Patents

Literature

262results about How to "Meet product quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

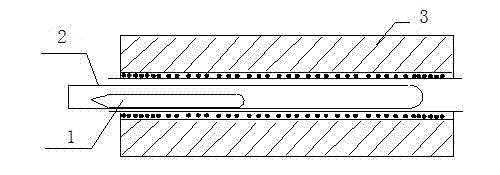

Aluminum plating method for plastic film

ActiveCN101503790AMeet product quality requirementsVacuum evaporation coatingSputtering coatingAluminum coatingEngineering

The invention relates to a plastic film aluminum plating method. The method comprises the following steps: opening a vacuum case, installing a plastic film onto a reel, fixing the reel onto a film passing tape for automatic film passing, and entering a production preparation status; arranging N carbon diboride evaporation boats in the vacuum case; arranging N discs of common aluminum wires with the purity above 99.99 percent in the vacuum case; closing the vacuum case; carrying out air extraction to make the vacuum degree in the vacuum chamber reach above 3.5*10mbar; setting the temperature of a filming drum at 0 to 2 DEG C; setting the working temperature of the evaporation boats at 1,300 to 1,350 DEG C; setting the wire feeding speed of the aluminum wires at 200 mm / min to 280 mm / min; setting the reeling speed of the plating film at 9.5 m / s to 13 m / s; turning on a plasma device; setting the thickness of an aluminum layer at 3.5 omega / (300) to 54 omega / (60); and observing the evenness of an aluminum coating layer and controlling the evenness within + / -2 percent as required. The error of the thickness and evenness of the aluminum coating layer is improved from + / -10 percent to + / -3 percent, and therefore the requirements on the product quality are met.

Owner:SHANGHAI RADIX VACUUM METALIZING

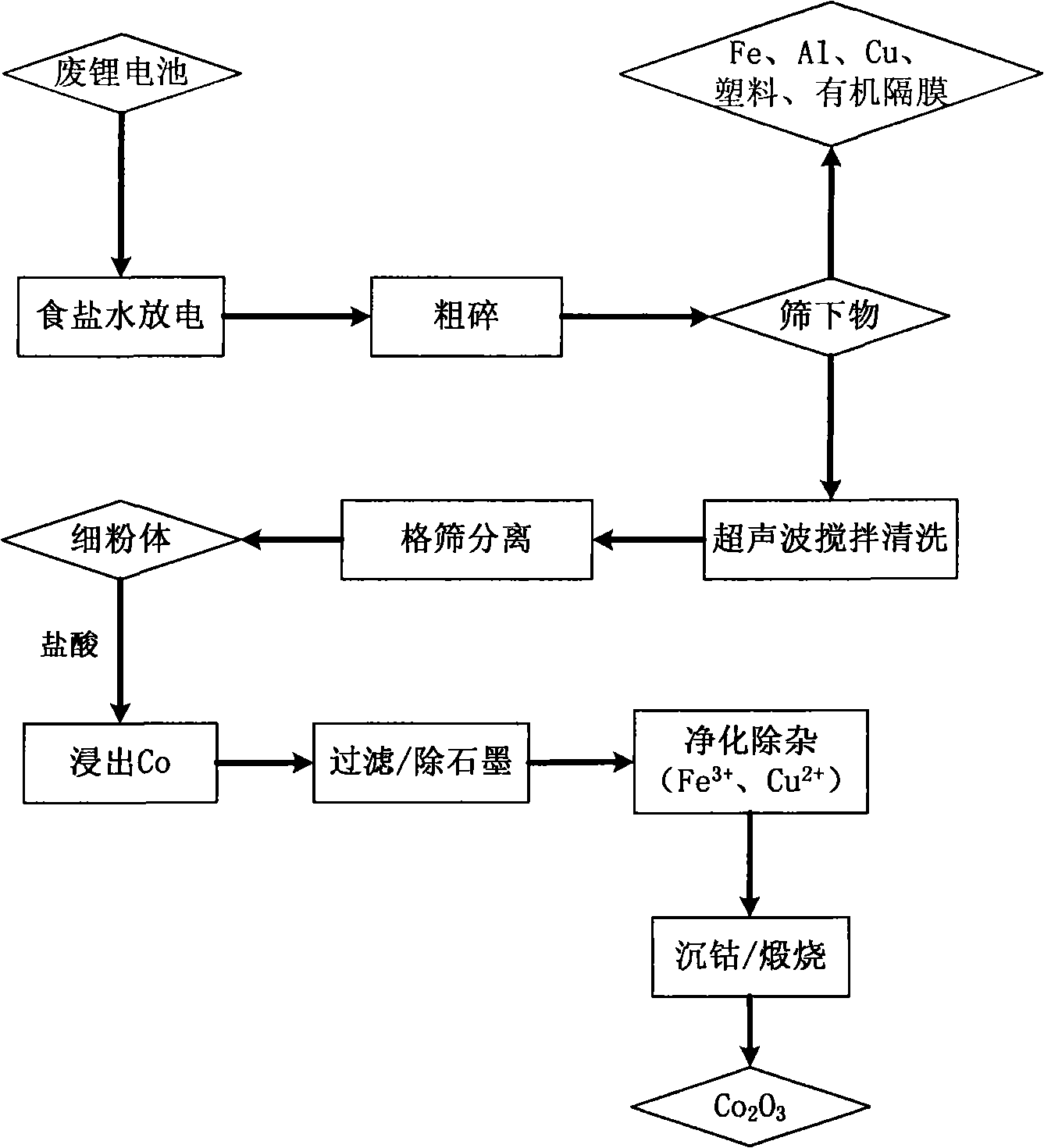

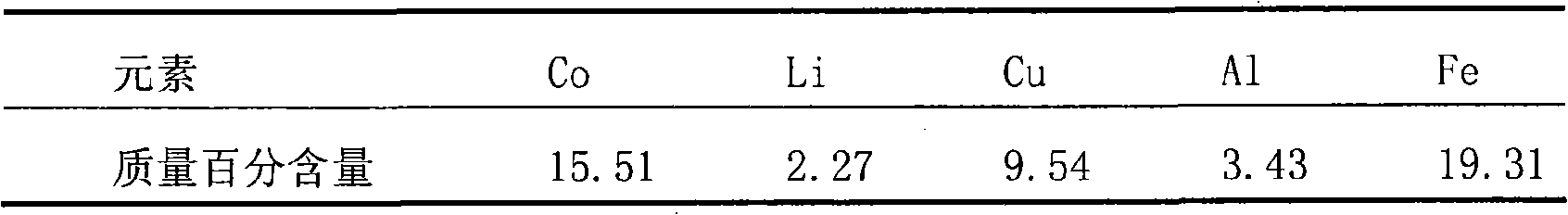

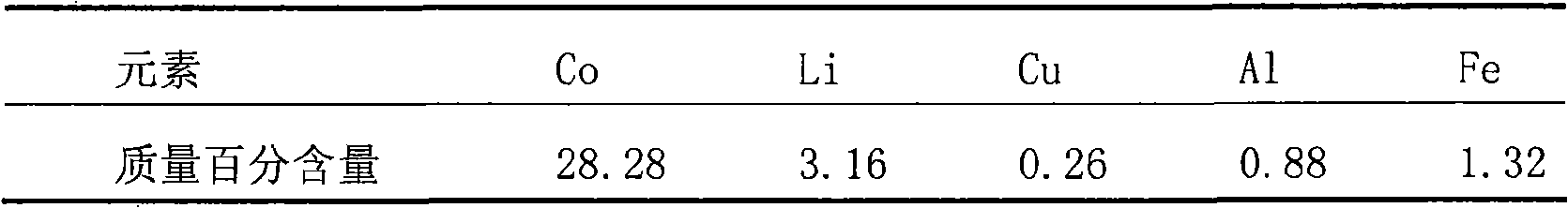

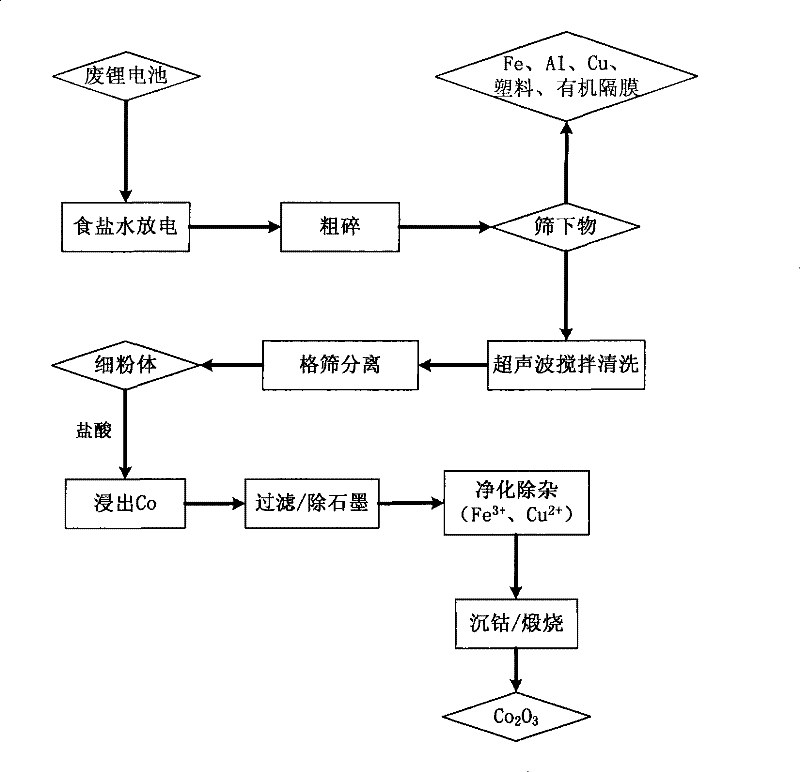

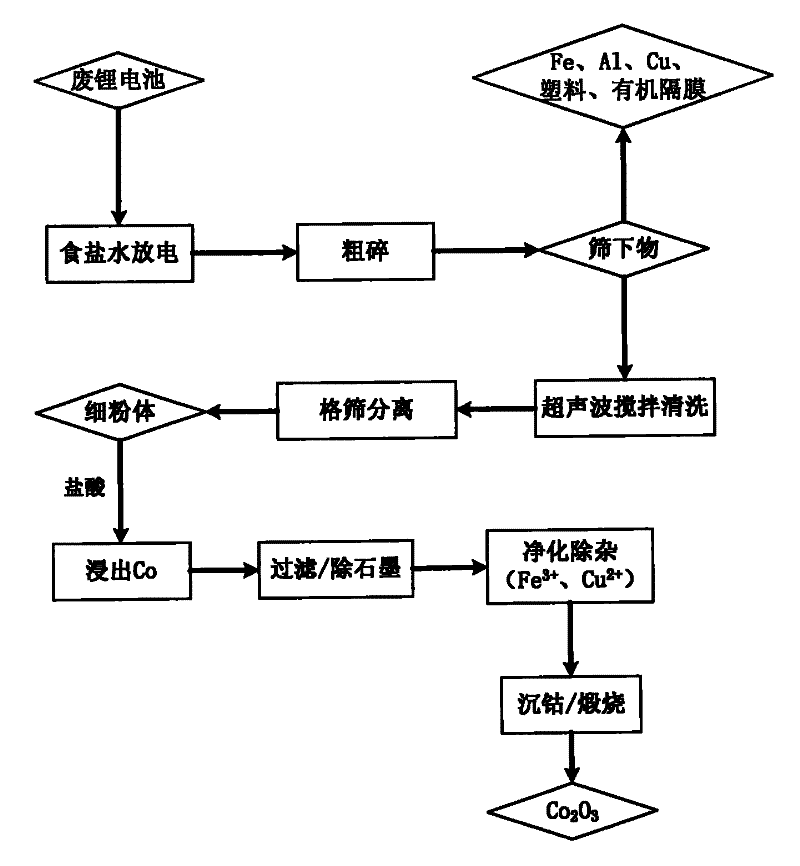

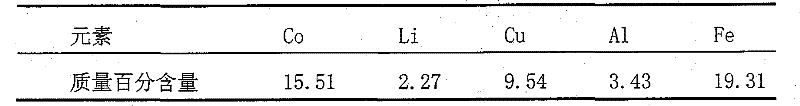

Method for recycling cobalt from waste and old lithium ion battery

InactiveCN101318712AMeet product quality requirementsEasy to manufactureCobalt oxides/hydroxidesEngineeringCobalt

The invention discloses a method for recovering cobalt from a waste lithium ion battery. The method comprises the following steps that: the waste lithium ion battery is placed into salt solution to be discharged; the discharged waste lithium ion battery is mechanically crushed; the crushed waste lithium ion battery is stirred and cleaned by ultrasonic wave; a grizzly screen is used to separate after the cleaning; the leaching of filtrate Co and Li is performed; Fe<3+> is removed through purification; Cu<2+> is removed through purification; the cobalt is precipitated by ammonium oxalate; and finally a filtered cobalt oxalate precipitate is cleaned by de-ionized water, is dried in a drying box, and then is placed into a muffle furnace for heat treatment for 2 hours at a temperature of 600 DEG C to produce Co2O3 powder. The method has simple and convenient and feasible preparation process, the produced Co2O3 can meet the requirement of product quality of Co2O3-Y1(GB6518-86), and the recovery rate of the Co during the whole process is more than 89 percent.

Owner:TSINGHUA UNIV

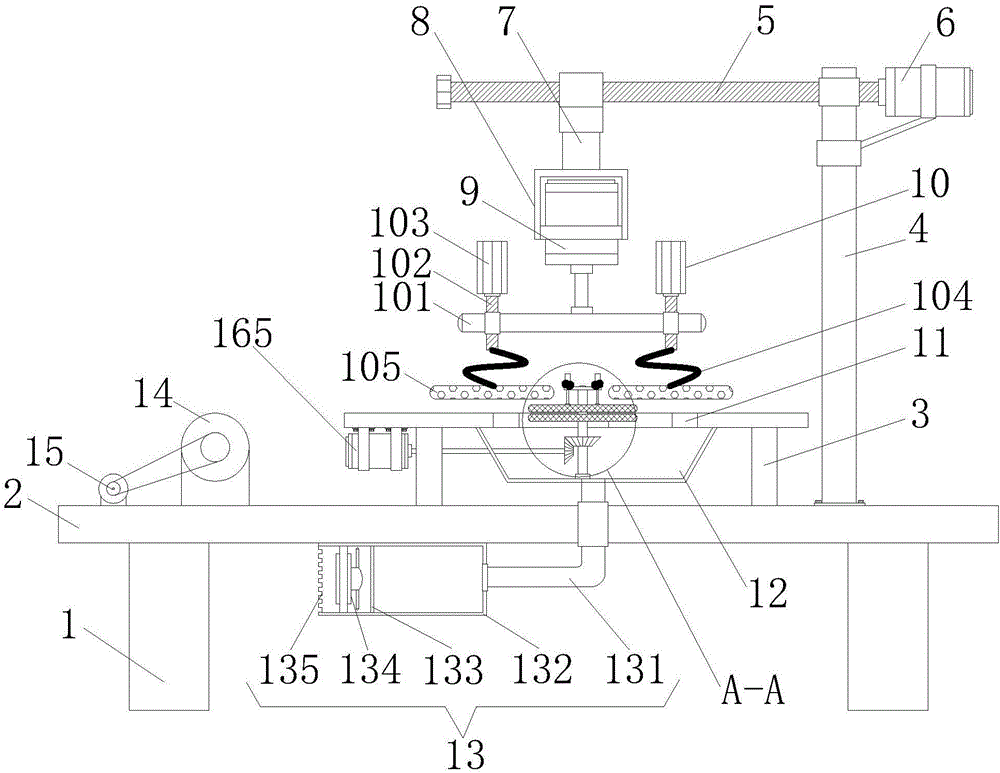

Deburring device for plastic processing

InactiveCN106239310AImprove adaptabilityChange heightEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention discloses a deburring device for plastic processing. The deburring device comprises support legs. A workbench is fixedly mounted at the tops of the support legs. An operating platform is fixedly mounted on the upper surface of the workbench. A moving screw rod is movably mounted at the end, located on the side face of the operating platform, of the upper surface of the workbench through a support. An output shaft of a first servo motor is fixedly connected to one end of the moving screw rod, wherein the output shaft of the first servo motor is fixedly mounted at the top of the support. An electric extending-and-contracting rod is fixedly connected with the moving screw rod through a connection block. A clamping seat is fixedly mounted at the end, far away from the moving screw rod, of the electric extending-and-contracting rod. A first driving motor is fixedly mounted inside the clamping seat. According to the deburring device, edge clearing mechanisms are arranged, and therefore support shafts can be driven by a second servo motor to rotate; furthermore, the first edge clearing mechanism and the second edge clearing mechanism are made to rotate synchronously, so that the purpose of clearing burs at the side edges of a plastic product is achieved; and the production requirements and the requirements for product quality can be effectively met.

