Wide heavy standard high strength ship plate steel and technique for producing the same

A production process, high-strength technology, applied in the direction of manufacturing tools, temperature control, metal processing equipment, etc., can solve the problems of low production efficiency, complex production process, uneven organization, etc., to achieve stable product performance, simple production process, The effect of small fluctuations in quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition of the wide and thick specification high-strength ship plate steel of the present embodiment is (percentage by weight): C 0.06%, Mn 1.53%, P 0.009%, S 0.002%, Si 0.20%, N 0.0060%, Ni 0.25%, Alt 0.036 %, Nb 0.040%, Ti 0.013%, and the rest is Fe content.

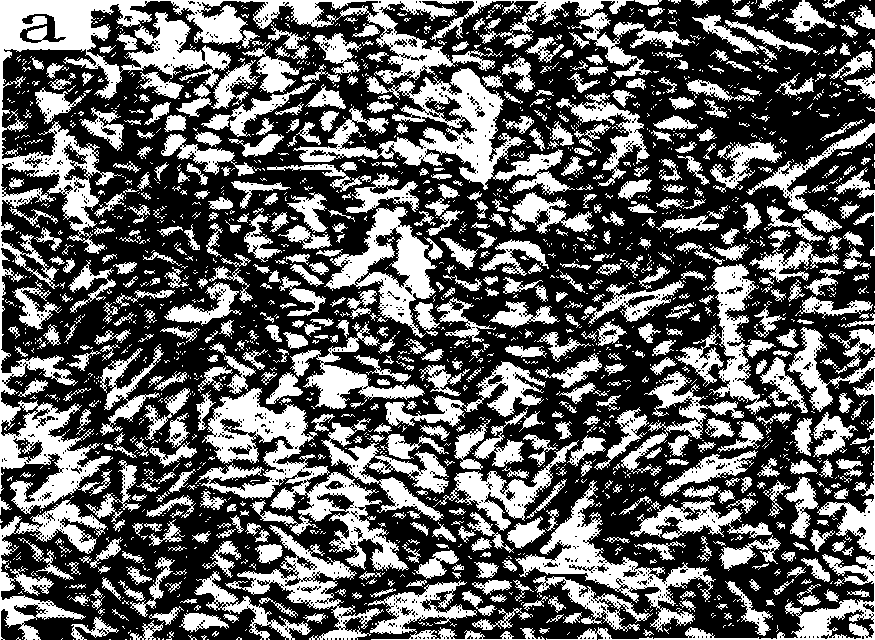

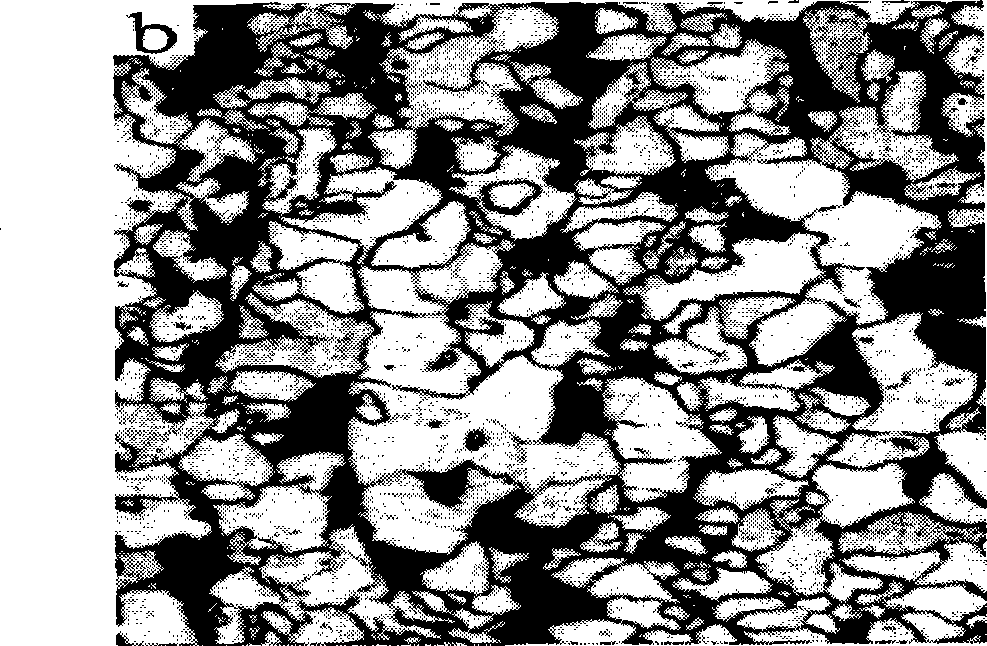

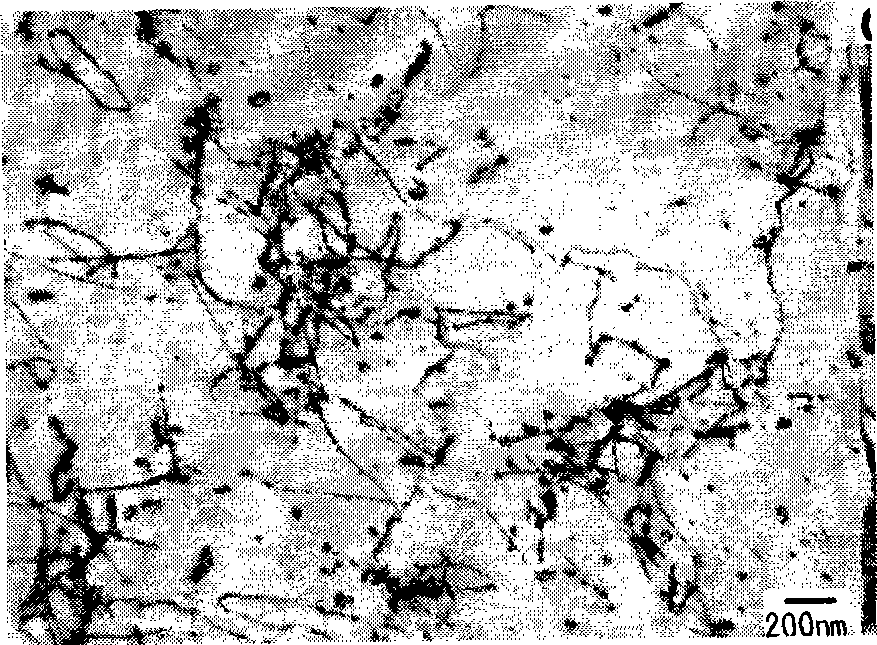

[0021] The production process of the high-strength ship plate steel with wide and thick specifications in this embodiment is as follows: put the slab into a heating furnace for heating, the heating temperature is 1200° C., and the heating time is 3.5 hours. Then it comes out of the furnace and enters the rough rolling stage. The rolling temperature is 1100°C, and 6 passes of rolling are carried out. During the 6 passes of rolling, the reduction of each pass is 12.5%, 13%, 15%, and 16% respectively. , 16%, 12%, the total reduction is 60%. Immediately after entering the finishing rolling stage, the rolling temperature was 840°C, and a total of 4 rolling passes were carried out. The reductions in each pass...

Embodiment 2

[0027] The composition of the wide and thick specification high-strength ship plate steel of the present embodiment is (percentage by weight): C 0.04%, Mn 1.20%, P 0.010%, S 0.009%, Si 0.10%, N 0.0090%, Ni 0.20%, Alt 0.030 %, Nb 0.002%, Ti 0.010%, and the rest is Fe content.

