Arc angle laser welding forming method of angle seam joints

A technology of laser welding and forming method, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of easy formation of undercut defects, reduce production efficiency, increase workload, etc., to eliminate differences in professional quality, achieve Automated production to ensure the effect of the appearance of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Such as Figure 1-Figure 5 , an embodiment of the present invention provides a circular arc angle laser welding forming method for corner seam joints, including:

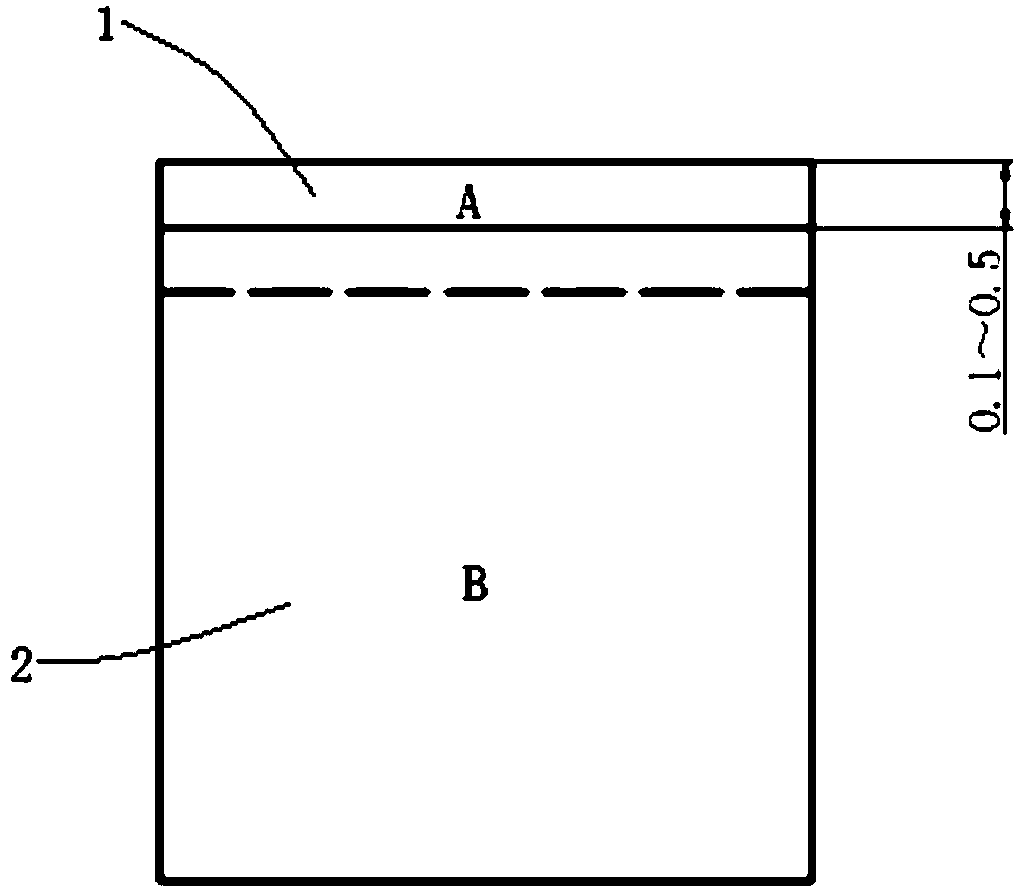

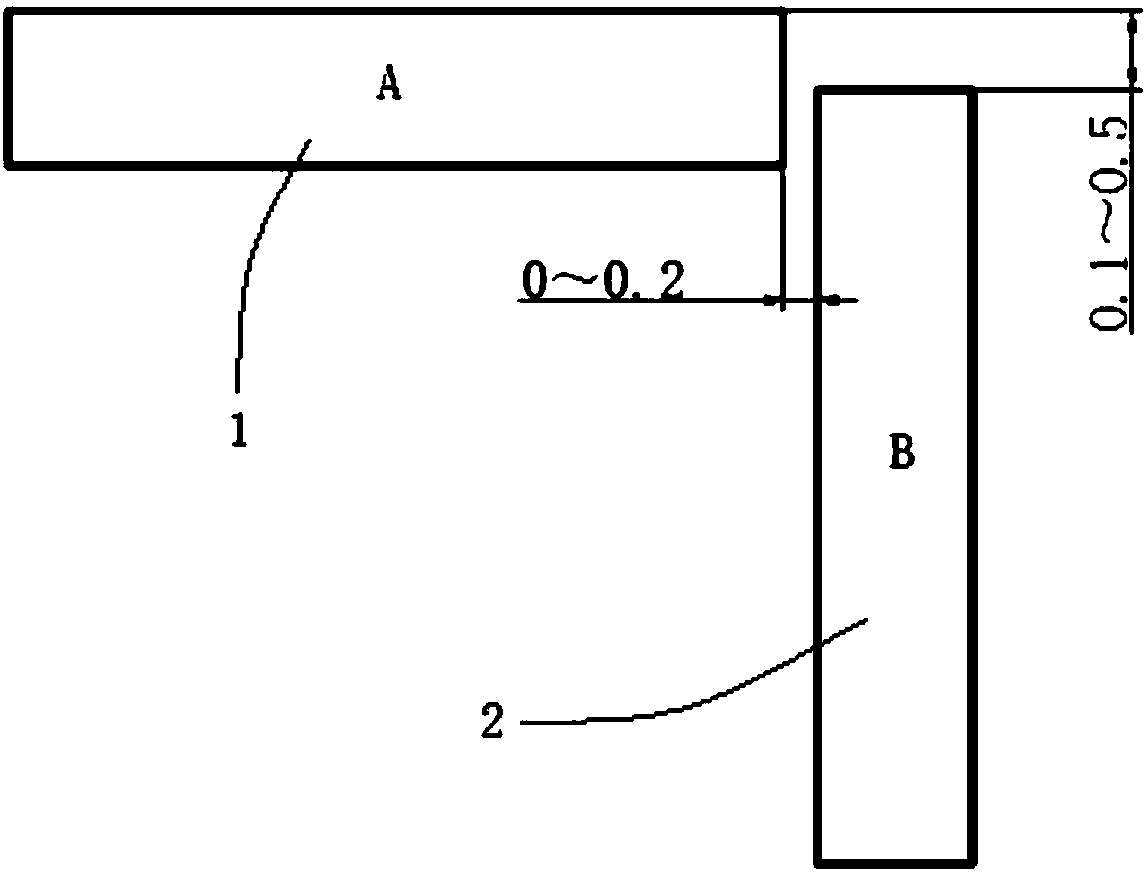

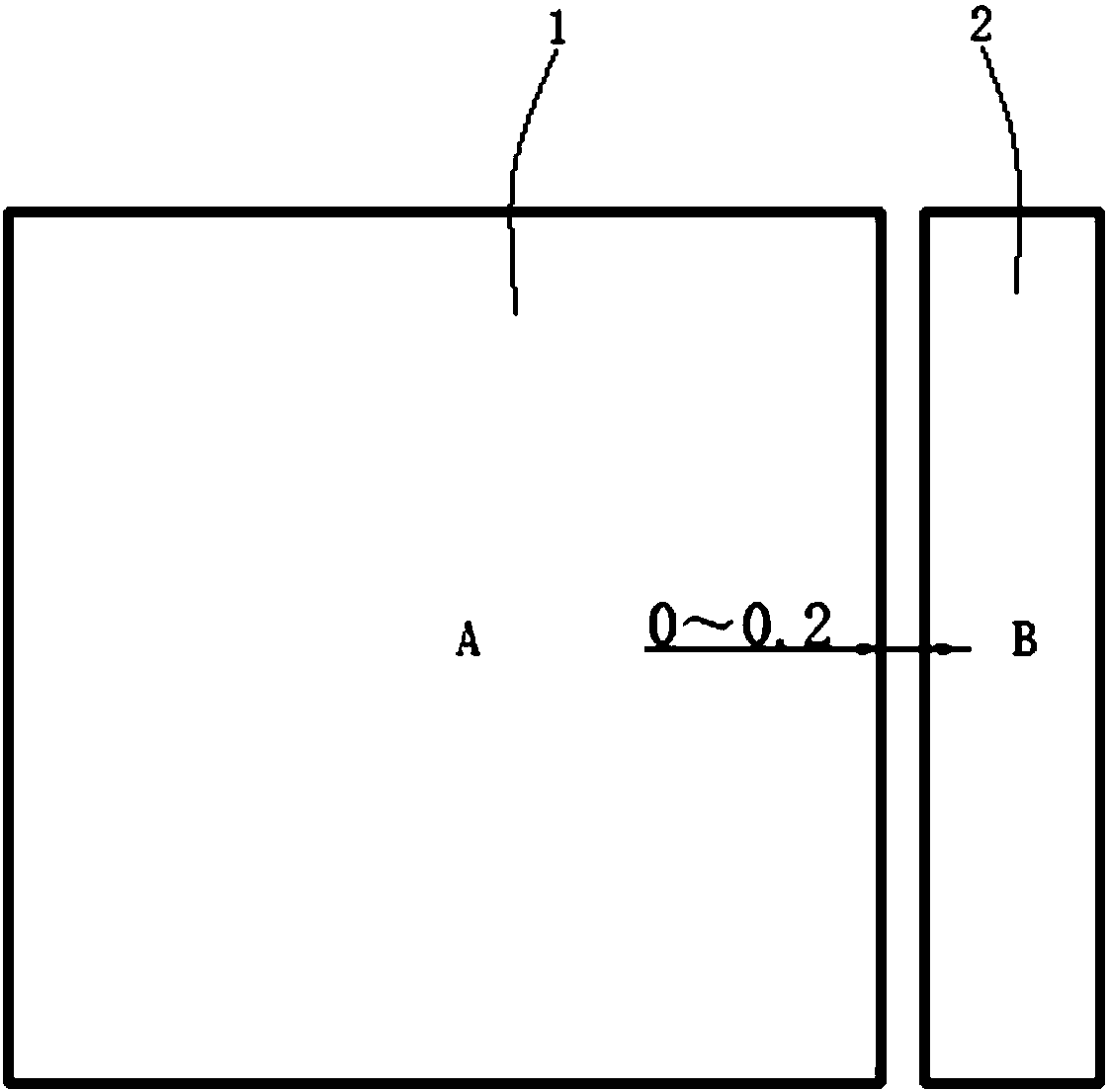

[0044] Position the two plates so that plate A 1 and plate B 2 are perpendicular to each other and the distance between them is controlled within the range of 0-0.2 mm. The end surface of plate B 2 to be welded is located between the two plates of plate A 1 The distance between the outer surfaces of the board A 1 is 0.1-0.5mm; it is welded and formed by laser self-fusion welding, wherein the focused spot diameter of the laser beam is 1.5-2.2mm.