Owner:新昌县厚道机械有限公司

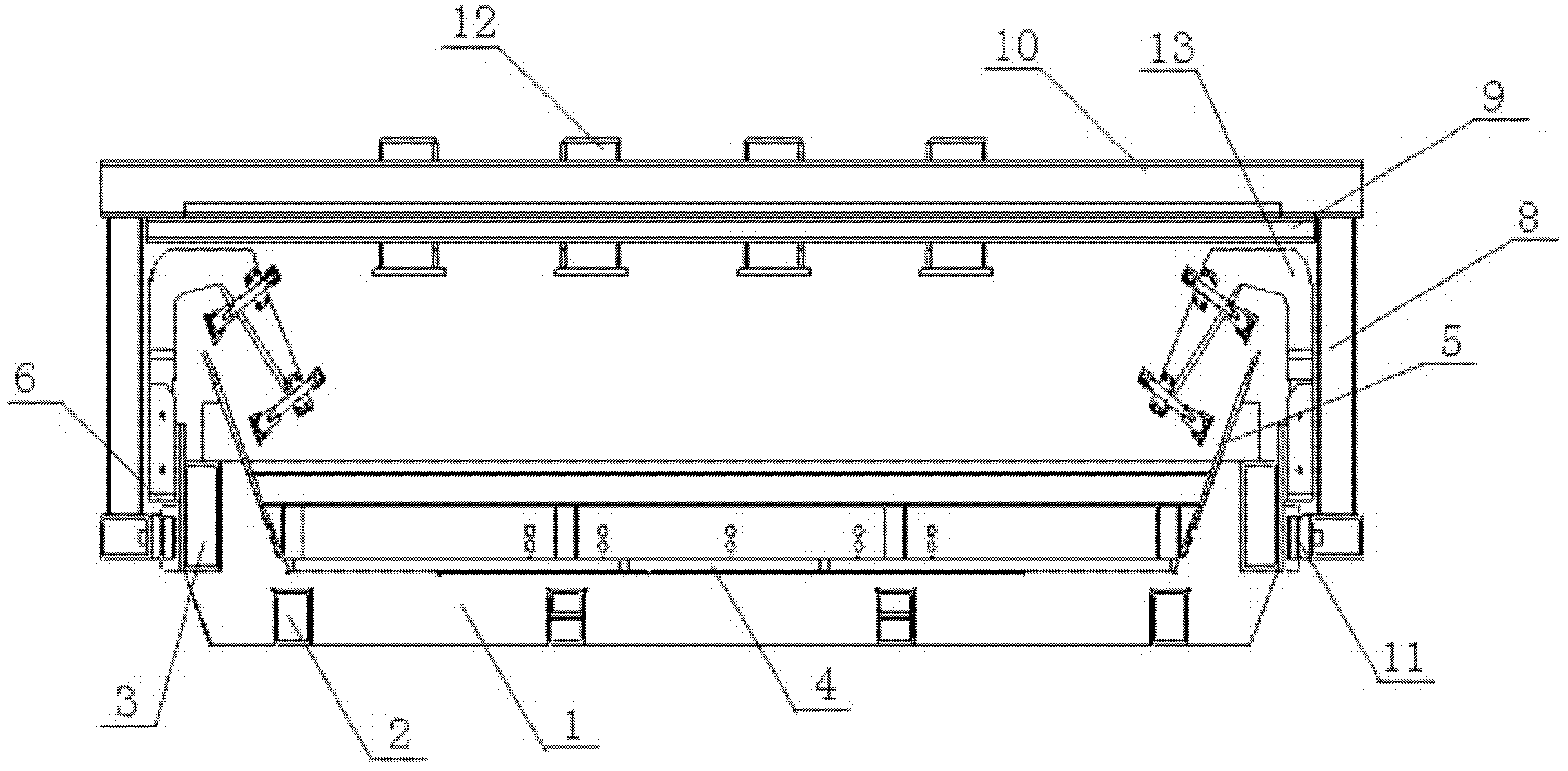

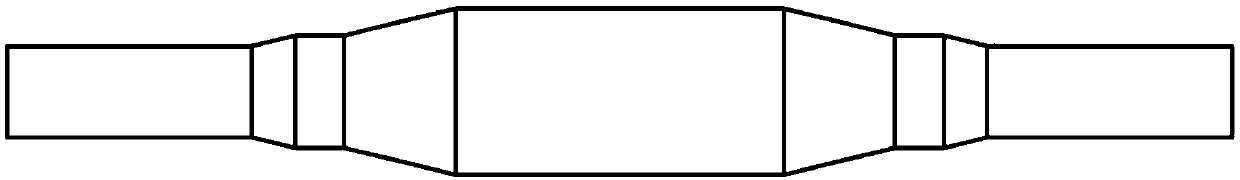

Electric locomotive roof assembly and welding tool

ActiveCN102500985ASolve the sinking deflectionGuaranteed validityWelding/cutting auxillary devicesAuxillary welding devicesCantileverElectric power

The invention relates to an electric locomotive roof assembly and welding tool, which comprises an integral frame, a gantry and a cylinder, wherein the integral frame consists of a reinforcing ribbed plate, a main beam, an edge beam, a bottom plate and a side wall board; the side wall board and the bottom plate form an inclination angle; a sliding track for mounting the gantry is arranged outside the side wall board; the gantry is provided with a movable cylinder fixing frame and is used for eliminating welding gap between an aluminum plate and the frame to guarantee welding quality; and the effect of reducing welding deformation is reduced by forming rigid fixing force for the aluminum plate and the frame. Side wall pressing cantilevers are uniformly distributed outside the edge beam; and the reinforcing ribbed plate is provided with a positioner connecting pipe. The interference between a product and the tool is eliminated in a movable pressing and fixed pressing combined mode, so that all products can be welded on the tool at one time. The working efficiency is increased. All positioning devices are used for quick and accurate positioning. The stability of the tool is effectively guaranteed, and the product quality requirements are met.

Owner:ZHUZHOU POWER LOCOMOTIVE PREUMATIC EQUIPOMENT

Microencapsulated amino-acid composition and preparation method of microencapsulated amino-acid composition

ActiveCN102908337AExcellent dispersion and instant solubilityFast absorptionOrganic active ingredientsDispersion deliveryAmino acid compositionBranched-chain amino acid

The invention provides a microencapsulated amino-acid composition and a preparation method of the microencapsulated amino-acid composition. The microencapsulated amino-acid composition can be dispersed quickly and dissolved clearly. The preparation method of the microencapsulated amino acid composition comprises the steps that auxiliary materials such as a coating agent and a wetting agent are added to an amino-acid mixture, and the wetting speed of composition particles to water is increased greatly by surface modification of microencapsulated crumby particles. A mass ratio of the amino acid to the auxiliary materials in the composition is 100 / 0.1-10.0. Compared with the conventional product, the composition has better dispersing and fast dissolving properties in the water, and a solution is transparent and free of sediment, floatage and foam. The shelf life of the composition is stable, the composition can be used more conveniently and rapidly, facilitates fast absorption of human bodies, and solves the problems that edible demands of humans cannot be met, the amino-acid is difficult to take and absorb, and taste and odor of the amino-acid get worse as branched-chain amino acid in the amino-acid is low in dissolvability and poor in hydrophilicity and stability. The preparation method is simple in technology, and facilitates the industrial production.

Owner:INNOBIO CORP LTD

Deep eutectic solvent and preparation method thereof and application thereof in process of preparing glucose by hydrolyzing celluloses

ActiveCN108950091ARaw material environmental protectionDifficult to volatilize and less pollutionSugar juice extraction using extracting agentsGlucose productionCelluloseSolvent

The invention discloses a deep eutectic solvent. A hydrogen bond donor of the deep eutectic solvent is a protonic acid; a hydrogen bond acceptor of the deep eutectic solvent is an ammonium salt containing a specific functional group; and the specific functional group is alkylene, a sulfonic acid group, a carboxyl group, an ether group, an amino group or a sulfhydryl group. The deep eutectic solvent can efficiently hydrolyze celluloses to glucose. The invention also discloses a method of preparing the glucose by using the deep eutectic solvent to hydrolyze cellulose biomasses. The method comprises the following steps of: adding the cellulose biomass and the deep eutectic solvent to a reactor, and reacting at the temperature of 80-120 DEG C for 0.5-10h to obtain the hydrolysate glucose. Themethod has the characteristics of high reduction selectivity and high yield of glucose products in the process of using the cellulose biomass to prepare the glucose, can ensure that the glucose product meets the production quality requirements, and has very good economic, environmental and social benefits.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

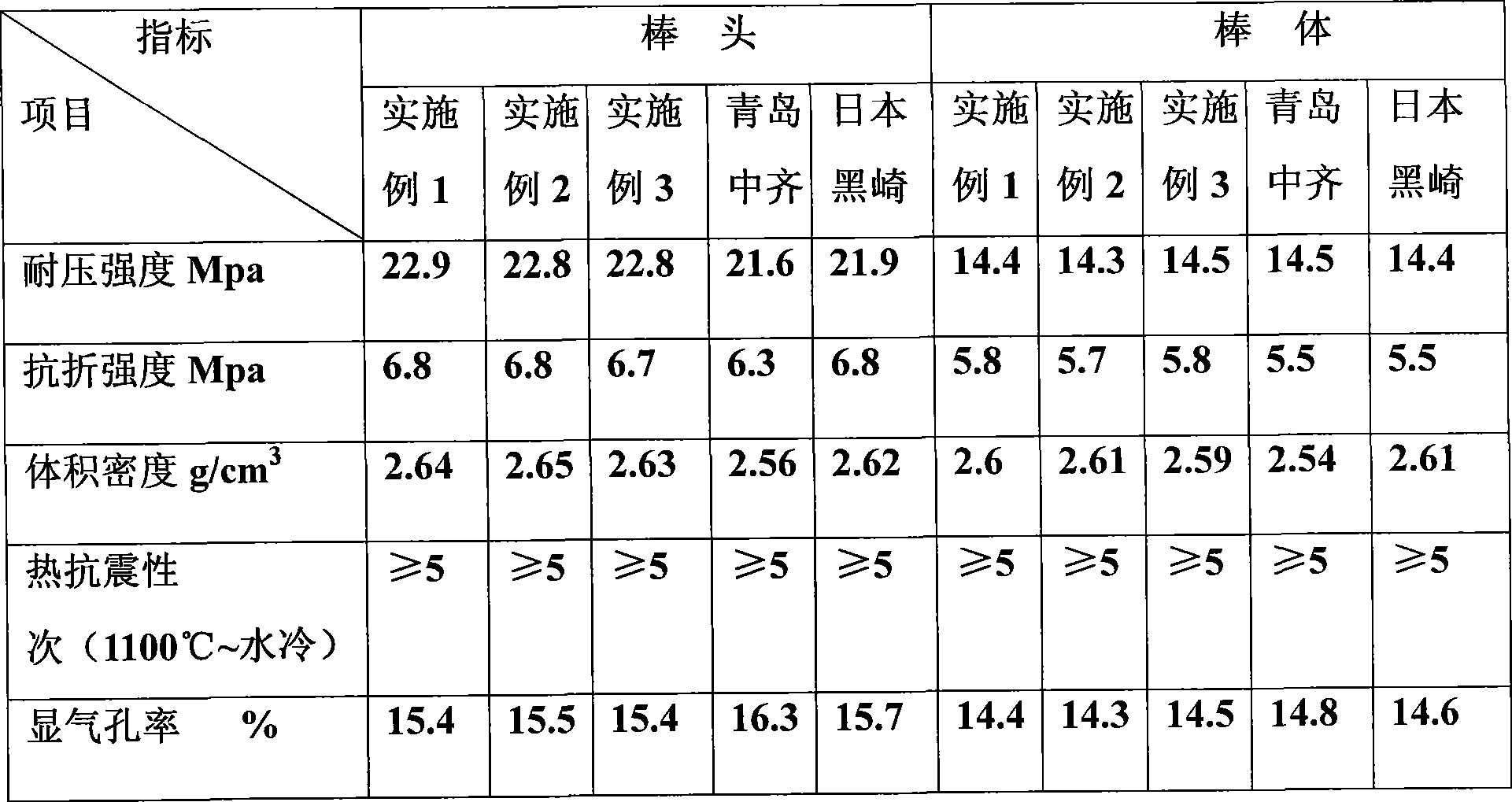

Composite baking-free stopper rod of magnesium aluminate spinel and production process thereof

InactiveCN101429040AEmission reductionImprove the operating environmentMelt-holding vesselsAntioxidantSlag

The invention relates to a magnesium-aluminum spinel composite baking-free plug bar. A plug bar head comprises the following raw materials: 15 to 25 percent of No. 18-36 magnesium-aluminum spinel, 20 to 30 percent of No. 70-120 magnesium-aluminum spinel, 30 to 35 percent of No. 325 magnesium-aluminum spinel, 8 to 12 percent of graphite powder, 1.5 to 3.5 percent of antioxidant, 2 to 4 percent of phenolic resin, and 3 to 7 percent of baking-free agent. A plug bar body comprises the following raw materials: 35 to 50 percent of No. 18-120 alpha-corundum aggregate, 25 to 35 percent of alpha-corundum aggregate, 20 to 30 percent of graphite powder, 1 to 3 percent of alumina powder, 1 to 5 percent of baking-free agent, and 3 to 5 percent of phenolic resin. The magnesium-aluminum spinel composite baking-free plug bar is formed by addition of the baking-free agent with special compositions, forming and low-temperature roasting. The product has the characteristics of strong slag erosion resistance, good thermal shock stability, high strength, erosion resistance, scour prevention, fire resistance, long service life, low production cost and so on, saves energy resources, and can meet the multi-furnace continuous casting performance requirement and the product quality requirement.

Owner:淄博大正新材料科技有限公司

Energy-saving environment friendly production method of concrete lining segment

ActiveCN102528917AGuaranteed lossReduce lossCeramic shaping apparatusProcess engineeringEnvironmental geology

The invention discloses an energy-saving environment friendly production method of a concrete lining segment. The energy-saving environment friendly production method comprises the following step of: carrying out dry-wet-heat curing on concrete after pouring, wherein the dry-wet-heat curing is finished in a sealed curing kiln and comprises four stages of static curing, heating, constant temperature keeping and temperature reducing. According to the energy-saving environment friendly production method of the concrete lining segment, disclosed by the invention, all procedures are connected closely and smoothly, wherein the dry-wet-heat curing directly ensures large shortening of curing time because of creation of a technical method, and compared with a traditional steam curing of keeping the constant temperature for 4h and total curing time of 8-10h, the energy-saving environment friendly production method disclosed by the invention has the advantage that the speed is largely accelerated, in addition, standing temperature reduction ensures that segment concrete is secondarily cured and is fully reduced in temperature, thus a quality defect due to an inner stress is avoided, the quality of products is improved, and good support is provided for long-term safe usage of the concrete lining segment.

