Coarse aggregate active powder concrete bridge deck slab production line and preparation method thereof

A technology of active powder and concrete, applied in unloading devices, manufacturing tools, auxiliary molding equipment, etc., to achieve the effects of stable quality, tight connection and shortening of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

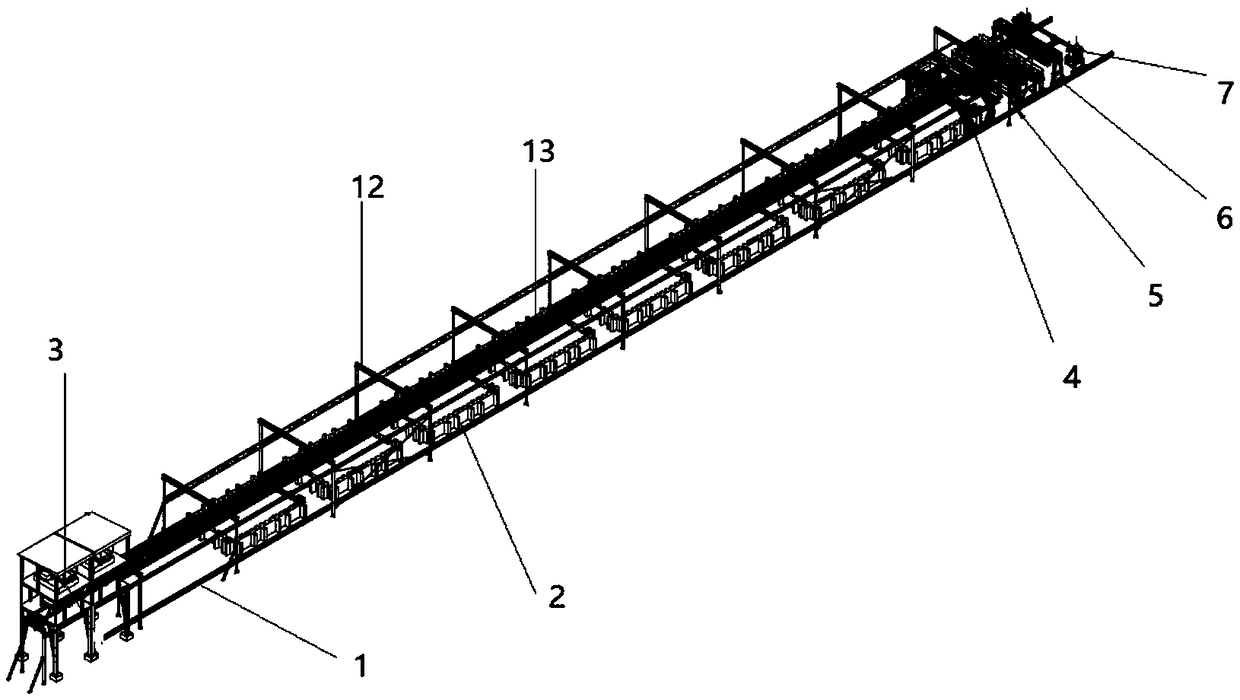

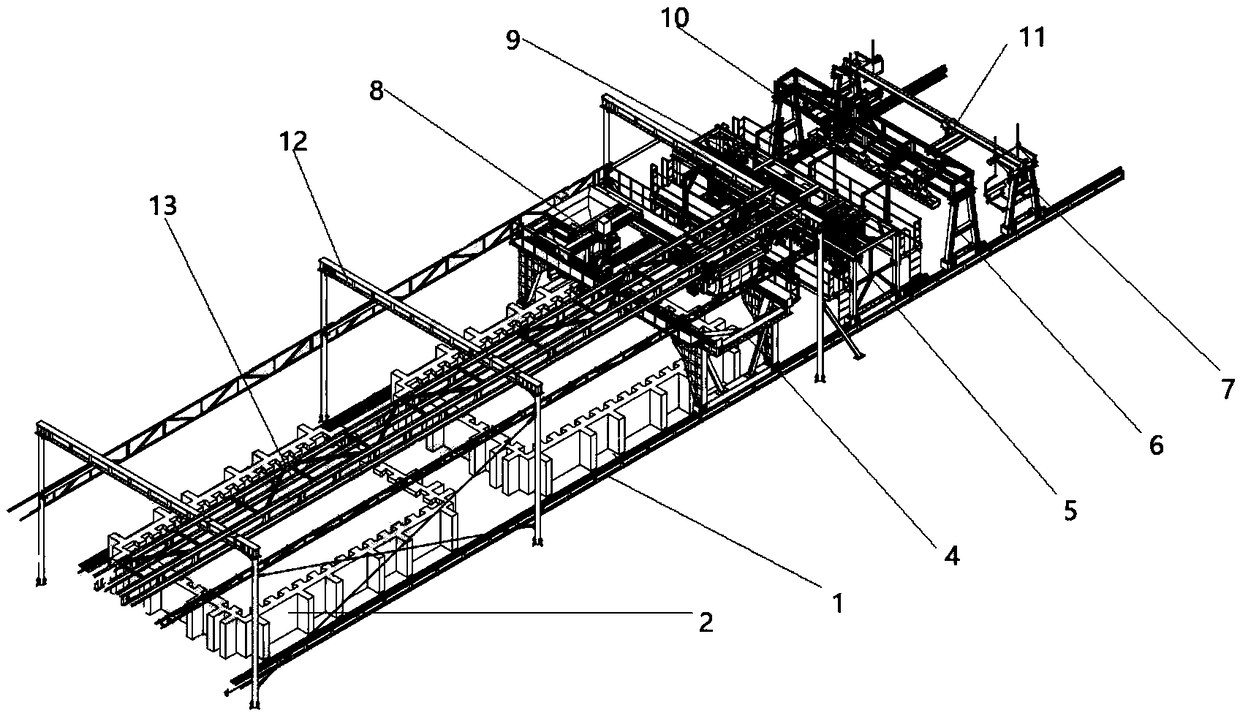

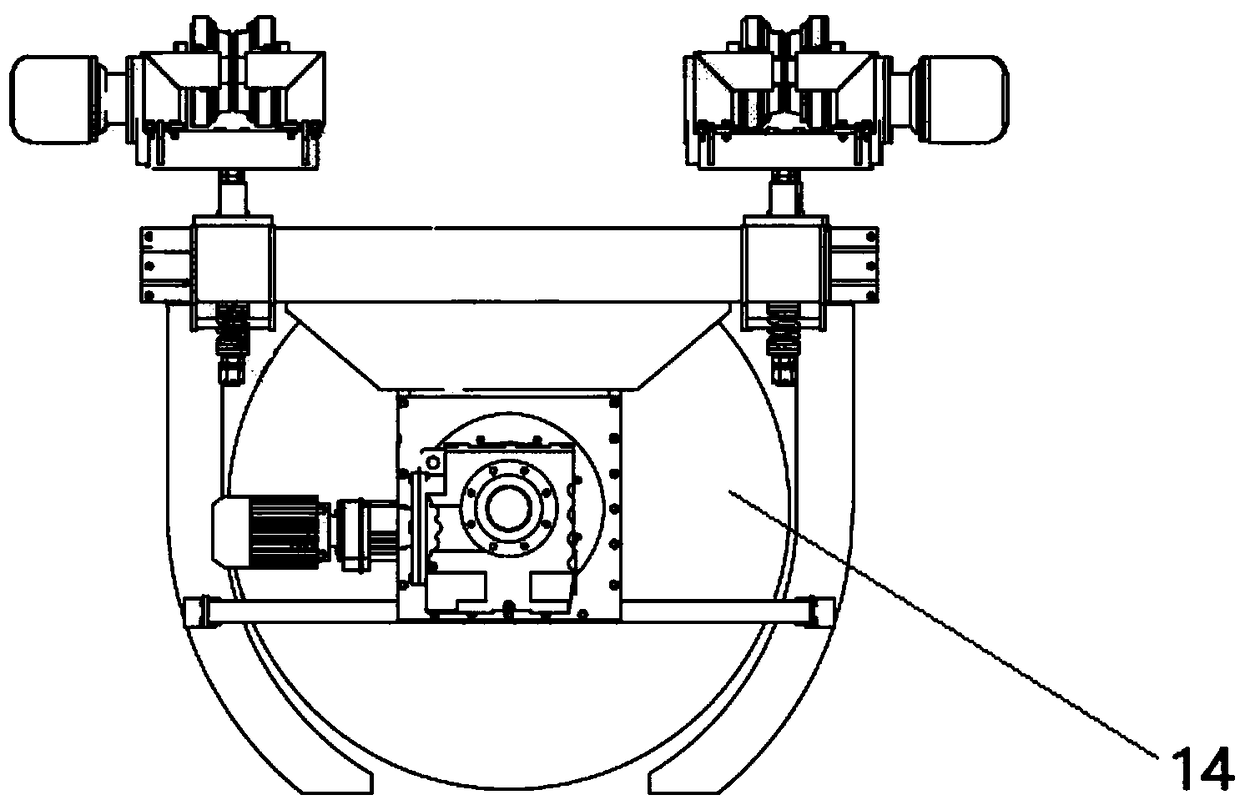

[0021] Such as figure 1 , figure 2 and image 3 The production line for a coarse aggregate reactive powder concrete bridge deck shown includes two parallel rails 1 fixed on the ground, a number of prefabricated slab molds 2 are arranged on the ground between the two rails, and the left ends of the two rails are There is an automatic mixing station 3, and the right ends of the two tracks are provided with the first gantry sliding bracket 4, the second gantry sliding bracket 5, the third gantry sliding bracket 6, and the fourth gantry sliding bracket 7 from left to right. There is a rack at the bottom, and the bottoms of both ends of the first gantry sliding bracket, the second gantry sliding bracket, the third gantry sliding bracket, and the fourth gantry sliding bracket are connected to the track through an automatic traveling mechanism. The autom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com