[0028] The production process of the high-strength ship plate steel with wide and thick specifications in this embodiment is as follows: put the slab into a heating furnace for heating, the heating temperature is 1180° C., and the heating time is 3.0 h. Then it comes out of the furnace and enters the rough rolling stage. The rolling temperature is 1080°C, and 4 passes of rolling are carried out. During the 4 passes of rolling, the reduction of each pass is 12%, 13%, 14%, and 11% respectively. , the total reduction is 50%. Immediately after entering the finish rolling stage, the rolling temperature was 800°C, and a total of 4 rolling passes were carried out. The reductions of each pass were 16%, 14%, 12%...

Embodiment 3

[0030] The composition of the wide and thick specification high-strength ship plate steel of the present embodiment is (percentage by weight): C 0.16%, Mn 1.60%, P 0.025%, S 0.025%, Si 0.30%, N 0.012%, Ni 0.40%, Alt 0.060 %, Nb 0.050%, Ti 0.02%, and the rest is Fe content.

[0031] The production process of the high-strength ship plate steel with wide and thick specifications in this embodiment is as follows: put the slab into a heating furnace for heating, the heating temperature is 1220° C., and the heating time is 4 hours. Then it comes out of the furnace and enters the rough rolling stage. The rolling temperature is 1120°C, and 6 passes of rolling are carried out. During the 6 passes of rolling, the reduction of each pass is 12.5%, 13%, 15%, and 16% respectively. , 16%, 12%, the total reduction is 60%. Immediately after entering the finish rolling stage, the rolling temperature was 900°C, and a total of 9 rolling passes were carried out, and the reductions in each pass we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com