Fiber reinforce plastic hollow plate continuous forming process

A molding process, glass steel plate technology, applied in the direction of hollow objects, other household appliances, flat products, etc., can solve the problems of low production efficiency, difficulty in realizing large-scale production, etc., and achieve the effect of improving production efficiency, small quality fluctuation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

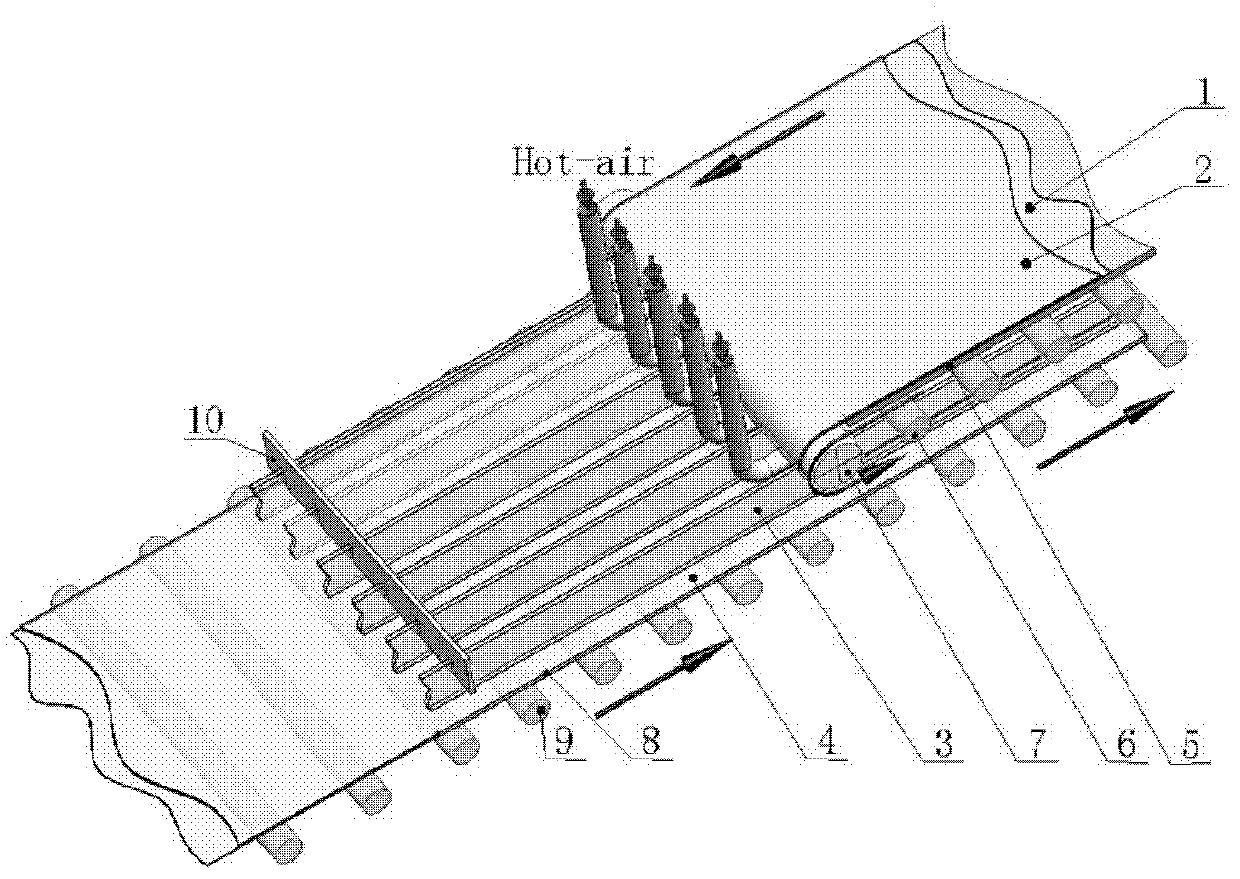

[0055] The continuous molding process of the FRP hollow plate of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