Owner:中铁八局集团第七工程有限公司

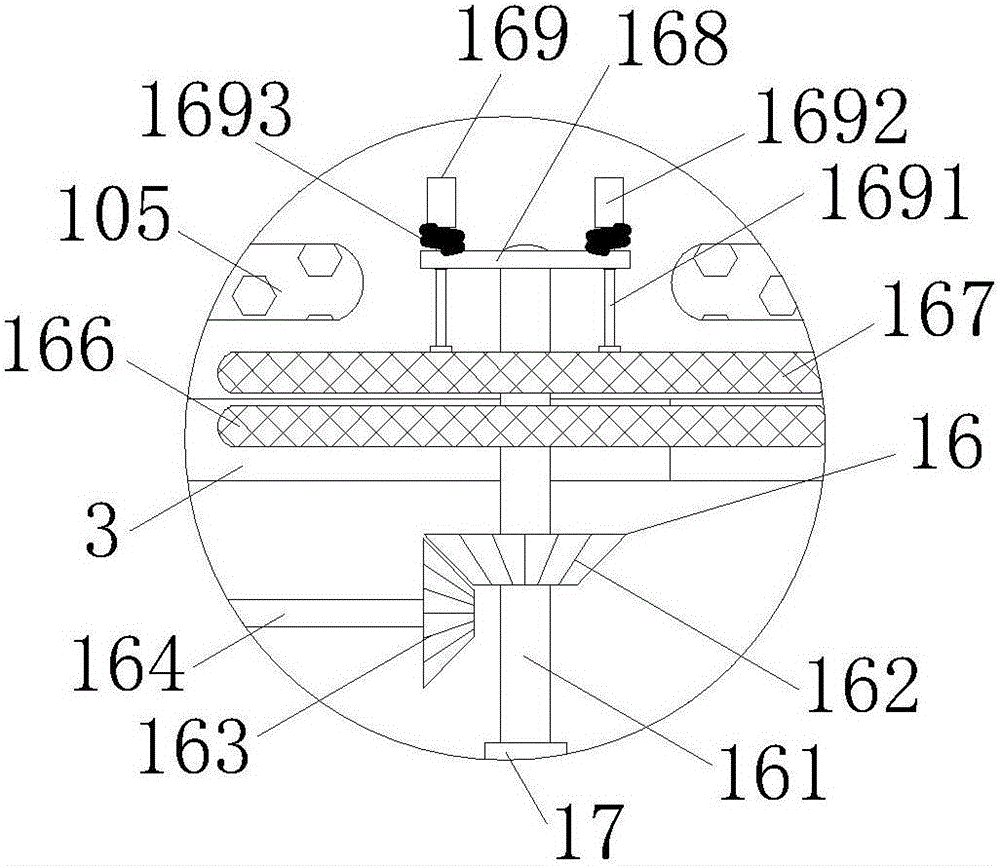

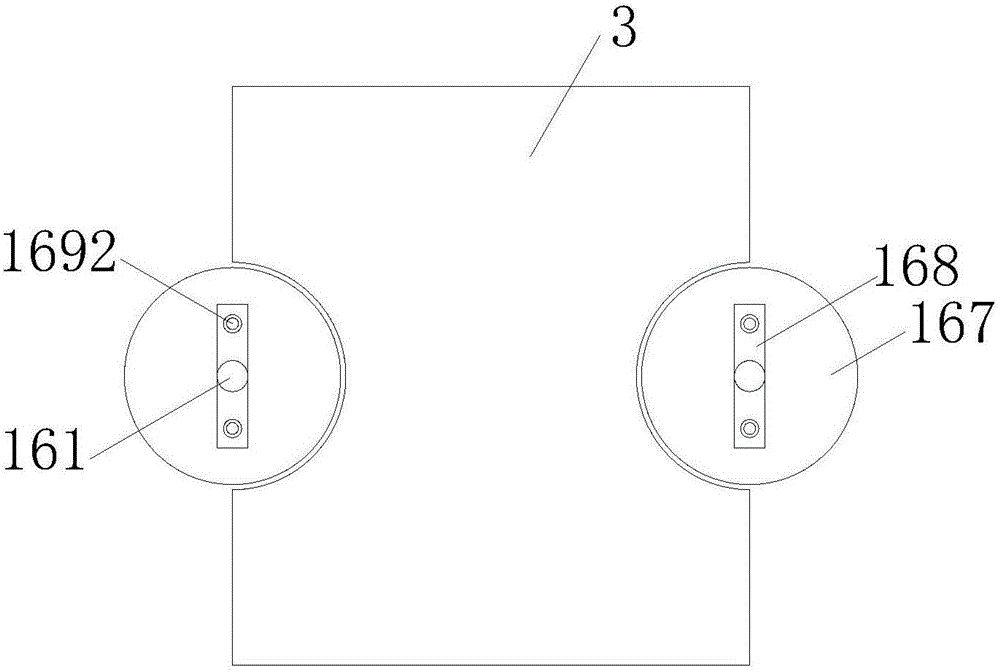

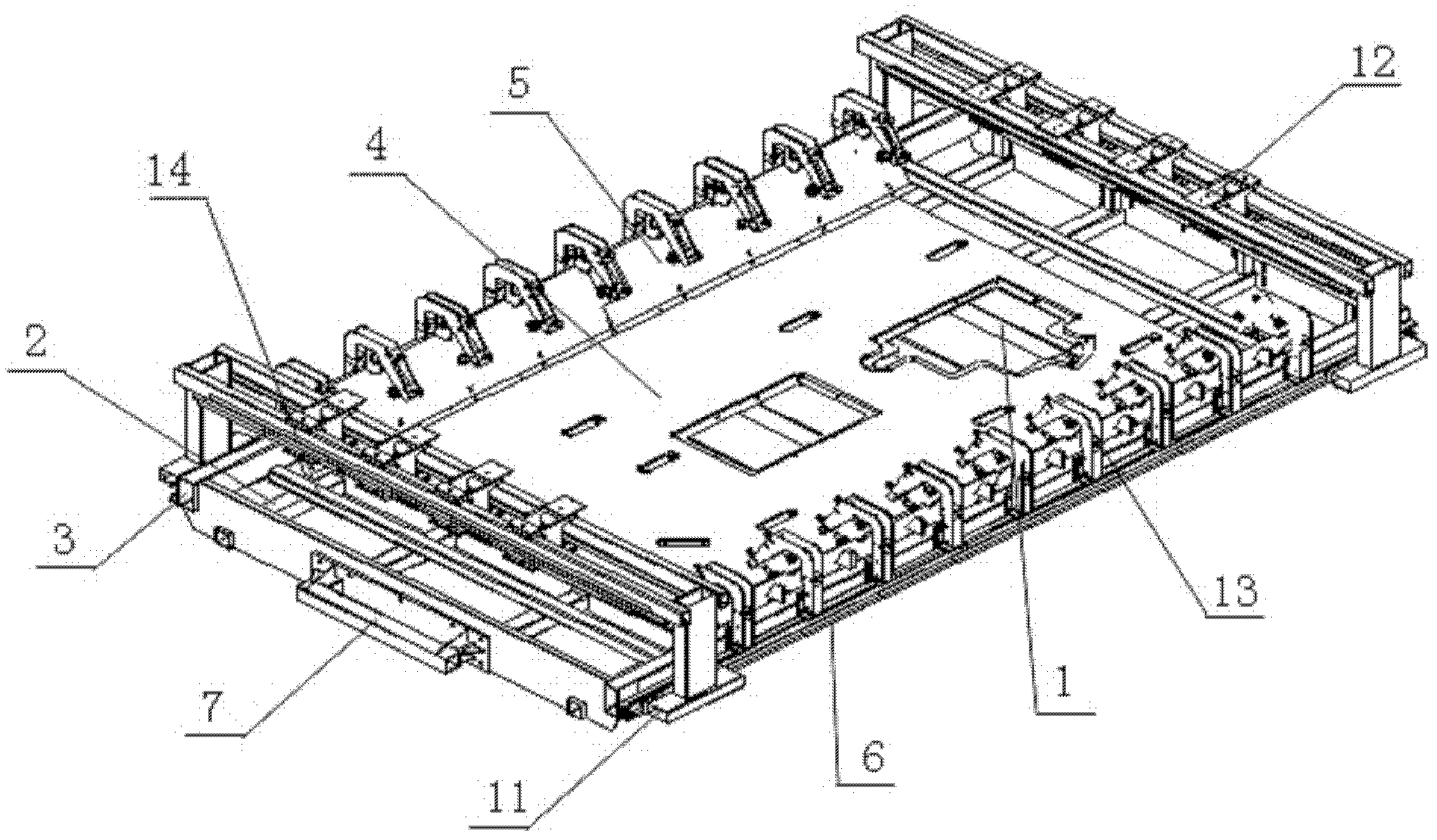

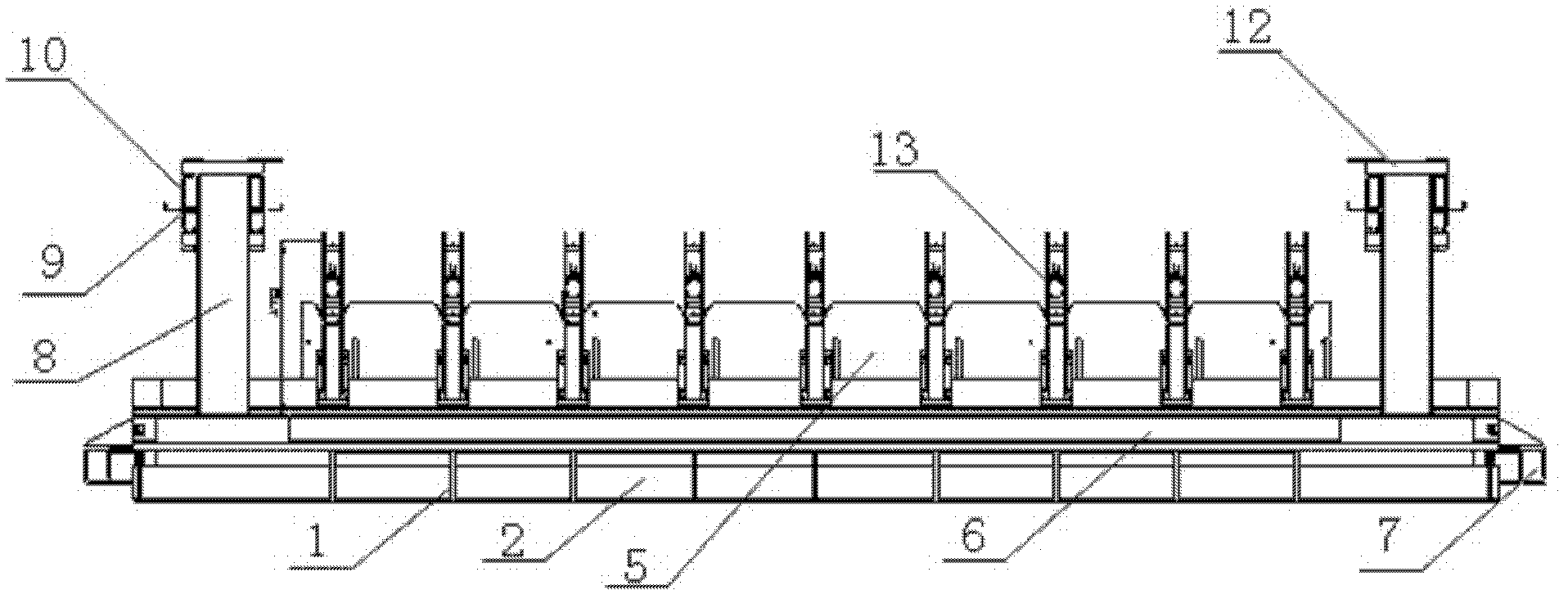

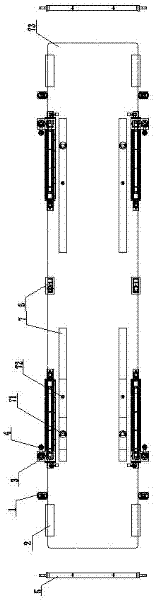

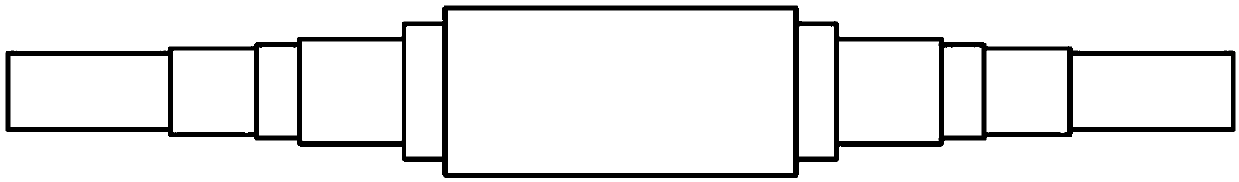

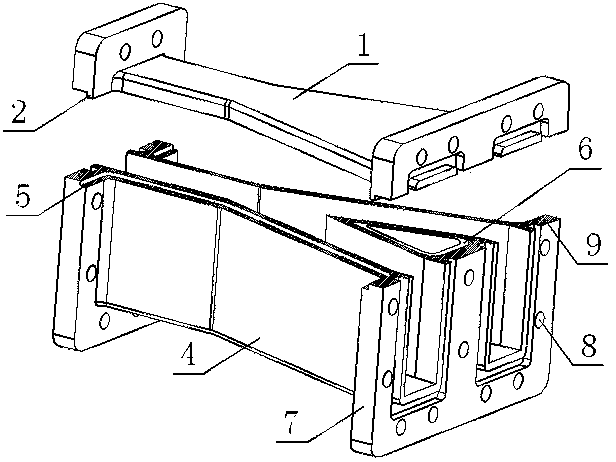

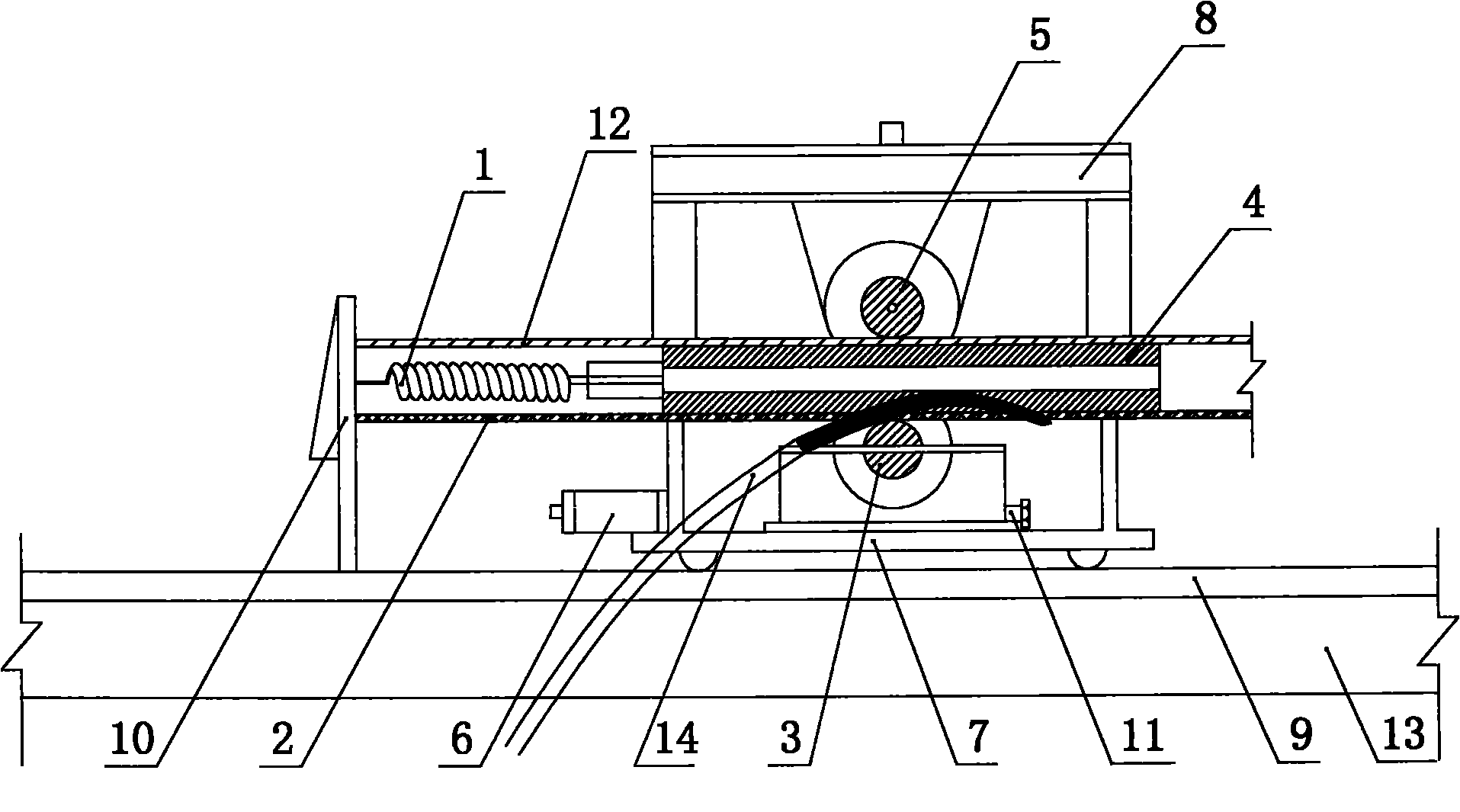

General device of locomotive body assembly

InactiveCN102233503AHigh degree of automationVersatileWelding/cutting auxillary devicesAuxillary welding devicesManufacturing qualityBiomedical engineering

The invention relates to the technical field of locomotive body manufacture and in particular relates to a general device of a locomotive body assembly. The general device comprises an end part tensioning device, an end part measuring platform, a side beam bearing device, a pressing device, a cross beam for tensioning an end part and a middle bearing jacking device, wherein the left side of the end part tensioning device is provided with the end part measuring platform, and the right side of the end part tensioning device is provided with the side beam bearing device and the pressing device; the end part tensioning device is fixedly connected with the cross beam for tensioning the end part; and one side of the pressing device is provided with the middle bearing jacking device. The general device of the locomotive body assembly has the advantages that the automation degree is high, the functions are complete, the operation is simple, the reliability and the safety are better, the process is improved, the auxiliary clamping time of assembly and welding is shortened, the working efficiency is improved, the labor intensity of workers is greatly reduced, the generality is strong, and the manufacture quality requirements of various types are met, and the general device can be popularized and applied easily.

