Low-pressure casting method and device thereof

A low-pressure casting and pressurizing chamber technology, applied in the field of casting, can solve the problems of difficulty in guaranteeing the quality of molten aluminum in a heat-preserving crucible, low control precision of pressurized pressure parameters, long pressurization process and long solidification time, etc. Improved process freedom, improved casting process freedom, and less fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

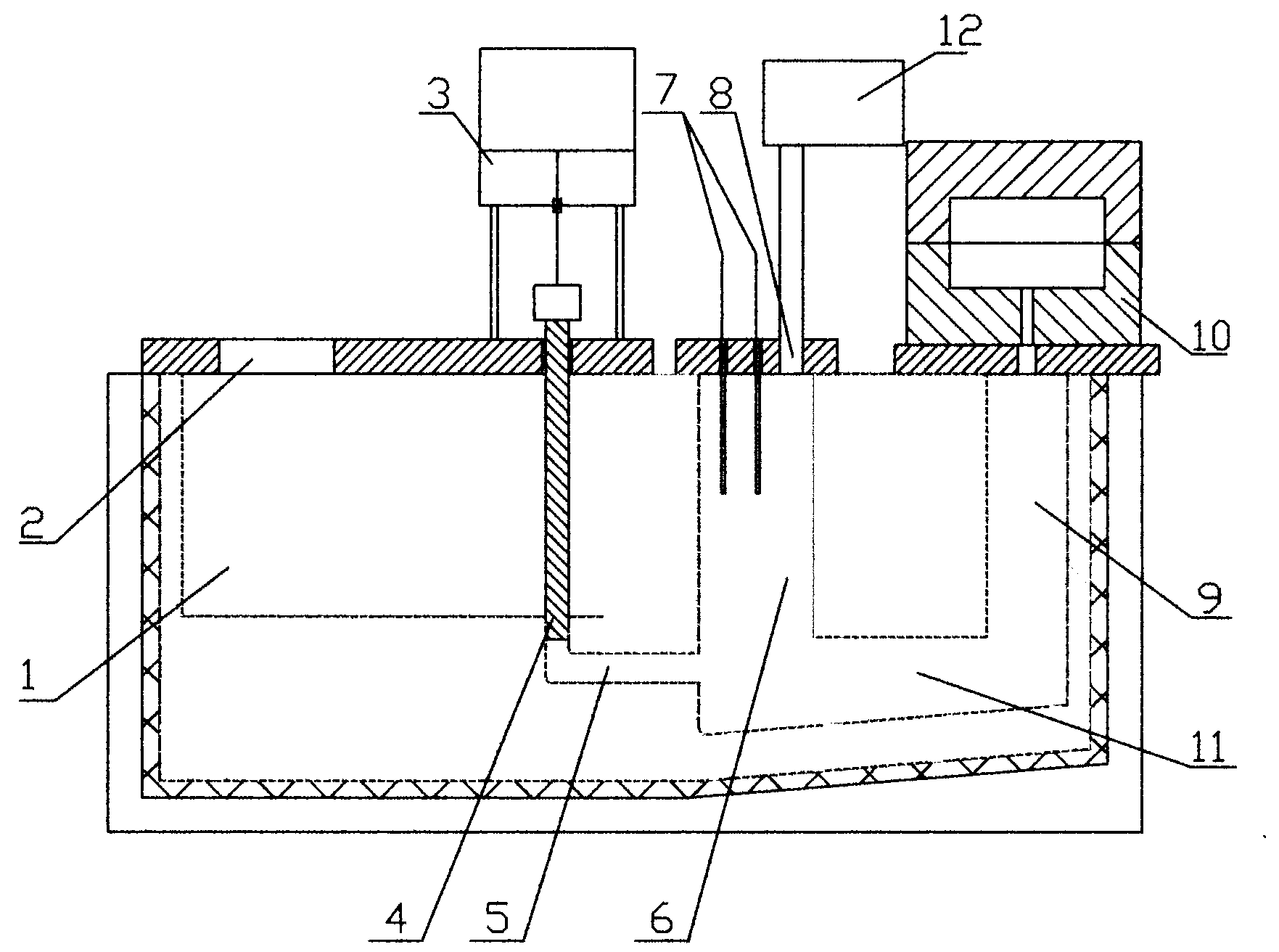

