Flattening device for welding seam of welded pipe

A technology for welded pipes and mounting seats, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of unsatisfactory knife marks on welded pipes, affect the quality of welded pipes, and reduce product quality, so as to achieve a wide range of applications and meet product quality requirements , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

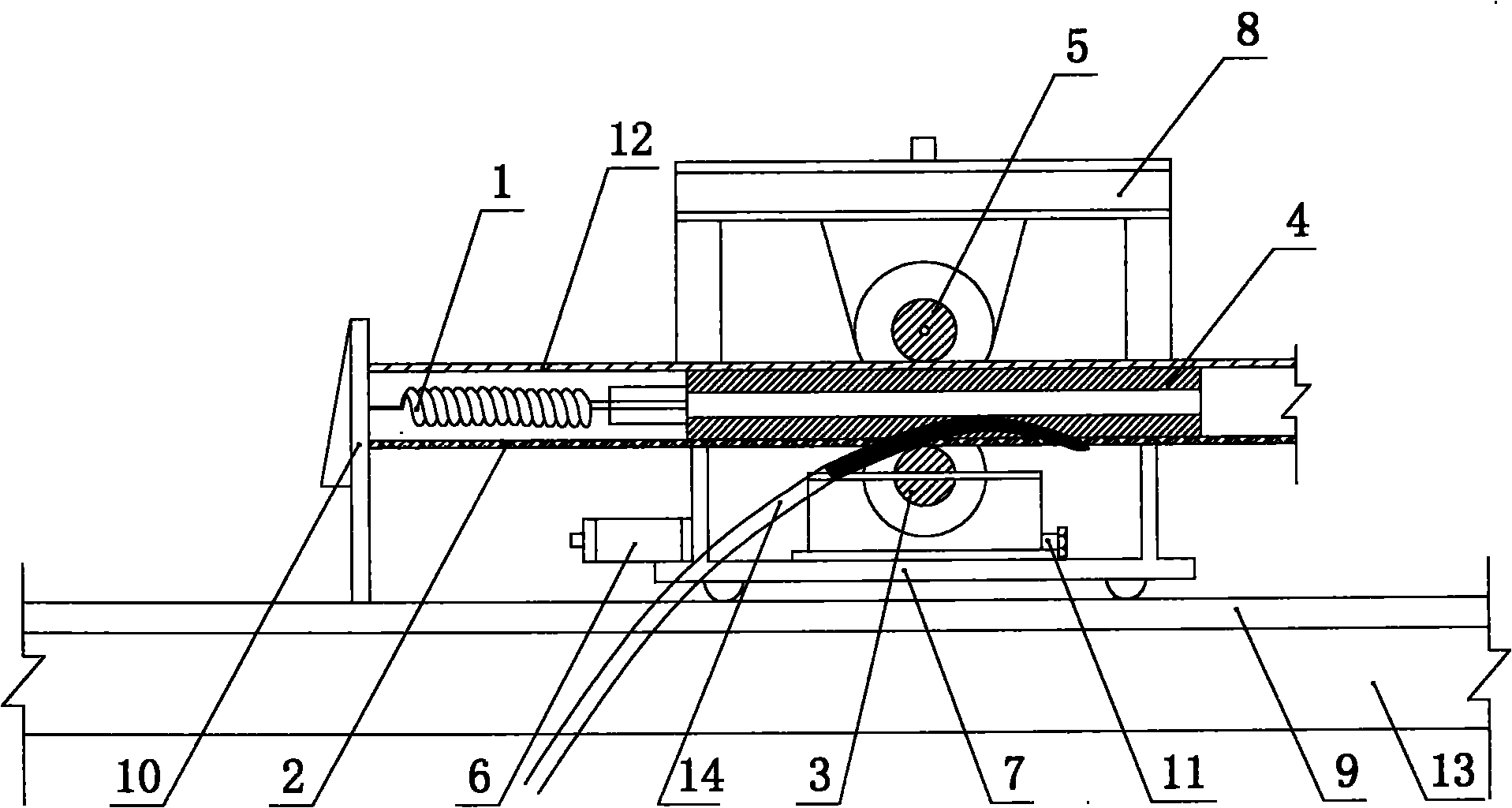

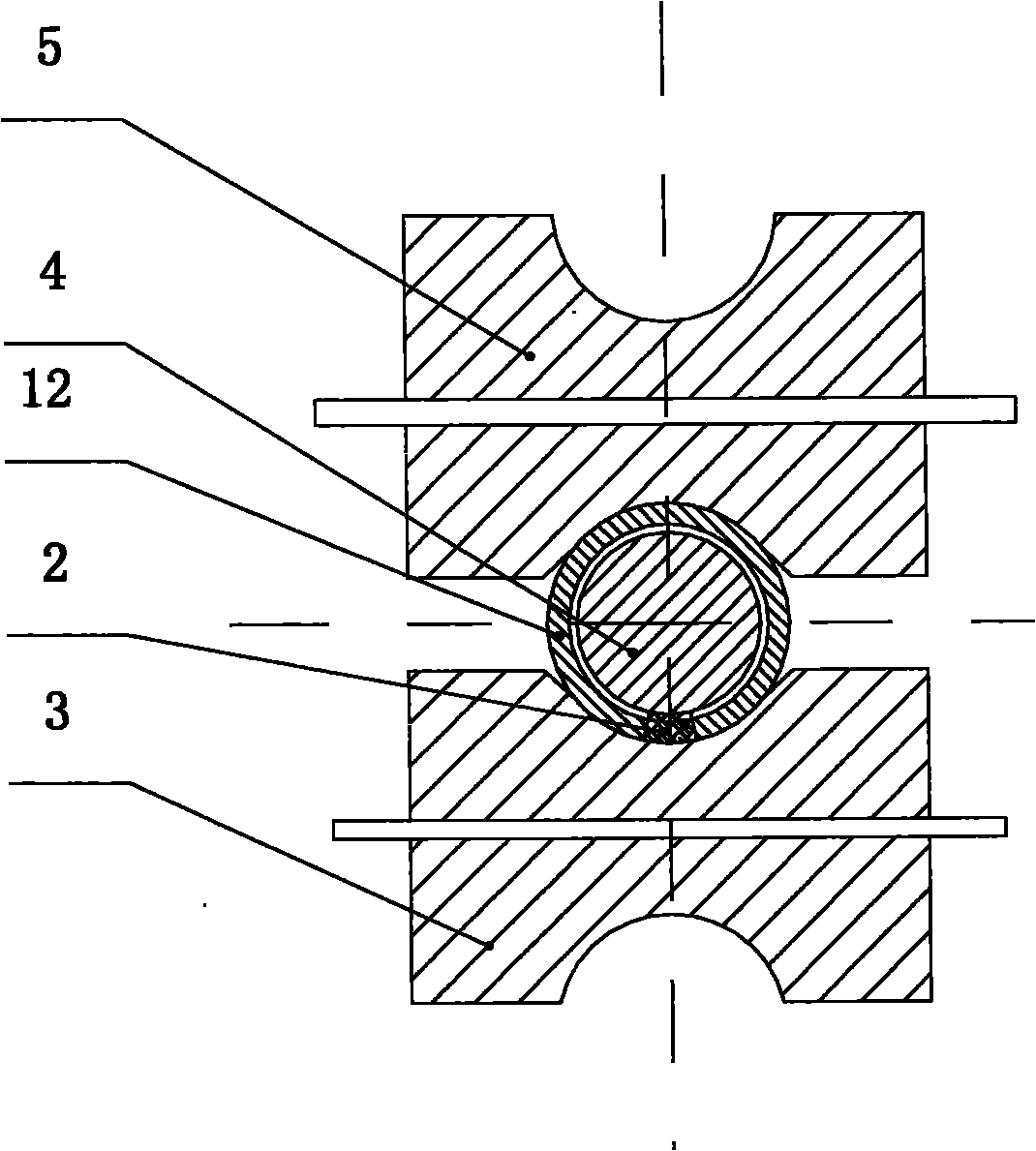