Owner:CRRC QISHUYAN CO LTD

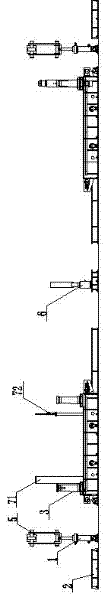

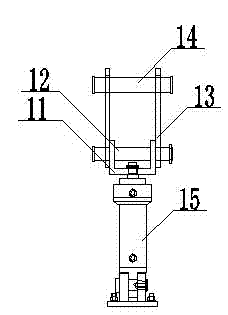

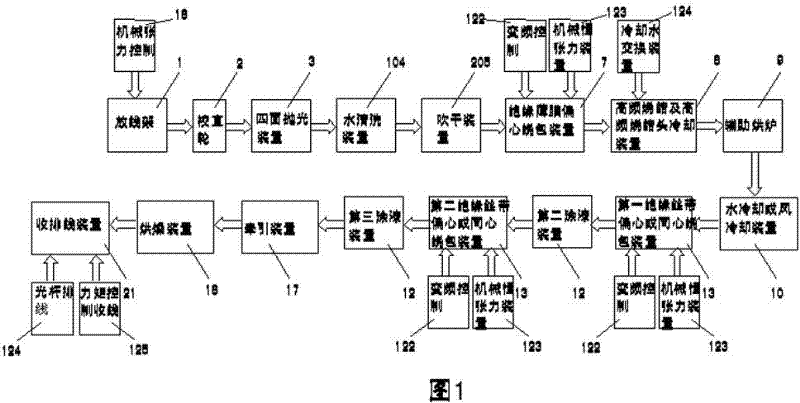

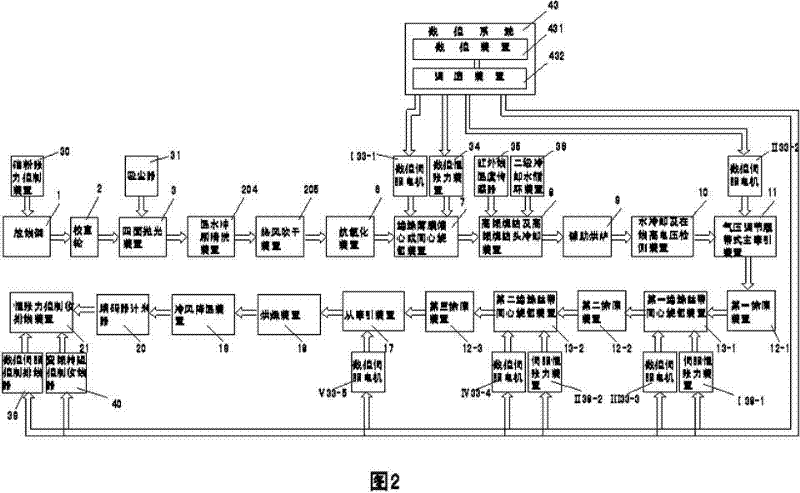

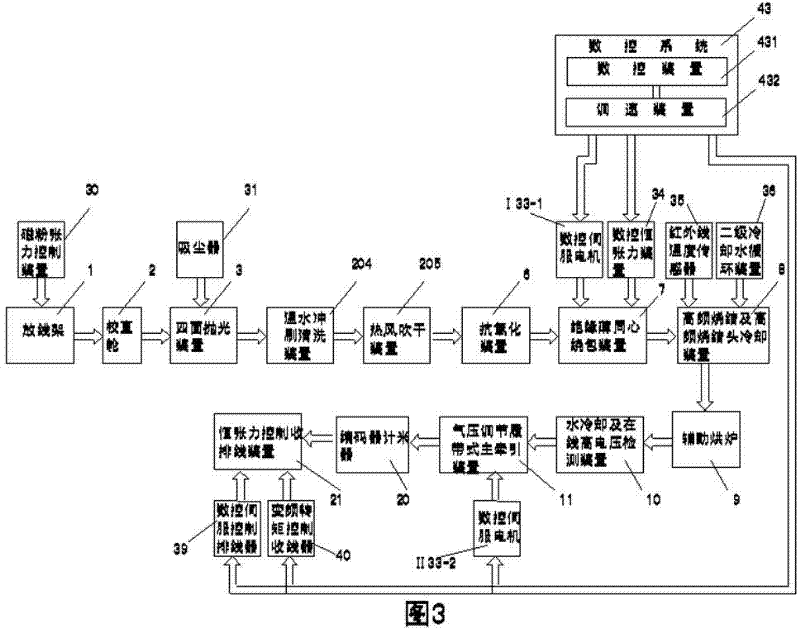

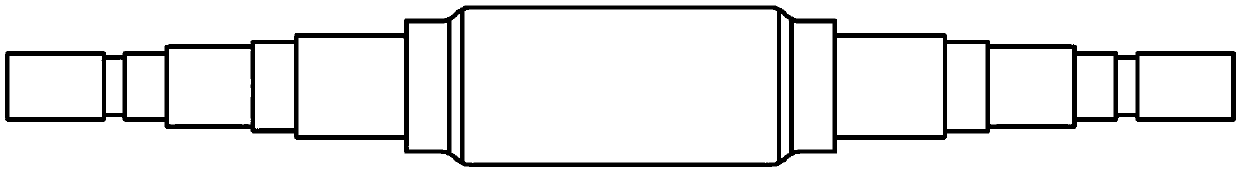

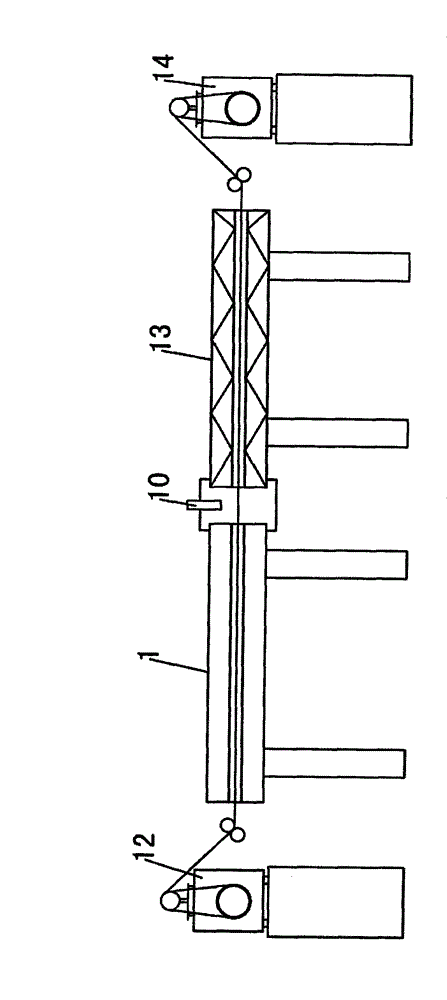

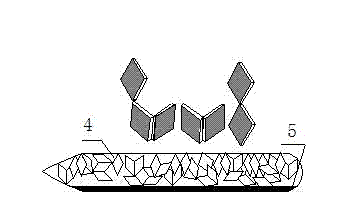

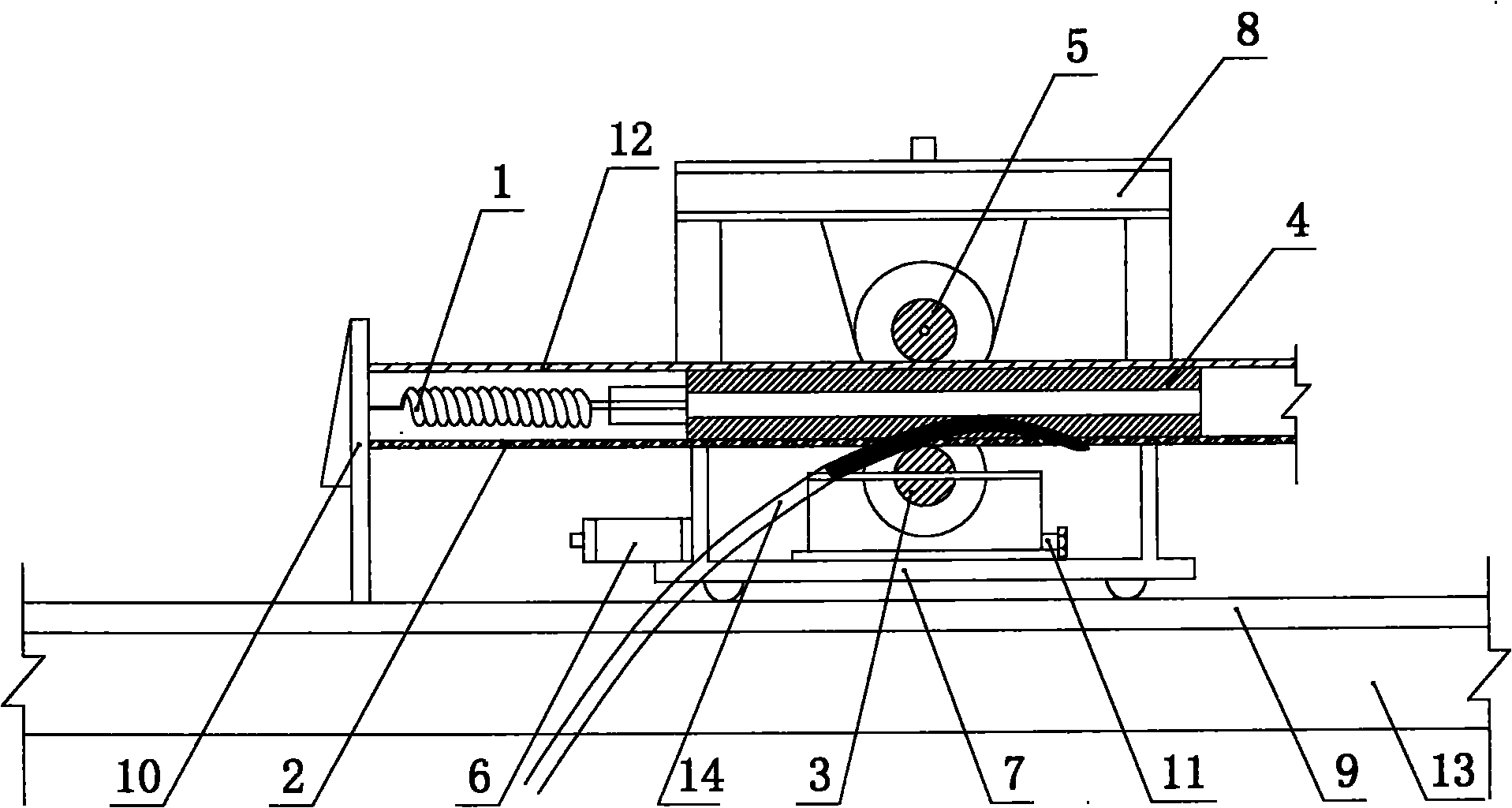

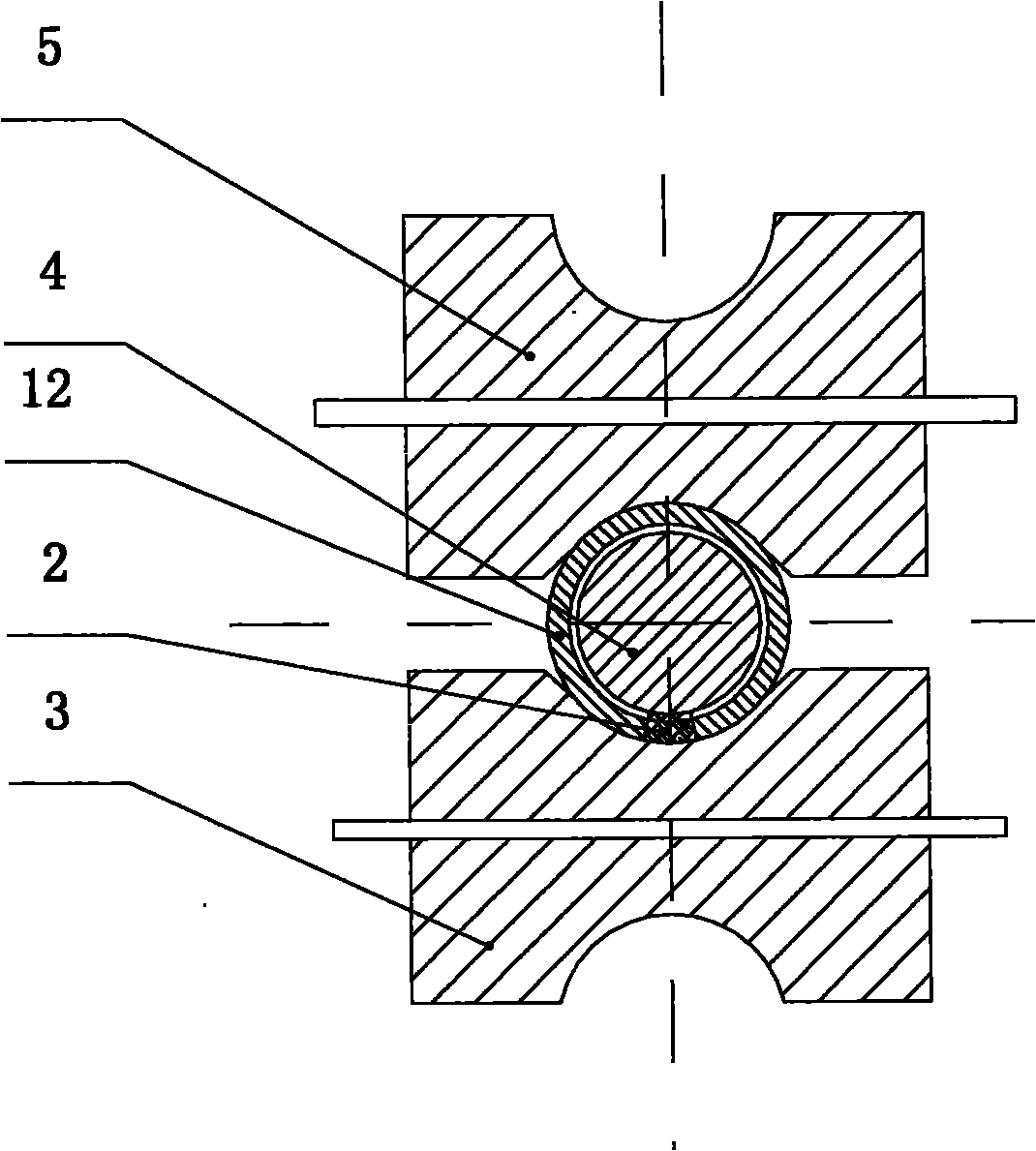

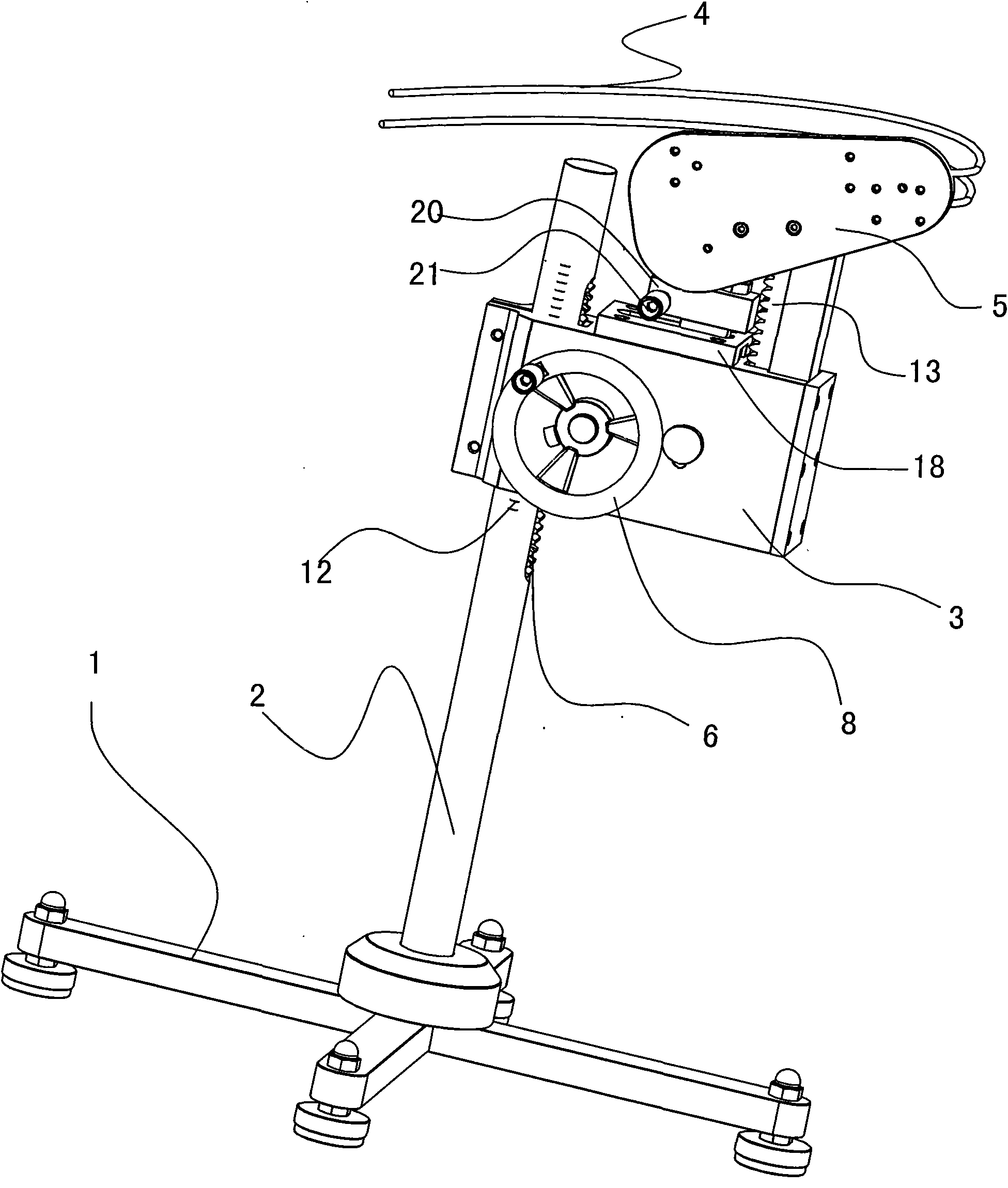

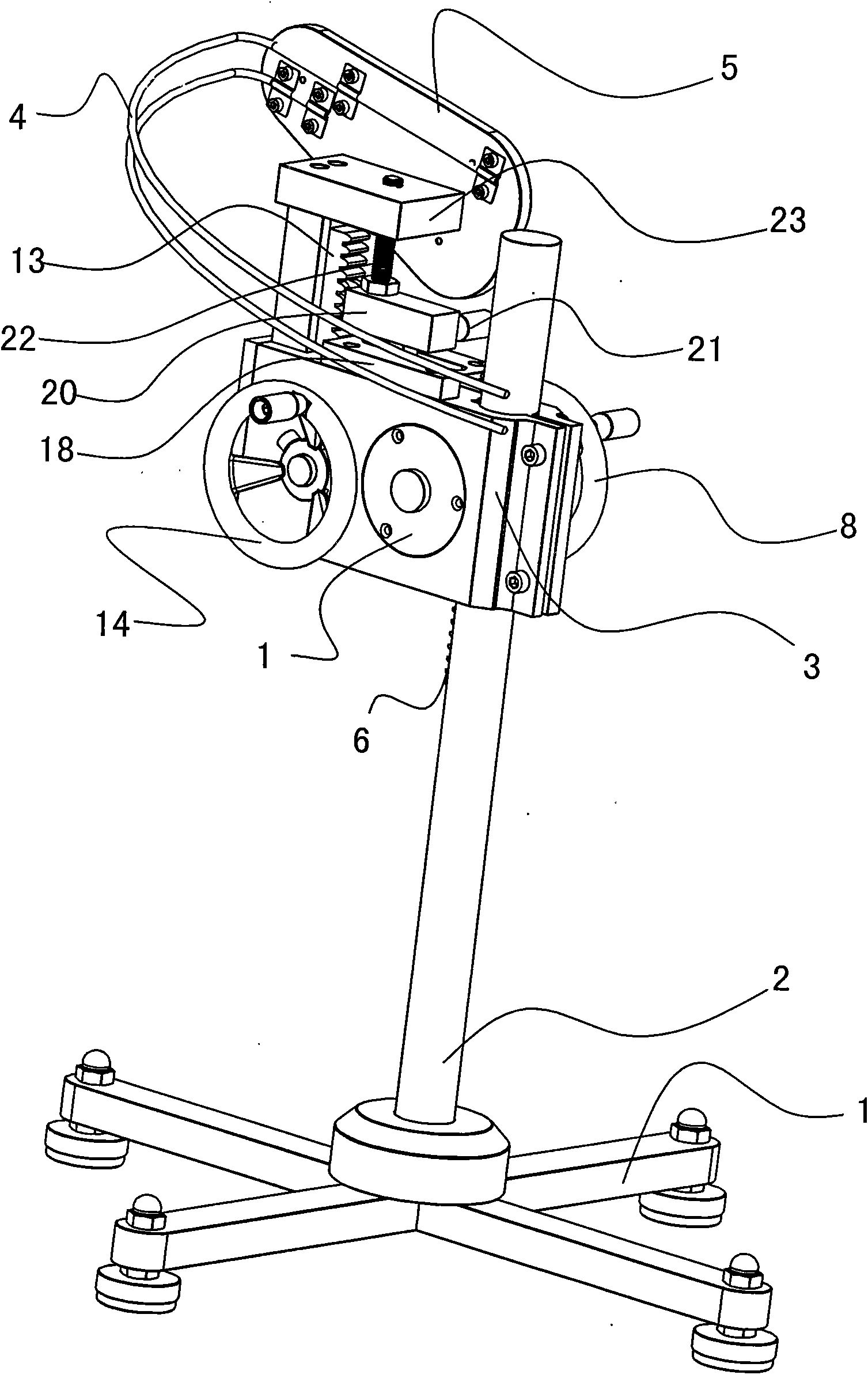

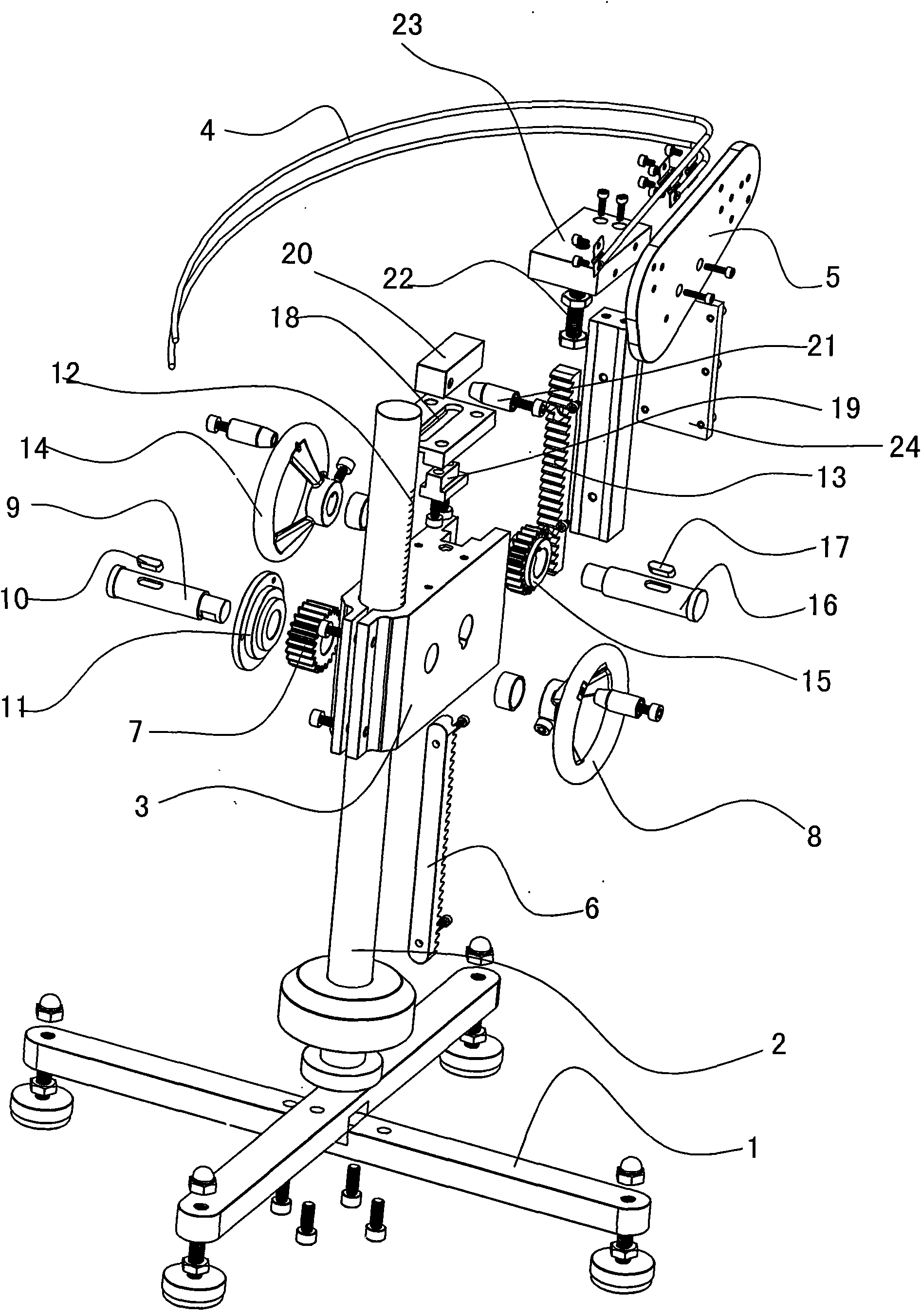

Numerical control multifunctional horizontal wrapping machine

ActiveCN102227091AImprove adhesionEasy to controlFilament handlingApplying solid insulationHigh frequencyBooster pump

The invention provides a numerical control multifunctional horizontal wrapping machine which comprises a constant tension line laying rack. The machine also comprises a straightening wheel, a four-side polishing device, a warm water washing cleaning device and a hot air blow-dry device which are installed on a first bench in order. The machine also comprises an insulation film eccentric or concentric wrapping device, a high frequency sintering and high frequency sintering head cooling device, an auxiliary oven and a water cooling and on-line high voltage detection device which are installed on a second bench in order. The machine also comprises a air pressure adjusting crawler type main draw gear, a first insulation ribbon eccentric wrapping device or concentric wrapping device, a second coating device, a second insulation ribbon eccentric wrapping device or concentric wrapping device, a third coating device, a draw gear, a drying device, and a wire arrangement collection device. The cleaning device is provided with a water heating device and a booster pump. An antioxidation device is provided between the hot air blow-dry device and the insulation film eccentric or concentric wrapping device. A constant tension device controlling film or filament disc material emptying on the wrapping head is a numerical control constant tension device. By using the numerical control multifunctional horizontal wrapping machine in the invention to wrap insulated wire, product quality and production efficiency of the insulated wire is raised.

Owner:GOLD CUP ELECTRIC APP CO LTD

Machining method for utilizing radial forging machine for producing multi-step cold-rolled work roller blank

ActiveCN108672625AReduce manufacturing costReduce blank process weightForging hammersFurnace typesSurface cleaningWater cooling

