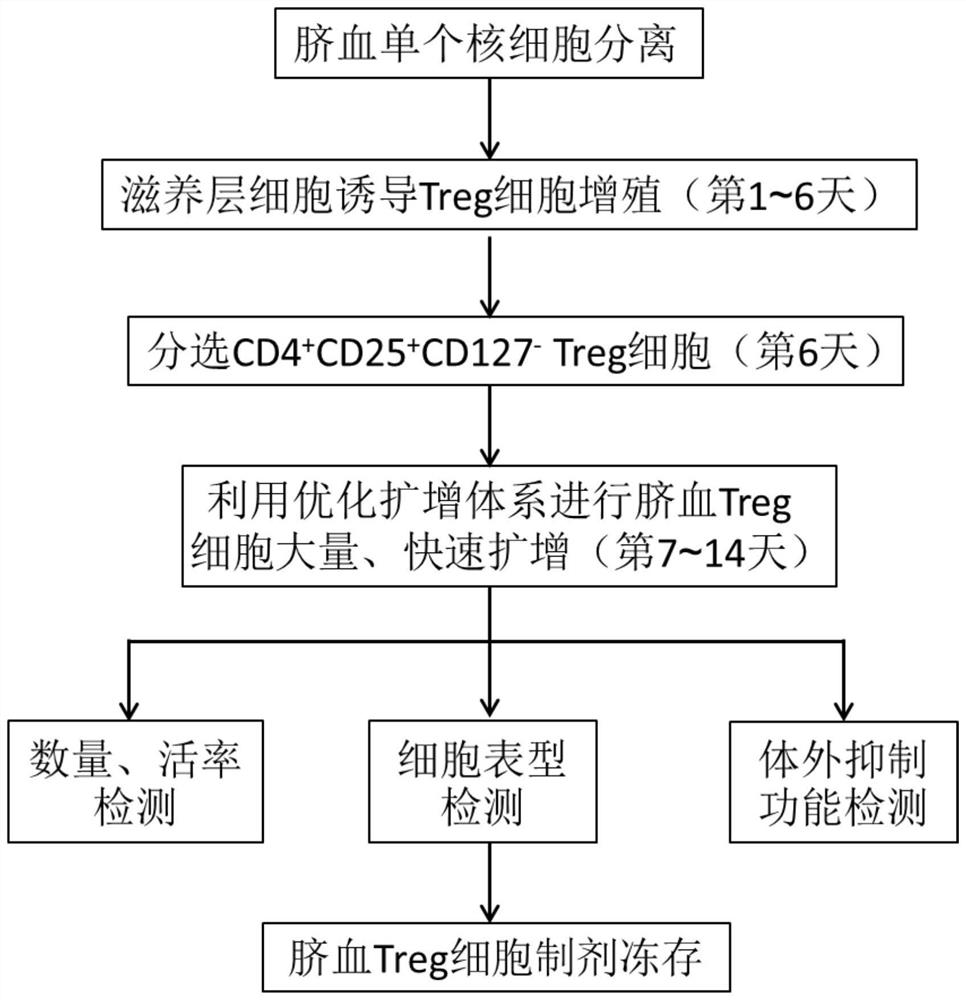

Umbilical cord blood Treg cell in-vitro amplification method based on trophoblastic cells and application

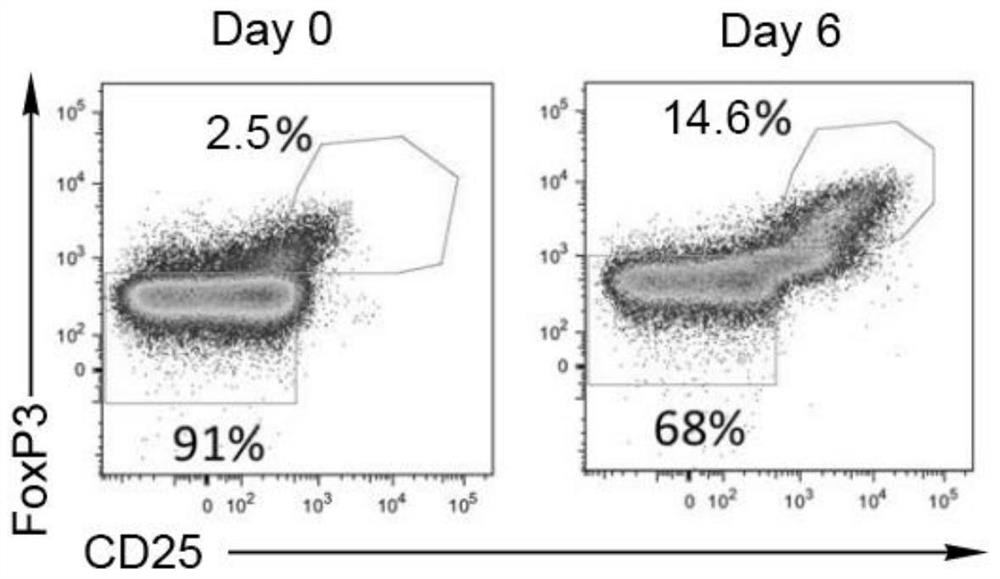

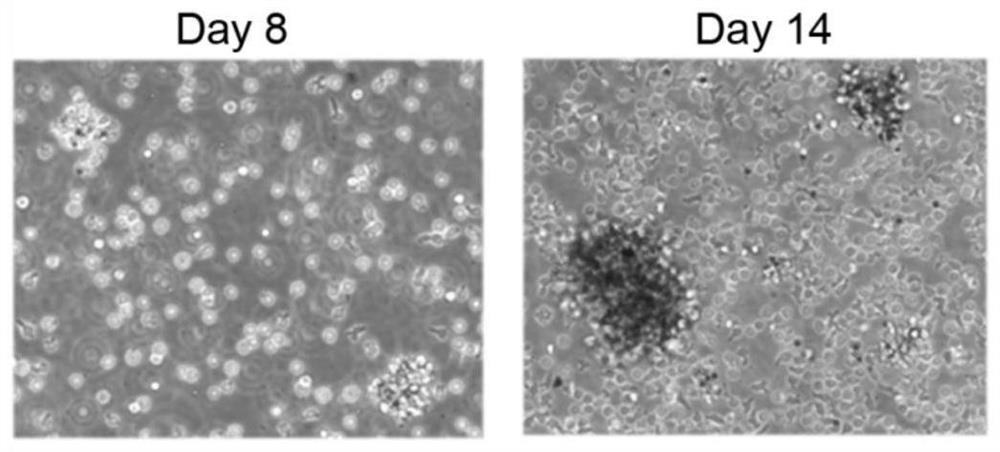

ActiveCN112458053APromote amplificationRaise the ratioAntipyreticDigestive systemAutoimmune diseaseTrophoblast

The invention discloses an umbilical cord blood Treg cell in-vitro amplification method based on trophoblastic cells and application. The specific technical method comprises the steps that firstly, umbilical cord Wharton's jelly mesenchymal stem cells are adopted as the trophoblastic cells to induce preliminary proliferation of Treg cells in umbilical cord blood mononuclear cells; then, pure Tregcells are obtained through magnetic bead sorting; and finally, the Treg cells are stimulated to be rapidly amplified by using optimized amplification factors. According to the amplification method, human AB plasma, IL-2, rapamycin, an RARA agonist and a DNA methyltransferase inhibitor are used as the optimized amplification factors, and a large number of umbilical cord blood Treg cells with high purity and high activity can be prepared within two weeks. Umbilical cord blood is used as a raw material for Treg cell amplification, batch preparation can be achieved, and Treg cell quality fluctuation caused by individual differences of samples can be reduced. The umbilical cord blood Treg cells have low immunogenicity and can be used as universal cells for clinical research, such as autoimmunediseases, graft-versus-host diseases and the like.

