Saw-tooth clothing for rollers and/or cylinders

A card clothing and sawtooth technology, which is applied in the field of all-steel sawtooth card clothing for rollers and/or cylinders, can solve problems such as sharpness loss, and achieve the effect of reducing sharpness loss and quality fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

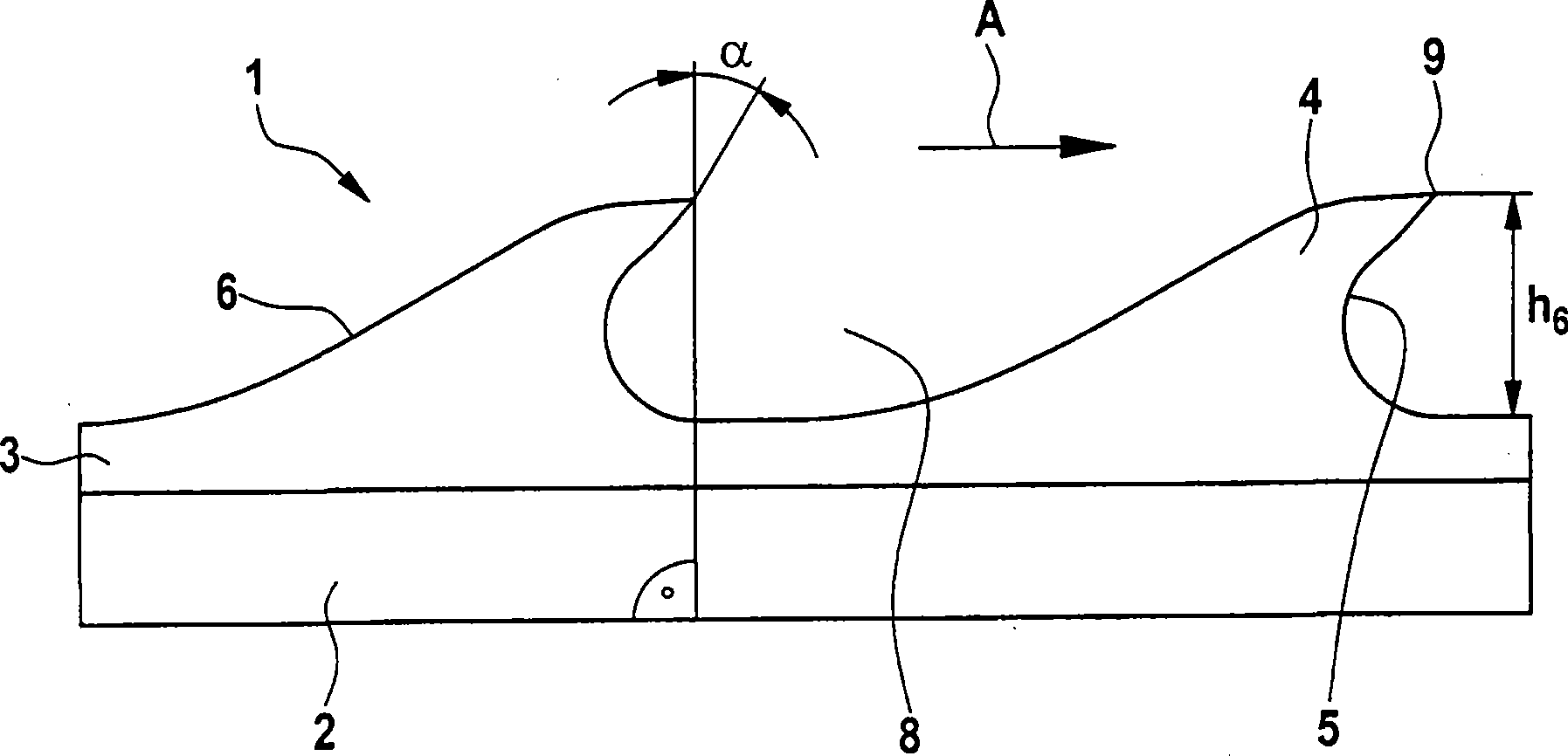

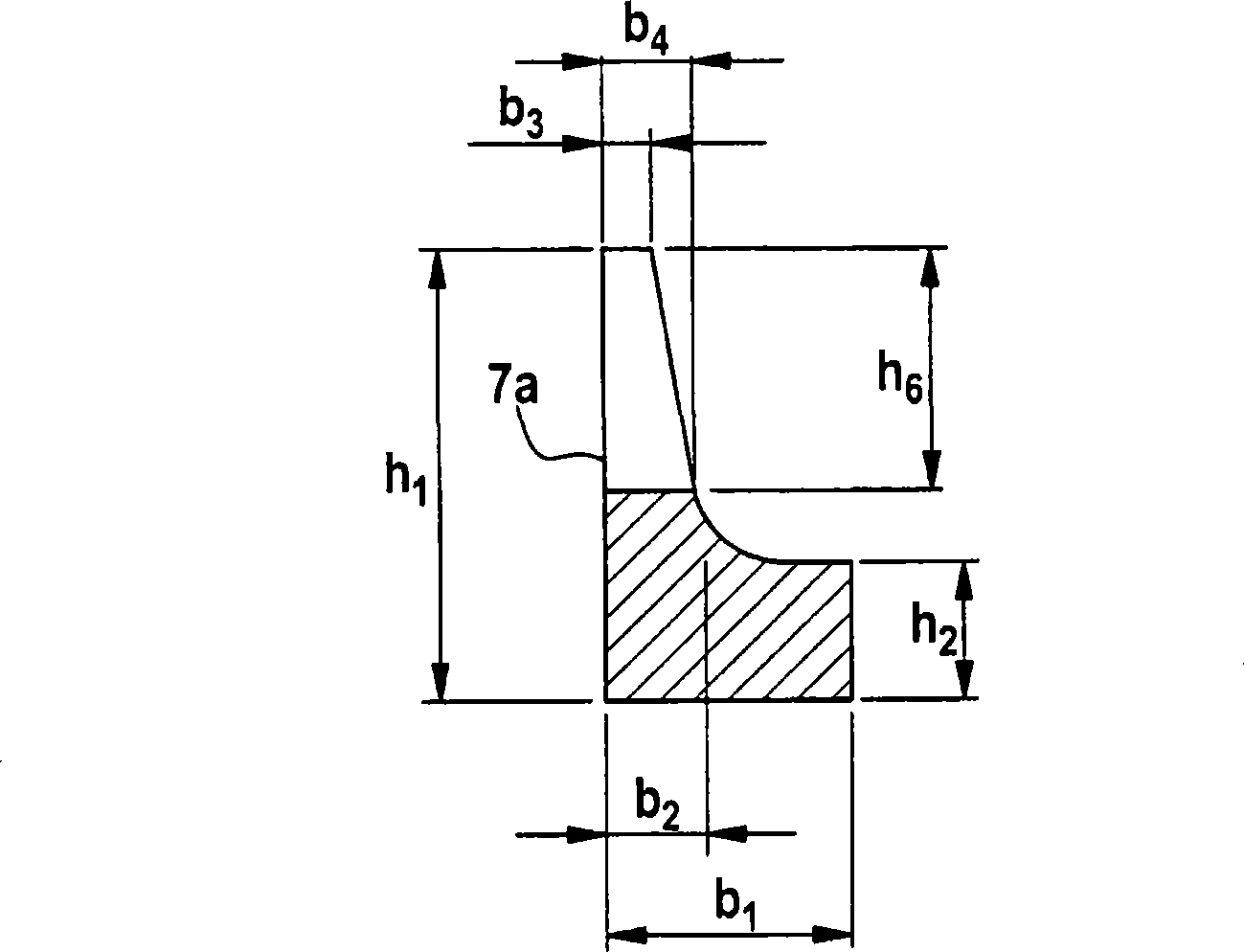

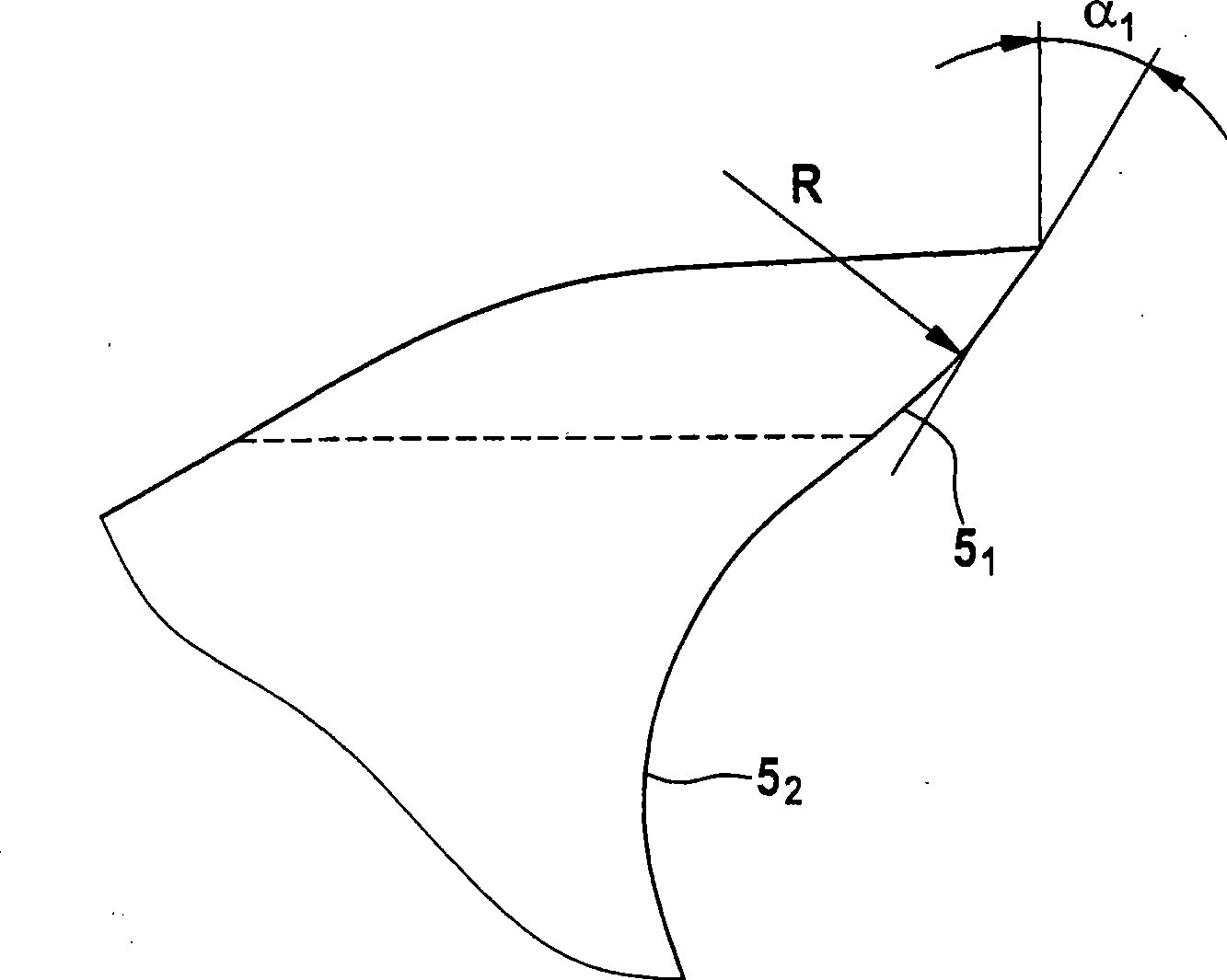

[0013] Figure 1a , 1b Showing a side view and a cross-sectional view respectively, the serrated wire 1 of the invention comprises an integral elongated base region 2 (tooth base) and an adjoining edge region 3 (tooth blade). The tooth 4 is formed by cutting at the tooth plate 3, and the tooth has a tooth front 5, a tooth back 6 and two sides 7a, 7b (cf. Figure 1b ). There is a tooth gap 8 between the tooth back 6 and the tooth front 5 of two teeth 4 arranged one behind the other. This tooth 4, ie the tooth flank 5, consists of two parts, the first part 5 of the tooth tip 9 1 With a positive working angle α, the working angle α (rake angle) refers to the convexly curved first portion 5 of the tooth tip 9 1 The angle between the tangent of the wire and the vertical axis of the wire base (the bottom surface of the tooth base 2). Located at the tooth tip 9 and the first part 5 of the tooth flank 5 (tooth front) 1 with the second part 5 2 The part between the transition zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com