The invention discloses a machining method for utilizing a radial forging machine for producing a multi-step cold-rolled work roller blank, and belongs to the technical field of metallurgical machinemanufacturing. After electric furnace smelting, LF furnace refining and VD vacuum treatment, fire cutting, annealing, surface shot blasting, coal gas baking and electroslag remelting are conducted tomanufacture an MC6B multi-step cold-rolled work roller blank electroslag ingot; then, annealing and surface cleaning are conducted, and the gas furnace heating heat preservation time is larger than orequal to 24 h; then, arc upsetting plate upsetting, first-time furnace returning heating, upper flattening, lower V-shaped anvil drawing-out, second-time furnace returning heating and radial forgingmachine forging are conducted to manufacture an MC6B multi-step cold-rolled work blank roller blank; and finally, hot saw cutting, normalizing after water cooling, two-segment type spheroidizing annealing and nondestructive inspection checking are conducted, and the radial forging machine is utilized for producing the multi-step cold-rolled work roller blank. According to the machining method, forge piece allowance of a produced roller blank forge piece is small, the machining time is shortened, accordingly, the forge piece technology weight is reduced, and the manufacturing cost is saved.

Owner:建龙北满特殊钢有限责任公司

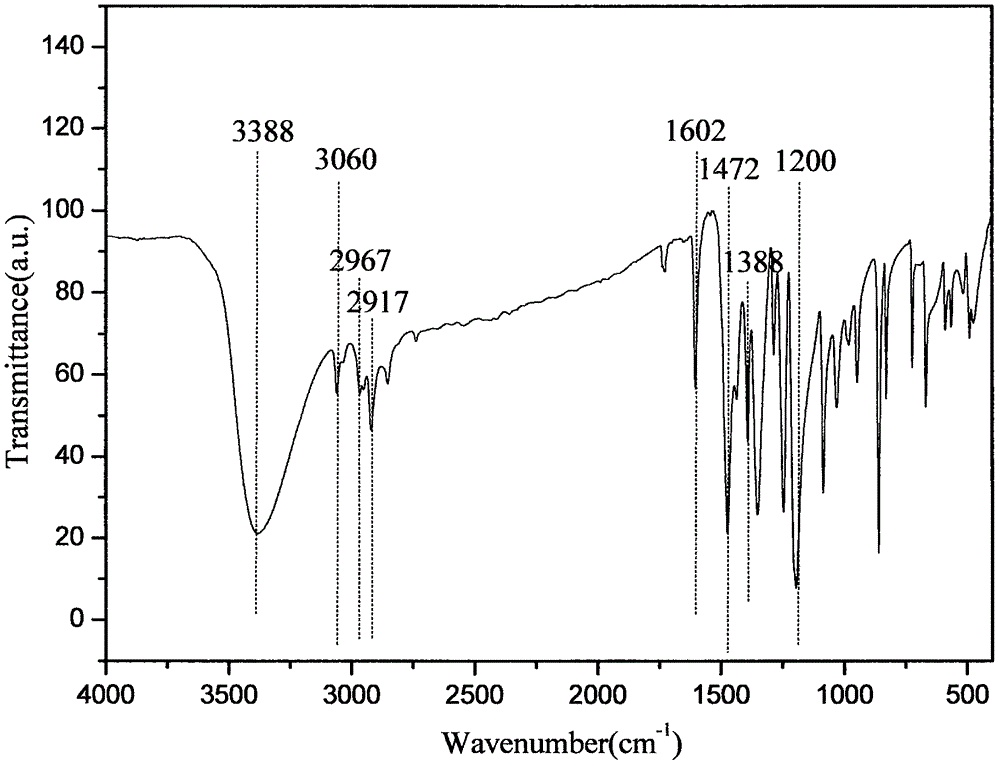

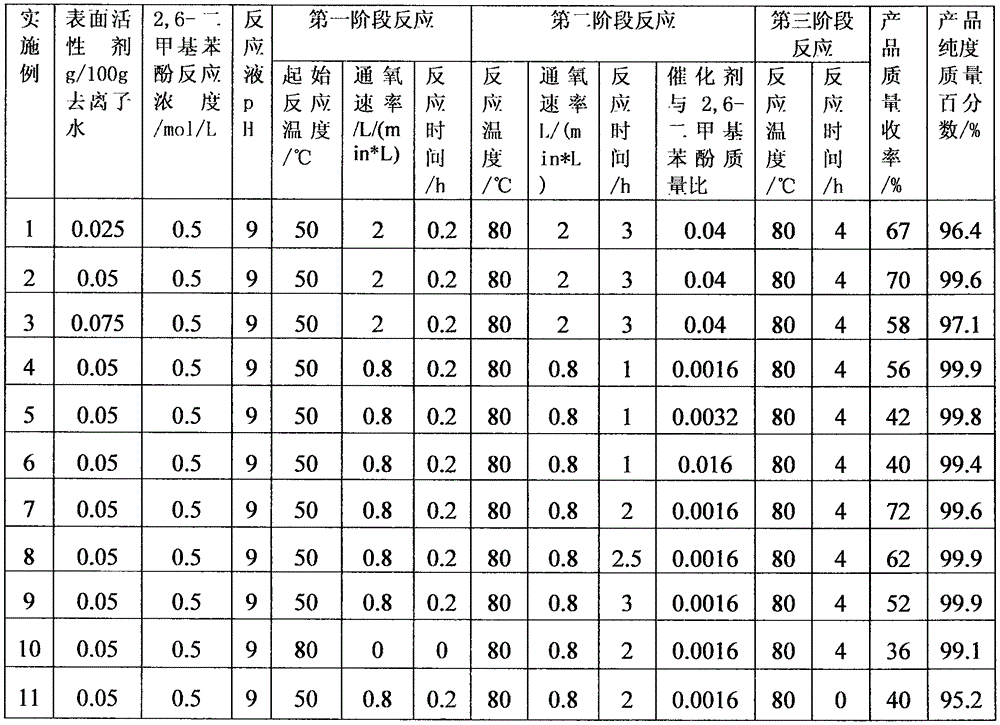

Method for synthesizing high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol

InactiveCN106831350AEasy to separate and removeImprove product quality requirementsOrganic chemistryOrganic compound preparationEpoxyEmulsion

The invention discloses a method for synthesizing high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol. In alkaline emulsion reaction conditions, three stages of combination reactions are performed, 2,6-dimethylphenol is oxidized and coupled into 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol, the 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol is cooled to form a 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol precipitation product in alkaline emulsion, the 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol precipitation product is filtered and washed with water to obtain the high purity 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol product with the product yield of 60-70% and purity mass percent up to 99%, alkaline emulsion filtrate and water washing liquid are recycled after recovery and deployment, a copper salt catalyst is small in amount, soluble in water and easy to remove, and product quality requirements of 3, 3 ', 5, 5'-tetramethyl-4, 4'-diphenol diglycidyl ether biphenyl epoxy molding compounds in microelectronics industry can be met.

