Polycarboxylic acid-lignin composite additive

A polycarboxylic acid and lignin technology, applied in the field of concrete admixtures, can solve the problems of incompatibility between naphthalene-based water-reducing agent and polycarboxylate water-reducing agent, and achieve the improvement of concrete quality, water reduction rate and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

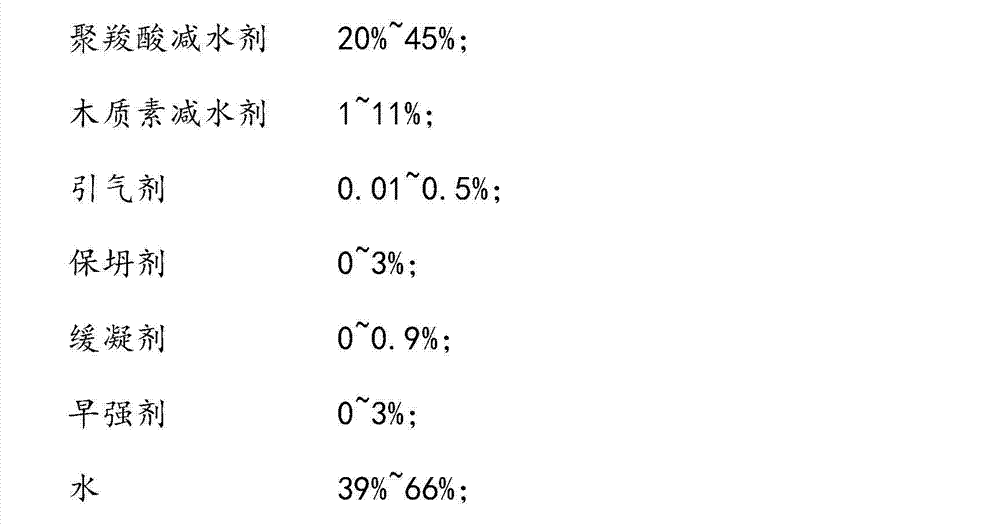

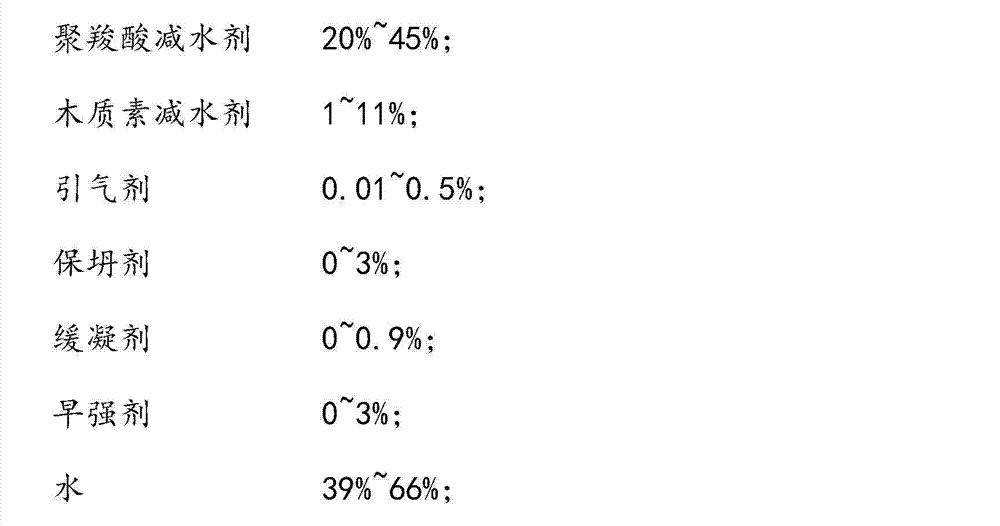

Method used

Image

Examples

Embodiment 1

[0024] In percent by weight: polycarboxylate superplasticizer (mass solid content: 20%) 38.5%, lignin superplasticizer 11%, air-entraining agent 0.1%, slump-retaining agent 2%, retarder 0.6%, water 47.8 %, add to the stirring tank in turn, and mix well to get this product. Adding this admixture accounting for 1% of the weight of cement can make the fluidity of the cement slurry with a water-cement ratio of 0.35 be 190mm. Adding 1% of the admixture to the concrete, the water-reducing rate of the concrete is 17%, the slump loss is 10mm in 1 hour, the setting time is extended for 2 hours, and the compressive strength ratio reaches 120% in 28 days.

Embodiment 2

[0026] In terms of weight percentage ratio: polycarboxylate water reducer (mass solid content is 20%) 45%, lignin water reducer 5%, air entraining agent 0.1%, early strength agent 2%, tap water 47.9%, add to Stir the tank, mix evenly to get this product. Adding this admixture accounting for 1.2% of the weight of cement can make the fluidity of the cement paste with a water-cement ratio of 0.35 be 210mm. Adding this admixture accounting for 1.2% of the total weight of the cementitious material in the concrete, the water-reducing rate of the concrete is 19%, the slump loss in 1 hour is 15mm, the 7-day compressive strength ratio is 130%, and the 28-day compressive strength ratio is 130%. is 115%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com