Owner:成都云测医学生物技术有限公司

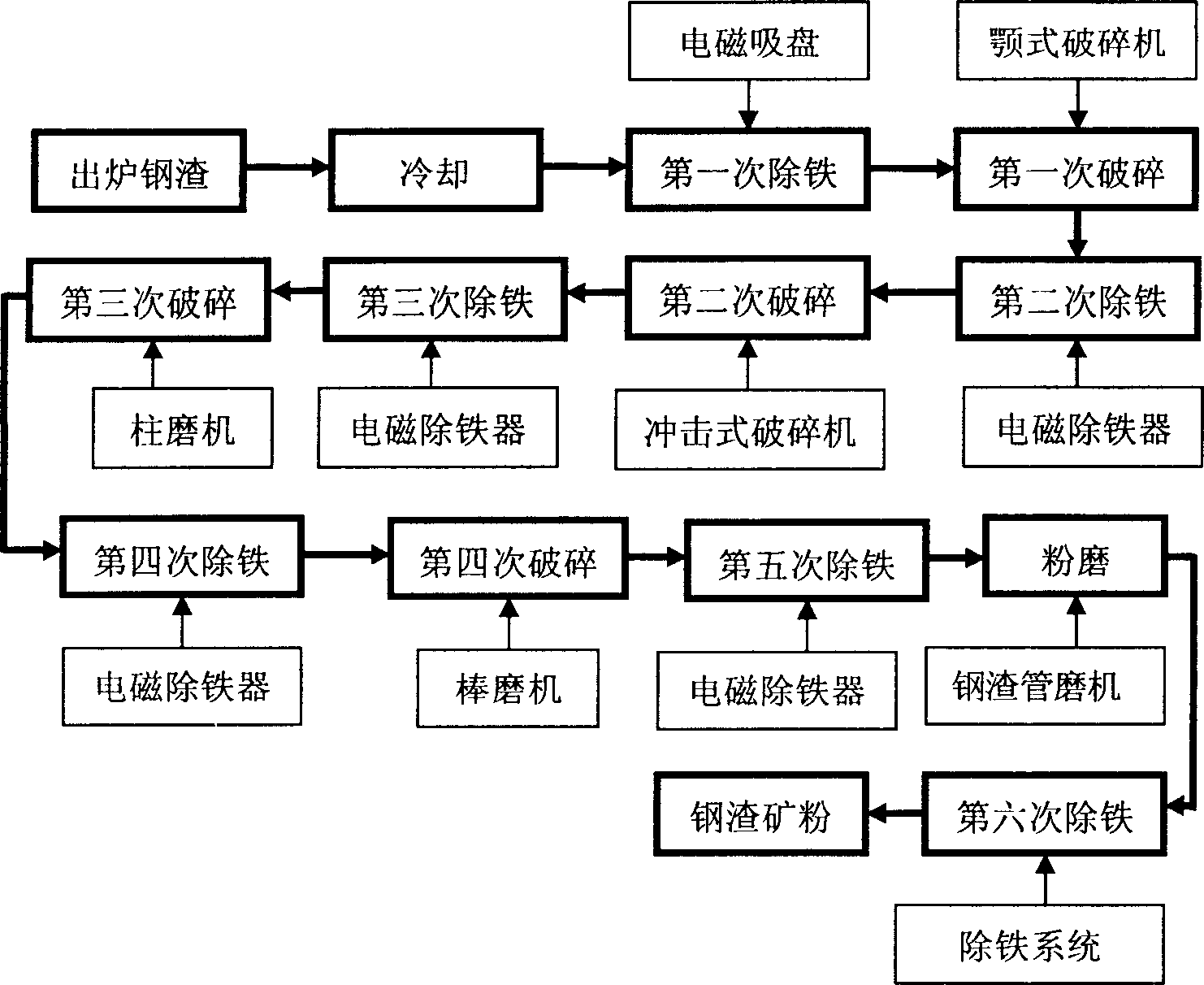

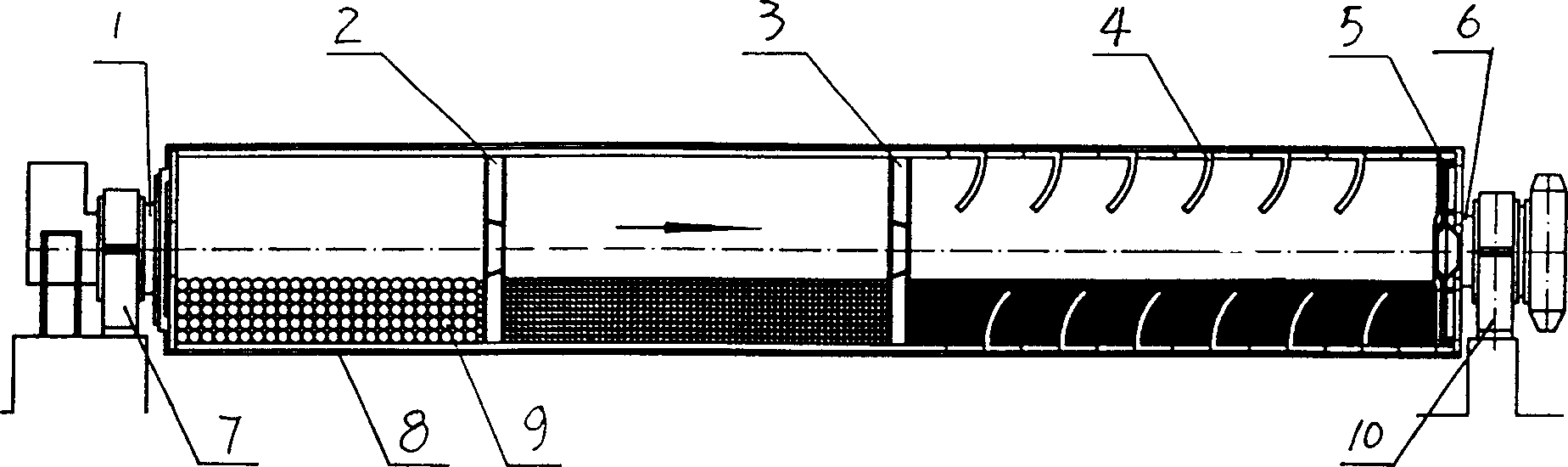

Production technology of high quality steel slag breeze

InactiveCN1718746AReduce energy consumptionReduce manufacturing costRecycling and recovery technologiesMagnetic separationSlagCrusher

A technology for preparing the breeze from steel slag includes such steps as cooling, removing iron by electromagnetic sucking disc, breaking by alligator, removing iron by ferroelectric magnetic iron remover, breaking by impact crusher, removing iron by ferroelectric magnetic iron remover, pulverizing by post grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by rod grinder, removing iron by ferroelectric magnetic iron remover, pulverizing by tube grinder, and removing iron by iron removing system. The product has low content of Fe and large specific surface area.