[0045] It is easy to know that the distance between the A board 1 and the B board 2 refers to the distance between the end to be welded of the A board 1 and the adjacent board surface of the B board 2; The board surface is located between the planes of the two board surfaces of A board 1. Correspondingly, one of the board surfaces of A board 1 is located between the...

Embodiment 2

[0065] The embodiment of the present invention provides a method for arc angle laser welding of corner seam joints. In the corner seam joints, the base material is stainless steel with a thickness of 1 mm. Plate A 1 is arranged horizontally, and plate B 2 is arranged vertically. When assembling, ensure that the horizontal distance between the two boards is controlled at about 0.05mm, and the distance between the top of B board 2 and the upper surface of A board 1 is about 0.2mm; use a coaxial shielding gas with a nozzle diameter of 8mm to protect the weld seam, and weld The distance between the gas nozzle and the welding seam plane is 5mm, the shielding gas is Ar with a purity of 99.999%, and the pressure of the shielding gas at the gas cylinder outlet is 0.1MPa; the incident angle of the laser beam relative to the surface of A-plate 1 is 4°; Welding parameters choose laser power 2000w, welding speed 45mm / s, spot diameter 2.0mm. When welding, use the left welding method ( Fi...

Embodiment 3

[0067] An embodiment of the present invention provides a method for arc angle laser welding of a corner joint. The base material of the corner joint is stainless steel with a thickness of 0.7 mm. Plate A 1 is arranged horizontally, and plate B 2 is arranged vertically; When assembling, ensure that the horizontal distance between the two boards is 0 (that is, the end to be welded of A board 1 is in contact with B board 2), and the distance between the top of B board 2 and the upper surface of A board 1 is about 0.1mm; use the air nozzle A coaxial shielding gas shielded weld with a diameter of 6mm, the distance between the gas nozzle and the weld plane is 3mm during welding, the shielding gas uses Ar with a purity of 99.999%, and the pressure of the shielding gas at the gas cylinder outlet is 0.05MPa; the laser beam is relatively The incident angle on the surface of A board 1 is 0; the welding parameters are selected as laser power 1500w, welding speed 50mm / s, and spot diameter 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle of incidence | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com