Patents

Literature

79results about How to "Anti-scour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

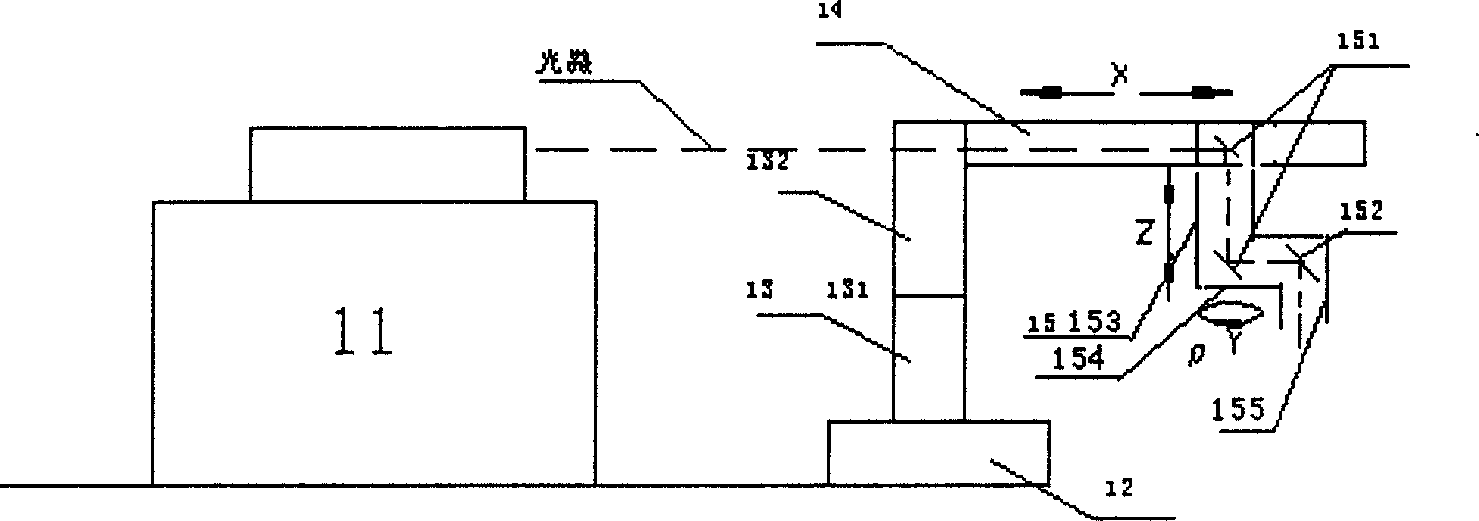

Laser method for repairing rotor shaft of generator and steam turbine and dedicated device

InactiveCN1660538AImprove controllabilityImprove automationMetallic material coating processesOther manufacturing equipments/toolsNondestructive testingElectric generator

Owner:SHENYANG DALU LASER TECH

Gunning mix for converter

InactiveCN101602612AGood adhesionImprove peeling resistanceManufacturing convertersGranularityMolten steel

The invention discloses a gunning mix for a converter, which comprises the following components in percentage by weight: 40 to 60 percent of forsterite of which the particle size is between 0.1 and 5 millimeters, 10 to 30 percent of dolomite of which the particle size is between 0.1 and 3 millimeters, 10 to 20 percent of sintered mid-range magnesia of which the particle size is between 0.01 and 0.088 millimeter, 0.5 to 5 percent of burning and coagulation accelerator, and 1 to 5 percent of bonding agent. When applied to the converter, the forsterite gunning mix prepared by adopting the formulation has the advantages of high adhesive rate, good spalling resistance, quick sintering, erosion resistance, scouring resistance and small high temperature expansion, and simultaneously is insusceptible to gun blockage during the construction. Besides, gunning mix has abundant available mineral products with low price so as to play a role of saving important energy resources, has no influence on the quality of molten steel in use, and is free from causing pollution to the environment.

Owner:陈红良

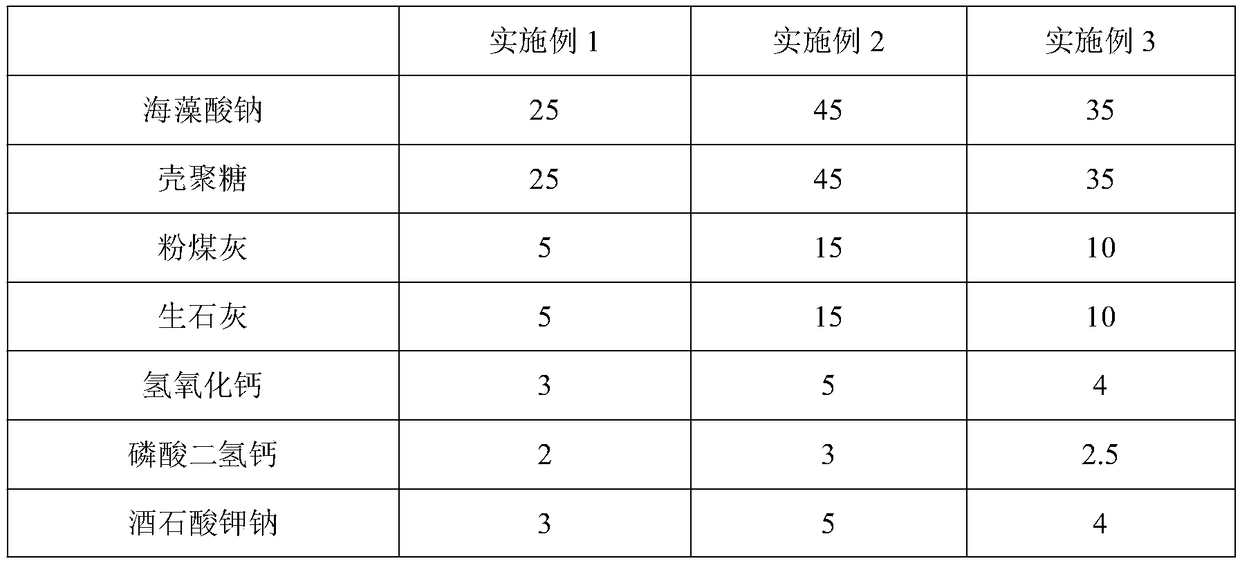

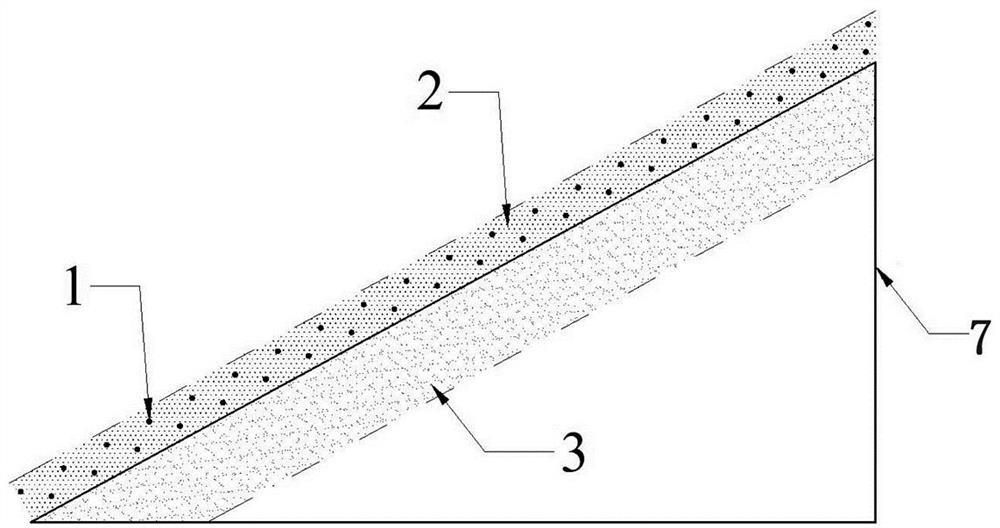

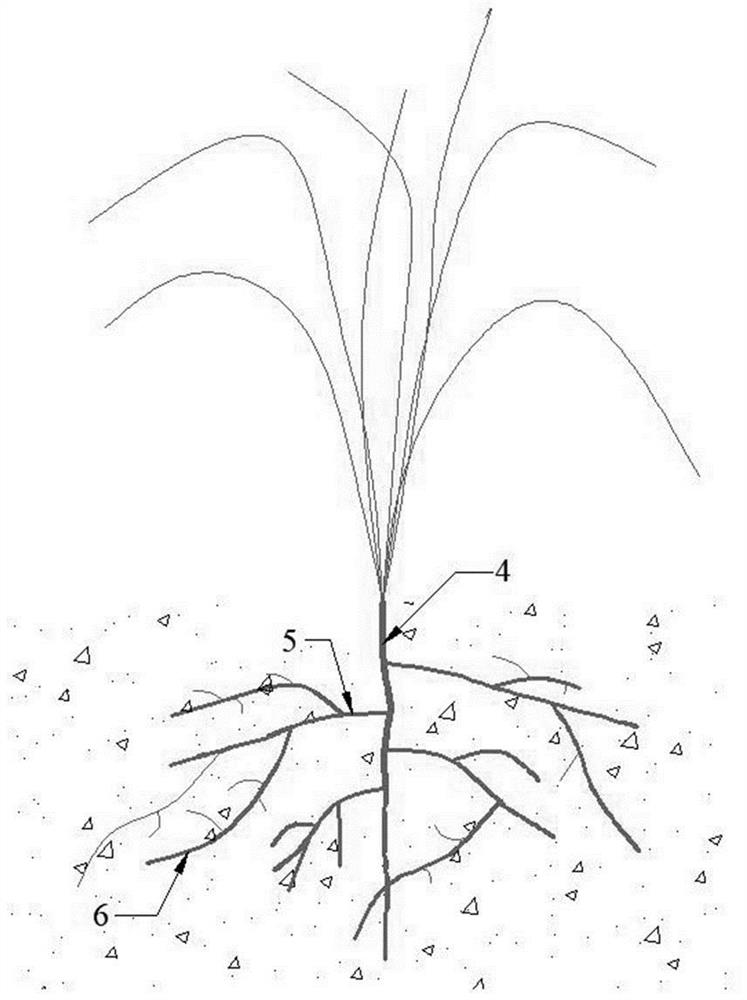

Ecological restoring method for stereoscopic greening of high stability slope

ActiveCN108797612AVarious ingredientsRapid Greening and Ecological RestorationGrowth substratesCulture mediaNutrientPopulation

The invention relates to an ecological restoring method for stereoscopic greening of a high stability slope. An ecological curing agent is used to spray the soil on the slope to form a curing film toplay the role of windproof and sand fixation, then a reinforcement net and concrete are added on the slope face to reinforce the slope face, the stability of the slope face is improved by being combined with a stable structure layer, the non-woven fabric and a plant fiber mesh layer in the reinforcement net is easy to degrade, and the environmental protection is achieved, so that a water-retainingnutrition matrix layer and the slope can be combined more stably, and the anti-scour performance, firmness, high durability and high stability are achieved; a water-retaining nutrition matrix structure and nutrients are superior to the ordinary soil and contain various elements, the composition is comprehensive the growth needs of the plants can be met well, the plant growth is matched, the rapidgreening and ecological restoration are achieved, and the greening effect is permanent; and the small arbors and the small shrubs are cold, drought and barren resistance and high in resistance, a arbor, shrub and grass three-dimensional protection ecosystem is adopted, the balance of the rapid growth and slow growth is achieved, the biodiversity and stability of the population are improved, and the stability of slope greening is further improved.