Owner:WUHAN UNIV OF TECH

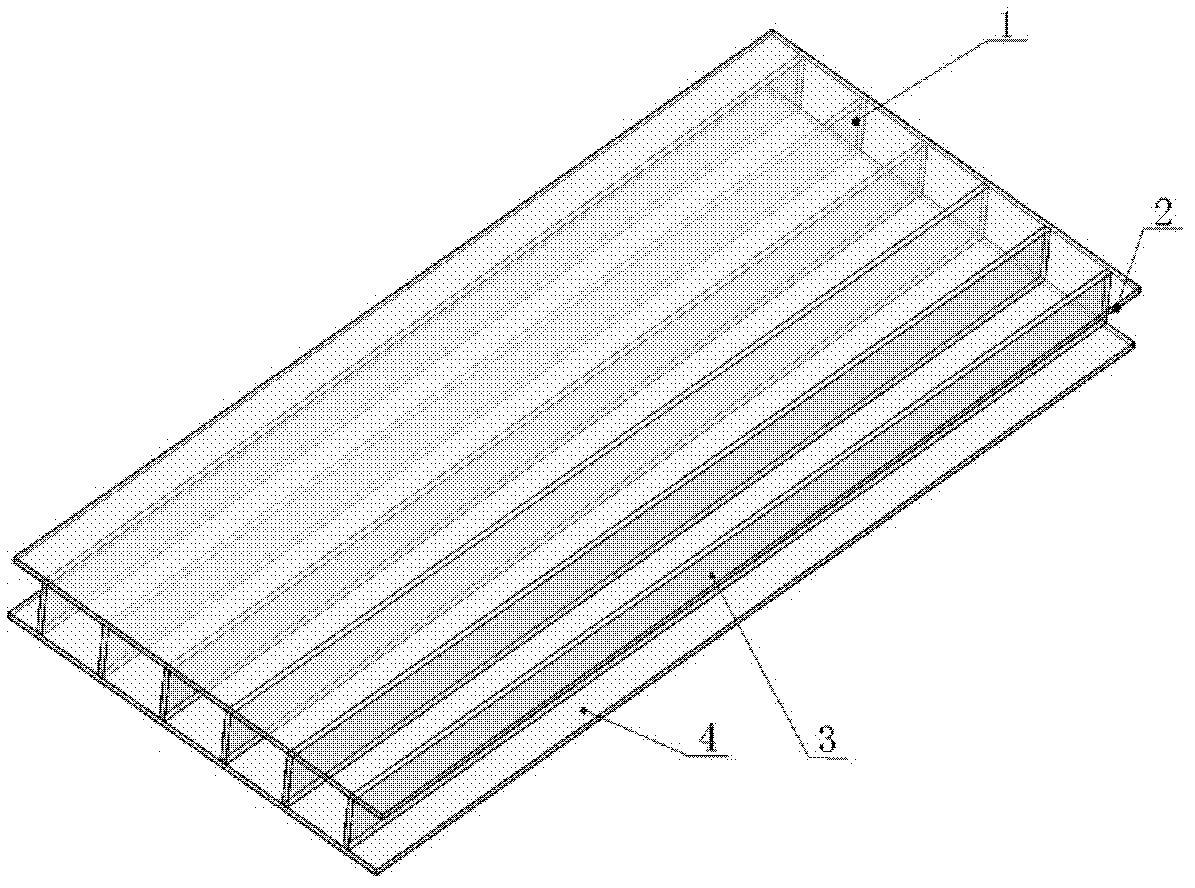

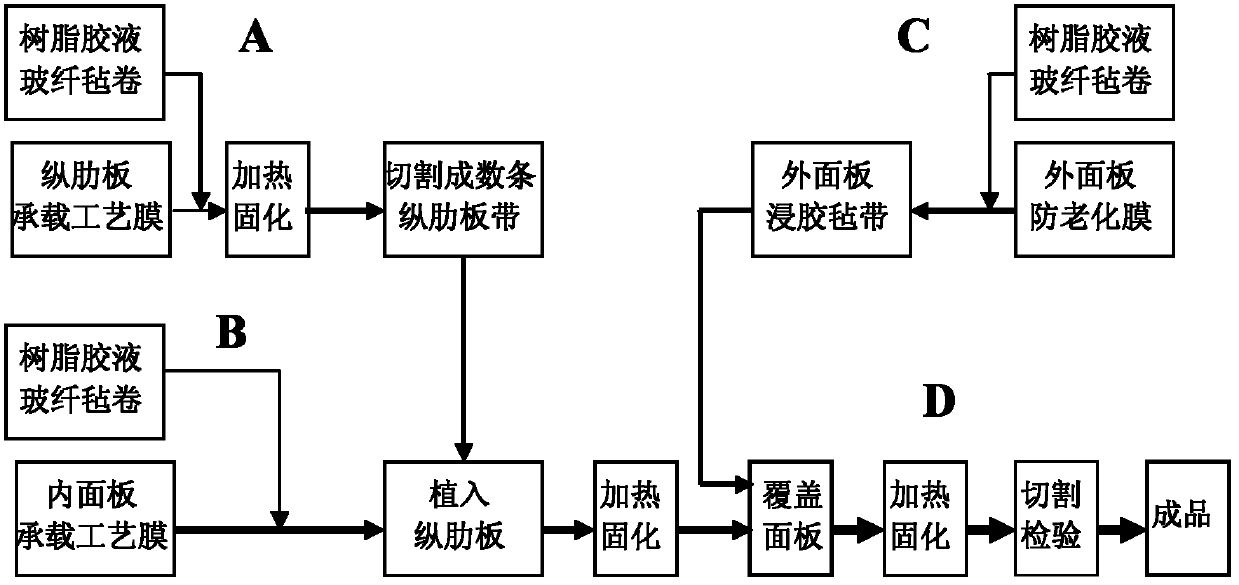

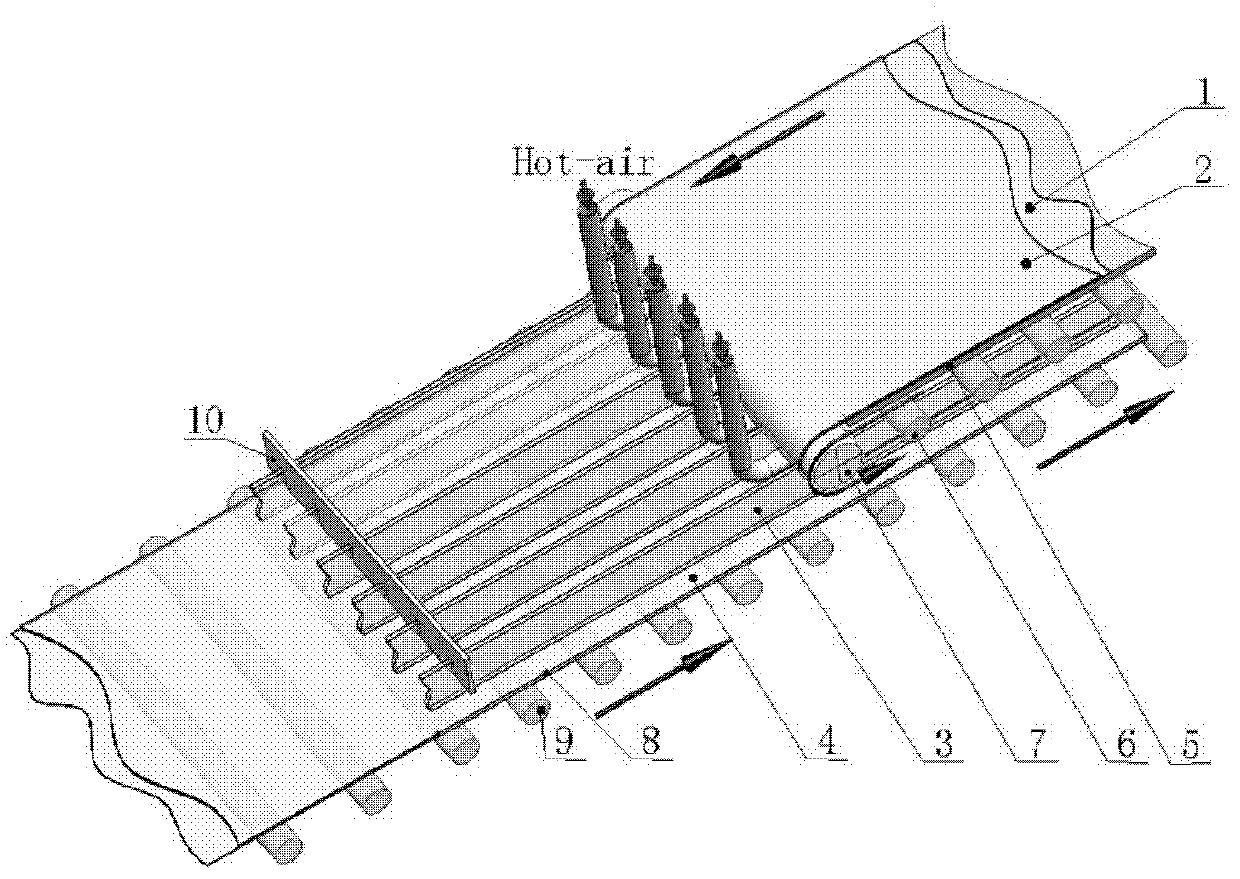

Fiber reinforce plastic hollow plate continuous forming process

ActiveCN103286966AIncrease productivityAchieve mass productionFlat articlesHollow articlesFiberEngineering

The invention belongs to the technical field of building cladding plate materials, and in particular relates to a fiber reinforce plastic hollow plate continuous forming process. A fiber reinforce plastic hollow plate produced by the invention is composed of an outer panel, a plurality of longitudinal rib plates and an inner panel which are bonded and combined from top to bottom into a whole, and is continuously formed by using a one-step method. A mode that films support gumming felts is applied to the outer panel, the plurality of longitudinal rib plates and the inner panel. The fiber reinforce plastic hollow plate continuous forming process comprises the following steps of: step A, preparing the continuous longitudinal rib plates; step B, preparing the inner panel and implanting the longitudinal rib plates in a wet state; step C, preparing the outer panel, covering and integrating; and step D, heating and curing, bonding and integrating during the continuous forming process, forming a longitudinal continuous hollow plate belt, and cutting according to the required dimension, thereby obtaining a finished product. The method provided by the invention is used for solving the technical problem that a single block forming process is low in production efficiency in the prior art and achieving the beneficial effects of improving the production efficiency and achieving scale production.