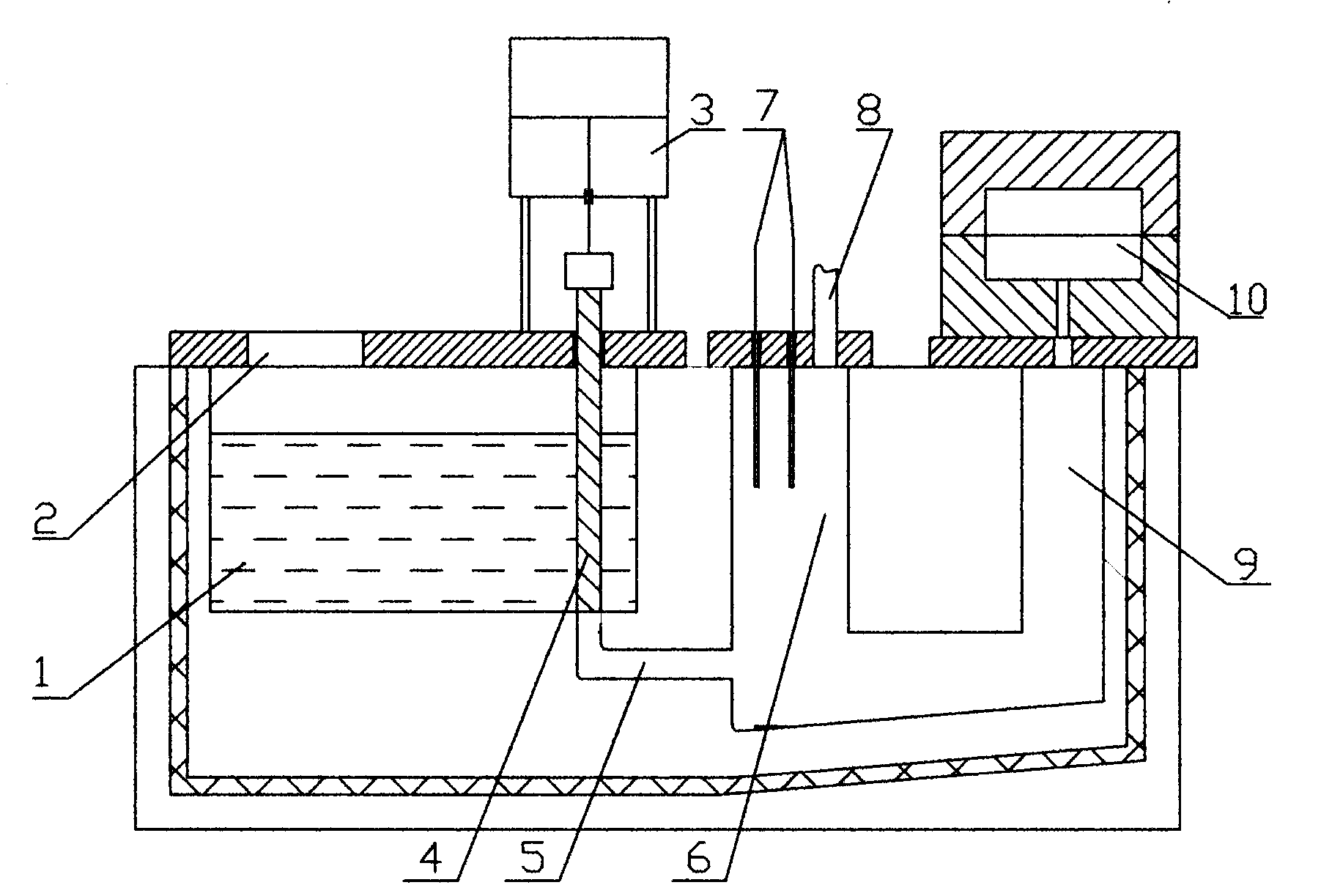

[0050] The low-pressure casting machine provided by the present invention is used to cast aluminum alloy cylinder head, the material of the cylinder head is ZL105 or ZL114, the casting mold is metal mold + sand core, the heat preservation chamber, the pressurization chamber and the liquid raising chamber adopt crucibles, the capacity of the crucible is 1500Kg, and the aluminum liquid The pouring temperature is 690°C, and the mold temperature is 200-300°C.

