Method for producing flat gaskets by coated sand shell mould process

A technology of coated sand and flat gaskets, applied in the direction of casting molds, cores, molding machines, etc., can solve the problems of poor product accuracy and low production efficiency of flat gaskets, achieve high production efficiency, eliminate trachoma, and reduce molding area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for producing a flat gasket by a film-coated sand shell type process, comprising the following steps:

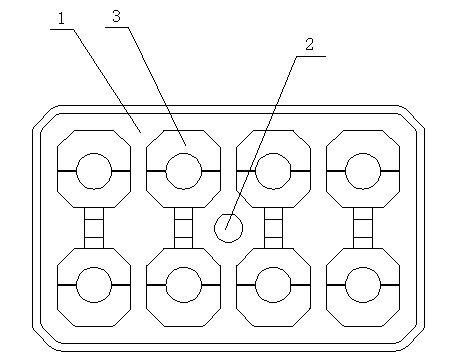

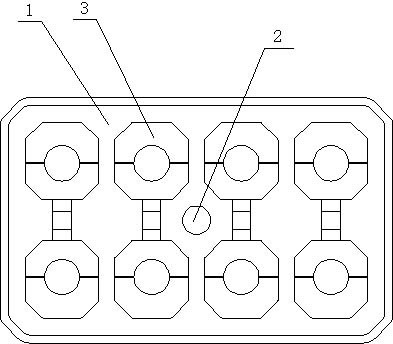

[0020] (1) Prepare the template: open the core-making mold, spray the release agent in the inner cavity of the core-making mold, and then use the sand-shooting machine's sand-shooting cylinder to press the sand-shooting hole of the core-making mold to shoot sand until the core-making mold After the inner cavity is filled, the sand shooting is finished. When the sand shooting machine is shooting sand, the pressure of the air compressor is controlled to be ≥ 0.5Mpa; after the sand shooting is completed, observe the color of the sand core from the sand shooting hole of the core making mold until After the color reaches yellowish brown, the core-making mold is opened, the mud core is taken out, and the coated sand shell type is obtained after cooling (see figure 1 );

[0021] (2), code type: ten coated sand shell type 1 (see figure 1 ) are stacked to form a pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com