Owner:秦皇岛耀华新材料有限公司

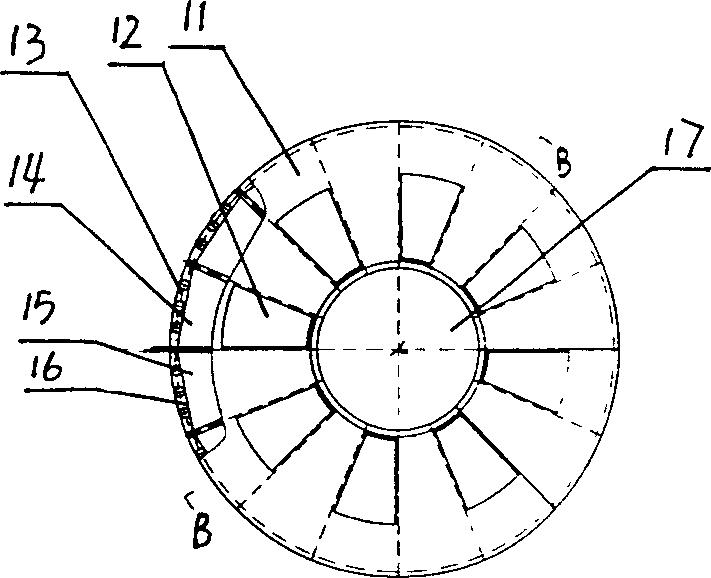

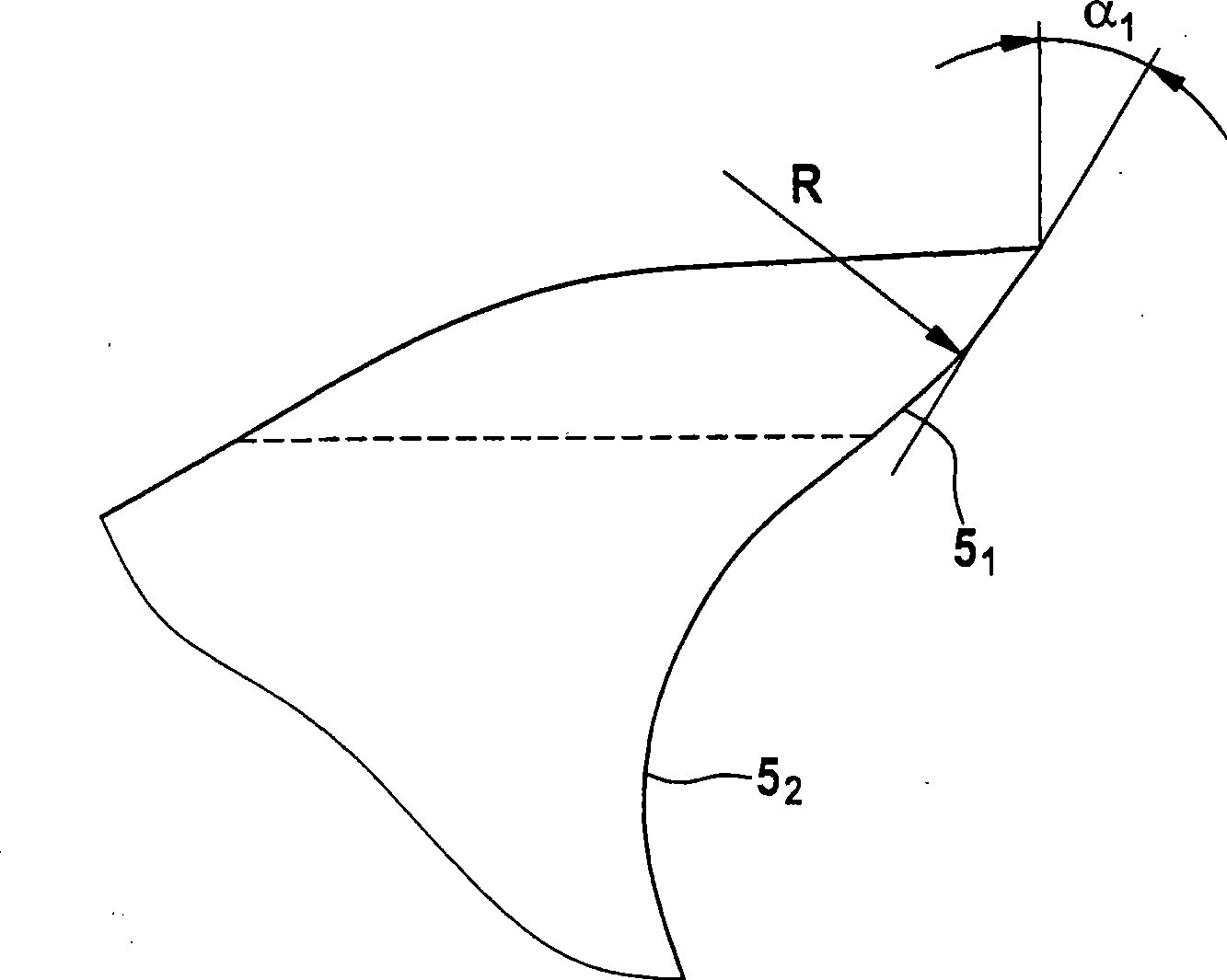

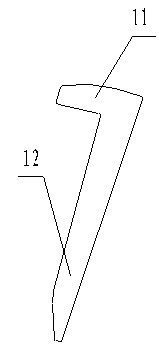

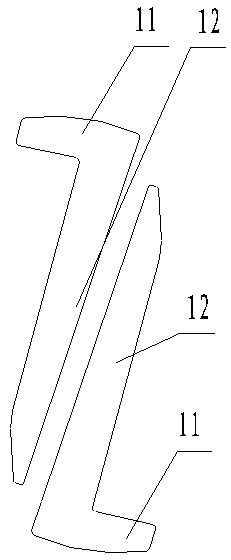

Saw-tooth clothing for rollers and/or cylinders

ActiveCN101463509AReduce quality fluctuationsLoss of sharpness mitigated or compensatedCarding machinesFoot regionEngineering

A saw-tooth clothing for rollers and / or cylinders of flat cards or roller cards has an elongate foot region and an adjoining tooth region (blade) in which teeth have been formed by cutting, with a tooth front a tooth back and two side flanks, wherein between the tooth back and the tooth front of two adjacent teeth there is a gullet and the teeth consist of at least two portions, with a first portion, forming a technologically effective region. In order to provide a clothing that retains a high level of aggressiveness over its lifetime, the first portion of the tooth front is convex or approximately convex in the direction of movement of the clothing.

Owner:TRUETZSCHLER GRP SE

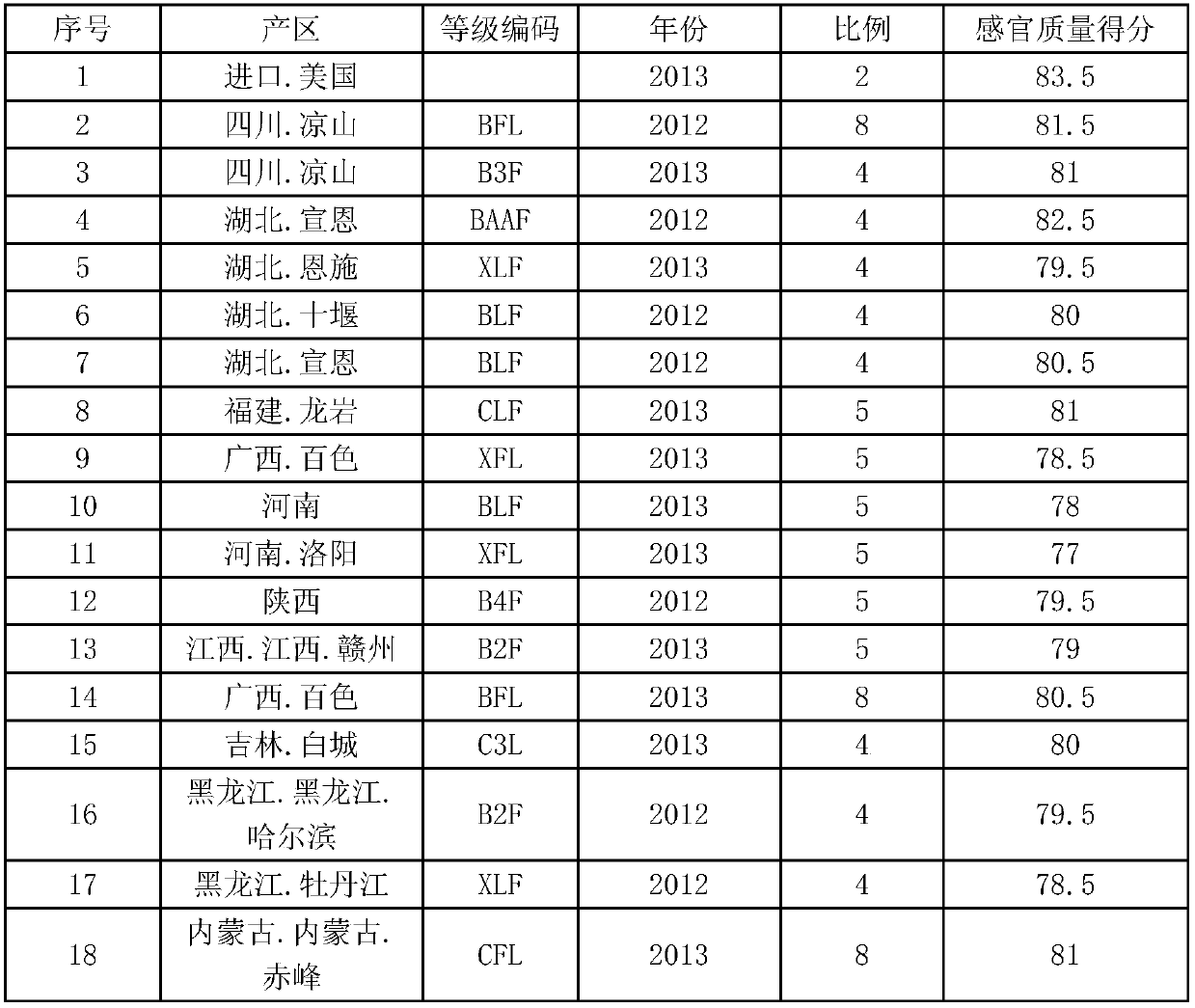

Processing material for improving quality of black coral tobacco

ActiveCN101744362ALess irritatingImprove toughnessTobacco preparationTobacco treatmentIrritationAscorbic acid

The invention provides a processing material for improving the quality of black coral tobacco, which is prepared from the following raw materials in parts by weight: 90 to 110 parts of water, 0.6 to 1.0 part of citric acid, 3 to 5 parts of brown sugar, 0.6 to 1.0 part of tripotassium clycyrrhizinate, 0.4 to 0.6 part of cacao powder, 0.05 to 0.15 part of D-ascorbic acid and 0.1 to 0.2 part of lactic acid or tartaric acid. The preparation method has the following steps: boiling the water; adding the brown sugar into the water until the brown sugar is fully dissolved to obtain a brown sugar solution; adding the lactic acid or the tartaric acid into the brown sugar solution to be boiled for 30 to 50 minutes under the condition that the temperature of the sugar solution is between 75 and 90 DEG C to obtain a monosaccharose solution; and adding the malic acid, the tripotassium clycyrrhizinate, the cacao powder and the D-ascorbic acid into the monosaccharose solution to be sufficiently stirred and uniformly mixed. When the processing material provided by the invention is used for processing the black coral tobacco, the irritation of smoke can be reduced, the chewing flavor and the fragrance can be improved, the toughness, the burning property, the corrosion prevention capability and the internal quality of tobacco leaves can be improved, and in addition, the quality fluctuation of the processed tobacco leaves is small.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Secondary formula treatment technology for tobacco leaves

ActiveCN108041668AEnsure stable applicationImprove usabilityTobacco preparationEngineeringTobacco leaf

The invention provides a secondary formula treatment technology for tobacco leaves. The treatment technology sequentially comprises the steps of slicing, loosening reversion, leaf structure improving,pre-mixing, secondary leaf moistening, leaf preparation and storage, leaf drying, cooling reversion, screening, metering packaging and the like. According to the cigarette formula requirement, tobacco leaves of different grades and small scale are compatible again, the new grade is formed, loosening, uniform mixing and packaging are performed through the secondary formula treatment technology fortobacco leaves to form the tobacco leaves of the new grade, tobacco leaves are treated and reduced into the original tobacco bale packaging mode, the small-scale tobacco leaves become the small scalecomponent for the tobacco leaves of the new grade, the scale of the tobacco leaves of the single grade can be enlarged by 25-50 times, and therefore stable application of the tobacco leaves in the formula is ensured, the quality fluctuation caused by tobacco leaf adjustment is lowered, the product quality stability is improved, and the tobacco leaf usability is improved.

