Secondary formula treatment technology for tobacco leaves

A treatment process and tobacco leaf technology, which is applied in the field of secondary formula tobacco sheet processing technology, can solve problems such as waste of raw materials, affecting product quality stability, frequent adjustment of formula, etc., to improve usability, selectivity of tobacco sheet structure, and guarantee stability Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

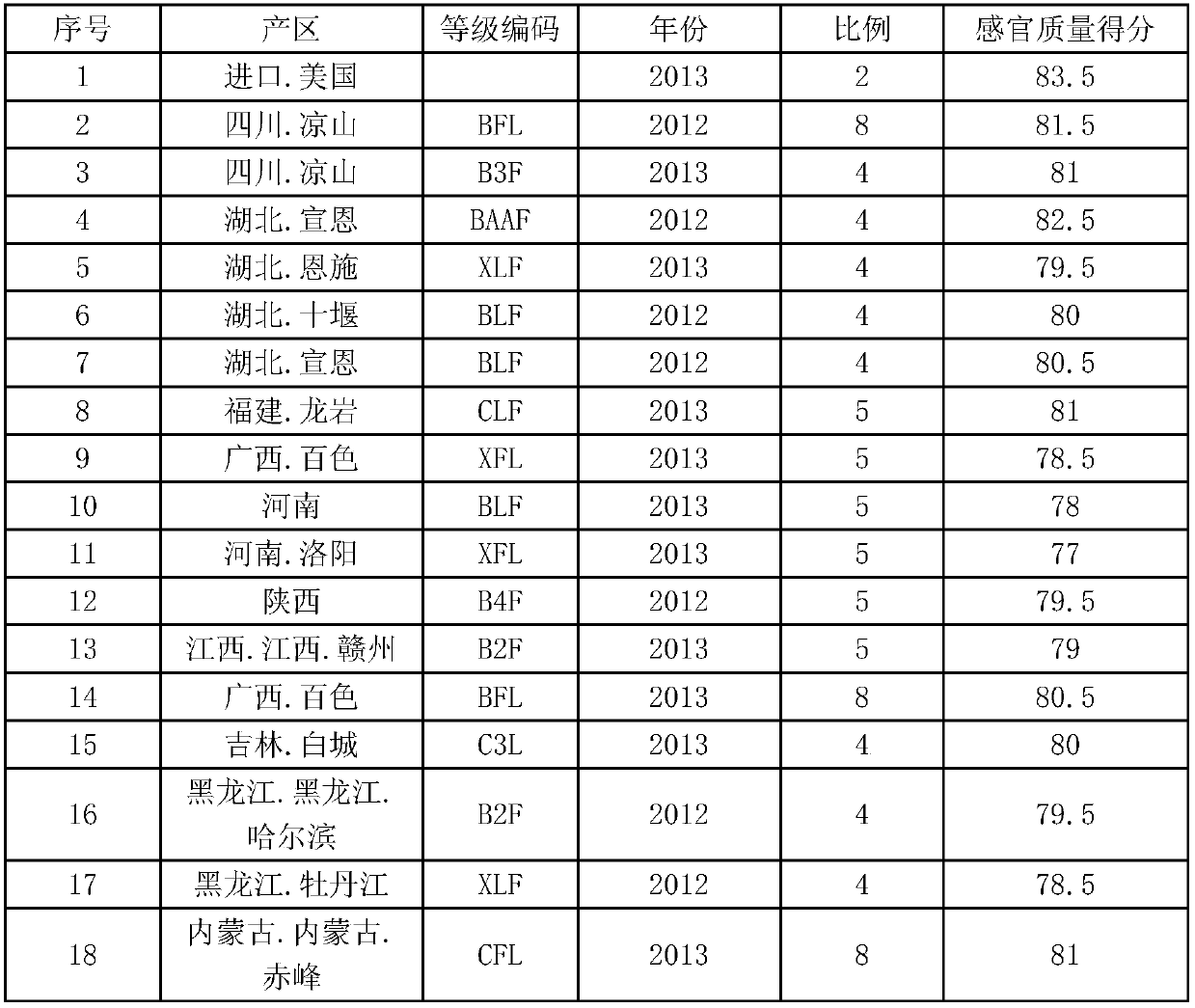

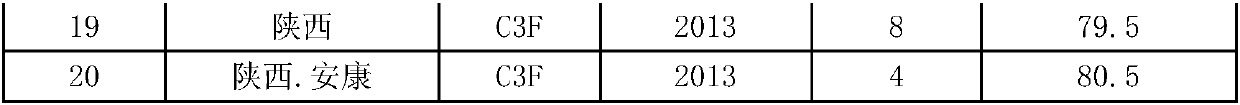

[0023] The process of the present invention will be further described below in conjunction with the examples. By analyzing the grades, types and sensory qualities of different tobacco bales remaining in the tobacco factory, the following tobacco leaf formulations were obtained:

[0024]

[0025]

[0026] 20 kinds of small-scale tobacco leaves in the above formula are processed according to the following process, and the specific processing steps are as follows:

[0027] (1) Select the cigarette bales in the above formula, unpack and slice the selected tobacco leaf bales of each grade, cut each cigarette bale with 4-5 knives, and the length of the tobacco bale after cutting is 18- 21cm; reduce the thickness of a single tobacco block after slicing, so as to facilitate the effective loosening of the tobacco leaves in the subsequent loosening and rehydration process, and increase the loosening rate of the tobacco leaves;

[0028] (2) All the cigarette bales cut in step (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com