Method for operating forging hammer

A forging hammer and hammer head technology, applied in the field of running forging hammers, can solve the problems of expensive and costly analog computing technology, and achieve the effects of low cost, optimized cycle time, and no time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

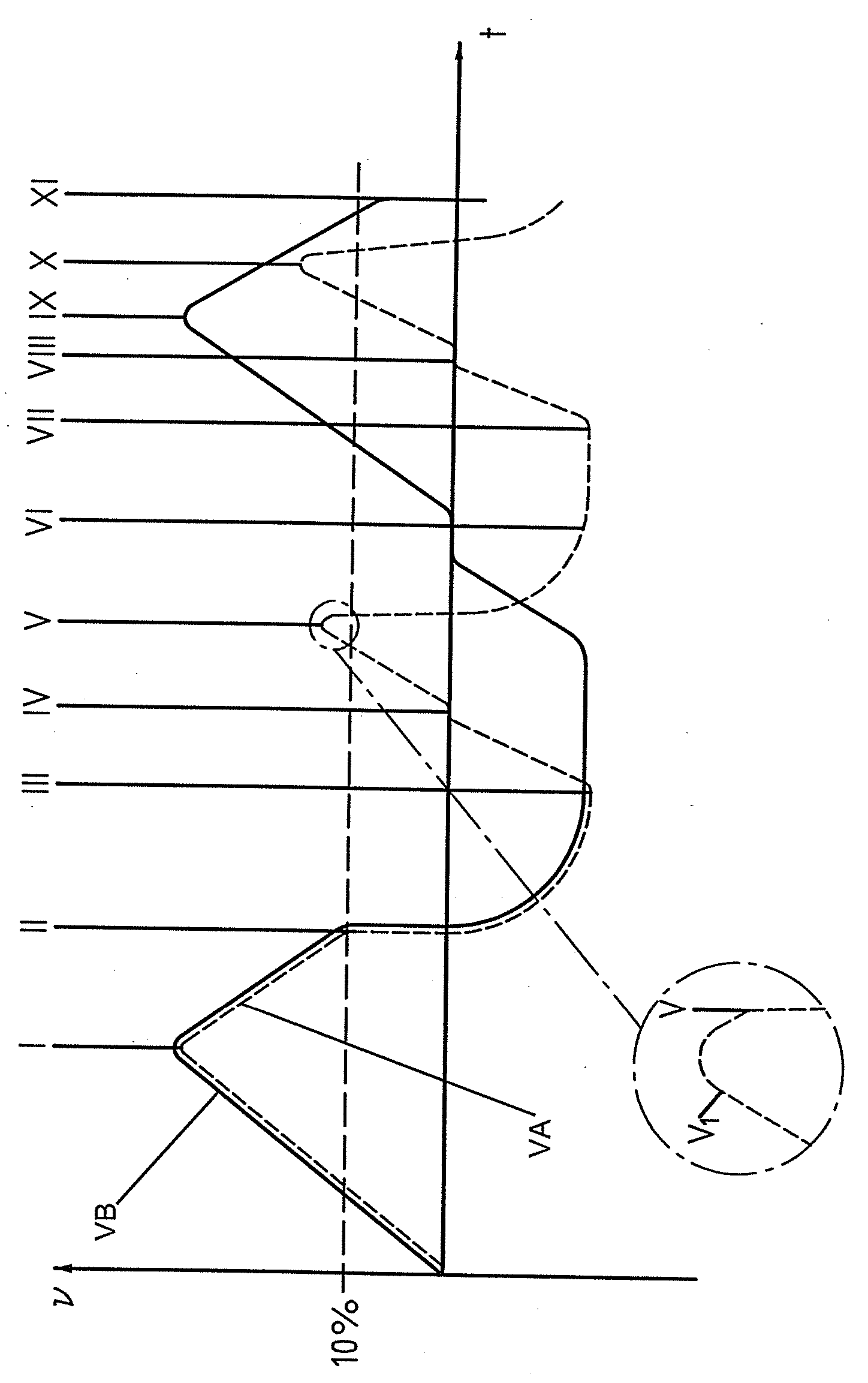

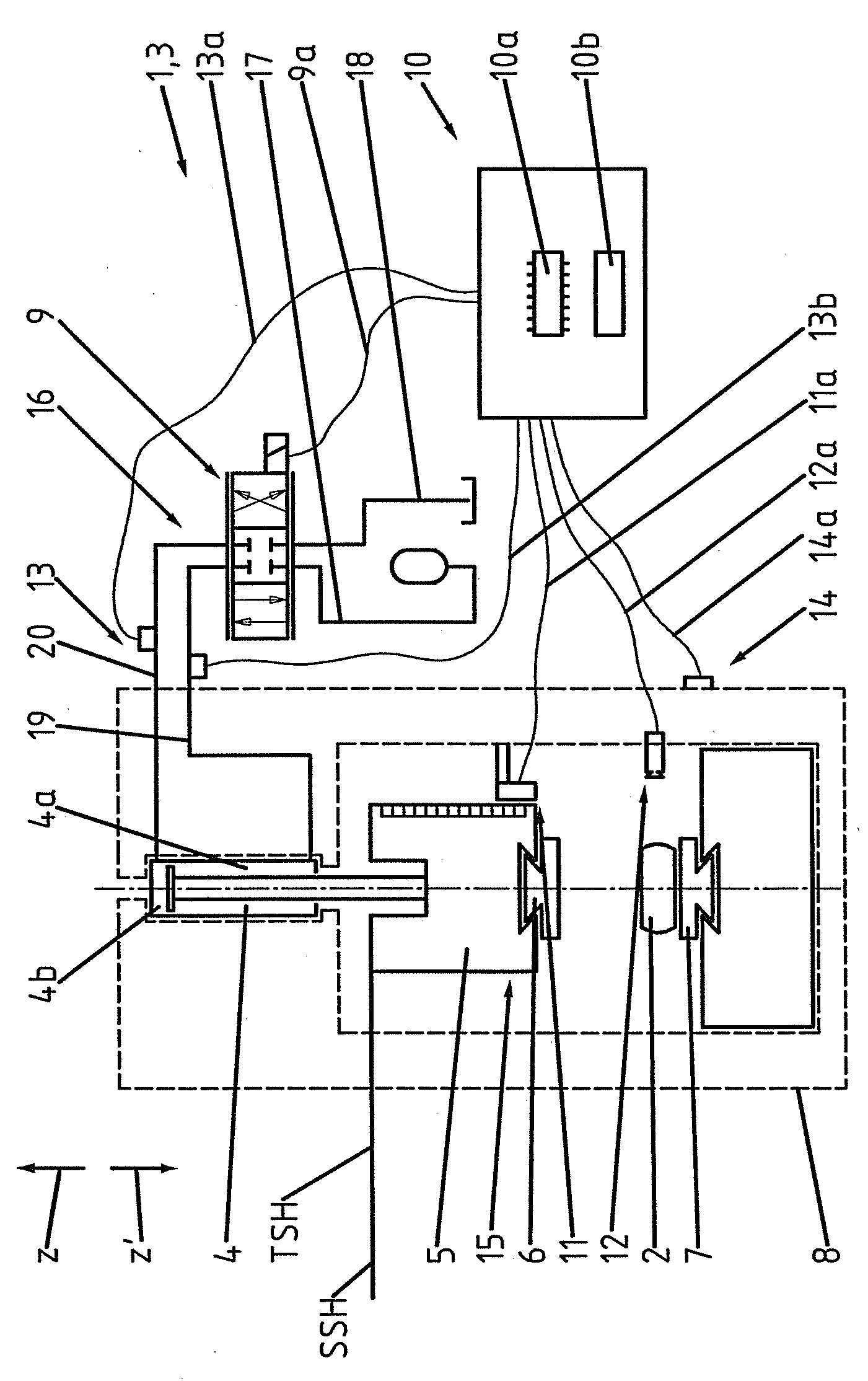

[0023] figure 1 The forging hammer 1 is shown schematically in FIG. The forging hammer 1 is provided for forging a workpiece 2 and is designed as a short-stroke die forging hammer 3 . The forging hammer 1 comprises a hydraulic cylinder 4 , a hammer head 5 , an upper die 6 , a lower die 7 , a machine frame 8 , a control valve 9 , an electronic control device 10 and four sensor devices 11 , 12 , 13 and 14 . The hammer head 5 and the upper die 6 constitute an upper tool 15 moved by the hydraulic cylinder 4 . Furthermore, the forging hammer 1 comprises a hydraulic circuit 16 in which the hydraulic cylinder 4 and the control valve 9 participate. The control valve 9 is connected to the oil inlet port 17 and the oil outlet port 18 and is connected to the double-acting hydraulic cylinder 4 via lines 19 , 20 . The sensor devices 11 to 14 and the control valve 9 are connected to the actuating device 10 via data lines 11a, 12a, 13a, 13b, 14a and 9a. The control device 10 includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com