Owner:HUBEI CHINA TOBACCO IND

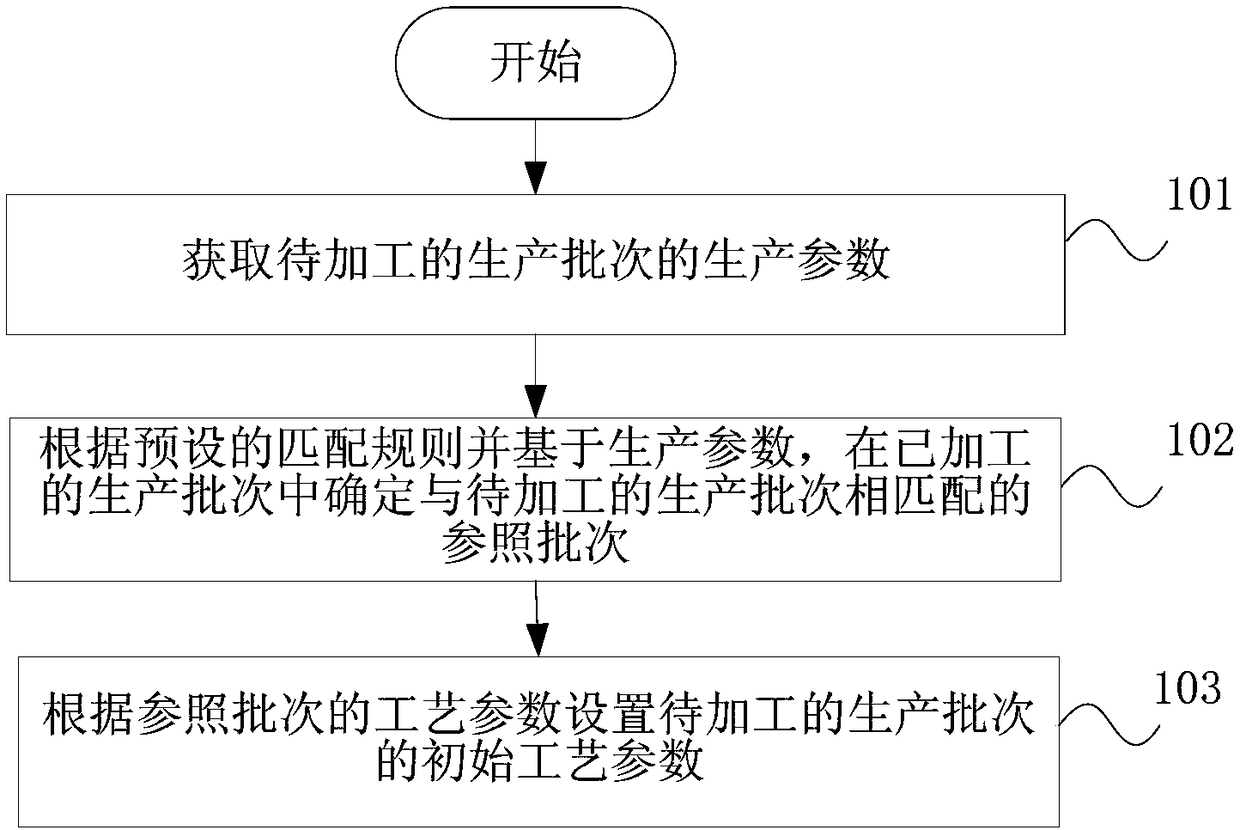

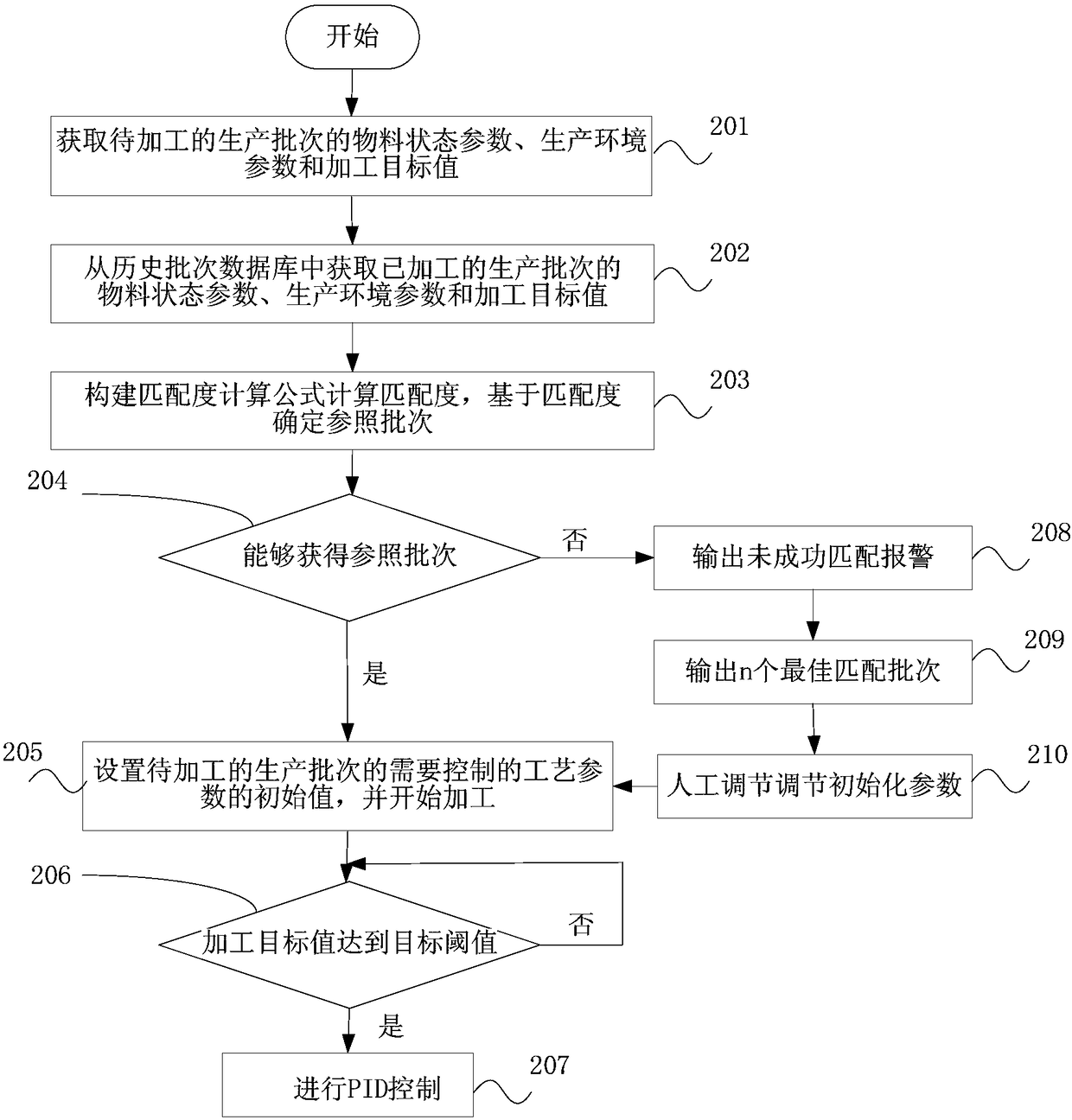

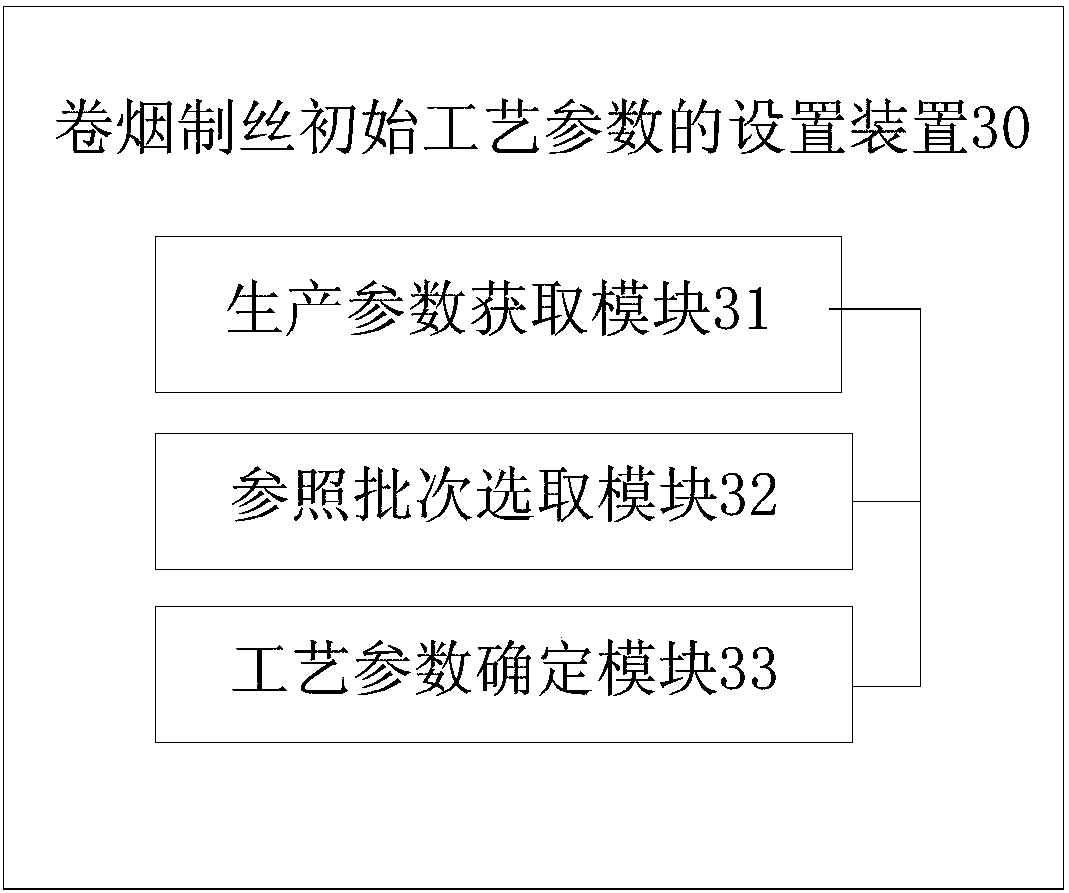

Method and a device for setting initial technological parameters of cigarette tobacco cutting

ActiveCN108932571AStable controlReduce quality fluctuationsTobacco treatmentResourcesManufacturing engineering

The invention discloses a method and a device for setting initial technological parameters of cigarette tobacco cutting and relates to the technical field of tobacco processing. The method comprises the following steps: a step of obtaining production parameters of a production batch to be processed, a step of determining a reference batch which is matched with the production batch to be processedin processed production batches according to a preset matching rule and based on production parameters, and a step of setting the initial technological parameters of the production batch to be processed according to the technological parameters of the reference batch. Via the method and the device for setting the initial technological parameters disclosed in the invention, a processed production batch which is maximally close to a current production state and of which production results maximally meet requirements is used as the reference batch, technological parameters are extracted and usedas initial technological parameters of the production batch to be processed, and production of material heads is started; switch to PID control is made after a target value to be processed is stable,and therefore rapid and stable control over material head time during processing operation can be realized; fluctuation of tobacco quality during the material head time can be reduced, and product quality can be improved.