Owner:JIANGSU DONGZHU LANDSCAPE CONSTR

Preparation method of specific high-performance wear-resistant castable for coal burner

InactiveCN101805195AImprove thermal shock resistanceStrong thermal shock resistanceWear resistantTemperature resistance

The invention discloses a preparation method of specific high-performance wear-resistant castable for a coal burner, which comprises the following steps that: (1) raw material which comprises corundum, carborundum, corundum powder, alumina powder, silica micro powder, pure calcium aluminate cement, stainless steel fiber, anti-explosion fiber and water reducing agent is homogenized; (2) the homogenized raw material is poured into a forced mixer to be mixed, dry material is put in at one step according to the capacity of the mixer to be dry mixed for 2 to 6min and added with water to be wet mixed for 4 to 8min, the input of the water is strictly controlled, so that the water is stably 4 to 5 percent of the total weight of the raw material; and (3) the product is naturally cured for more than 50h at 25DEG C of ambient temperature and stripped after being fully hardened. The product prepared by the preparation method is characterized by high temperature resistance, anti-erosion, wear resistance and other performance, and has long service life.

Owner:蒋美芳

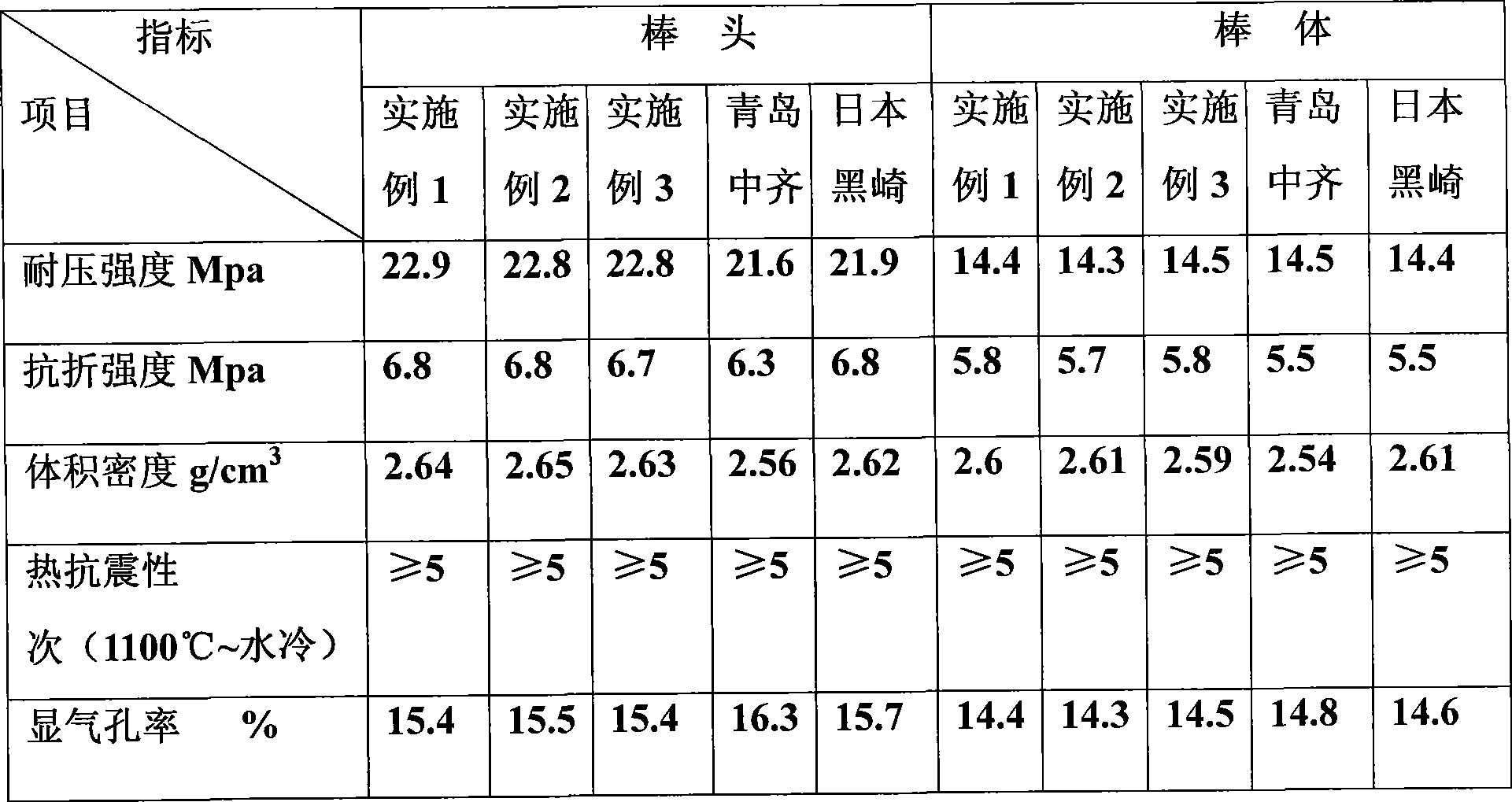

Composite baking-free stopper rod of magnesium aluminate spinel and production process thereof

InactiveCN101429040AEmission reductionImprove the operating environmentMelt-holding vesselsAntioxidantSlag

The invention relates to a magnesium-aluminum spinel composite baking-free plug bar. A plug bar head comprises the following raw materials: 15 to 25 percent of No. 18-36 magnesium-aluminum spinel, 20 to 30 percent of No. 70-120 magnesium-aluminum spinel, 30 to 35 percent of No. 325 magnesium-aluminum spinel, 8 to 12 percent of graphite powder, 1.5 to 3.5 percent of antioxidant, 2 to 4 percent of phenolic resin, and 3 to 7 percent of baking-free agent. A plug bar body comprises the following raw materials: 35 to 50 percent of No. 18-120 alpha-corundum aggregate, 25 to 35 percent of alpha-corundum aggregate, 20 to 30 percent of graphite powder, 1 to 3 percent of alumina powder, 1 to 5 percent of baking-free agent, and 3 to 5 percent of phenolic resin. The magnesium-aluminum spinel composite baking-free plug bar is formed by addition of the baking-free agent with special compositions, forming and low-temperature roasting. The product has the characteristics of strong slag erosion resistance, good thermal shock stability, high strength, erosion resistance, scour prevention, fire resistance, long service life, low production cost and so on, saves energy resources, and can meet the multi-furnace continuous casting performance requirement and the product quality requirement.

Owner:淄博大正新材料科技有限公司

Dry-type gunning material for steel refining furnace

The invention relates to the field of fireproof materials for steel metallurgy, and in particular relates to a dry-type gunning material for a steel refining furnace. The dry-type gunning material comprises the following components in percentage by weight: 70 to 80 percent of magnesite, 5 to 20 percent of magnesium olive sand, 5 to 20 percent of magnesium-aluminum spinelle, 3 to 10 percent of mullite and 3 to 10 percent of adhesive, wherein the adhesive is a combination of one or any two or any three of industrial sodium tripolyphosphate, sodium hexametaphosphate and sodium metasilicate. The dry-type gunning material has the outstanding advantages of high adhesiveness, high adhesive rate, high sintering rate, high intensity, high steel erosion resistance and high slag iron erosion, and the service life of a gunned layer is prolonged; and furthermore, the raw materials are readily available and low in cost, so that the gunning efficiency can be effectively improved, and the steel refining cost is reduced.

Owner:JIANGSU UNIV

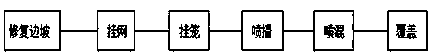

Method for greening side slopes with greening brick cages

InactiveCN104160860AEffective greeningGuaranteed efficient growthExcavationsHorticultureGrowth plantSoil science

A method for greening side slopes with greening brick cages includes the following steps that restoration is performed, wherein the slope surfaces of the side slopes are finished according to slope ratios, slope heights and flatness of the side slopes, sundries on the slope surfaces are cleaned up, and thus the handled slope surfaces are regular and consistent in slope ratio; meshes are hung, wherein after anchor rods are fixed to the side slopes, the wire meshes are connected with the anchor rods, and the wire meshes are fixed to the side slopes; the cages are hung, the wire mesh brick cages are connected with the anchor rods and the wire meshes so that the wire mesh brick cages can be fixed to the side slopes; borrowed-soil spray-seeding is performed, wherein mixed soil is sprayed in the mesh cages and the wire meshes, and continuous hardened bodies with plant growth matrixes are formed; mixture spraying is sprayed, wherein a mixture made of grass seeds is sprayed onto the mixed soil to form spray-seeding faces; covering is performed, the spray-seeding faces are covered with covering materials. With the method, the side slopes can be effectively greened, borrowed soil can be fixed to the side slopes more firmly, the borrowed soil layers are high in constitutive property, fast greening of the side slopes is achieved, the problem about water and soil loss is solved, and the side slopes have the advantages of being resistant to scouring and landslide, firm, durable and long in greening effect time.

Owner:SHENZHEN HEJING LANDSCAPING CO LTD

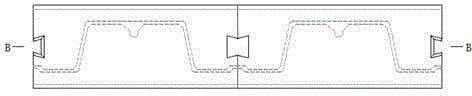

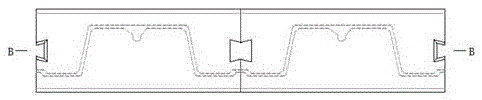

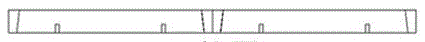

Revetment structure composed of plastic steel plate piles and concrete

ActiveCN104695380AReduce the impactCombination structure is stableBreakwatersQuaysStructural engineeringRevetment

The invention relates to a revetment structure composed of plastic steel plate piles and concrete. The revetment structure comprises plastic steel plate piles and a concrete coping, wherein the plastic steel plate piles are connected through a connector having two mutually matched ends; the concrete coping is preformed and can be stably buckled with the upper ends of the plate piles. The revetment structure can be used for revetments of rivers or lakes, is safe and stable, high in construction speed, low in construction cost, environment-friendly and pollution-free, less in influence on the surrounding environment, and long in durability, can be further used for resisting the seepage of embankments and dike bodies of rivers and protecting dams.

Owner:海盐汇祥新型建材科技有限公司

Coating for centrifugal casting high alloy furnace tube metal mould and method thereof

InactiveCN1520951AHigh low temperature strengthImprove plasticityFoundry mouldsFoundry coresCelluloseSodium Bentonite

The present invention is metal type paint for centrifugal casting high-alloy furnace tube and its production process. The material includes zirconite powder, silica sol, fluotrite powder, cellulose, PVA and bentonite; and the mixing production process includes dry mixing zirconite powder, fluotrite powder and bentonite inside a crushing roller mill for 15 min, dissolving cellulose and PVA in water and mixing and milling for 3 hr, and adding silica sol and mixing and milling for 30 min. The paint can form coating with increased low temperature strength, increased low temperature plasticity, raised flush resistance and vibration resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP

Slope protection method and structure based on earthwork standard room and mixture of fiber and clay

ActiveCN104831740AHigh strengthHigh density of soilExcavationsVegetative propogationFertilizerEngineering

The invention discloses a slope protection method and structure based on an earthwork standard room and a mixture of fiber and clay. The slop protection method comprises the steps that 1 the slope plane of the slope is leveled, and the earthwork standard room is paved on the slope plane; 2 the clay is crushed, then polypropylene fiber, fertilizer and water are added, and stirring is conducted till the mixed materials are in a liquid plastic state; 3 the mixed materials are paved on the slope plane of the slope and is floated; 4 grass seed is sown on the slope plane in a spraying mode, a protection geomembrane is covered, and then artificial protection is conducted. The slope protection method and structure based on the earthwork standard room and the mixture of fiber and clay have the advantages that multiple functions of anti-washing, anti-infiltrating, conserving water, keeping warm, facilitating the growth of plants and the like are possessed, the slope plane can be protected from being eroding and infiltrating of rain before a turf is formed, and the purposes of strengthening the slope and beautifying the environment are achieved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