Owner:XIANGTAN UNIV

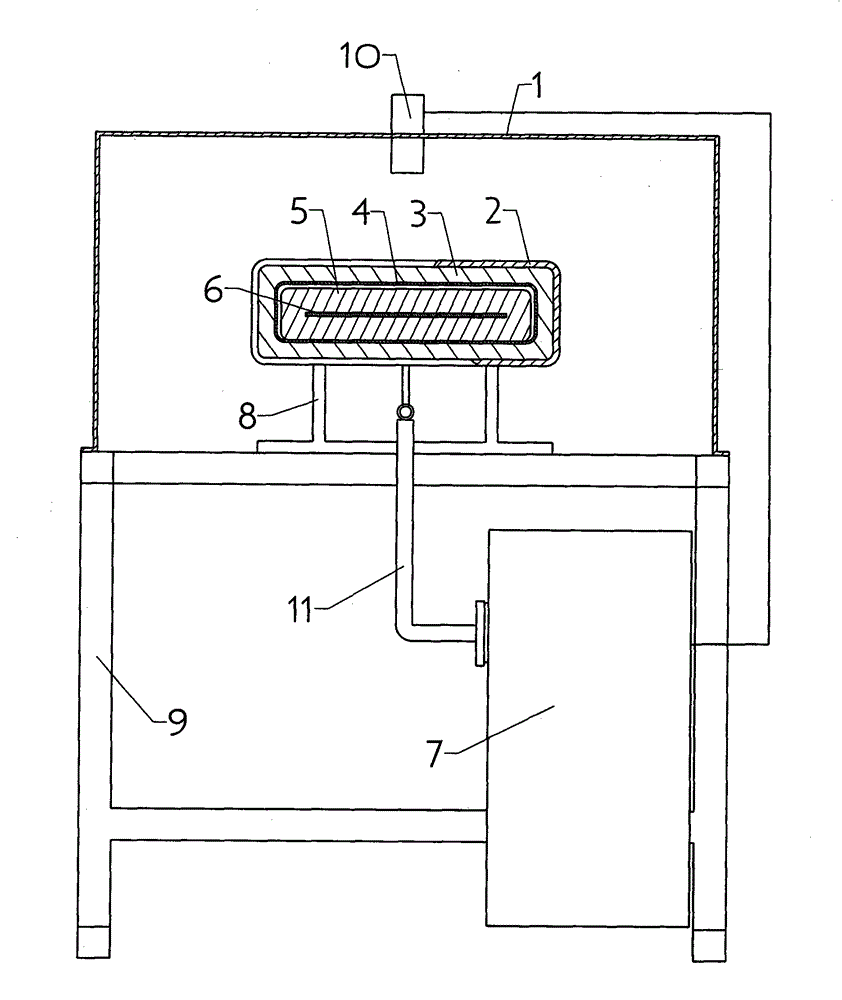

Inducing heating device for thin steel strip coil and heat treatment process thereof

InactiveCN102747204ACompact structureReasonable designFurnace typesIncreasing energy efficiencyFiberGraphite

The invention relates to an inducing heating device for a thin steel strip coil and a heat treatment process of the inducing heating device. An expanding bright annealing device is used for carrying out tension-free annealing to the thin steel strip coil, and the residual stress of the annealed product is eliminated. In addition, the heating mode is changed, and the reliability of the annealing device is improved. The temperature uniformity of the thin steel strip coil product is controlled in the temperature range of 2 DEG C, the heat treatment efficiency and the product quality are improved significantly, and a large amount of energy and time is saved. The inducing heating device for the thin steel strip coil comprises a furnace shell, an inducing heating coil, a high-temperature resistant fiber isolation furnace lining, a quartz tube, a graphite lining, a graphite inner cavity, a power supply device, a bracket, a base, a temperature measuring device and a water-cooled cable device. The base is correspondingly arranged below the furnace shell of the inducing heating device. The bracket is arranged in the middle part above the base. The rectangular inducing heating coil on the bracket is arranged in the furnace shell of the inducing heating device and internally provided with the high-temperature resistant fiber isolation furnace lining with a rectangular section.

Owner:洛阳用功感应加热设备有限公司

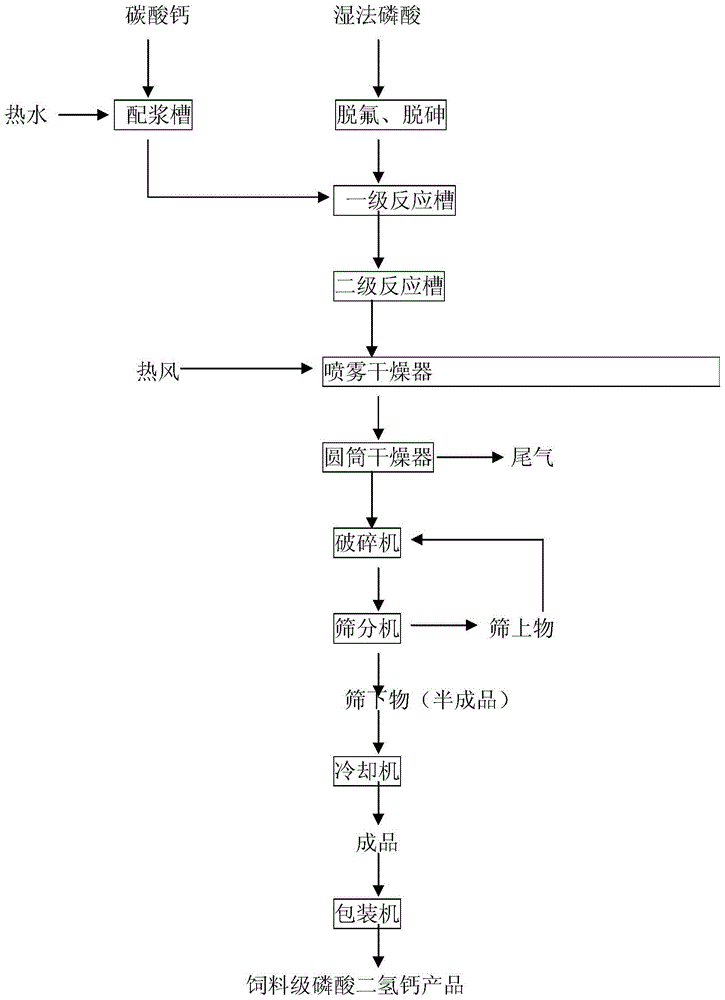

Production method for feed-grade monocalcium phosphate

InactiveCN105417516AMeet product quality requirementsEliminate the ripening processPhosphorus compoundsFirst-order reactionPhosphoric acid

The invention discloses a production method for feed-grade monocalcium phosphate. The method comprises the following steps: (1) preparation of a phosphoric acid raw material; (2) slurrying of a calcium carbonate raw material; (3) first order reaction; (4) second order reaction; (5) spray drying and cylinder drying of slurry; (6) crushing and screening; (7) cooling and packaging to obtain the product. Compared with the existing technology, the production method disclosed by the invention has the following advantages: (1) a curing procedure in an original process is omitted, and the production time is greatly shortened; (2) the area of a used production site is greatly reduced, and the construction investment is saved; (3) the process is easy to control and simple to operate; (4) the product accords with a quality requirement of a feed product. The production method is applicable to producing the feed-grade monocalcium phosphate product.

Owner:WENGFU (GRP) CO LTD

Method for recycling cobalt from waste and old lithium ion battery

InactiveCN101318712BMeet product quality requirementsEasy to manufactureCobalt oxides/hydroxidesEngineeringLithium-ion battery

Owner:TSINGHUA UNIV

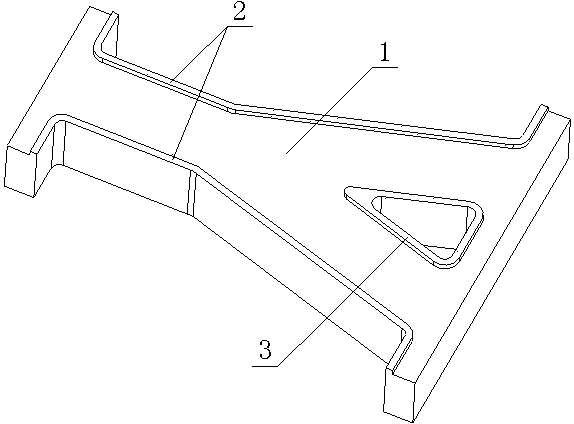

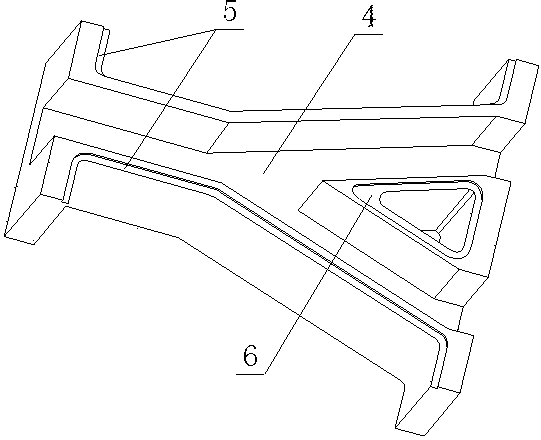

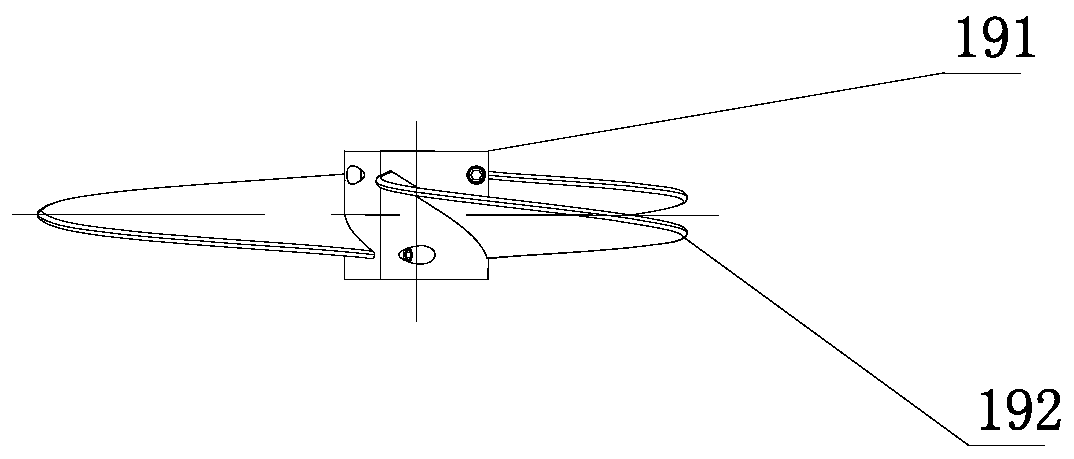

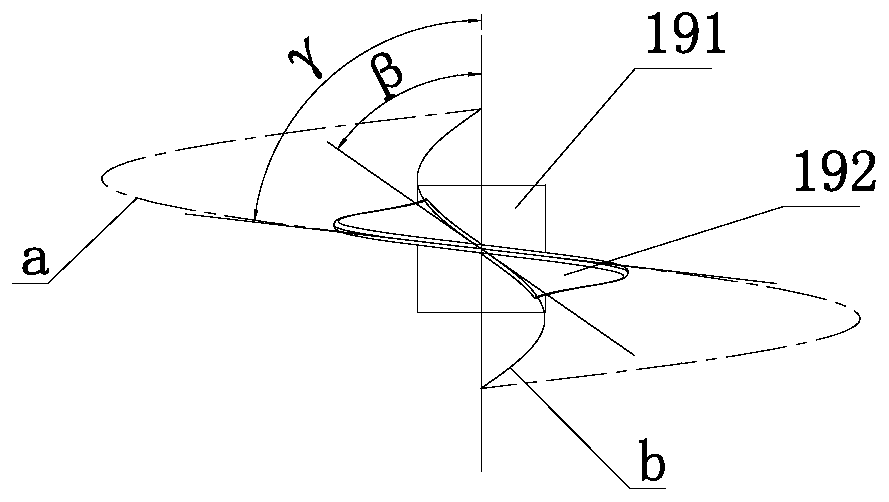

Y-shaped power divider manufacturing technology

InactiveCN104347923AHigh dimensional accuracyQuality improvementCoupling devicesNumerical controlManufacturing technology

The invention discloses a Y-shaped power divider manufacturing technology which comprises upper cover plate processing, lower cavity processing and vacuum brazing molding and specifically comprises the steps of S31: mounting an upper cover plate and a lower cavity in trial, and guaranteeing that an edge boss (2) and an edge groove (5) as well as a Y-branch slot convex bayonet (3) and a Y-branch slot concave bayonet (6) are tightly attached; S32: performing pickling to remove impurities; S33: assembling the upper cover plate, the lower cavity and a brazing material; S34: performing vacuum brazing; S35: performing numerical control processing on the appearance of a power divider and a flange disk; S36: drilling and hinging pin holes; S37: performing electrochemical treatment; S38: testing telecommunications parameters. According to the Y-shaped power divider manufacturing technology, the welding deformation caused by multi-time manual flame welding is avoided; the upper cover plate and the lower cavity are positioned by the boss, the groove and the bayonets, so that the size consistency and the precision of the power divider are guaranteed; when the parts such as the boss, the groove and the bayonets are designed, the embedding thickness of a welding sheet is considered; furthermore, a fit clearance is increased to 0.02-0.04mm, so that the flowability of brazing material joint filling is guaranteed during welding, and the cavity size precision of the assembled power divider is guaranteed.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

Preparation method of ultra-high-purity arsenic monocrystal pieces

ActiveCN102899712AAchieve the purpose of growthFulfil requirementsPolycrystalline material growthFrom solid stateLiquid stateTube furnace

The invention discloses a preparation method of ultra-high-purity arsenic monocrystal pieces. The method comprises the steps that: (1) quartz tube surface treatment is carried out; (2) ultra-high-purity arsenic deoxidation package is carried out; (3) the material is placed in a horizontal tube furnace; and (4) the material is melted in the horizontal tube furnace, and cooling crystallization is carried out. According to the invention, with the sealed quartz tube and pressure generated by arsenic high-temperature melting, purposes of arsenic melting and crystal growth are achieved. Under a normal temperature undercooling condition, crystals grow when liquid-state arsenic in the tube reaches an undercooling degree. 30-60 pieces are grown in each tube, and monocrystal pieces are produced with a twin-crystal manner. Therefore, domestic product quality requirements and export quality requirements can be satisfied. The method has good application prospect.