Owner:LONGYAN CIGARETTE FACTORY

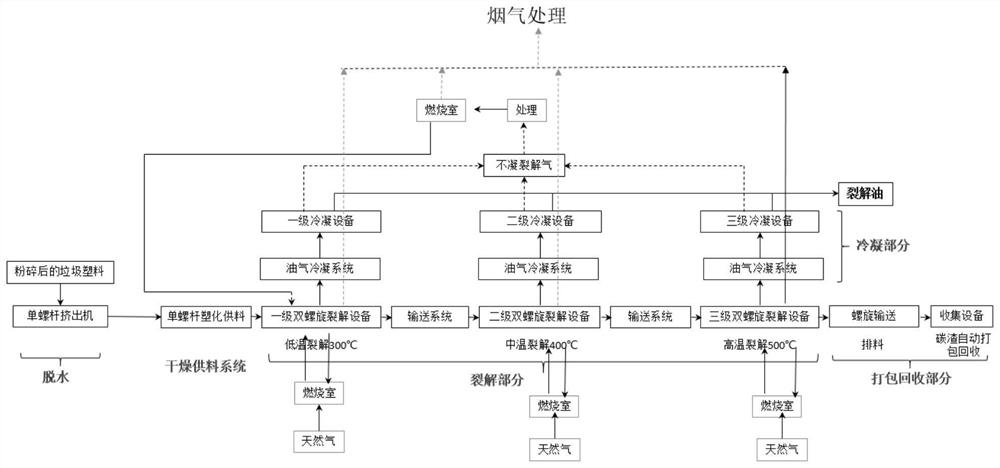

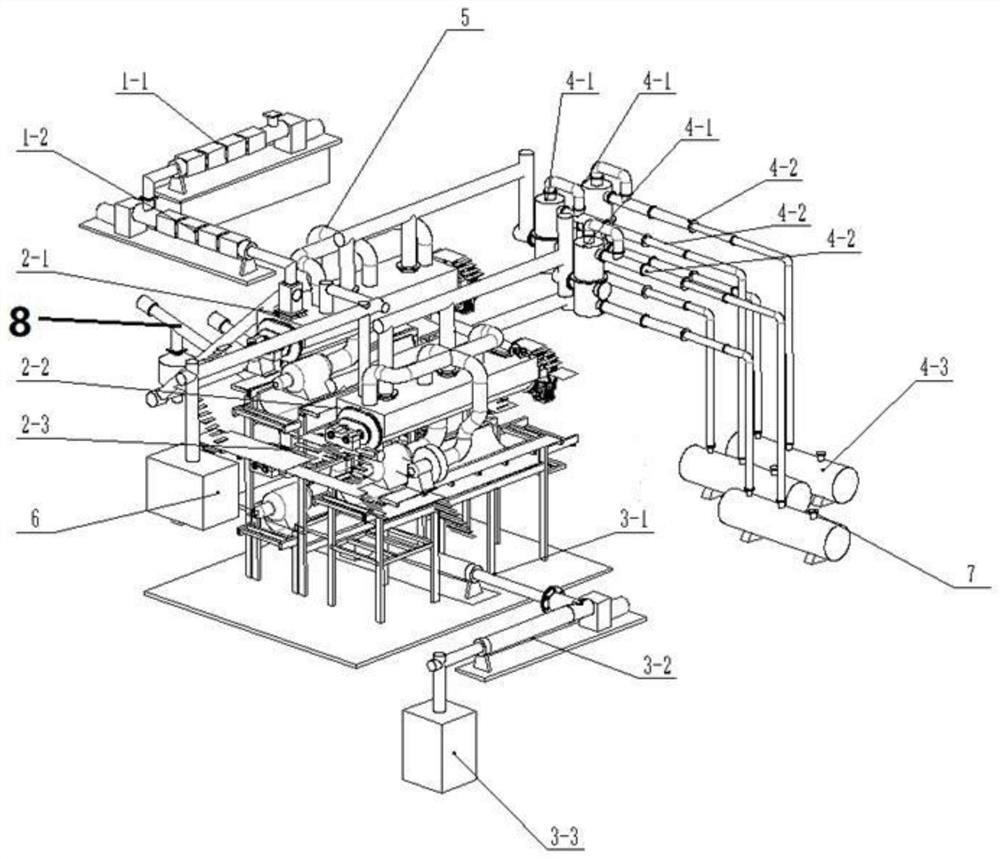

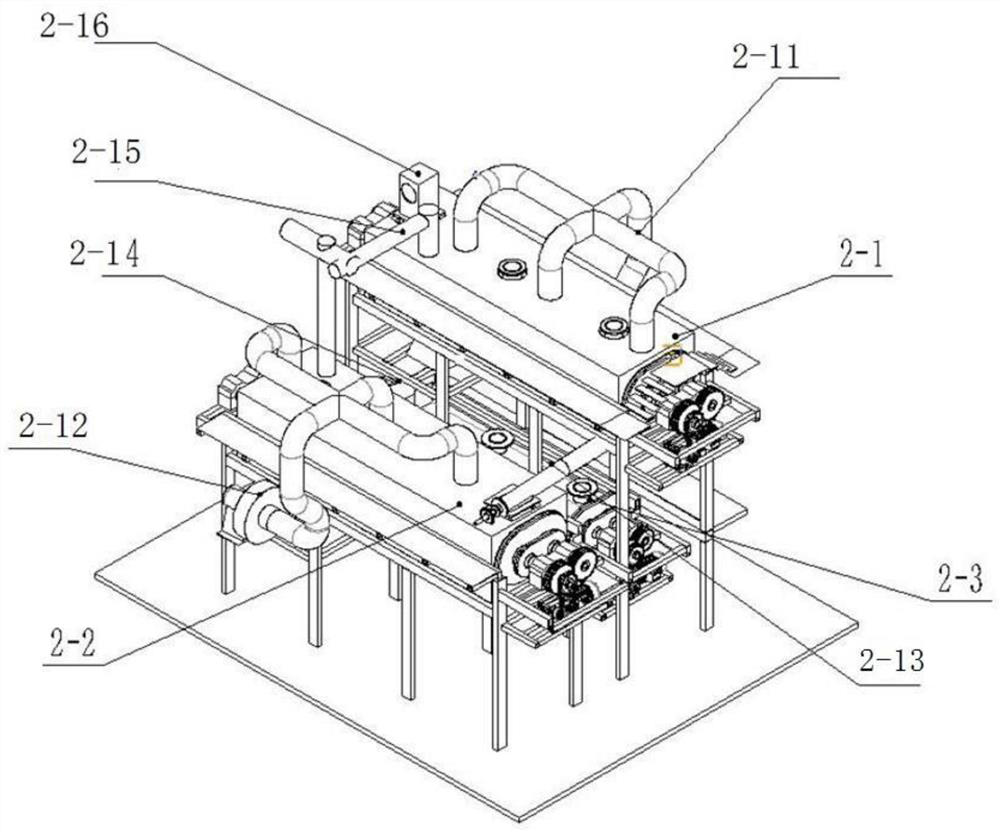

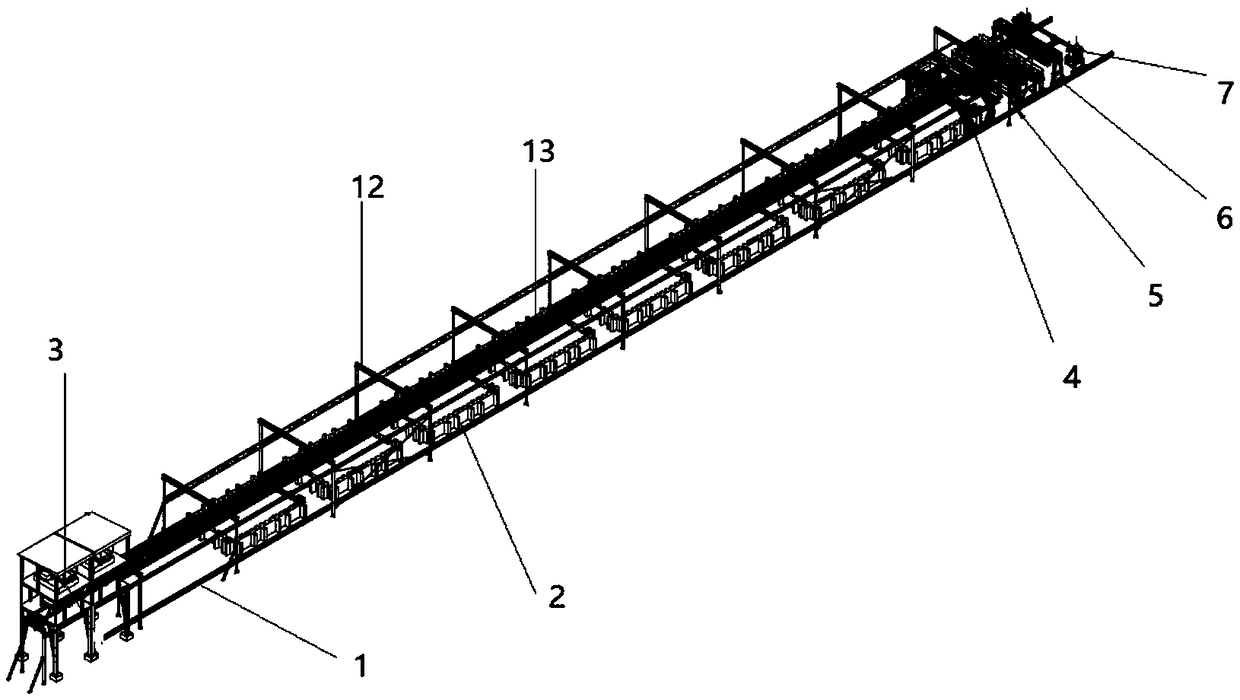

Low-temperature industrial continuous catalytic cracking method and equipment for waste organic polymer material

ActiveCN112029524ARealize deliveryAchieve serializationProductsGas treatmentThermodynamicsCombustible gas

The invention discloses a low-temperature industrial continuous catalytic cracking method and equipment for a waste organic polymer material. The method comprises the following steps: 1) carrying outearlier-stage treatment on a waste organic polymer material, 2) dehydrating and drying the waste organic polymer material, 3) carrying out a sectional catalytic cracking process on the waste high polymer material, 4) condensing and collecting cracking gas, 5) driving the melt material to move through an anti-coking heat-conducting medium, so that the heat and mass transfer effect is enhanced, 6) continuously discharging the pyrolysis carbon, 7) by non-condensable combustible gas generated by cracking supplies, heating the third-stage cracking reactor, 8) dividing the high-temperature flue gasinto three parts to be recycled, and discharging redundant parts through a tail gas treatment device, and 9) discharging tail gas. According to the invention, graded cracking of mixed waste organic polymer materials can be realized, cracked oil products are respectively recycled according to different decomposition temperatures of all the components, the maximum economic benefit of cracking products is realized, and the equipment is reasonable in structural design, can improve the production efficiency and realizes automatic production.

Owner:QINGDAO UNIV OF SCI & TECH

Coarse aggregate active powder concrete bridge deck slab production line and preparation method thereof

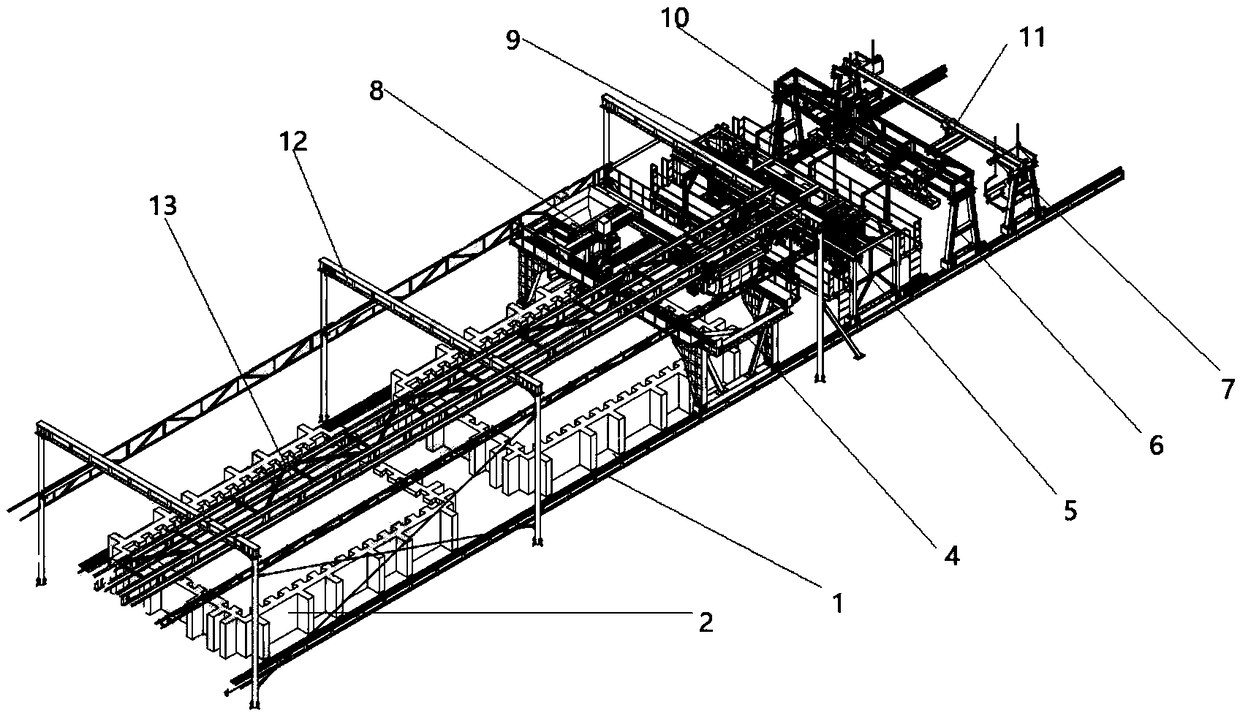

ActiveCN109203209AClosely connectedReduce waiting timeDischarging arrangementCeramic shaping plantsProduction lineBridge deck

The invention relates to the technical field of prefabricated bridge deck slab preparation and discloses a coarse aggregate active powder concrete bridge deck slab production line. The coarse aggregate active powder concrete bridge deck slab production line comprises two parallel tracks fixed to the ground; a plurality of prefabricated slab molds are arranged on the ground between the two tracks;an automatic stirring station is arranged at the left end of the two tracks; an automatic distributor is arranged on a first portal sliding support; an automatic vibrator is arranged on a second portal sliding support; an automatic planer is arranged on a third portal sliding support; an automatic rolling film laminator is arranged on a fourth portal sliding support; a plurality of portal steel frameworks are arranged above the two tracks; the bottoms