Laboratory mix proportion design method of permeable recycled aggregate concrete

A technology of mix proportion design and recycled aggregate, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of many cracks in recycled aggregate, low reliability, large dispersion of design results, etc., and achieve small quality fluctuations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

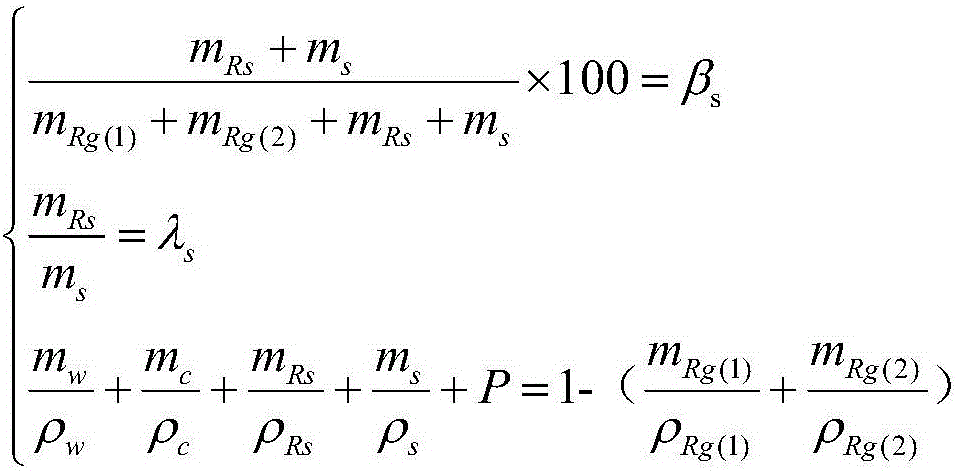

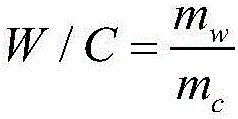

Method used

Image

Examples

Embodiment 1

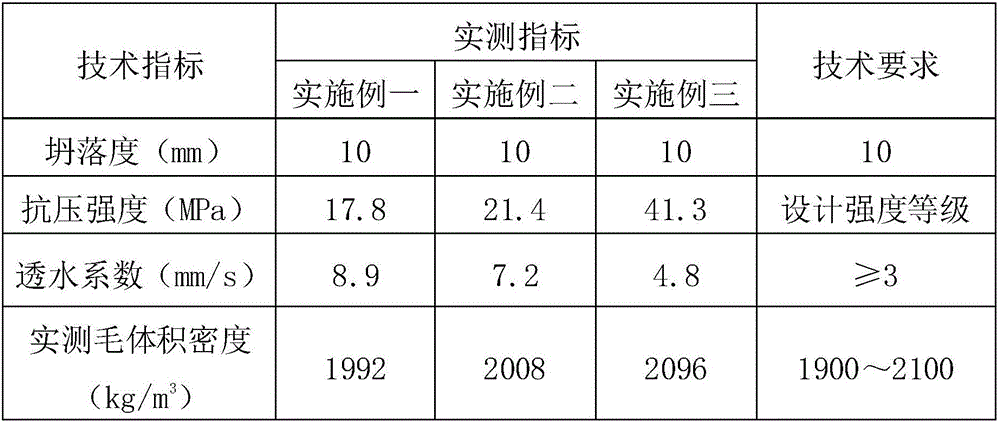

[0065] A design method for laboratory mix ratio of C15 permeable concrete using construction waste recycled aggregates, including the following parts by weight of raw materials: cement: water: natural sand: recycled sand: recycled coarse aggregate (1): recycled coarse aggregate ( 2)=252:51:63:57:1021:448. Among them, the target void ratio is 18%, the water-cement ratio is 0.20, the sand ratio is 8%, and the design quality of the recycled coarse aggregate (1), (2) is the surface dry quality.

[0066] Among them, the cement is ordinary Portland cement with a strength grade of P.O42.5; recycled coarse aggregate (1) is 5-25mm, recycled coarse aggregate (2) is 5-10mm, and its surface dry density is 2.314g / cm 3 , 2.286g / cm 3 , The water absorption rate is 5.8%, 8.3%, the blending ratio of recycled coarse aggregate (1), (2) is 70:30, and the tamped density of the mixed recycled coarse aggregate is 1407kg / m 3 ; Reclaimed sand is medium sand, fineness modulus is 2.87, apparent density is...

Embodiment 2

[0072] A design method for laboratory mix ratio of C20 permeable concrete using construction waste recycled aggregates, including the following parts by weight of raw materials: cement: water: natural sand: recycled sand: recycled coarse aggregate (1): recycled coarse aggregate ( 2)=310:84:126:116:1021:448. Among them, the target void ratio is 15%, the water-cement ratio is 0.27, the sand ratio is 15%, and the design quality of the recycled coarse aggregate (1), (2) is the surface dry quality.

[0073] Among them, the cement is ordinary Portland cement with a strength grade of P.O42.5; recycled coarse aggregate (1) is 5-25mm, recycled coarse aggregate (2) is 5-10mm, and its surface dry density is 2.314g / cm 3 , 2.286g / cm 3 , The water absorption rate is 5.8%, 8.3%, the blending ratio of recycled coarse aggregate (1), (2) is 50:50, and the tamped density of the mixed recycled coarse aggregate is 1298kg / m 3 ; Reclaimed sand is medium sand, fineness modulus is 2.87, apparent density...

Embodiment 3

[0080] A method for designing a laboratory mix ratio of C40 permeable concrete using construction waste recycled aggregates, including the following parts by weight of raw materials: cement: water: natural sand: recycled sand: recycled coarse aggregate (1): recycled coarse aggregate ( 2)=355:71:98:90:1021:448. Among them, the target void ratio is 10%, the water-cement ratio is 0.3, the sand ratio is 12%, and the design quality of the recycled coarse aggregates (1) and (2) are both surface dry quality.

[0081] Among them, the cement is Portland cement with a strength grade of P.Ⅱ52.5; recycled coarse aggregate (1) is 5-25mm, recycled coarse aggregate (2) is 5-10mm, and its surface dry density is 2.314g / cm. 3 , 2.286g / cm 3 , The water absorption rate is 5.8%, 8.3%, the blending ratio of recycled coarse aggregate (1), (2) is 60:40, and the tamped density of the mixed recycled coarse aggregate is 1349kg / m 3 ; Reclaimed sand is medium sand, fineness modulus is 2.87, apparent density i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com