Owner:峨嵋半导体材料研究所

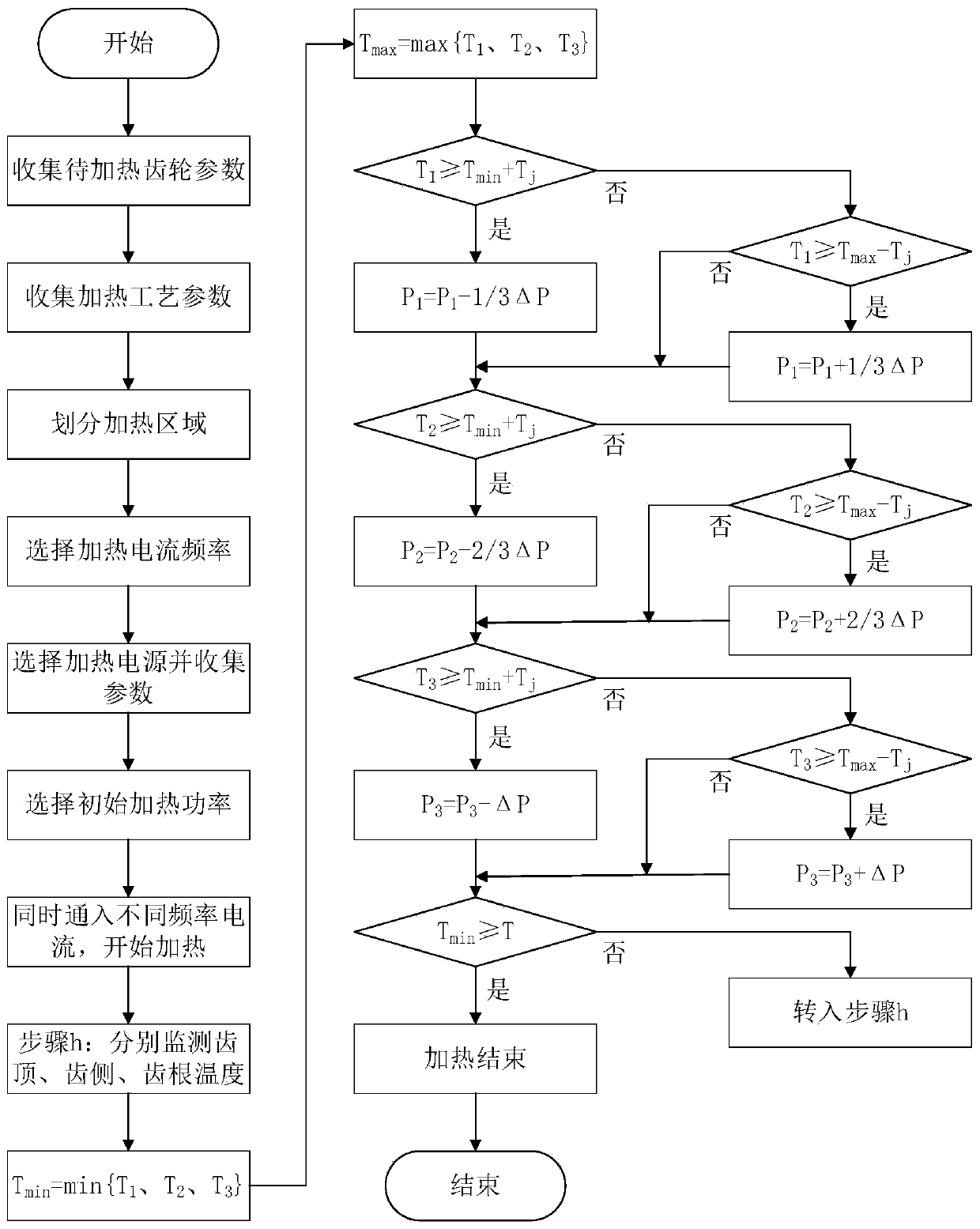

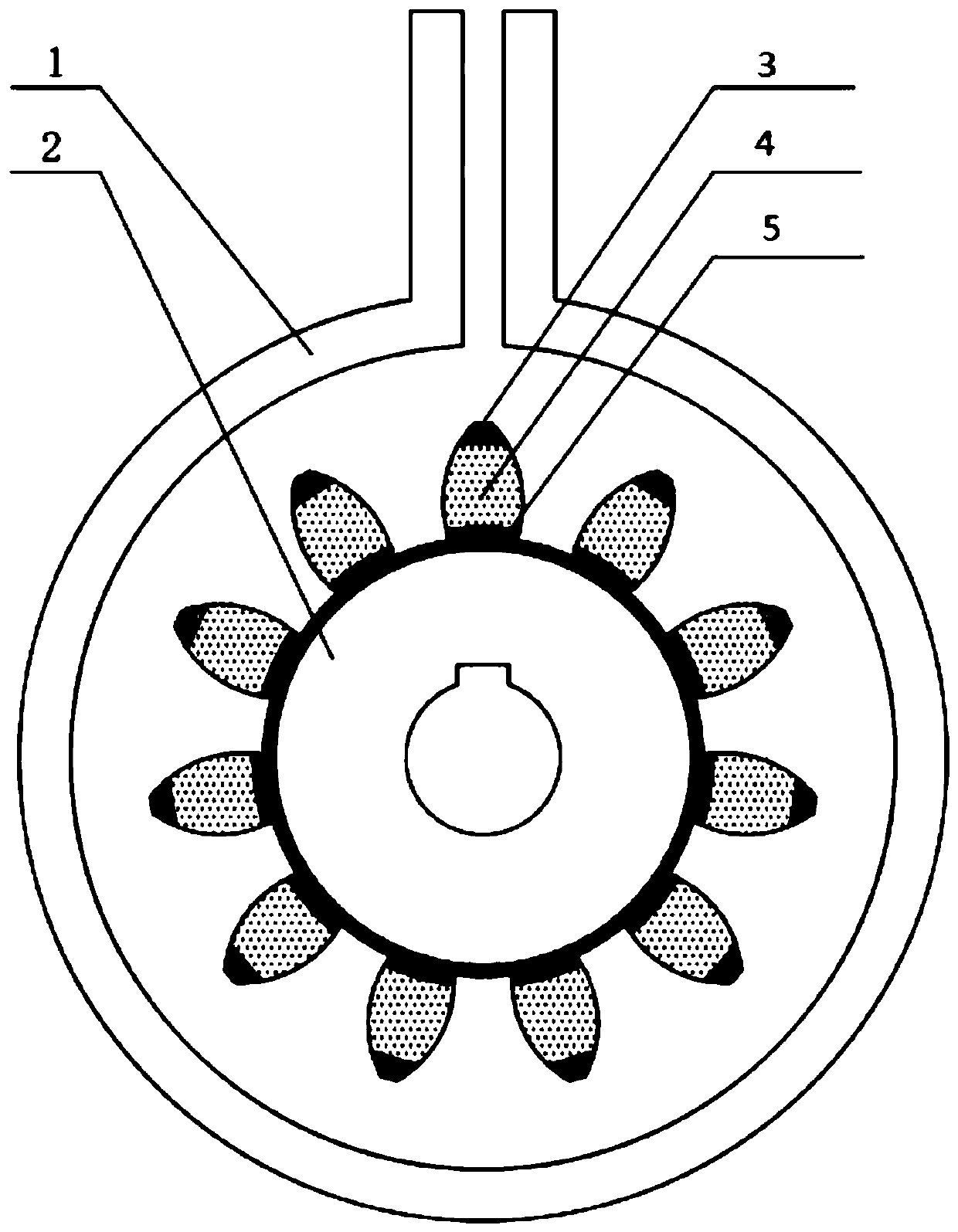

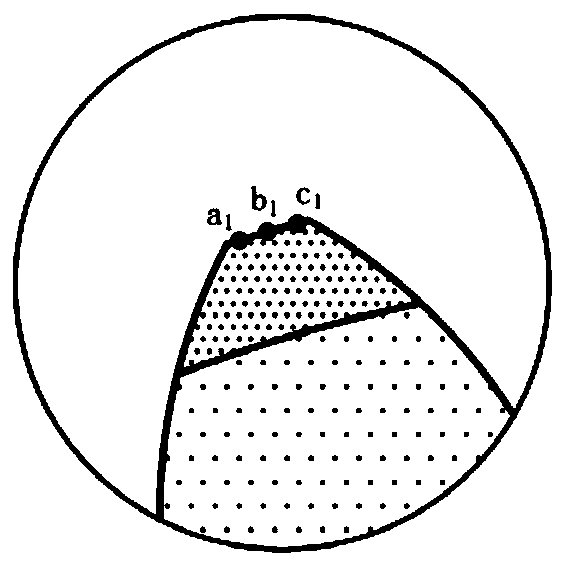

Control method for heating weathering steel gear

ActiveCN111424158AMethods for Realizing Partition ControlUniform temperatureFurnace typesIncreasing energy efficiencyThermodynamicsGear wheel

The invention relates to a control method for heating a weathering steel gear, and belongs to the technical field of gear production. The technique uses the characteristic that different frequency currents have different penetration depths to divide the teeth of the gear to be heated into three different heating areas, and uses three single-frequency power supplies to synchronously switch on current of three different frequencies, which are respectively high, medium and medium frequencies, to a circular coil, so as to heat the operation parts including the tooth top, tooth side and tooth rootof the gear to be heated. Meanwhile, the temperature monitoring of the tooth top, tooth side and tooth root is carried out in real time, the temperature difference of the respective parts is calculated, and the power supply heating power regulation corresponding to the respective parts is carried out based on the temperature difference feedback of the respective parts to realize high-precision gradient heating control of the gear to be heated. The temperature difference is controlled within the temperature accuracy, the production cost is reduced under the condition of meeting the requirementsof production quality, and the best economic benefit can be achieved for the enterprise.

Owner:YANSHAN UNIV

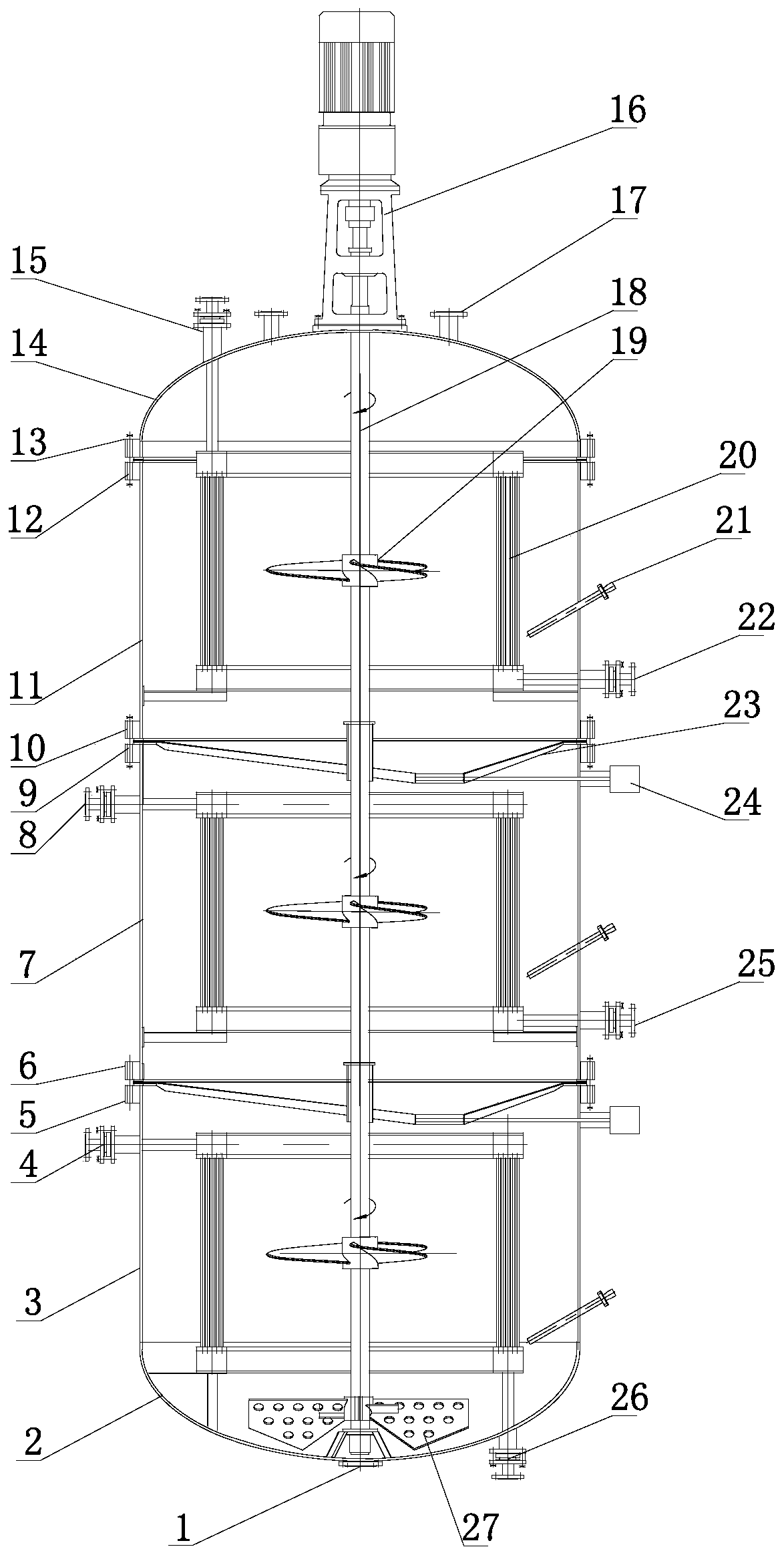

Continuous multi-stage constant-temperature-difference cooling crystallizer

PendingCN109893880AGuaranteed uptimeRun continuouslySolution crystallizationTemperature controlTemperature difference

The invention belongs to the technical field of chemical equipment and particularly relates to a continuous multi-stage constant-temperature-difference cooling crystallizer, comprising a crystallizerbody; the top and bottom of the crystallizer body are provided with a feed port and a discharge port respectively; the inside of the crystallizer body is divided into multiple cavities through cavitypartitions; each cavity partition is provided with a fluid passage which is openable; a heat exchange device and a stirrer are arranged in each cavity, and independent temperature control is carried in each cavity; a bottom stirrer is arranged at the lower portion of the bottom cavity; the stirrer in every cavity and the bottom stirrer are connected with a driving device through a stirring shaft.The continuous multi-stage constant-temperature-difference cooling crystallizer is suitable for continuous production, so that labor intensity is reduced, energy consumption for material transfer andpollution are decreased, and equipment utilization efficiency is improved; it can be ensured that crystallized products are good in quality stability and reliability and that the technique is reproducible, and differences between different batches of one material are decreased.

Owner:江苏和诚制药设备制造有限公司

Flattening device for welding seam of welded pipe

InactiveCN101934446AMeet product quality requirementsHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamMechanical engineering

The invention relates to a flattening device for a welding seam of a welded pipe, which comprises a guide seat and a roll mounting seat arranged on the guide seat. The flattening device is characterized in that the roll mounting seat comprises a trolley which is equipped with a horizontal cylinder, a lower roll, an upper roll, an elevating cylinder connected with the upper roll and an adjusting knob connected with the lower roll; and the flattening device is further equipped with a core rod arranged in the welded pipe, a core rod fixed block fixed on the guide seat and a spring for connecting the core rod fixed block with the core rod together. In the invention, the welding seam of the welded pipe is flattened by a rolling mode to realize smooth transition between welding beads as well as welding beads and base metal after use, and performance parameters of the welding beads and the base metal have small difference, thus fully meeting the requirements for product quality; the flattening device is controlled by a PLC, thus achieving high precision; and the flattening device is provided with the adjusting knob to meet the diameter of the welded pipe within a wider range, thus achieving wide application range.

Owner:BAOLAI STAINLESS STEEL TECH (KUNSHAN) CO LTD

Method for preparing high-purity lithium chloride, high-purity lithium formate and high-purity lithium carbonate

ActiveCN109809440AMeet production quality requirementsEasy to operateCarboxylic acid salt preparationLithium halidesLithium chlorideOrganic solvent

The invention discloses a method for preparing high-purity lithium chloride, high-purity lithium formate and high-purity lithium carbonate. The method for preparing high-purity lithium chloride comprises: S1, mixing crude lithium chloride and an organic solvent, heating until boiling, removing water in reflux liquid, refluxing the organic solvent until the water content in the reflux liquid and that in the mixed liquid are detected to be both lower than or equal to 0.5 percent by weight, stopping heating and cooling to room temperature to obtain turbid liquid; S2, while stirring, introducing ammonia gas into the turbid liquid, and maintaining stirring for a period of time, so that lithium chloride suspended in the organic solvent is all dissolved, and insoluble matter impurities are filtered to obtain filtrate; S3, adding pure water into the filtrate, uniformly stirring, then dropwise adding refined and decontaminated pre-prepared liquid, thoroughly stirring, filtering, adding at leastone of oxalic acid, oxalate or oxalate ester into the filtrate, stirring, lowering the temperature to -5 DEG C or below, and keep cold to filter insoluble matters in a solution to obtain an organic solution of refined lithium chloride, wherein the purity (dry basis) of lithium chloride is greater than or equal to 99.9 percent by weight.

Owner:SHENZHEN MAXCHEMTECH

Extinction method of slushing mold

The invention relates to an extinction method of a slushing mold, belonging to a mold surface treatment method. The method includes the following steps: firstly, quartz sands with 0.1-0.2 Mum of diameter and glass balls with 0.3-0.4Mum of diameter are mixed in the proportion of 1:1-1:5; secondly, the figured zone of the mold is treated by a high-pressure ejection gun, the nozzle of the ejection gun has 1.0-1.2mm of diameter, the distance from the ejection gun to the surface of the mold is 200-300mm and the horizontal traveling speed of the ejection gun is 0.02-0.04m / s in the ejection process. The invention has the advantages that the extinction method is applicable not only to the surface treatment of various electroplated nickel casing in the automobile interior ornament product production field, but also to the surface treatment of nickel molds in other fields which demand for high surface gloss. The extinction method is convenient for operation, the raw materials are easily found and the cost is low.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

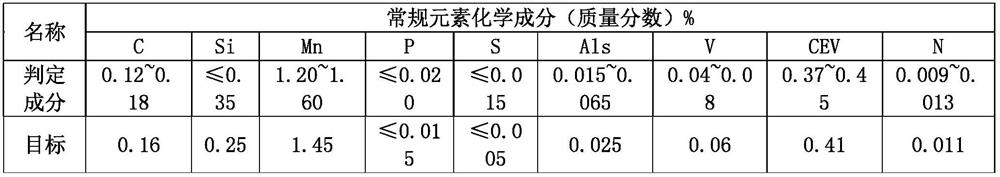

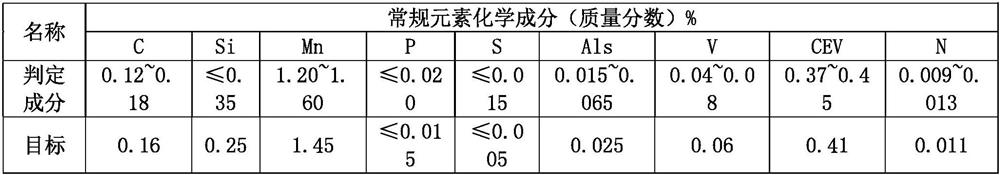

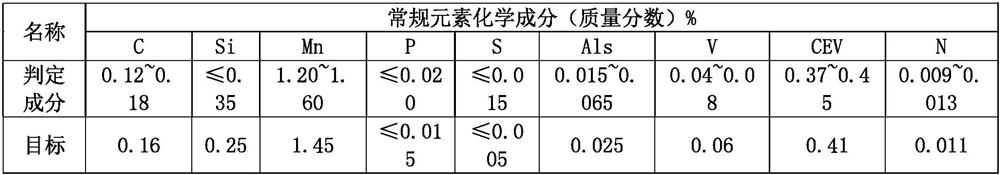

RH nitrogen-blowing alloying process capable of accurately controlling nitrogen content of nitrogen-containing steel grade

ActiveCN112899440AImprove hit rateReduce manufacturing costManufacturing convertersProcess efficiency improvementVacuum pumpingNitrogen gas

The invention discloses an RH nitrogen-blowing alloying process capable of accurately controlling the nitrogen content of a nitrogen-containing steel grade. The RH nitrogen-blowing alloying process capable of accurately controlling the nitrogen content of the nitrogen-containing steel grade comprises the following steps: desulfurized molten iron and scrap steel are smelted in a converter, oxygen is blown from the top, and nitrogen is blown from the bottom; LF refining and RH vacuum refining are sequentially carried out on molten steel, a mechanical pump vacuum system is adopted for RH, specifically, argon / nitrogen switching is carried out on RH circulation gas, the nitrogen flow is 90-150 Nm<3> / h, the nitrogen pressure is 1.0-1.8 Mpa, RH vacuum air-pumping is carried out, the pressure is reduced to 273 Pa or below from atmospheric pressure, and RH air-pumping lasts for 5-10 min; temperature measurement and sampling are carried out, and the chemical components and the nitrogen component content of the molten steel are analyzed; the component content of the molten steel is adjusted according to the sampling analysis result, the RH vacuum degree is adjusted to 4-15 kpa, nitrogen is rapidly increased in the molten steel, and the average nitrogen increasing amount is 3.0-3.50 ppm / min; and after the molten steel meets the technical requirements of the steel grade, the RH is finished, re-pressing is carried out, a steel ladle is opened for blowing argon from the bottom, and calcium treatment in a metal calcium feeding line is carried out. According to the invention, the nitrogen content fluctuation of the molten steel can be accurately controlled to be + / -5ppm, the technical requirements of the steel grade are met, the quality of the steel grade is ensured, and the production cost is reduced.