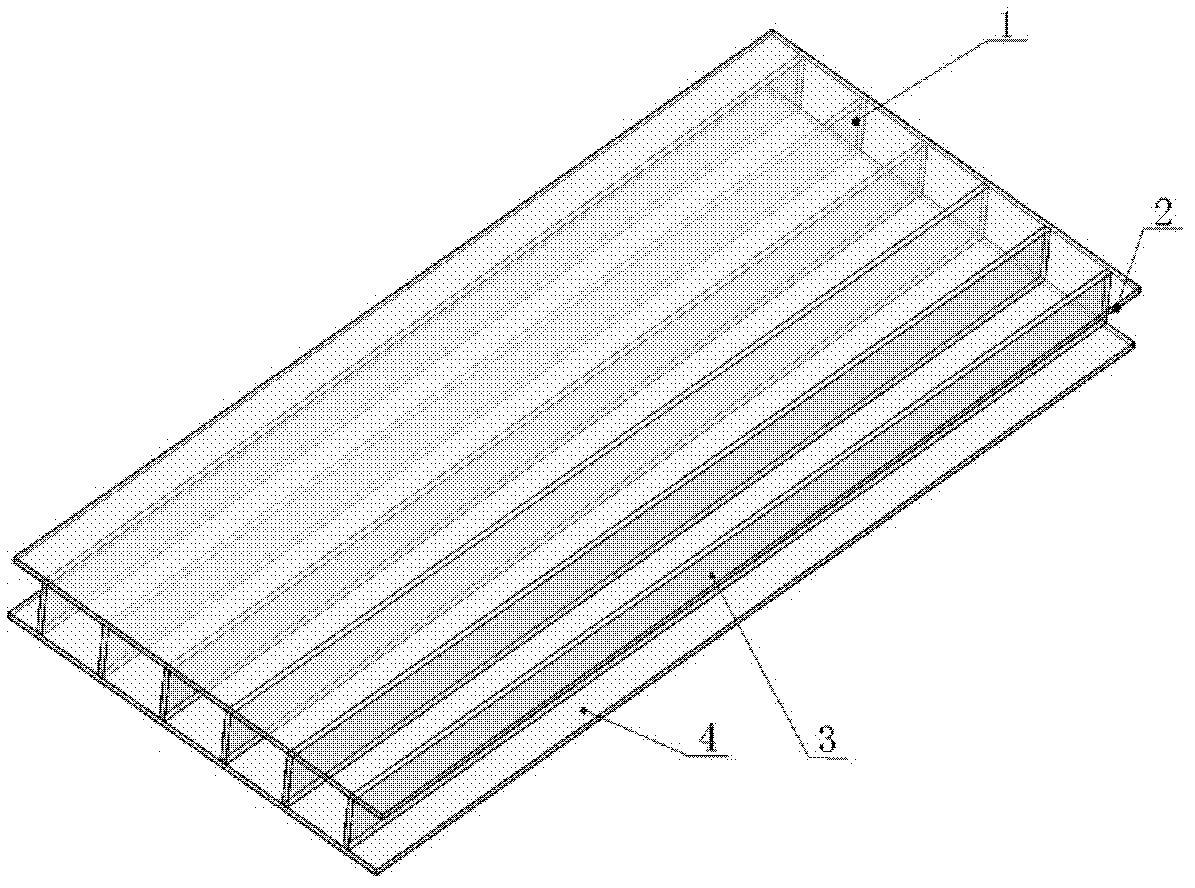

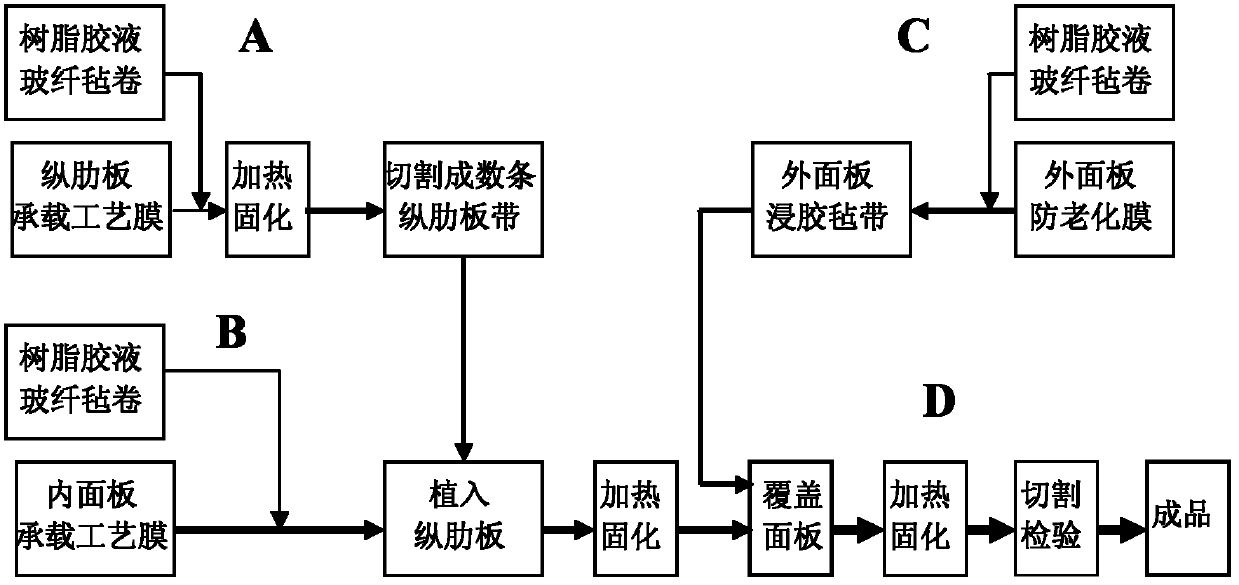

[0056] Such as figure 1 As shown, a FRP hollow panel produced by the continuous molding process of FRP hollow panels of the present invention includes an outer panel 2, several longitudinal ribs 3 and an inner panel 4, the outer panel 3 and the inner panel 4 are arranged horizontally, and the longitudinal ribs 3 is vertically supported between the outer panel 2 and the inner panel 4 which are parallel to each other. Among them, the outer panel and the inner panel are rectangular FRP flat plates with the same size, and the upper end surface of the outer panel 2 is coated with anti-aging film 1; The panels 4 have the same length and are placed vertically parallel to the long sides of the outer panel 2 and the inner panel 4. The upper and lower end surfaces are respectively connected to the outer pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com