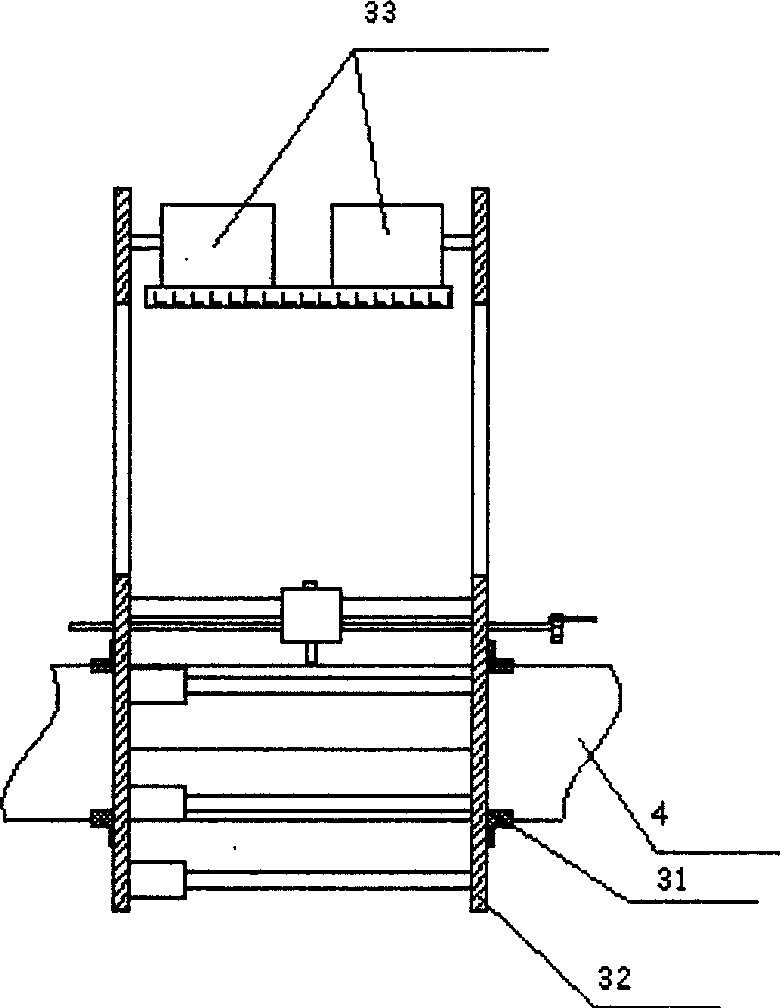

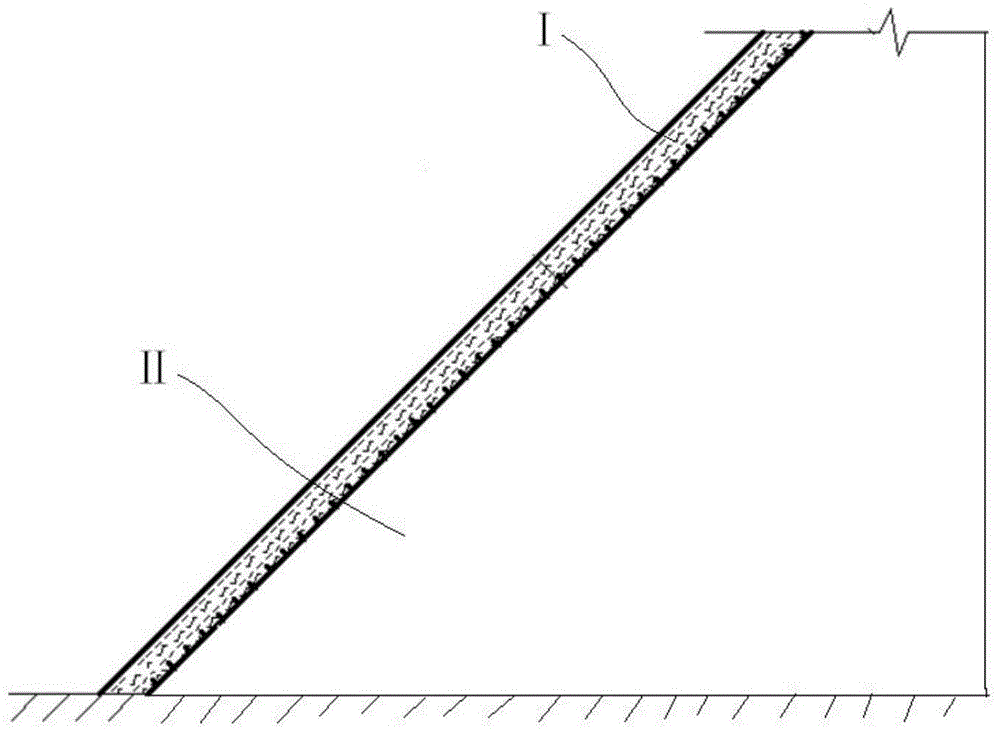

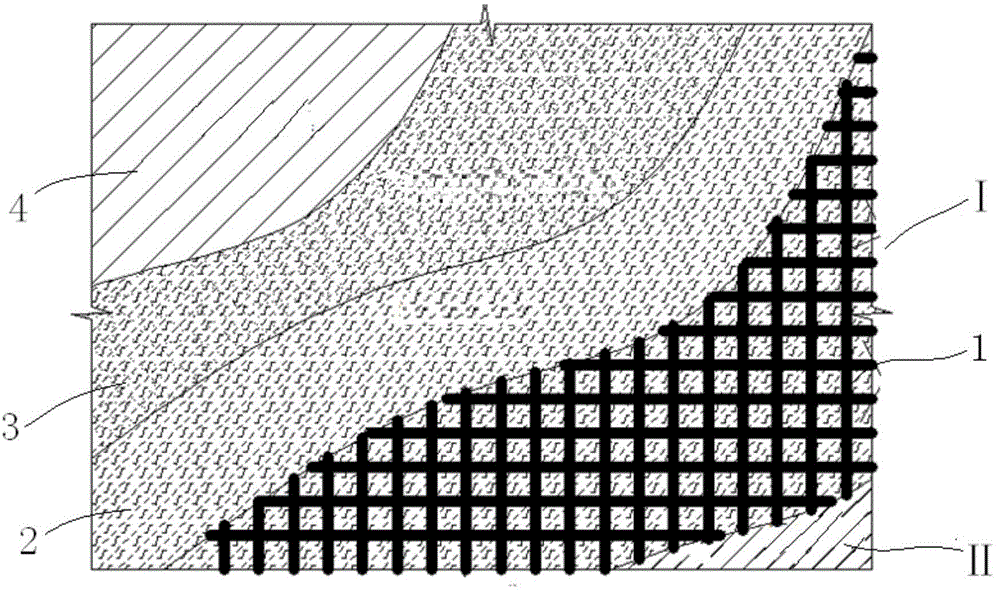

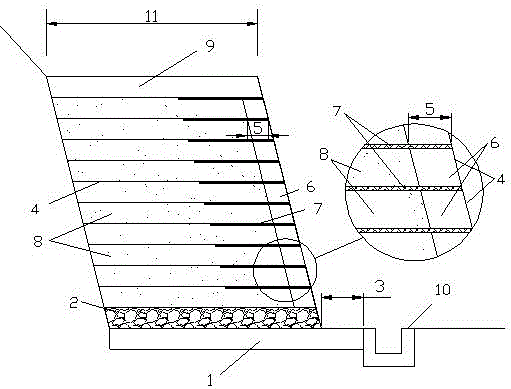

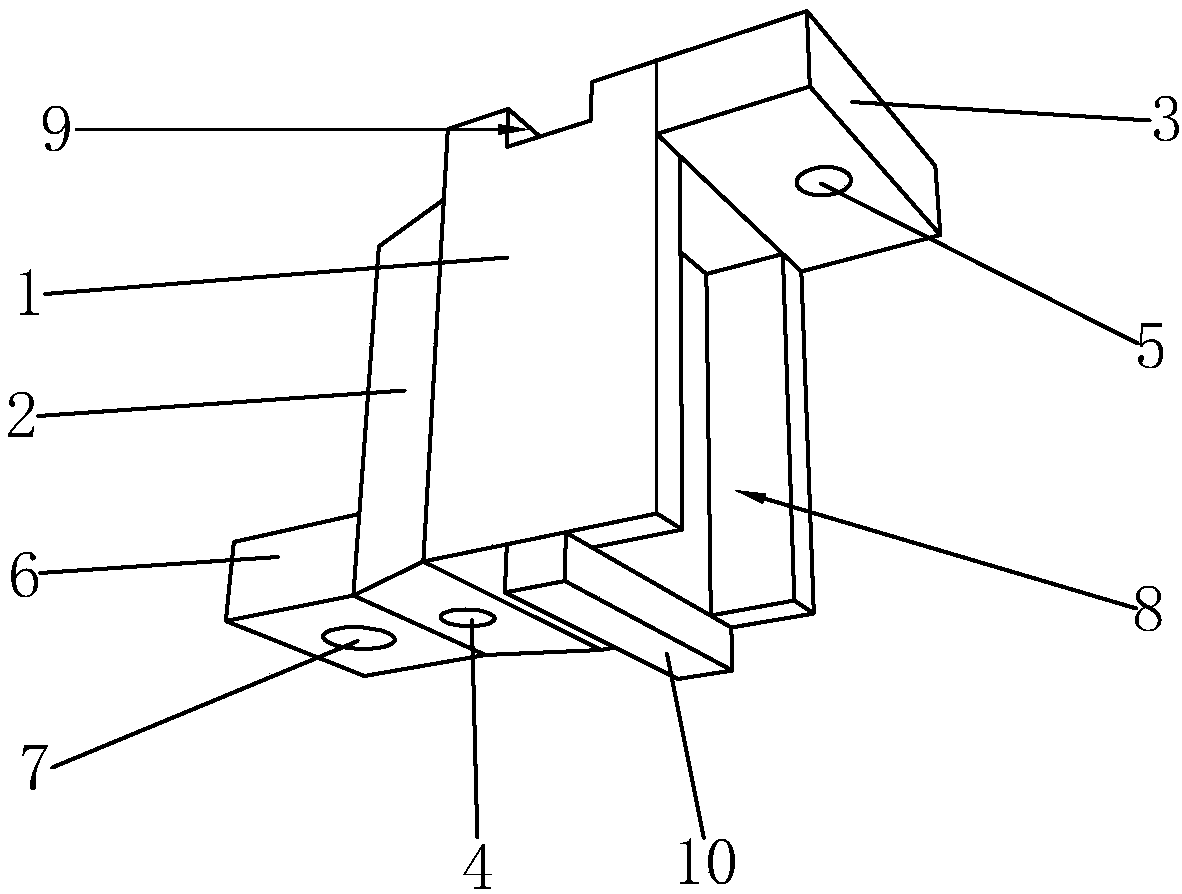

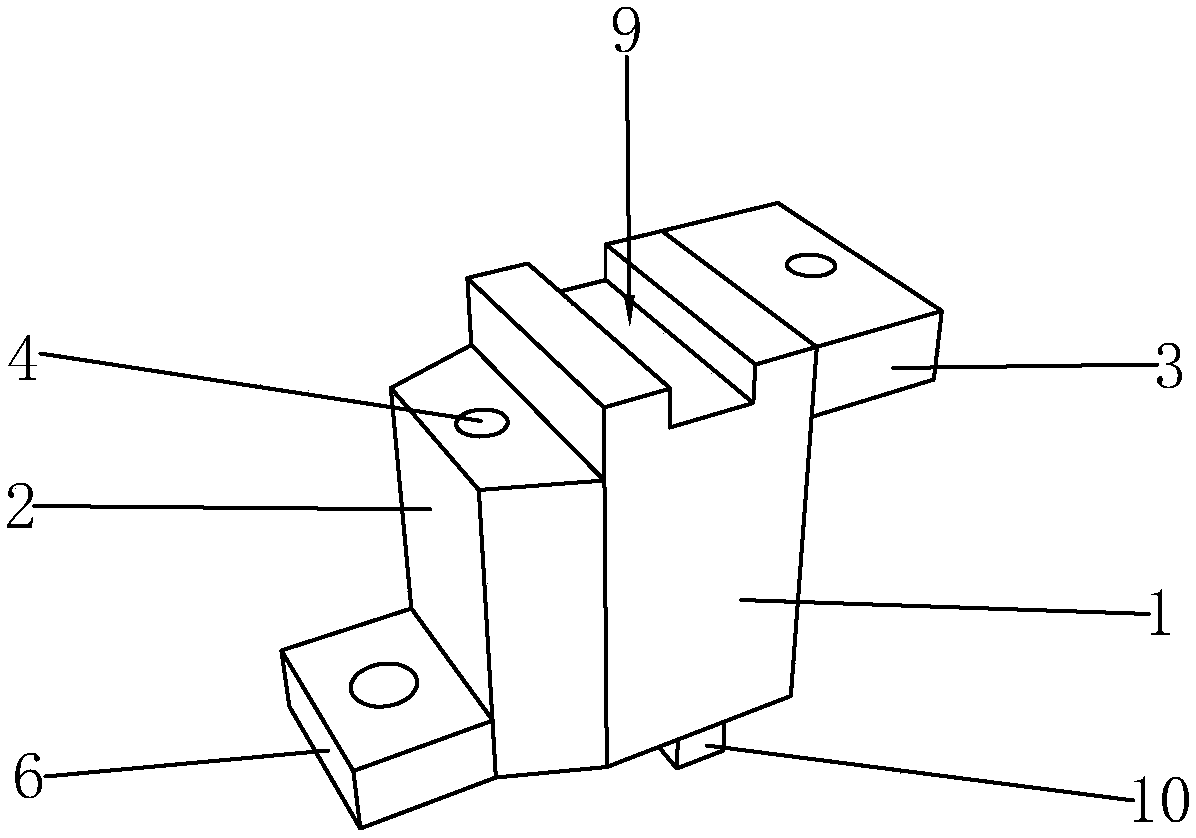

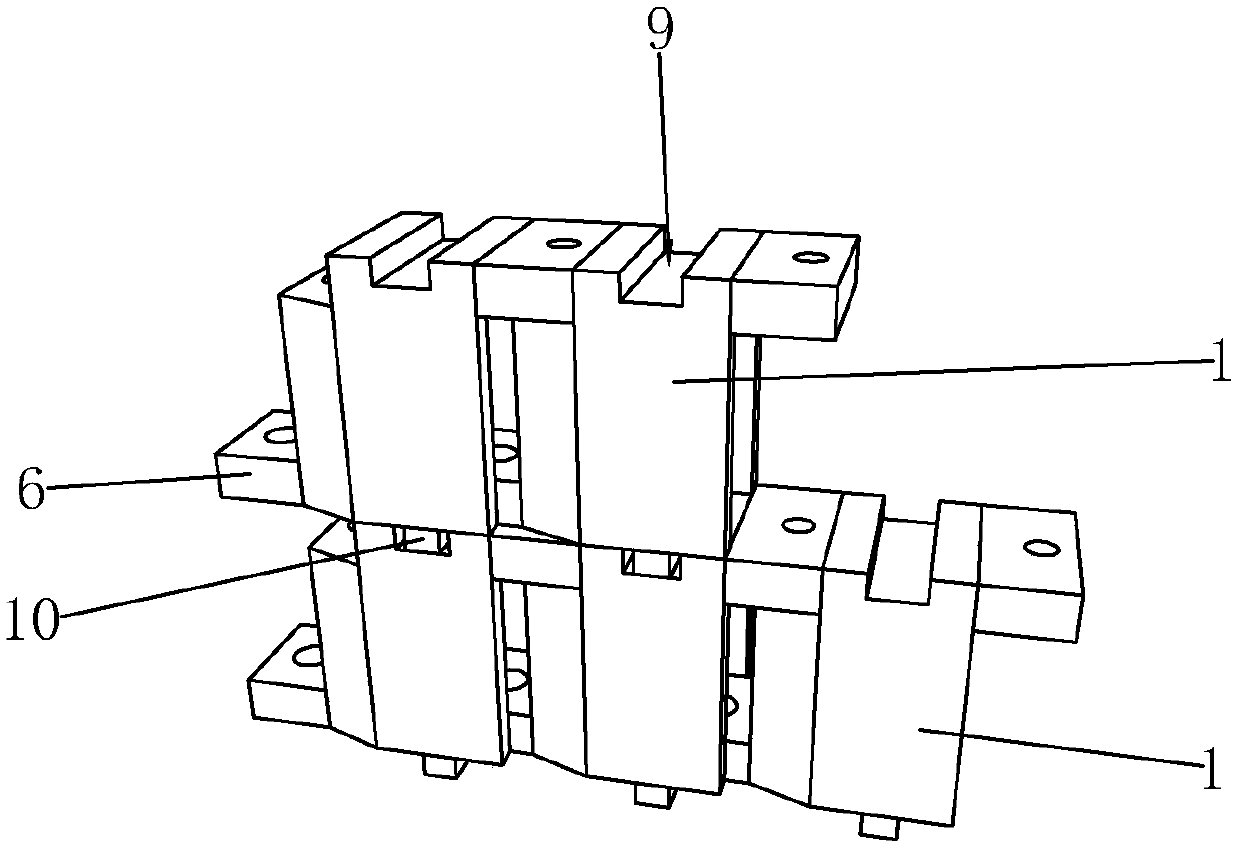

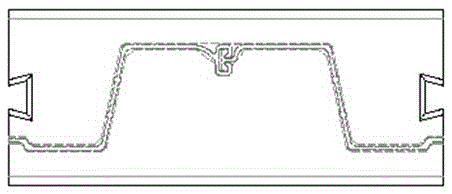

Cement modified soil strengthened geogrid reinforced soil structure and construction method thereof

The invention discloses a cement modified soil strengthened geogrid reinforced soil structure and a construction method thereof. The cement modified soil strengthened geogrid reinforced soil structure (shown in a figure 1) is composed of four parts including a base layer (1) and a cover layer (9) composed of cement modified soil, a water drainage layer (2) and a cement modified soil strengthened geogrid reinforced soil layer thereof, and is a novel geogrid reinforced soil structure which is formed by improving similar structures through utilizing good properties including solidification, high wetting resistance, high anti-scouring and flood damage resisting properties, high shearing strength and the like of cement modified soil. Compared with an existing similar structure, the novel geogrid reinforced soil structure and the