Composite baking-free stopper rod of magnesium aluminate spinel and production process thereof

A magnesia-aluminum spinel and stopper technology, which is applied in the field of stoppers, can solve the problems of expensive zirconia, energy consumption, and seldom use, and achieve strong resistance to slag erosion, long service life, and satisfying multiple requirements. Effect of Furnace Continuous Casting Performance Requirements and Product Quality Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The weight proportion of rod head composition raw material is:

[0033] 18# (referring to particle size requirements) magnesium aluminum spinel 22%, 100# magnesium aluminum spinel 26%, 325# magnesium aluminum spinel 32%, graphite powder 10%, antioxidant (silicon carbide) 3% , 4% liquid phenolic resin and 3% non-burning agent;

[0034] The weight proportion of rod body composition raw material is:

[0035] 100# α-corundum aggregate 40%, α-corundum powder (325#) 30%, graphite powder 25%, alumina powder 1%, non-burning agent 1% and liquid phenolic resin 3%.

[0036] Wherein the weight composition of the burn-proof agent is as follows: the total amount of raw materials of the burn-proof agent is 100%: 35% of aluminum oxide powder, 15% of boron carbide, 5% of solid phenolic resin and 45% of metal silicon powder.

[0037] Produced according to the production process described in the present invention.

Embodiment 2

[0039] The weight proportion of rod head composition raw material is:

[0040] 36# (referring to particle size requirements) magnesia-alumina spinel 15%, 70# magnesia-alumina spinel 30%, 325# magnesia-alumina spinel 35%, graphite powder 8%, antioxidant (silicon carbide) 2.5% , 2.5% liquid phenolic resin and 7% non-burning agent;

[0041] The weight proportion of rod body composition raw material is:

[0042] 18# α-corundum aggregate 44%, α-corundum powder (325#) 25%, graphite powder 20%, alumina powder 3%, non-burning agent 3% and liquid phenolic resin 5%.

[0043] Wherein the weight composition of the burn-proof agent is as follows: the total amount of raw materials of the burn-proof agent is 100%: 40% of aluminum oxide powder, 10% of boron carbide, 5% of solid phenolic resin and 45% of metal silicon powder.

[0044] Produced according to the production process described in the present invention.

Embodiment 3

[0046] The weight proportion of rod head composition raw material is:

[0047] 22# (referring to particle size requirements) magnesium aluminum spinel 25%, 120# magnesium aluminum spinel 20%, 325# magnesium aluminum spinel 30%, graphite powder 12%, antioxidant (metal silicon powder) 3 %, liquid phenolic resin 4% and non-burning agent 67%;

[0048] The weight proportion of rod body composition raw material is:

[0049] 60# α-corundum aggregate 50%, α-corundum powder (325#) 25%, graphite powder 20%, alumina powder 1%, non-burning agent 1% and liquid phenolic resin 3%.

[0050] Wherein the weight composition of the burn-proof agent is as follows: the total amount of raw materials of the burn-proof agent is 100%: 30% of alumina powder, 10% of boron carbide, 10% of solid phenolic resin and 50% of metal silicon powder.

[0051] Produced according to the production process described in the present invention.

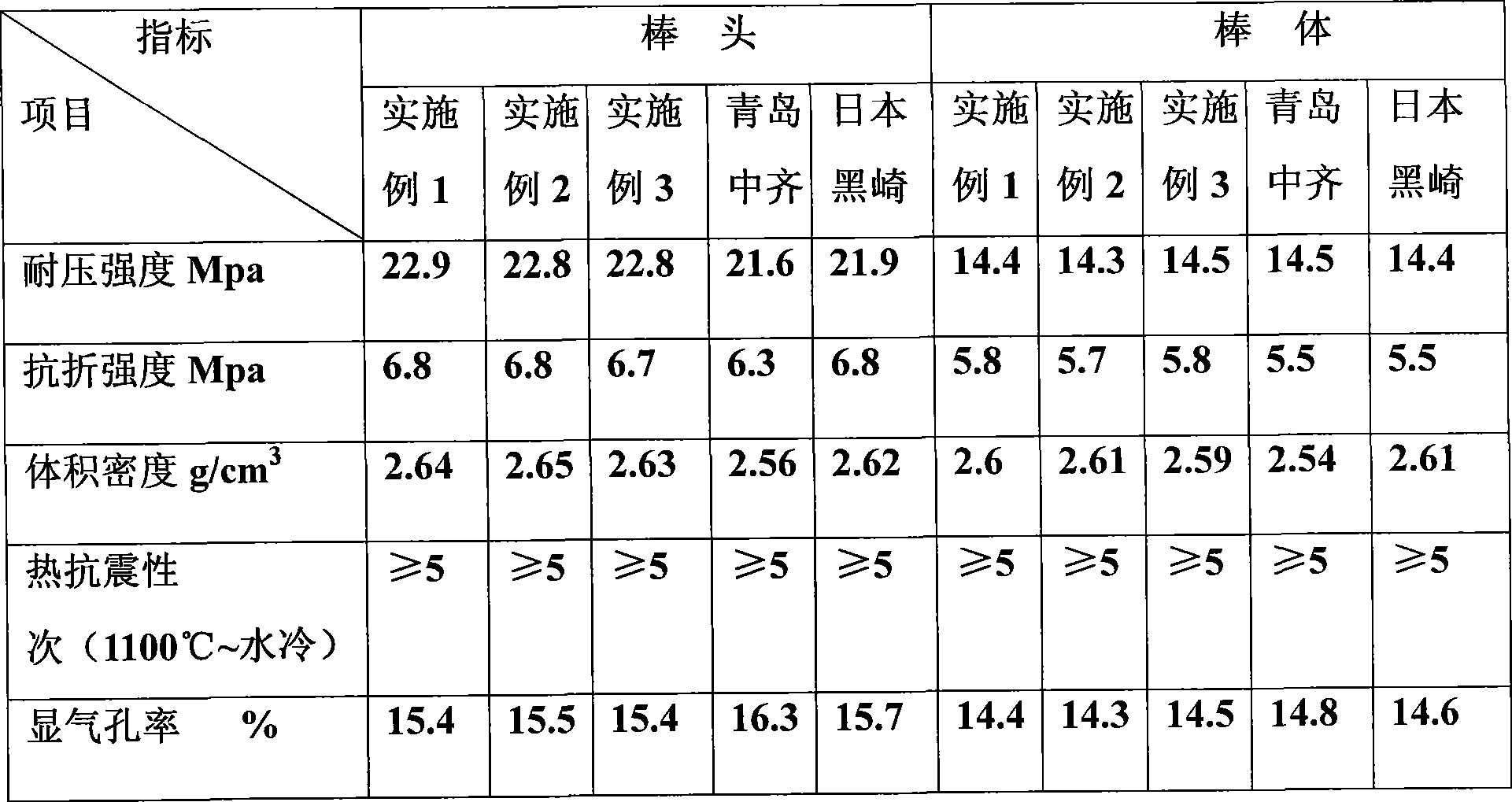

[0052] The main technical properties of the magnesia-aluminum-spinel co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com