Owner:CHONGQING IRON & STEEL CO LTD

Method for making fried melon seeds

The invention provides a method for making fried melon seeds. The method comprises the following steps: winnowing raw materials; preparing; boiling; frying; cooling; winnowing; selecting; packaging; and warehousing. The making method is not only reasonable and practical, but also has simple operation and good effect, contributes to wide popularization, and has excellent guarantee in benefit and economy.

Owner:青岛清光食品有限公司

Production process of extracting antibody immune globulin from hen's egg

The present invention relates to medicine and food field and to a production process of extracting antibody immune globulin with hen's egg. The production process with egg of the hen after antigen injection includes raw material conversion, cleaning and sterilizing, yolk extraction, dilution and dispersion with water, antigen immune globulin separation, drying and product treatment. The product reaches the technological indexes of medicine and food and may be used directly as medicine and food. The said method may be also used in the production of other specific matter obtained through the biological conversion of hen's egg.

Owner:孙亮

Method cutting lower hem of skirt and cutting machine

InactiveCN101929062AIncrease productivityMeet product quality requirementsSevering textilesMechanical engineeringEngineering

The invention discloses a method for cutting the lower hem of a skirt and a cutting machine. A cutting device is fixedly arranged on an installation rack at an adjustable height and adopts a motor to drive a circular cutting knife, the cutting machine is matched with a rotatable contour figure of human body, the skirt is sleeved on the contour figure of human body, the contour figure of human body rotates to lead the lower hem of the skirt to stretch into the cutting knife, and the lower hem is cut by the cutting knife while the non-cut lower hem is fed into the cutting knife by the rotary contour figure of human body continuously so as to cut the whole lower hem. By the invention to cut the lower hem of the skirt, the consistent height of the lower hem of the skirt can be ensured, the product quality requirement can be achieved, and the production efficiency is greatly improved.

Owner:陈永洪

Method for processing materials for manufacturing tobacco sheets and tobacco sheets manufactured with method

InactiveCN104382217AImprove performanceReserve lengthTobacco preparationTobacco treatmentCross-linkPorosity

The invention belongs to the technical field of tobacco sheet manufacturing, and discloses a method for processing materials for manufacturing tobacco sheets with tobacco waste and the tobacco sheets manufactured with the method. The method includes the steps that after a mixture of tobacco stems and tobacco powder is extracted, the concentration is gradually lowered under the medium concentration condition; multistage soft defibrination processing is carried out; smashing and defibrination are carried out on materials obtained through defibrination processing and outer-fiber long-fiber stuff; and obtained slurry is evenly mixed to obtain materials used for manufacturing tobacco sheet base sheets. According to the method, gradual, sufficient and even mixing and defibering are carried out on the solid-phase mixture of the tobacco stems and the tobacco powder in the multistage soft defibrination processing process; moderate thin fibrillation is generated; the cutting effect and the damage effect on the materials in the defibrination process are reduced; the high thin fibrillation degree of the outer-fiber long-fiber stuff is obtained under the high pulping strength; the adsorption effect and the cross linking effect on thin components in the materials are facilitated; the retention rate of the tobacco powder and packing on a net is improved; the yield is improved; and the porosity and the physical performance of the tobacco sheet are improved.

Owner:SOUTH CHINA UNIV OF TECH

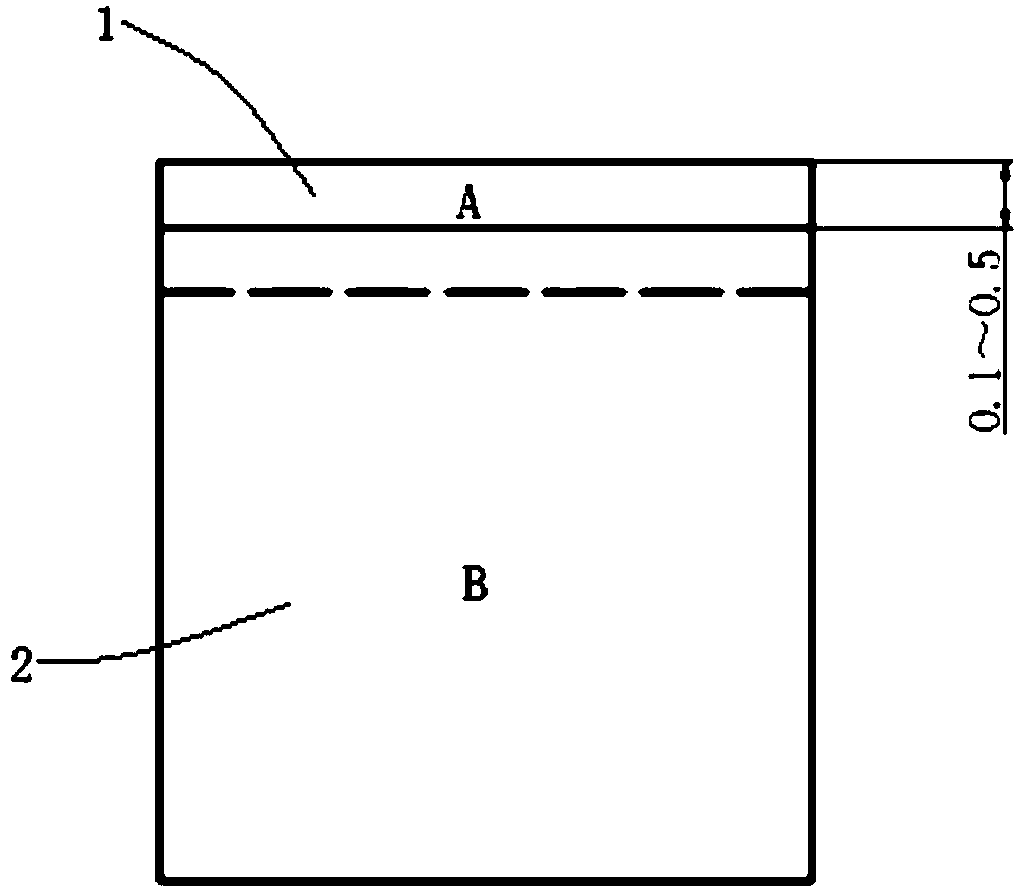

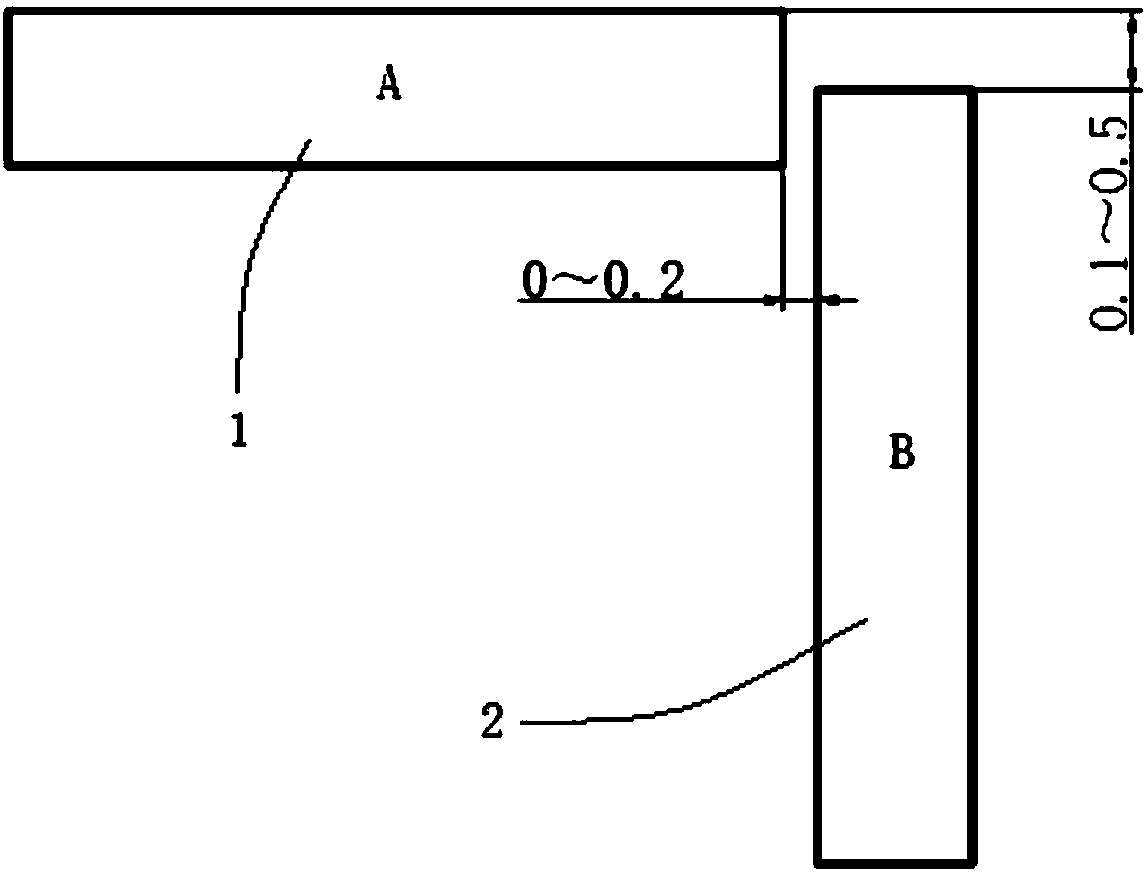

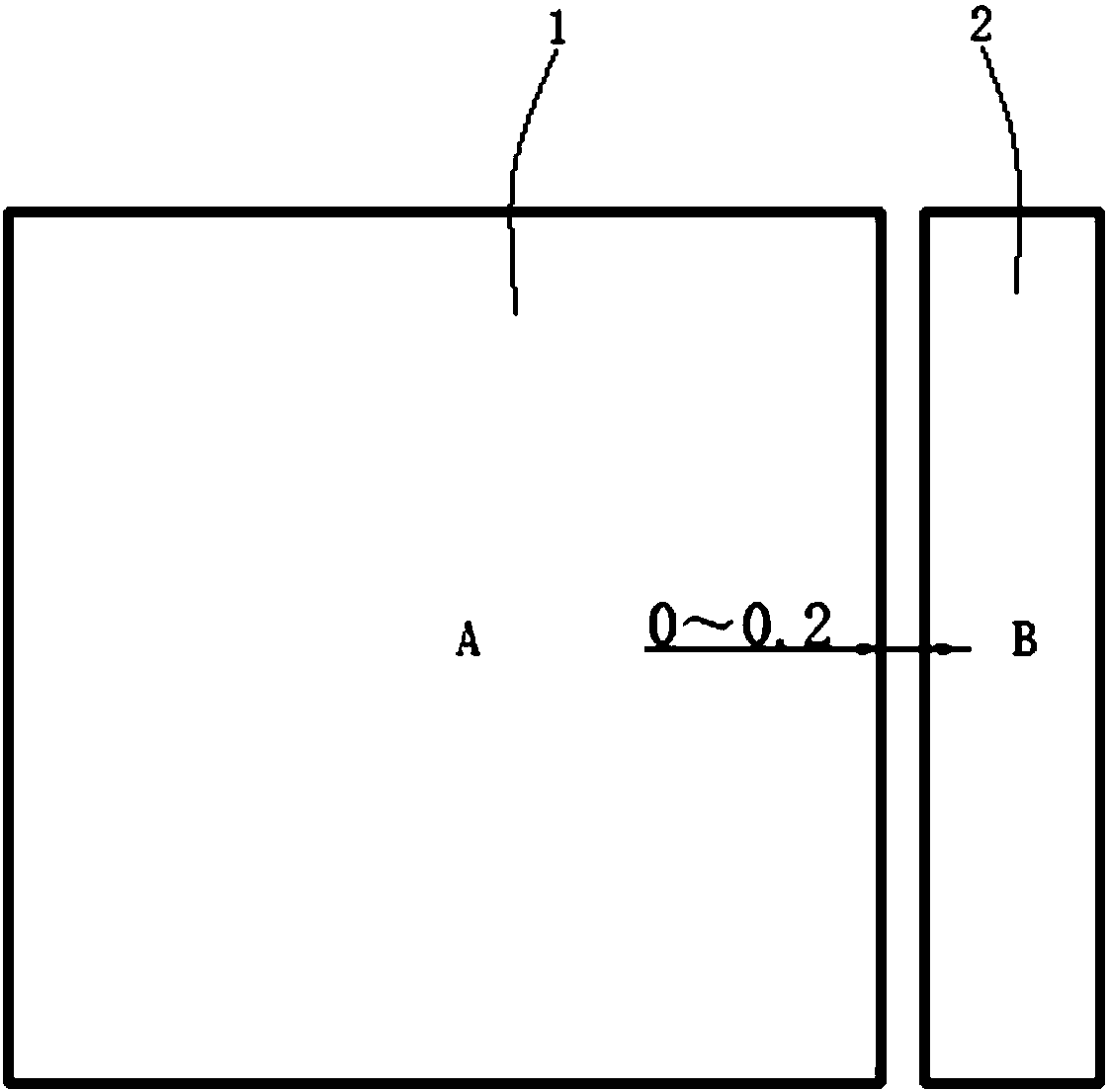

Arc angle laser welding forming method of angle seam joints

InactiveCN108326420AHigh heat input efficiencyLow heat inputLaser beam welding apparatusEngineeringFusion welding

The invention relates to an arc angle laser welding forming method of angle seam joints. The method comprises the steps as follows: two plates are positioned, the plate A and the plate B are perpendicular, the distance between the two plates is controlled within the range of 0-0.2 mm, the to-be-welded end surface of the plate B is located between two plate surfaces of the plate A, and the distancebetween the to-be-welded end surface of the plate B and the outer side plate surface of the plate A is in a range of 0.1-0.5 mm; a laser self-fusion welding manner is adopted for welding forming, andthe focus spot diameter of laser beams is 1.5-2.2 mm. A special welding joint splicing form is adopted, the space occupied by surplus height of appropriate weld seams is reserved, the weld seams haverelatively flat surfaces after welding and form smooth arc angle seams, the weld seam appearance requirement is guaranteed, and the weld seam arc angle forming requirement can be better met; a large-focus spot diameter laser welding technology is adopted, welding seam forming can meet the product requirement, simple polishing treatment is needed only in the later period, and stable production with high quality, efficiency and benefits is realized.

Owner:WUHAN HGLASER ENG CO LTD

Method for producing cogging by air-valve steel rolling

ActiveCN101069894AResolution cycleSolve the problem of low metal forming rateRoll mill control devicesFurnace typesIngotHot working

The present invention discloses a production method of valve steel billet. It is characterized by that said production method adopts a hot-working cogging process of 'using continuous heating furnace to heat steel ingot and utilizing rolling mill to roll in one heat'.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

Method for producing flat gaskets by coated sand shell mould process

InactiveCN102430720AMeet product quality requirementsAccurate cavity sizeFoundry mouldsMoulding machinesUltimate tensile strengthMaterials science

The invention discloses a method for producing flat gaskets by a coated sand shell mould process. The flat gaskets are produced by use of a coated sand mould in a casting manner, the strength of the coated sand mould is high, and the size of a cavity is accurate, thus the sizes of cast products are completely qualified, the defects of sand holes and air holes are eliminated, the yield of cast products is more than 98%, the production efficiency is high, and the moulding area is reduced.

Owner:安徽省辉煌机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com