construction method thereof, provided by the invention, can realize panel-free construction of an abrupt-slope reinforced soil structure, and can also remarkably improve the wetting resistance, anti-scouring property and whole shearing strength of the geogrid reinforced soil structure; the cement modified soil strengthened geogrid reinforced soil structure is especially suitable for protecting and reinforcing edge slopes, which are easy to scour and damage by flood, of abrupt-slope sections.

Owner:湖南高速华达工程有限公司

High-wear-resisting high-chromium alloy material

The invention discloses a high-wear-resisting high-chromium alloy material. The high-wear-resisting high-chromium alloy material comprises the following main components in percentage by mass: 3.0%-3.3% of C, 31.0%-33.0% of Cr, 0.8%-1.0% of Mo, 0.6%-0.7% of B, 0.8%-1.0% of Cu, 0.6%-0.7% of Ni, 0.3%-0.5% of Al, 0.3%-0.4% of Ti and 0.6%-0.8% of Nb as well as the following secondary components in percentage by mass: 0.005%-0.008% of Mg, 0.01%-0.03% of Zn, less than or equal to 0.025% of S, less than or equal to 0.03% of P and the balance of Fe. According to the manner, the high-temperature resistance, corrosion resistance, wearing resistance and the like of the high-chromium alloy can be improved.

