Low-temperature high-toughness ship plate steel and production method thereof

A production method and technology of ship plate steel, applied in the field of steel smelting, can solve the problems of small thickness of ship plate steel, poor low-temperature impact toughness and yield strength, etc., and achieve the effects of small quality fluctuation, good low-temperature impact toughness, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

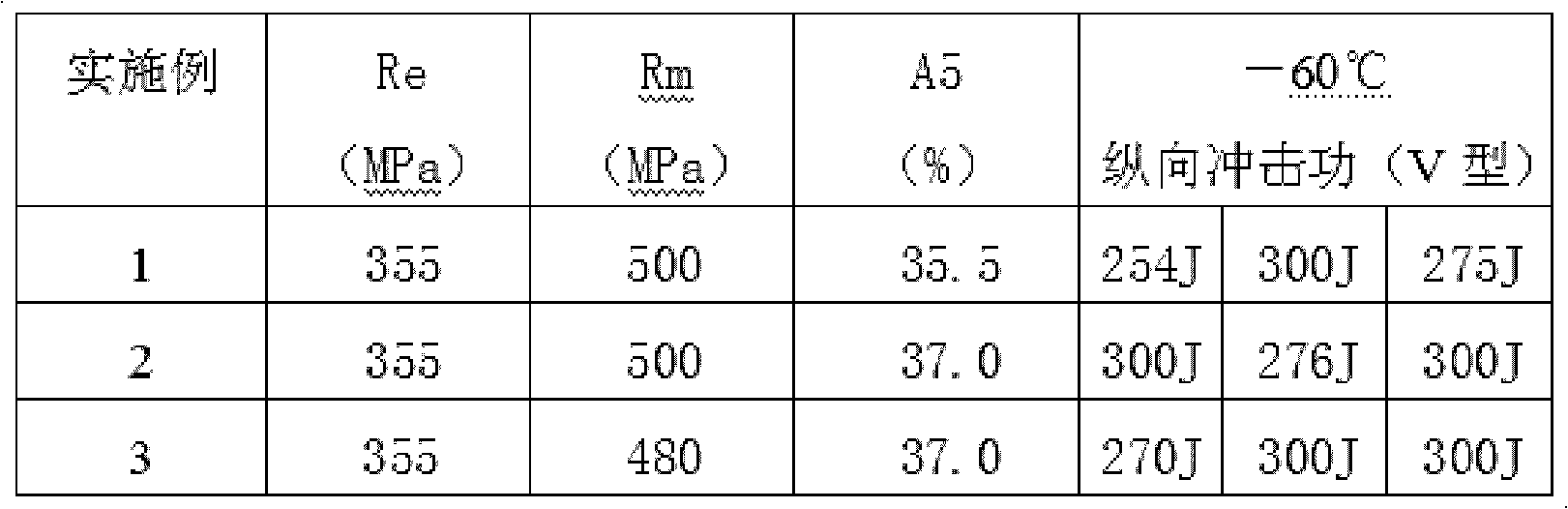

Examples

Embodiment 1

[0021] Low temperature and high toughness ship plate steel, the composition mass percentage of ship plate steel is: C: 0.11%, Si: 0.26%, Mn: 1.50%, P: 0.008%, S: 0.003%, Ni: 0.40%, Cr: 0.06% , Cu: 0.05%, Mo: 0.009%, Nb: 0.03%, Ti: 0.003%, and the rest are Fe and inevitable impurities.

[0022] The production method of low temperature and high toughness ship plate steel comprises the following steps:

[0023] (1) smelting process: the molten steel containing the above-mentioned components is sent to the LF refining furnace for refining after being smelted in an electric furnace, after the refining is completed, the vacuum treatment of the hanging bag VD furnace is carried out, and the SiCa block is added before the vacuum, and the consumption of SiCa is 1kg / ton steel, and the vacuum The temperature is 0.5 Torr, and the vacuum is broken when the vacuum is kept for 25 minutes;

[0024] (2) Casting process: After the vacuum is broken, the temperature is kept at 1330-1340 °C, and ...

Embodiment 2

[0032] Low temperature and high toughness ship plate steel, the composition mass percentage of ship plate steel is: C: 0.10%, Si: 0.20%, Mn: 1.42%, P: 0.009%, S: 0.003%, Ni: 0.27%, Cr: 0.04% , Cu: 0.20%, Mo: 0.020%, Nb: 0.022%, Ti: 0.002%, and the rest are Fe and inevitable impurities.

[0033] The production method of low temperature and high toughness ship plate steel comprises the following steps:

[0034] (1) smelting process: the molten steel containing the above-mentioned components is sent into the LF refining furnace for refining after being smelted by an electric furnace, after the refining is completed, the vacuum treatment of the hanging bag VD furnace is carried out, and the SiCa block is added before the vacuum, and the consumption of SiCa is 0.5kg / ton steel, The vacuum degree is 0.4 Torr, and the vacuum is broken when the vacuum is kept for 15 minutes;

[0035] (2) Casting process: After the vacuum is broken, the temperature is kept at 1330-1340 °C, and casting ...

Embodiment 3

[0043]Low temperature and high toughness ship plate steel, the composition mass percentage of ship plate steel is: C: 0.15%, Si: 0.30%, Mn: 1.30%, P: 0.009%, S: 0.003%, Ni: 0.20%, Cr: 0.15% , Cu: 0.12%, Mo: 0.005%, Nb: 0.015%, Ti: 0.01%, and the rest are Fe and inevitable impurities.

[0044] The production method of low temperature and high toughness ship plate steel comprises the following steps:

[0045] (1) smelting process: the molten steel containing the above-mentioned components is sent into the LF refining furnace for refining after being smelted in an electric furnace, after the refining is completed, the vacuum treatment of the hanging bag VD furnace is carried out, and the SiCa block is added before the vacuum, and the consumption of SiCa is 0.7kg / ton steel, The vacuum degree is 0.45 Torr, and the vacuum is broken when the vacuum is kept for 20 minutes;

[0046] (2) Casting process: After the vacuum is broken, the temperature is kept at 1330-1340 °C, and casting i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com