of the two ends of the portal steel frameworks are fixedly connected with the ground on the outer side of the two tracks; a material vehicle track is arranged in the middle of the portal steel frameworks; and a material vehicle is arranged at the bottom of the automatic stirring station. The prefabricated slab mold is fixed, the material vehicle, the automatic distributor, the automatic vibrator, the automatic planer and the automatic rolling film laminator move along the tracks, and preparation of large-size bridge deck slabs is achievedeasily.

Owner:南京市公共工程建设中心 +2

Environment-friendly type special combined slurry for jean

InactiveCN101476244APoor biodegradabilityThe advantages of environmental protection are obviousFibre treatmentDenimEthylic acid

The invention relates to a environment-friendly type denim special combined sizing agent used or sizing on the 7-32 warp threads for weaving denim, which comprises polyacrylic acids sizing agent, wax pieces, oxidized starch and acetic ester starch, according to the weight proportion of: oxidized starch 72-82 parts, acetic ester starch 10-20 parts, polyacrylic acids sizing agent 3 parts and wax pieces 5 parts. The method for preparing the sizing agent in the invention is: adding the oxidized starch, acetic ester starch, polyacrylic acids sizing agent and wax pieces into a mixing pot in order; mixing uniformly and obtaining the finished product. The invention replaces the PVA in prior art formula by acetic ester starch, consequently, achieves the advantages of environmental protection, reduce cost, easy preparation and stable quality.

Owner:DONGGUAN DONGMEI FOOD

Production process of rail spikes

InactiveCN102284672AHigh precisionReduce quality fluctuationsMetal-working apparatusHooksMachine pressPressure - action

The invention discloses a production process method for a rail spike, comprising the following steps of: (1) blanking; (2) heating; (3) pre-forging and forming in a pre-forging die; (4) final-forging and forming in a final-forging die, placing a Z-shaped or C-shaped blank in a corresponding final-forging die, and forging and forming under the pressure action of a press machine or a punch press; and (5) placing the finally-forged blank in a punching-blanking die, locating by the large ends of the spike heads of two products, and punching the two products under the pressure action of the punch press or a blanker to form a final product. In the invention, the pre-forging die, the final-forging die and the punching-blanking die are utilized; the middle blank and the final formed spike are formed in the dies, and the precision is greatly increased; the spikes of different batches have a less quality fluctuation and a more stable quality respectively; the production efficiency is greatly increased, the production cost is decreased, and the labour intensity of workers is decreased by utilizing a mechanized device.