Owner:KUSN QIAORUI METAL PRODS

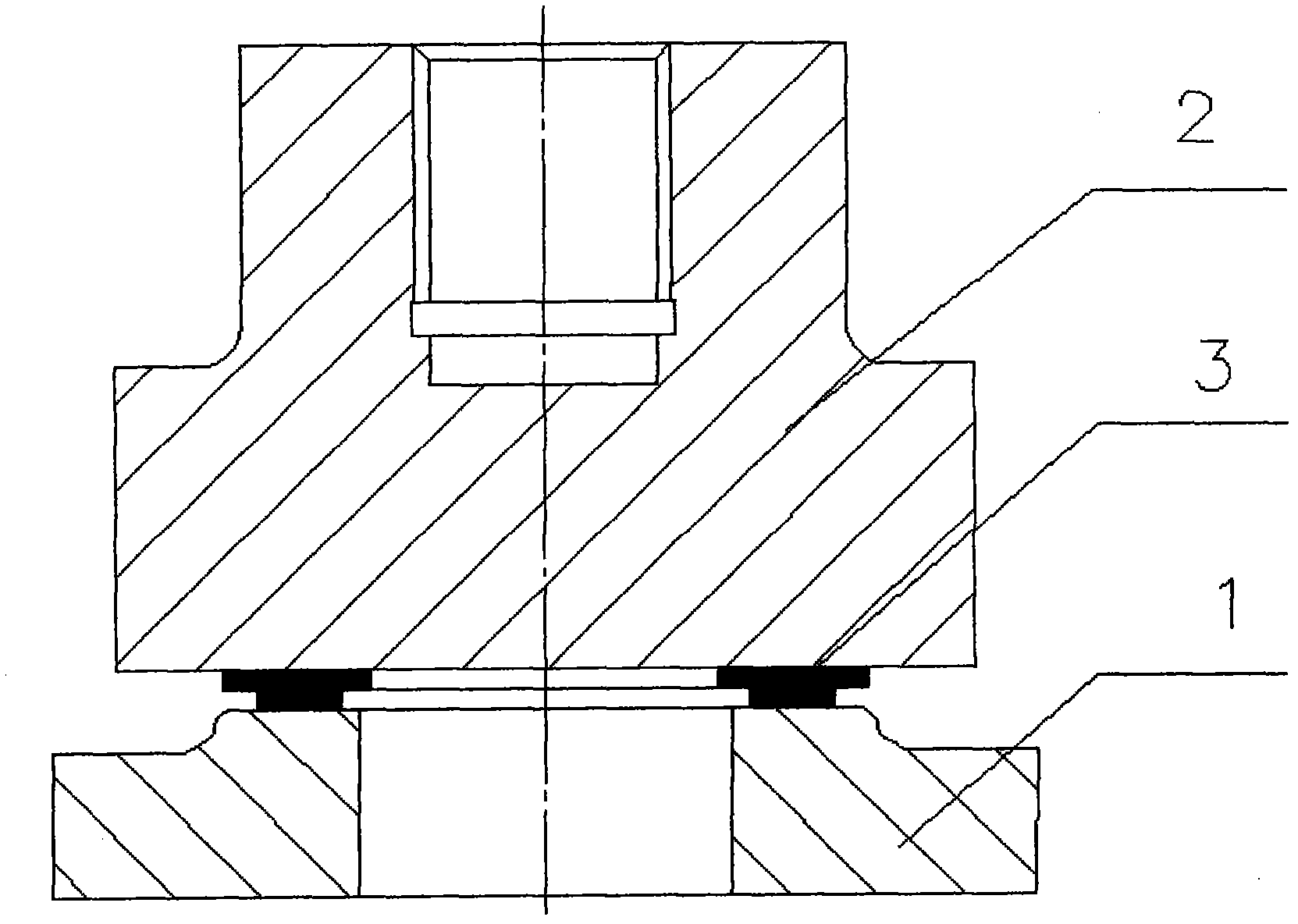

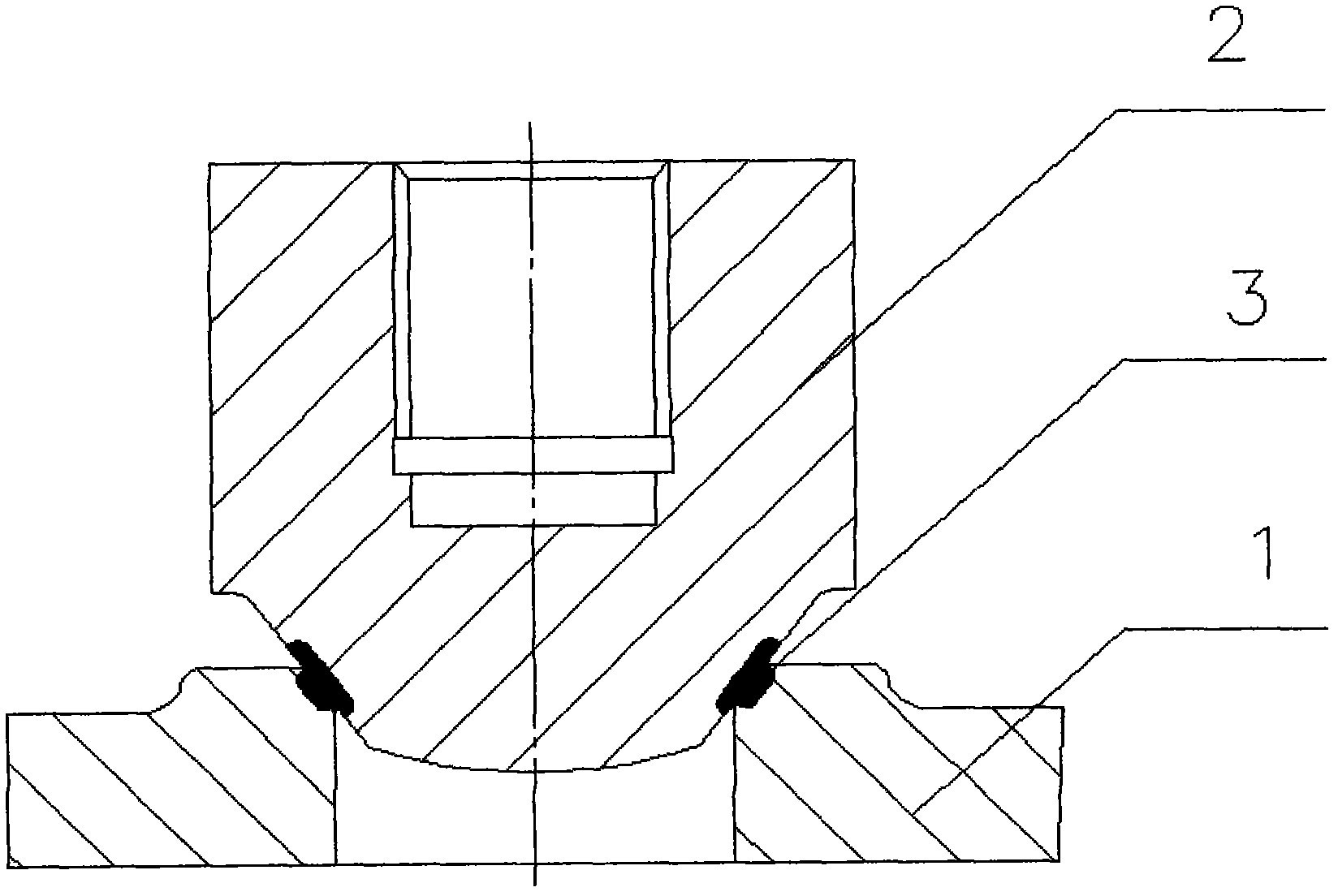

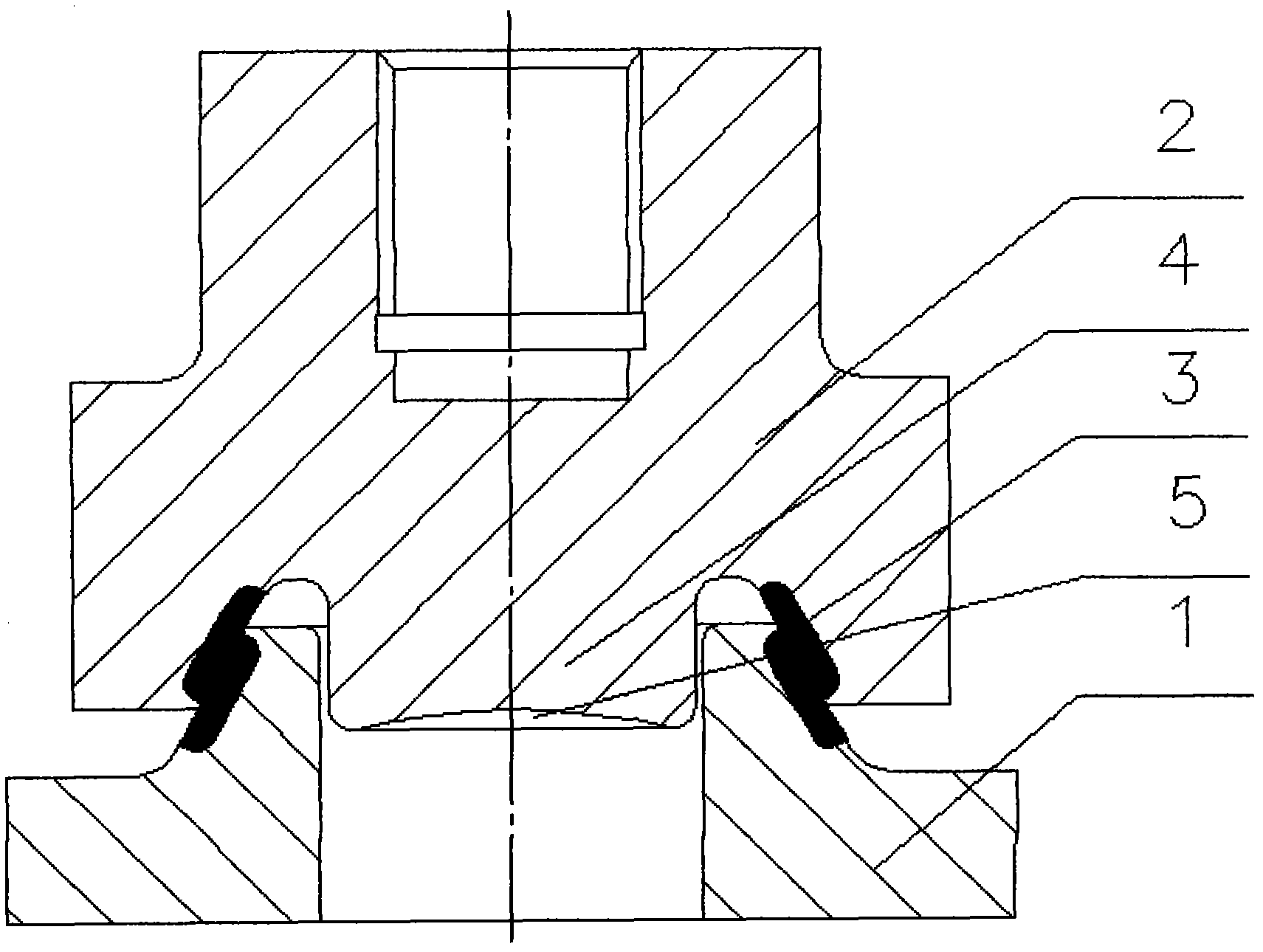

Erosion-prevention stop valve seal pair

The invention relates to an erosion-prevention stop valve seal pair which comprises a valve seat and a valve clack which are corresponding to each other; the seal surface of the valve seat is an outer conical surface; the seal surface of the valve clack is an inner conical surface which is matched with the outer conical surface; the center of the valve seat is provided with a valve seat hole; thecentral part of the inner conical surface of the valve clack is provided with a column structure which can insert in the valve seat hole; the lower end surface of the column structure is set into an arc-shaped concave surface and lower than the seal surface of the valve clack. According to the invention, on the basis of keeping the original seal effect of the stop valve seal pair, the erosion andcorrosion of a medium to the seal surface is relieved, thus the seal ring is always protected, the seal effect is more reliable, and the erosion-prevention stop valve seal pair is especially suitablefor the flow rate control of high-temperature high-pressure gas media.

Owner:SUNGO VALVES GRP CO LTD

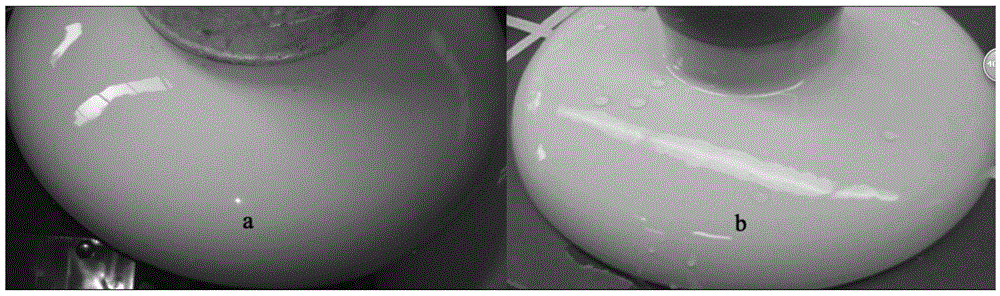

Inorganic hydrophobic antifouling glaze used for porcelain insulator as well as preparation method and application thereof

The invention relates to an inorganic hydrophobic antifouling glaze used for a porcelain insulator as well as a preparation method and an application thereof and belongs to the technical field of improvement of glazes used for the porcelain insulators. The inorganic hydrophobic antifouling glaze used for the porcelain insulator is prepared from the following raw materials in percentage by weight: 3-14% of silica sol, 0.5-4% of methylsilane, 12-21% of acetic acid and 75-89% of propyl alcohol. The inorganic hydrophobic antifouling glaze used for the porcelain insulator is simple in formula, hydrophilicity of the surface of the traditional porcelain insulator is changed, antifouling property is improved, and the inorganic hydrophobic antifouling glaze used for the porcelain insulator has the advantages of aging resistance, scour resistance, good weather resistance, high strength and long life. The invention also provides a simple preparation method and an application of the inorganic hydrophobic antifouling glaze.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

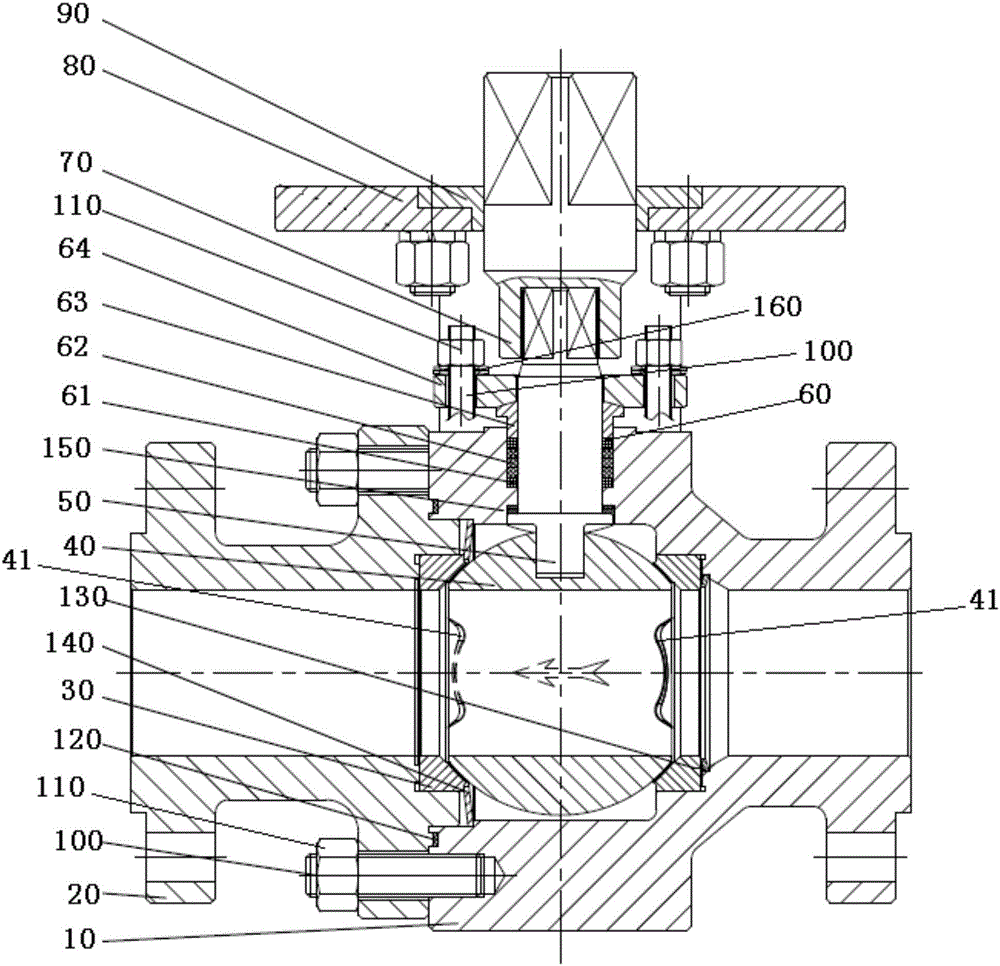

Wear-resistant high-temperature-resistant metal rigid seal ball valve

InactiveCN106763870AReduce coefficient of frictionExtended service lifeSpindle sealingsPlug valvesBall valveValve stem