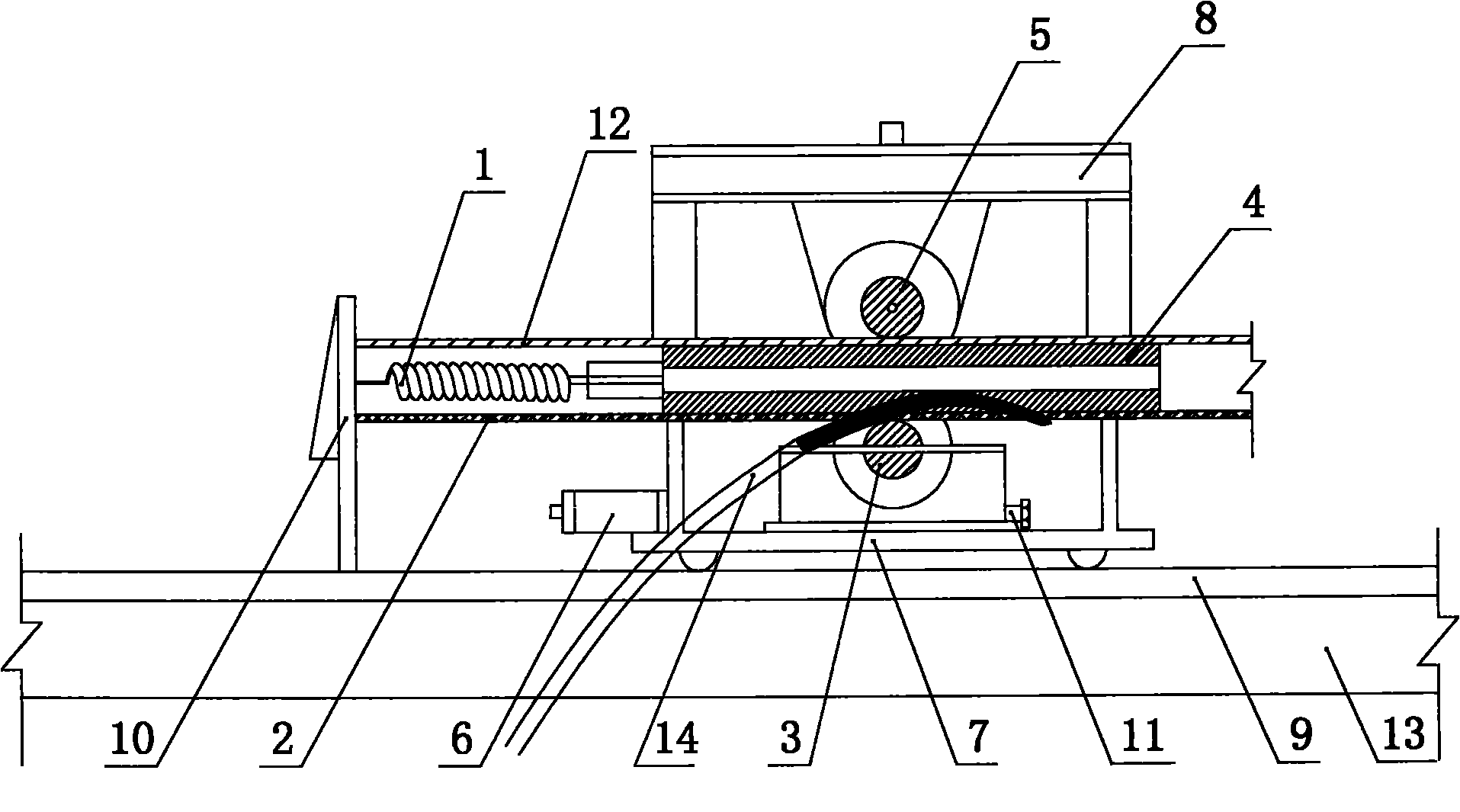

[0016] see figure 1 and figure 2 , a welding seam flattening device for welded pipes, comprising a guide seat and a roll mounting seat arranged on the guide seat, the roll mounting seat includes a trolley 7, and the trolley 7 is provided with a horizontal cylinder 6, a lower roller 3, an upper roller 5, and an upper roller The lifting cylinder 8 connected to the roll 5 and the adjustment knob 11 connected to the lower roll 3; in addition, a mandrel 4 placed in the welded pipe 12, a mandrel fixing block 10 fixed on the guide seat and a connecting mandrel fixing block 10 are provided. Spring 1 with mandrel 4. The guide seat includes a frame 13 and two parallel guide rods 9 that are horizontally arranged on the frame 13 .

[0017] After the welded pipe steel strip is rolled and welded, a mandrel 4 and a spring 1 connected thereto are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com