Owner:唐亮

Production method of high-viscosity cotton pulp

InactiveCN111395026AReasonable workmanshipRealize industrial mass productionPulp de-wateringPulp bleachingManufacturing engineeringCotton linters

The invention provides a production method of high-viscosity cotton pulp, which comprises the following steps: (a) pulping cotton linters, mixing the pulped cotton linters with steam and cooking liquor, and carrying out horizontal pipe continuous steaming to obtain cooked pulp, wherein the temperature of the horizontal pipe continuous steaming is 122 DEG C to 127 DEG C, the rotating speed is 1.5 r / min to 1.9 r / min, the time is 65 min to 100 min, and the pressure is 0.1 MPa to 0.18 MPa; (b) sequentially carrying out pulp extrusion, washing, impurity removal, previous refining, first desanding,first concentration, pre-acidification and chloridizing alkalization on the cooked pulp obtained in the step (a) to obtain to-be-bleached pulp; (c) bleaching the to-be-bleached pulp obtained in the step (b) to obtain bleached pulp; and (d) sequentially carrying out second desanding, second concentration, refining after bleaching, defibrination and papermaking on the bleached pulp obtained in the step (c) to obtain the high-viscosity cotton pulp. Compared with the prior art, the production method has the advantages that stable, reliable, continuous and rapid production of the high-viscosity cotton pulp can be realized, the obtained product meets the performance requirements of the high-viscosity cotton pulp 2600 product, and the quality fluctuation is small.

Owner:ANHUI SNOW DRAGON FIBER TECH

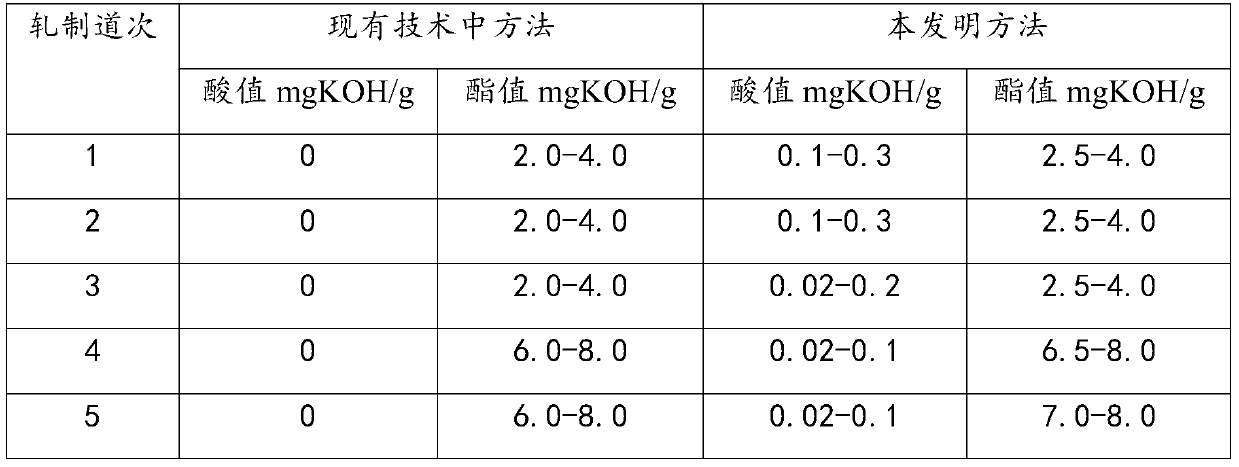

Preparation method for double-sided light aluminum foil

InactiveCN109759474AIncrease pass reduction rateGuarantee the shape qualityReduction rateRoom temperature

The invention discloses a preparation method for a double-sided light aluminum foil. The preparation method comprises the following steps that (1) cast-rolling is performed, wherein an aluminum alloymaterial and an aluminum ingot are put into a melting furnace for melting, after standing is performed through a standing furnace, a molten liquid is filtered, and a cast-rolled plate is obtained after multiple times of cast-rolling is performed by a cast-rolling machine; (2) cold rolling is performed, wherein the cast-rolled plate is cooled to room temperature, multiple times of cold pressing isperformed by a cold press, and then multiple times of annealing treatment is performed to obtain an aluminum foil stock; (3) an aluminum foil working procedure is performed, wherein the aluminum foilstock undergoes five passes of rolling working procedures to obtain a finished aluminum foil, the first pass of the rolling working procedure to the third time of the rolling working procedure are rough rolling, the thickness of the obtained aluminum foil is 0.03 mm, the fourth pass of the rolling working procedure is intermediate rolling, the thickness of the obtained aluminum foil is 0.014 mm, the fifth pass of rolling working procedure is finish rolling, and the aluminum foil with the thickness of 0.009 mm is obtained. According to the method, the distribution of reduction pass of an aluminum foil rolling working procedure is adjusted again, the pass reduction rate of the third pass is properly improved, the pass reduction rate of the fifth pass, namely, the pass reduction rate of the final pass is reduced, so that the reduction process speed is reduced, and the thickness of the product is reduced easier.

Owner:HANGZHOU FIVE STAR ALUMINUM

Forming mould for flue gas exhausting pipeline

The invention discloses a forming mould for a flue gas exhausting pipeline, and the forming mould provided by the invention comprises a left side frame and a right side frame, wherein a plurality of external mould plates and internal mould plates, which are detachable, are arranged between the left side frame and the right side frame; an external mould cavity is defined by the plurality of external mould plates; an internal mould cavity is defined by the plurality of internal mould plates in the external mould cavity; forming cavities are formed between the external mould plates and internal mould plates; and a feed port is formed on at least one of the external mould plates. By using the forming mould provided by the invention, the mechanical mould production for a thin-wall flue gas exhausting pipeline can be realized, the problem that the mechanical production cannot be achieved in the field of forming of prefabricated noncircular thin-wall component is solved, the product is formed through one step, the production efficiency is increased, the labor intensity of a worker is reduced, places for production are greatly saved, the production process is supplemented by virtue of vibration molding, the product intensity and quality are high, and the quality fluctuation and the raw material waste which are caused by manual operation are reduced simultaneously.

Owner:韩文强

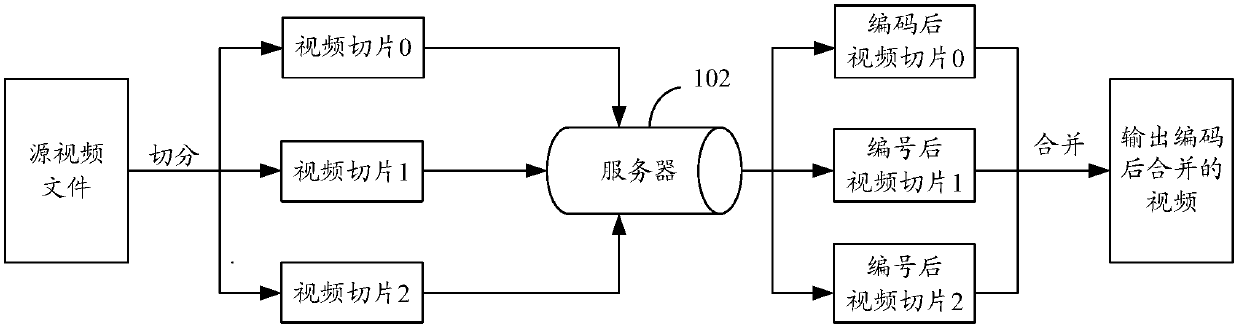

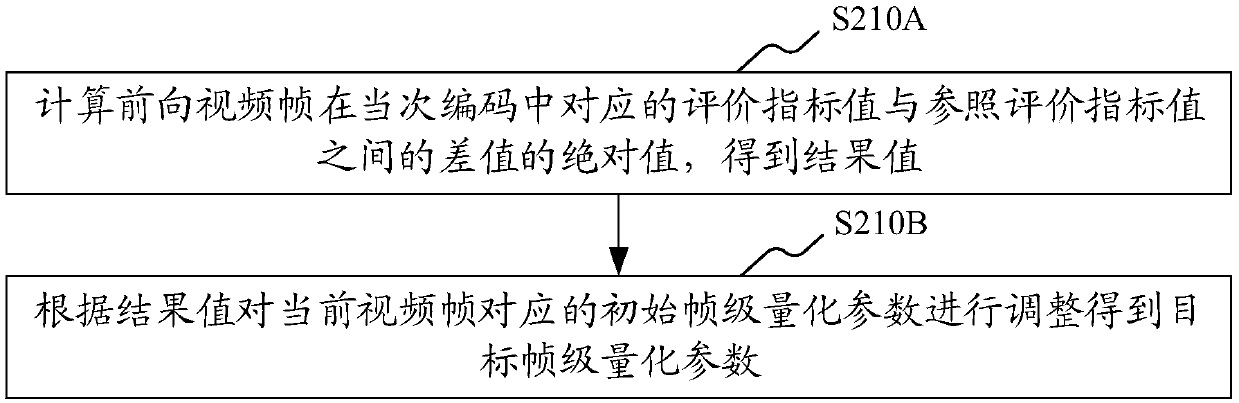

Video coding method and device, computer equipment and storage medium

ActiveCN110139168AReduce quality fluctuationsQuality improvementTelevision systemsDigital video signal modificationPattern recognitionVideo encoding

The invention relates to a video coding method. The method comprises the following steps of: obtaining a forward video frame of the current video frame to be coded, obtaining corresponding evaluationinformation of the forward video frame in the current coding, determining a reference video slice corresponding to the current video frame, obtaining a reference video frame from the reference video slice, calculating and obtaining reference evaluation information corresponding to the current video frame according to the evaluation information corresponding to the reference video frame in the previous coding; obtaining an initial frame level quantization parameter corresponding to the current video frame in the current coding, and adjusting the initial frame-level quantization parameter according to the evaluation information corresponding to the forward video frame in the current coding and the reference evaluation information corresponding to the current video frame to obtain a target frame-level quantization parameter, and coding the current video frame according to the target frame-level quantization parameter. According to the video coding method, quality fluctuation at the jointis effectively reduced, and the video quality after video merging is improved. In addition, the invention also provides a video coding device, computer equipment and a storage medium.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com