The invention discloses a wear-resistant high-temperature-resistant metal rigid seal ball valve, comprising a main valve body, an auxiliary valve body, a valve seat, a ball, a valve stem, a stuffing box, a coupling, a support and a positioning block; the inlet end of the valve seat is arranged at the inner wall of the main valve body, a first disc spring is arranged between the inlet end of the valve seat and an adjacent plane of the main valve body, a second disc spring is arranged between the outlet end of the valve seat and the adjacent plane of the auxiliary valve body, a passage port of the ball is provided with asymmetric arc notches, and an antifriction pad is arranged between the valve stem and the main valve body. The wear-resistant high-temperature-resistant metal rigid seal ball valve is long in service life, good in airtightness, and resistant to scour, wear, and high temperature and high pressure.

Owner:上海凯工阀门股份有限公司

Gabion retaining wall construction method applied to bank slope protection

ActiveCN107859055AReduce construction costsSimple technologyArtificial islandsCoastlines protectionEngineeringGabion

The invention discloses a gabion retaining wall construction method applied to bank slope protection. The method comprises the steps of (a) excavation of a foundation pit, (b) reinforcement of the foundation pit, (c) gabion rock filling, (d) backfilling, (e) afforesting and (f) monitoring and measurement. The method includes few construction procedures and is convenient to operate, low in cost, high in environmental affinity, high in overall construction efficiency and easy in quality and safety control, the construction progress can be accelerated through cooperation of manpower and machinery, the good economic benefit can be obtained, and the method is suitable for more projects, has the broad application prospect and is worthy of popularization and application.

Owner:浙江永安工程咨询集团有限公司

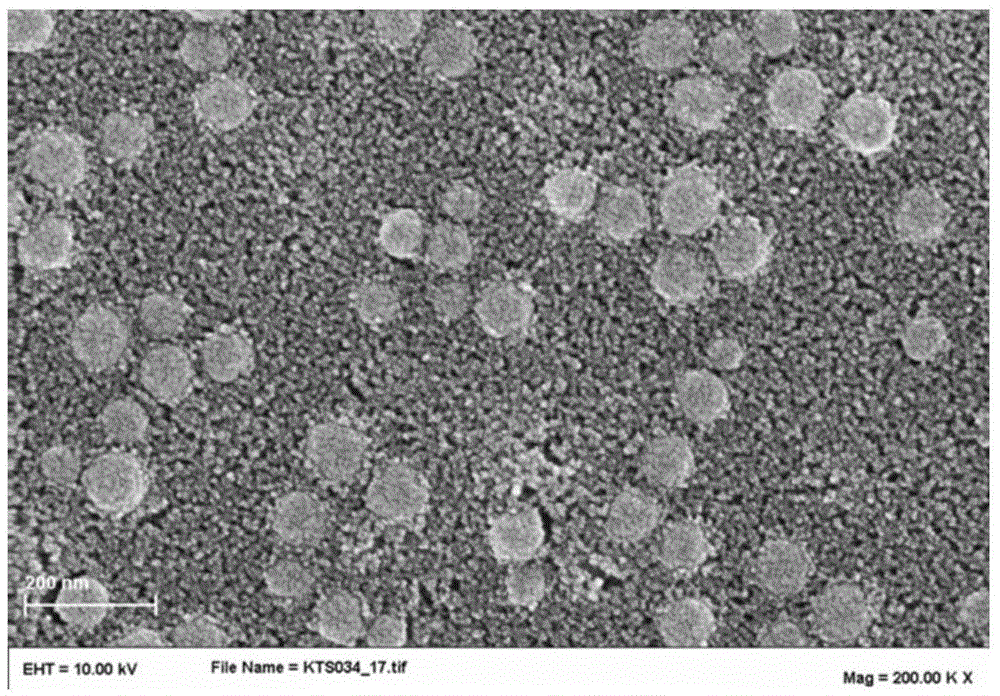

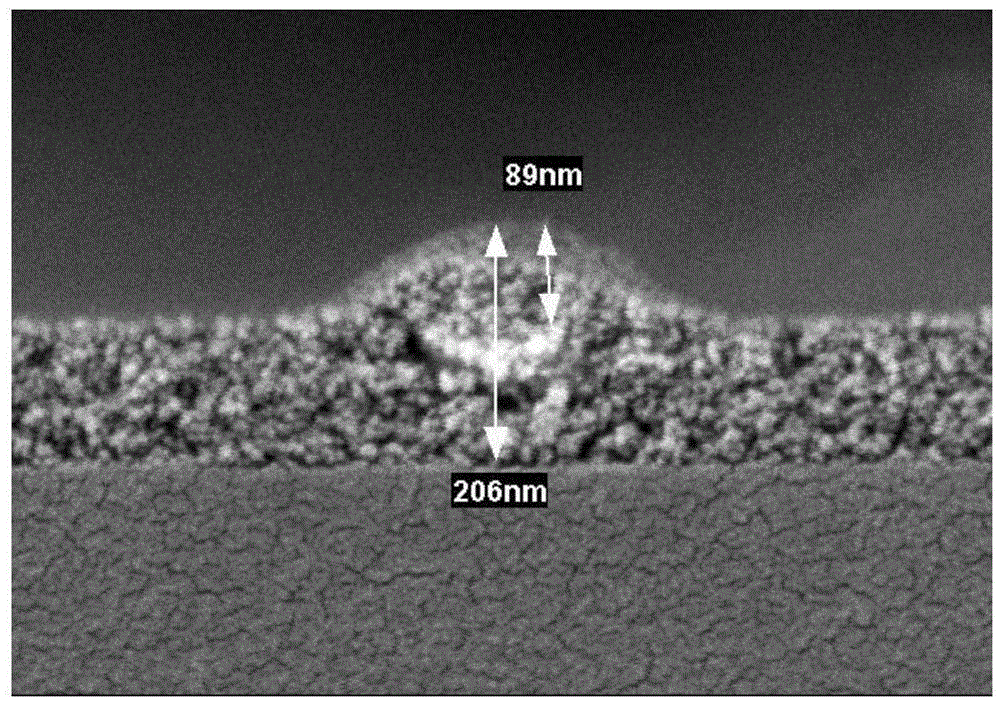

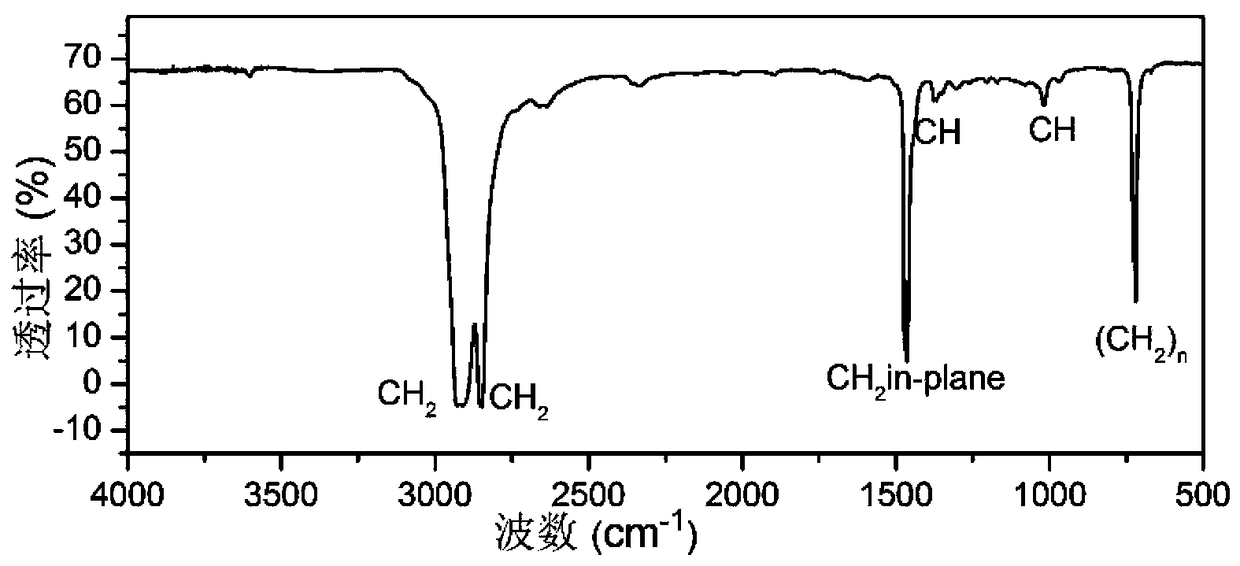

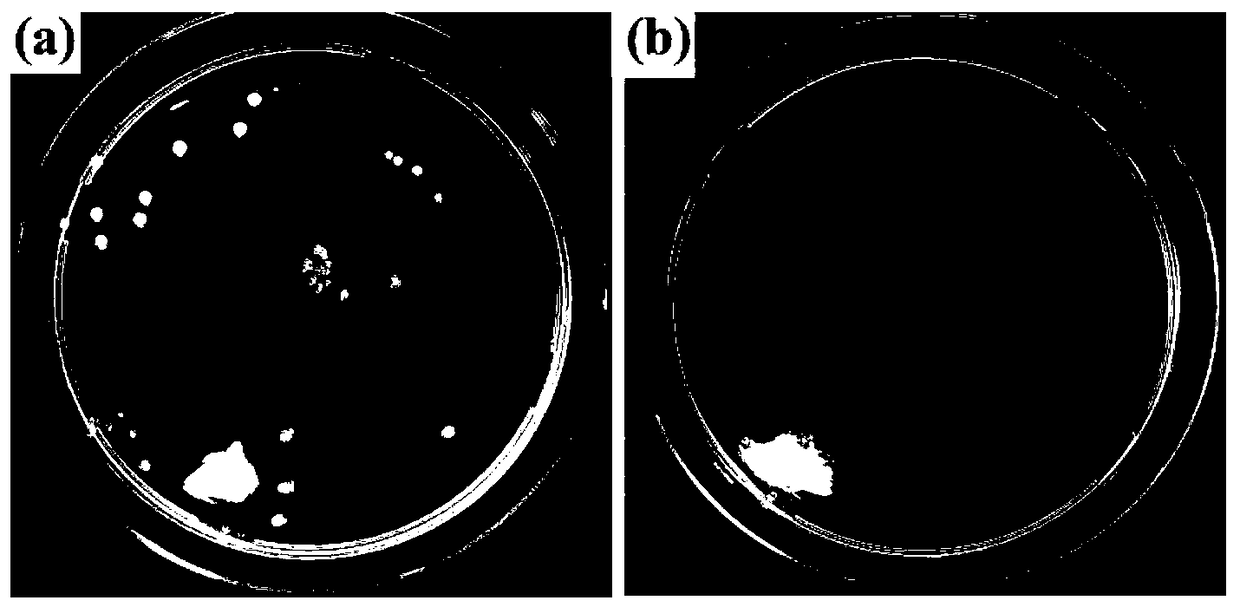

Polyethylene composite antibacterial coating containing nanometer silver particles and preparation method thereof

