Mould for forming prefabricated exhaust pipeline

A technology for forming molds and pipes, applied in the direction of molds, etc., can solve the problems of waste of raw materials, easy breakage, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention aims to solve the problem that mechanization cannot be produced in the field of prefabricated non-circular thin-walled components, realize the mechanized mold production of thin-walled flue gas exhaust pipes, make the thin-walled flue gas exhaust pipes one-time molding, improve production efficiency, and save production costs Need venue. The present invention will be specifically described below through preferred specific embodiments.

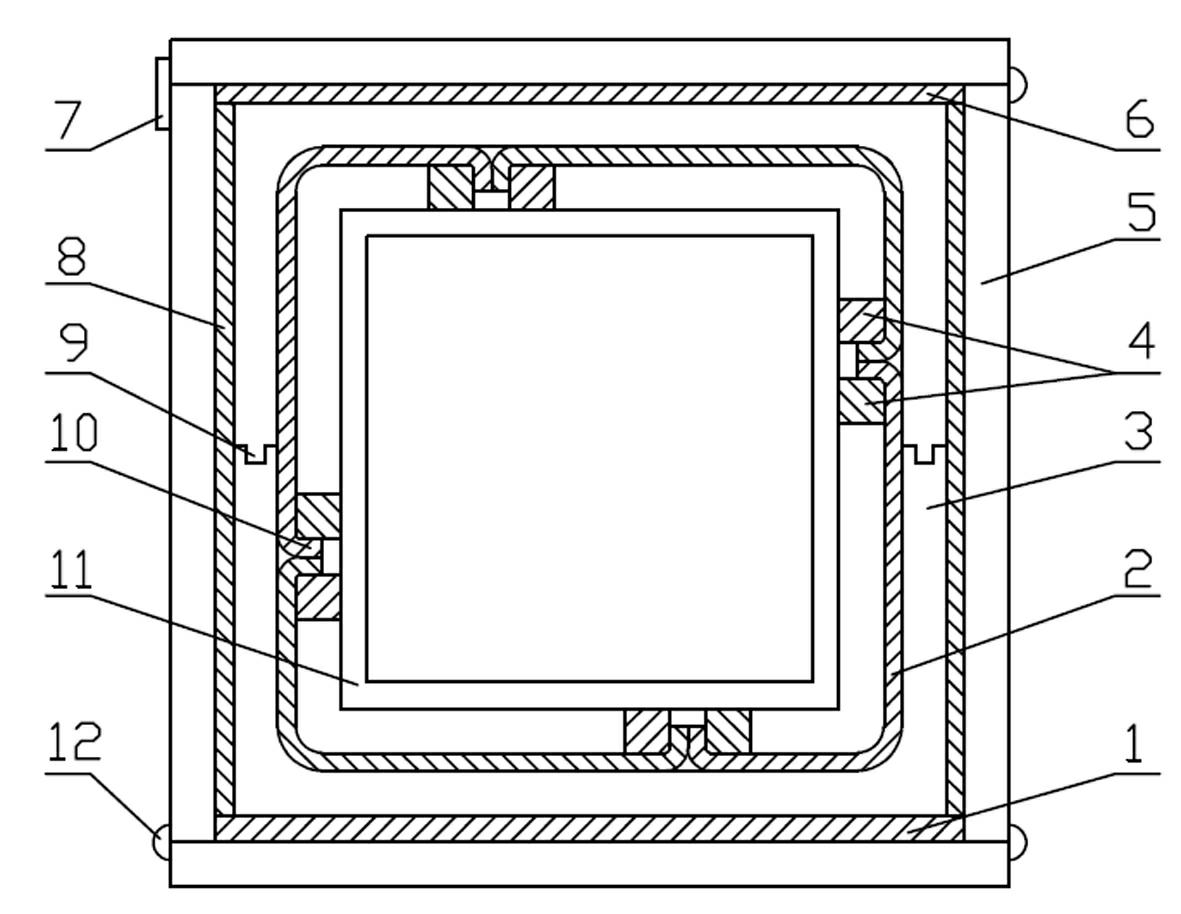

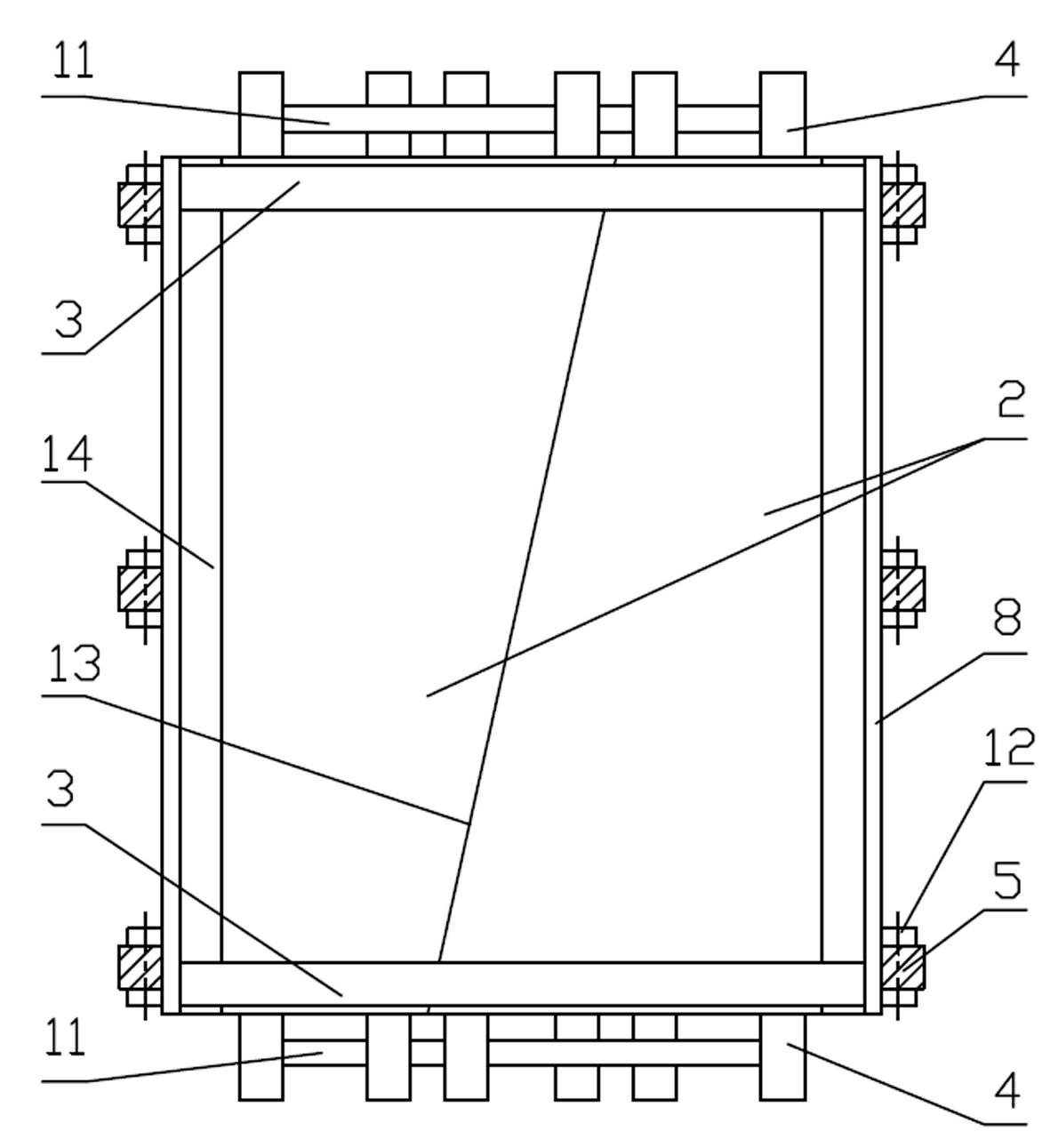

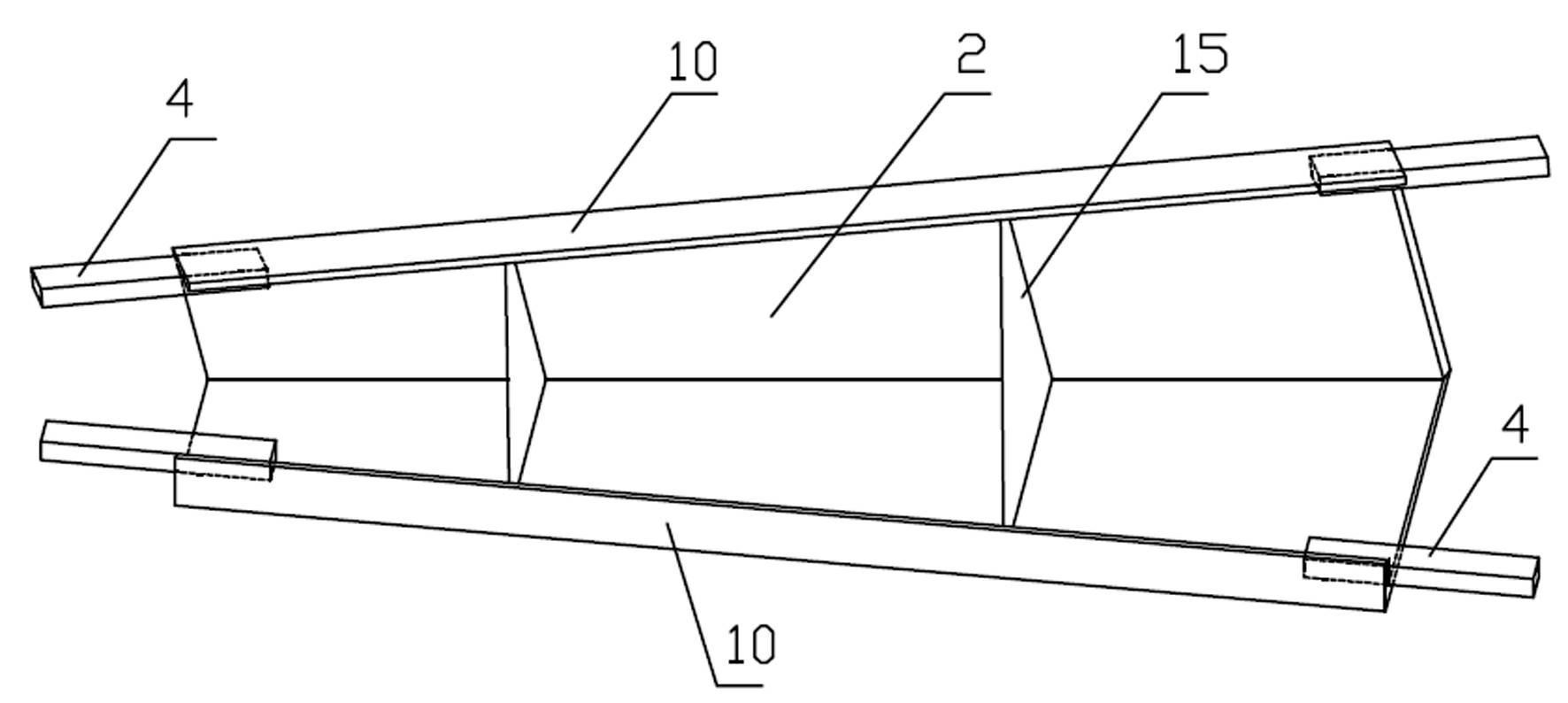

[0029] With reference to the accompanying drawings, the prefabricated exhaust gas duct forming mold includes an outer template and an inner template 2, the outer template includes an outer bottom template 1 and two outer templates 8 that cooperate with the outer bottom template 1, the outer bottom template 1, the two outer templates 8 Enclosing the outer mold cavity, the connection between the two outer formworks 8 and the outer bottom formwork 1 can be inserted or hinged. Positioning pin holes are arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com