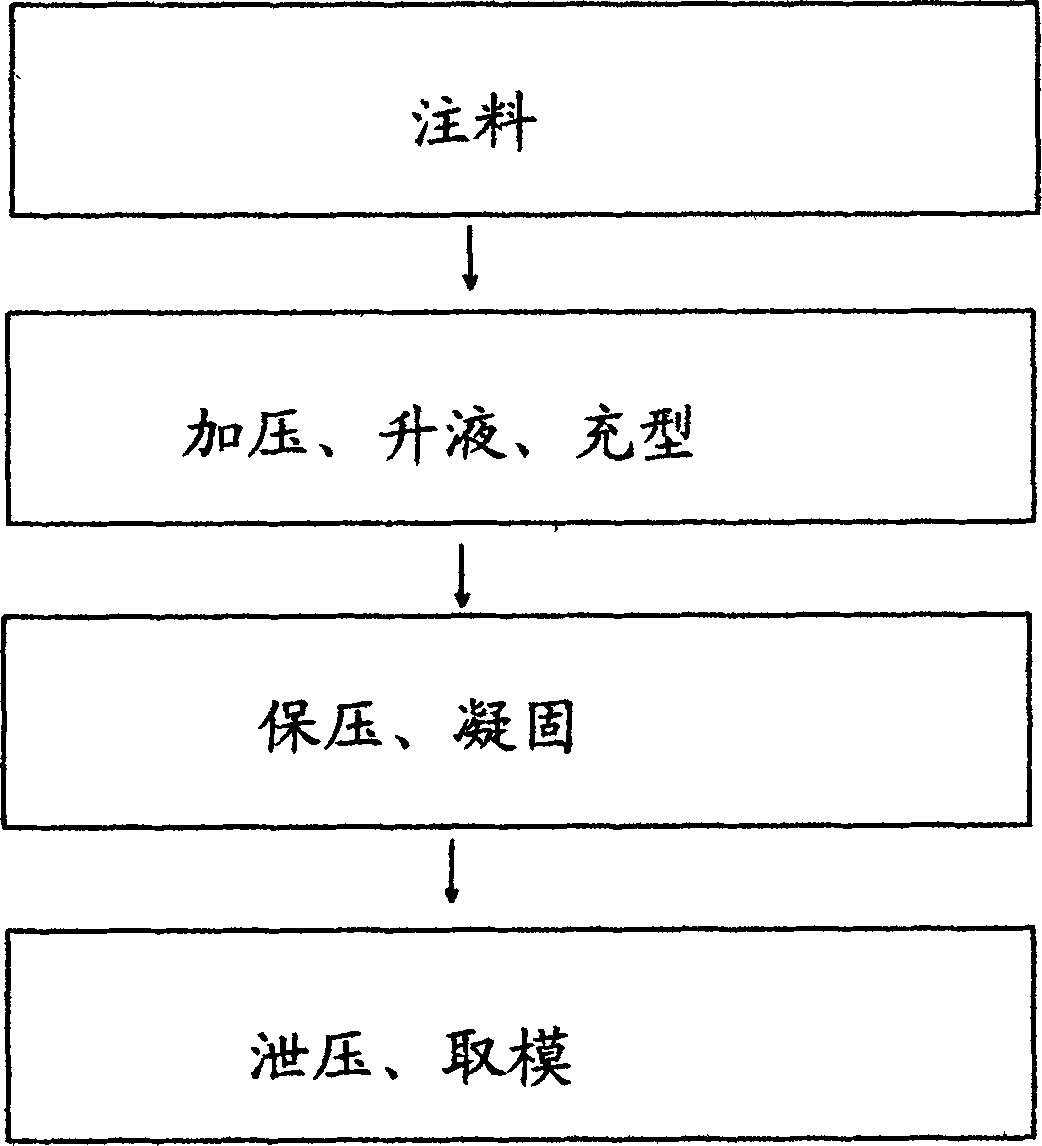

[0051] Injection: Open the stopper rod 4, and the aluminum alloy liquid that meets the requirements flows into the pressurization chamber 6 and the liquid lifting chamber 9 through the channel 5 between the heat preservation chamber 1 and the pressurization chamber 6. When the aluminum alloy liquid in the pressurization chamber 6 When the two poles of the liquid level sensor 7 are touched, the sensor is connected, and the hydraulic cylinder / pneumatic cylinder controls the plug rod 4 to close, and the filling process is compl...

Embodiment 2

[0058] The low-pressure casting machine provided by the invention is used to cast the aluminum alloy wheel hub, the material is ZL101, the casting mold is a metal mold, the crucible capacity is 1800Kg, the aluminum liquid pouring temperature is 700°C, and the mold temperature is 200-300°C.

[0059] Operation process is described with embodiment 1.

[0060] Continuous production is realized, with a productivity of 14 pieces / hour and a shift output of 112 pieces.

Embodiment 3

[0062] The low-pressure casting machine provided by the present invention is used to cast the aluminum alloy instrument cabin shell, the material is ZL114, the casting mold is a self-hardening resin sand mold, the crucible capacity is 1200Kg, and the aluminum liquid pouring temperature is 700°C.

[0063] Concrete operation process is described with embodiment 1.

[0064] The productivity reaches 8 pieces per hour, and the shift output is 64 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com