ActiveCN108610760AHigh bonding strength of coatingExtended service lifeAntifouling/underwater paintsPretreated surfacesThermal sprayingSilver particles

The invention relates to a polyethylene composite antibacterial coating containing nanometer silver particles and a preparation method thereof. The polyethylene composite antibacterial coating containing nanometer silver particles comprises polyethylene and nanometer silver particles uniformly distributed in polyethylene, wherein the mass fraction of the nanometer silver particles in the polyethylene composite antibacterial coating containing the nanometer silver particles is no less than 0.0714 wt%, preferably 0.0714 to 0.714 wt%. The preparation method of the invention has the advantages ofeasy operation, low spraying temperature, high efficiency, etc.; since a thermal spraying process is not utilized, the degradation and oxidation of polyethylene are effectively prevented, and the physical and chemical performance of the polymer is maintained unchanged. The polyethylene composite antibacterial coating containing the nanometer silver particles is applicable to the industries of foodpackaging, medical apparatuses and instruments, space equipment materials and the like. The coating can effectively reduce the consumption of Ag.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Gunning mix for kiln repair

The invention discloses a gunning mix for kiln repair. The gunning mix is characterized by comprising the following components by mass percent: 37-41% of dead burnt magnesia, 56-61% of forsterite, 1.0-1.4% of borax, 0.4-0.6% of inorganic salt, 0.2-0.4% of sodium tripolyphosphate and 0.4-0.6% of sodium hexametaphosphate. The gunning mix has the beneficial effects that forsterite and dead burnt magnesia are adopted as main raw materials; the gunning mix prepared with the formula has the advantages of high adhesive rate, good antistrip performance, high sintering speed, erosion resistance, anti-scouring performance and low high-temperature expansibility when applied to kilns and thermal equipment, and has more than 95% of adhesive rate; the mineral resources of the raw materials including magnesia and forsterite are abundant and the auxiliary raw materials can be obtained everywhere, so that the formula is simple and the inventory costs of the raw materials are reduced; the high adhesive rate of the product is favorable for not only achieving reduction of the production cost but also reducing the adverse effects of residues on molten steel.

Owner:浙江攀盛冶金材料有限公司

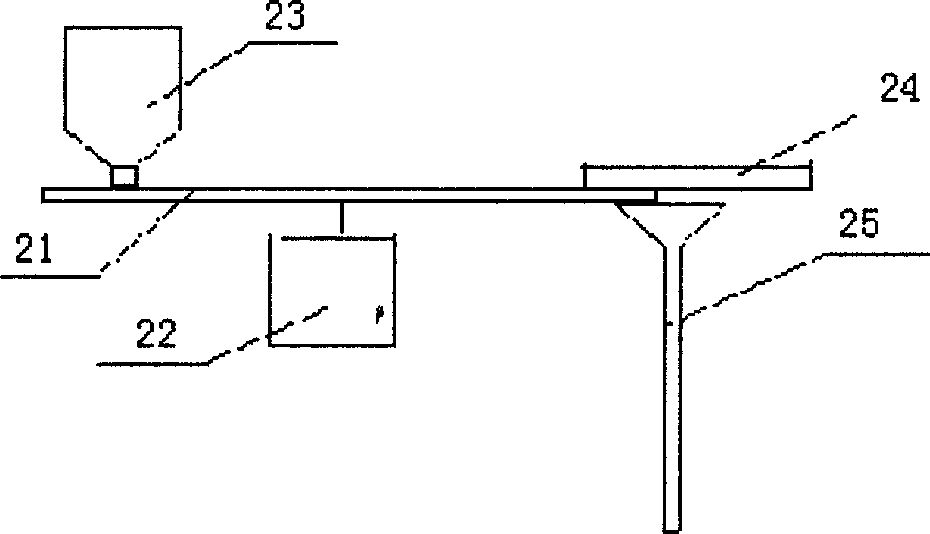

Preparation method of gunning mix for kiln repair

The invention discloses a preparation method of a gunning mix for kiln repair. The preparation method comprises the following steps in sequence: breaking dead burnt magnesia into large dead burnt magnesia particles; grinding the large dead burnt magnesia particles into small dead burnt magnesia particles; grinding part of the small dead burnt magnesia particles into dead burnt magnesia fine powder with a particle size of 0.088mm; breaking forsterite into large forsterite particles; grinding the large forsterite particles into small forsterite particles with particle sizes of 0.1-3mm; weighting borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate, premixing the materials and conveying the materials to a mixing system after premixing; screening the materials according to the difference of particle sizes; filling the small particles and the micro powder into a mixing system tank and conveying the materials to the mixing system after the materials are mixed; stirring dead burnt magnesia, forsterite, borax, inorganic salt, sodium tripolyphosphate and sodium hexametaphosphate in the mixing system simultaneously and then subpackaging the product, thus obtaining a finished product of the gunning mix. The preparation method has the beneficial effects that the formula is simple, thus reducing the inventory costs of the raw materials; the prepared product has a high adhesive rate, thus lowering the production cost.

Owner:浙江攀盛冶金材料有限公司

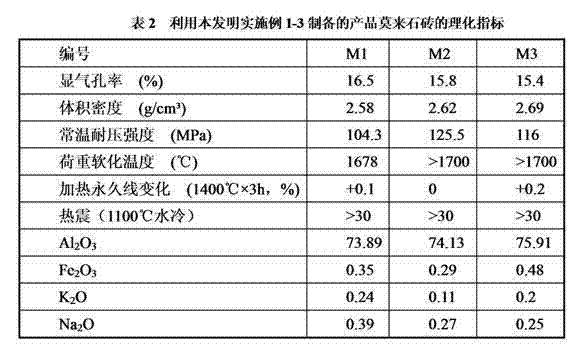

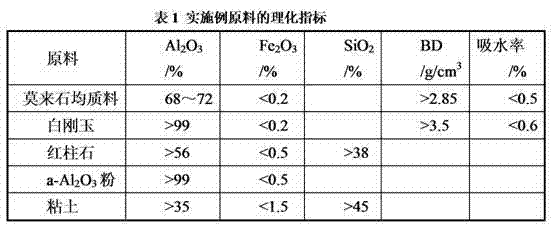

Mullite brick used for furnace bottom of COREX furnace and its production method

The invention relates to a mullite brick used for furnace bottom of a COREX furnace, which comprises the following raw materials: 50-70% of mullite homogenizing material, 10-20% of white corundum, 10-20% of andalusite, 5-10% of a-Al2O3, 3-5% of clay, and paper pulp waste liquid accounting for 2-5% of total weight of the above raw materials. The porosity of the mullite brick is low which is less than 16.5%, the compression strength is greater than 100MPa, the thermal shock stability is greater than 30 times, refractoriness under load is greater than 1678 DEG C, all indexes are superior to those of common domestic corundum mullite bricks, and the mullite brick provided by the invention has the characteristics of high mechanical strength, high temperature resistance, erosion resistance and scouring resistance.

Owner:TONGDA REFRACTORY TECH CO LTD +1

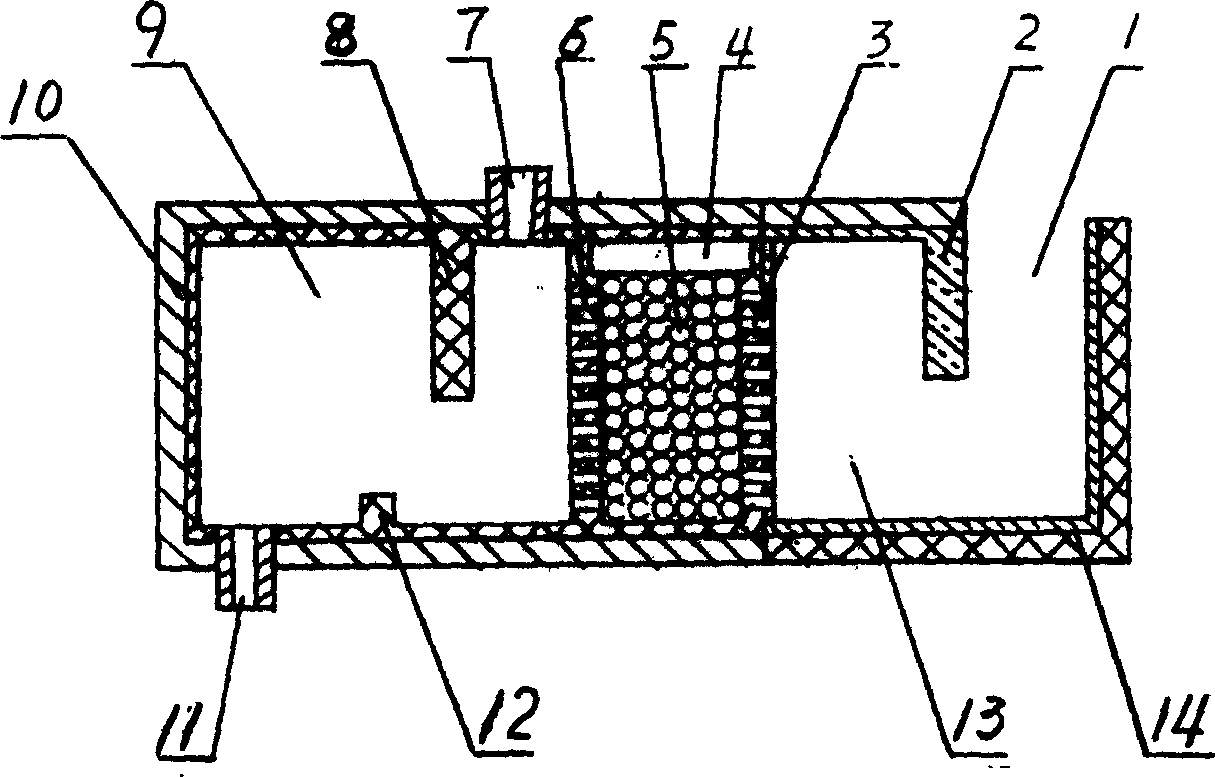

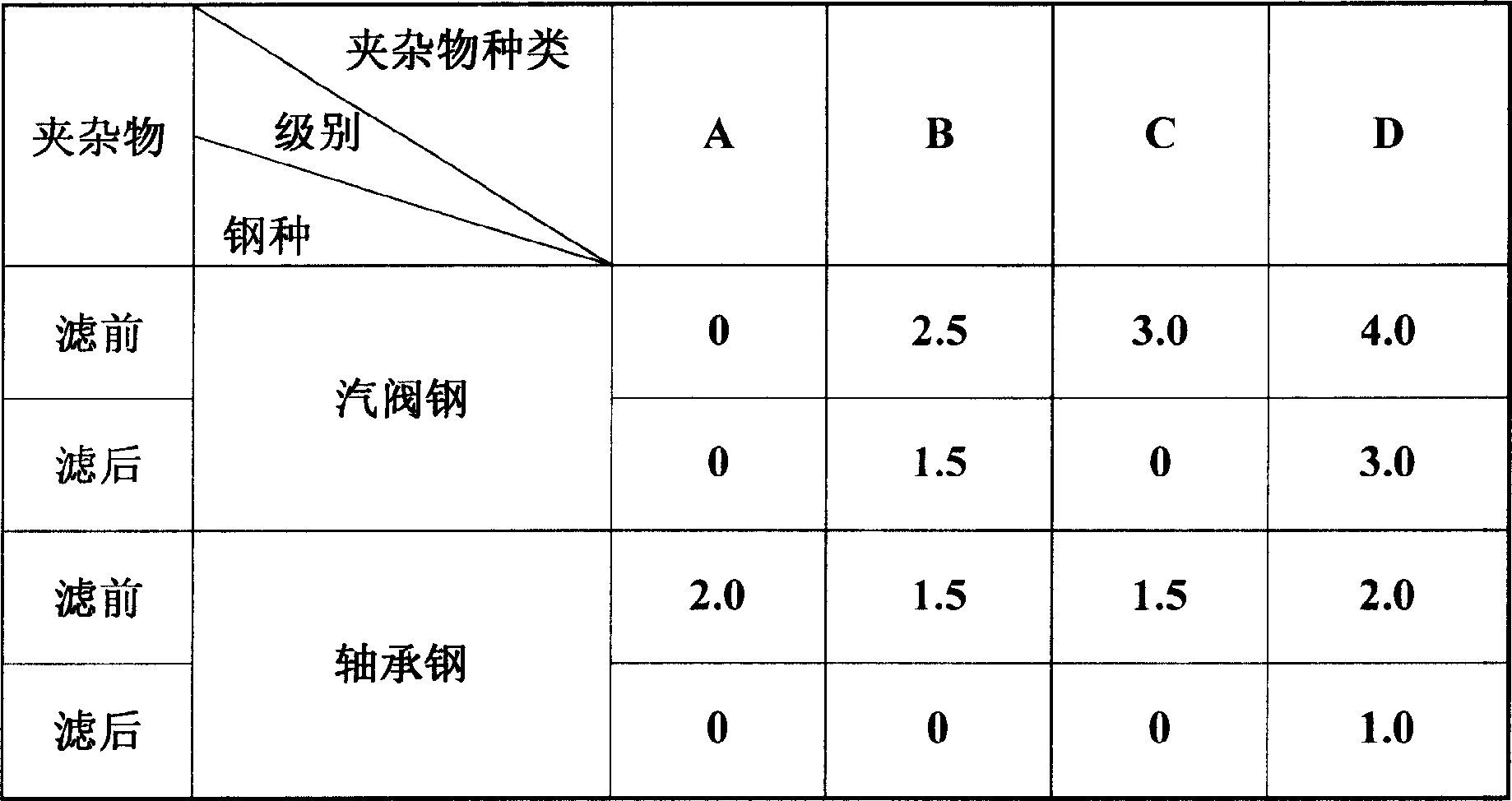

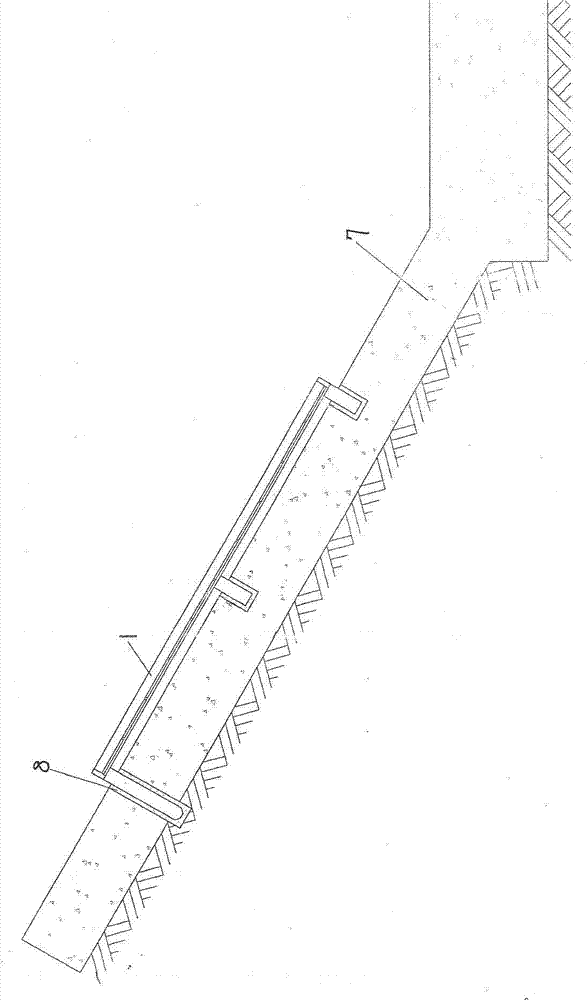

High-strength functional form filtration apparatus made of magnesium and its making process

InactiveCN1546256AOptimizing the Portfolio StructureMutual configuration is reasonableFiltrationHigh intensity

The invention is a kind of magnesio high intensity functional filter device, which is box type structure. It is made up of compound left and right boxes, and the middle multiaperture mask. The right box inner cavity has a liquid steel inlet and steel channel of calcium oxide dredge blocking board. The multiaperture is made up of right compound multiaperture board, magnesio multiaperture board, the calcium oxide equal-radius sphere in it and upper magnesio multiaperture board. The left box inner cavity is clean steel room, on top of which there has an air outlet and magnesio dredge blocking board, there has a magnesio dredge blocking weir and liquid steel outlet. The process: the invention uses magnesium oxide as base material, uses calcium oxide, calcium carbonate, zirconium dioxide, titanium dioxide as functional materials. The box body and pieces are pressed and formed, assembled, dried, and baked in the mould. The merits are: the intensity is high, impact resisting, the functional material reacts with nonmetal in the liquid steel, thus 60%-90% impurities in the liquid steel.

Owner:金毓林

Rapid repairing material prepared from waste high-aluminum brick and preparation method thereof

The invention relates to a rapid repairing material prepared from a waste high-aluminum brick and a preparation method thereof. The rapid repairing material comprises, by weight, 10-20 parts of waste high-aluminum brick, 5-8 parts of zirconium silicate sand, 20-30 parts of bauxite, 10-18 parts of clay powder, 3-5 parts of kyanite, 2-3 parts of a composite additive and 15-18 parts of a composite binder. The rapid repairing material prepared from a waste high-aluminum brick can replace a high-cost ramming material, realizes recycle of a waste high-aluminum brick, beautifies the environment and reduces a cost. The rapid repairing material is an ideal refractory material for fast first-aid repair of steel rolling and ironmaking thermal furnaces and has the characteristics of high thermal state strength, quenching and quick heating resistance, washing resistance and no baking. Compared with the existing first-aid repair material, the rapid repairing material can shorten a production period by 5-8 days and create large benefits for a client.

Owner:鞍山市永恒特种耐火材料制造有限公司

Ecological grass planting technical method for ecologically improving concrete paving

InactiveCN103758082AWith in-situ anti-seepageAnti-scourCoastlines protectionExcavationsSeeds sourcePolyvinyl chloride

The invention discloses an ecological grass planting technical method for ecologically improving concrete paving. The ecological grass planting technical method includes arranging grass planting molds on the concrete paving; covering grid plates at the bottoms of the grass planting molds by breathable non-woven geotextiles with filter functions; arranging nutrient soil on the non-woven geotextiles; mixing seed sources of selective herbaceous plants in the nutrient soil or directly laying commercial grass carpets on nutrient soil substances. The grass planting molds are made of PVC (polyvinyl chloride) environment-friendly materials. The nutrient soil contains biological humus, nitrogen, phosphorus and potassium compound fertilizers and viscous or sub-viscous soil substrates. The ecological grass planting technical method has the advantages that the grass planting molds are reasonable in structure, and the ecological grass planting technical method can be used for ecologically improving and rehabilitating concrete paving of river channels, lakes, water reservoirs and ponds.

Owner:南通大学技术转移中心有限公司

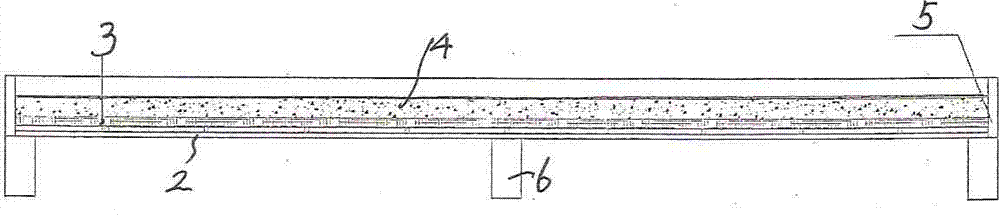

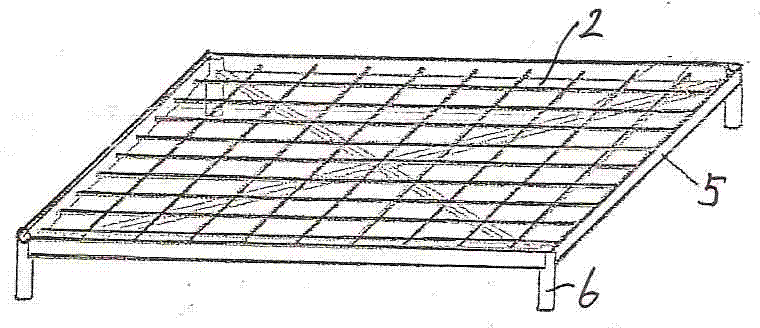

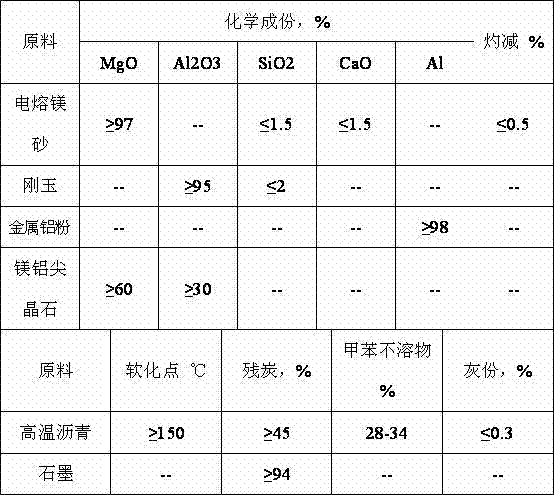

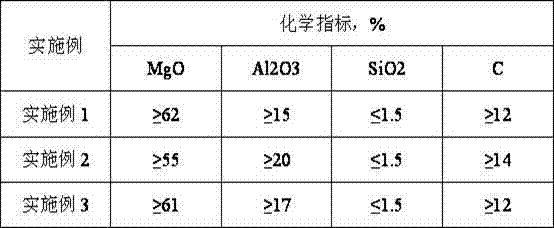

Anti-scouring tapping hole sleeve brick

The invention relates to an anti-scouring tapping hole sleeve brick, which comprises the following components by weight part: 50-65 parts of fused magnesia, 15-25 parts of corundum, 5-10 parts of magnesium aluminate spinel, 12-14 parts of graphite, 1-2 parts of high temperature asphalt, 1.5-3 parts of metal aluminium powder, 1-2 parts of resin-oatmeal, and 1-3 parts of binder. According to the invention, corundum is a high-grade aluminium raw material which has anti-scouring effect; and the added magnesium aluminate spinel is capable of increasing the high temperature intensity of sleeve brick. The sleeve brick has good anti-scouring and antioxidation effects under high temperature state, service life is greatly increased, and replacing frequency is shortened. The average service life can reach more than 300 heat.

Owner:营口东邦环保科技股份有限公司

Solidified mud soil and construction waste recycled aggregate composite inorganic material and molding method thereof

ActiveCN108505409AEasy to absorbEasy to handleRoadwaysSoil preservationAggregate (composite)Environmental engineering

The invention belongs to the technical field of solid waste resource utilization, and discloses a solidified mud soil and construction waste recycled aggregate composite inorganic material and a molding method thereof; a skeleton structure is formed by a graded and mixed construction waste recycled aggregate, gaps of the graded and mixed construction waste recycled aggregate are filled with solidified mud soil, and the solidified mud soil is obtained by adding a high-efficiency water-reducing powder curing agent into engineering waste mud with a certain moisture content for evenly mixing. Thevolume ratio of construction waste regeneration aggregate to solidified mud soil is (80% to 60%): (20% to 40%). The solidified mud soil and construction waste recycled aggregate composite inorganic material adopts waste resources as main raw materials, is low in cost and easy to produce, realizes resource recycling and is in line with the sustainable development strategy; the solidified mud soil and construction waste recycled aggregate composite inorganic material has the characteristics of scour resistance, high strength, good water stability and dry shrinkage and the like after being formed, and is applicable to all kinds of urban road subgrades, subbases, grassroots, mountain landscaping project mountain filling and other projects.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

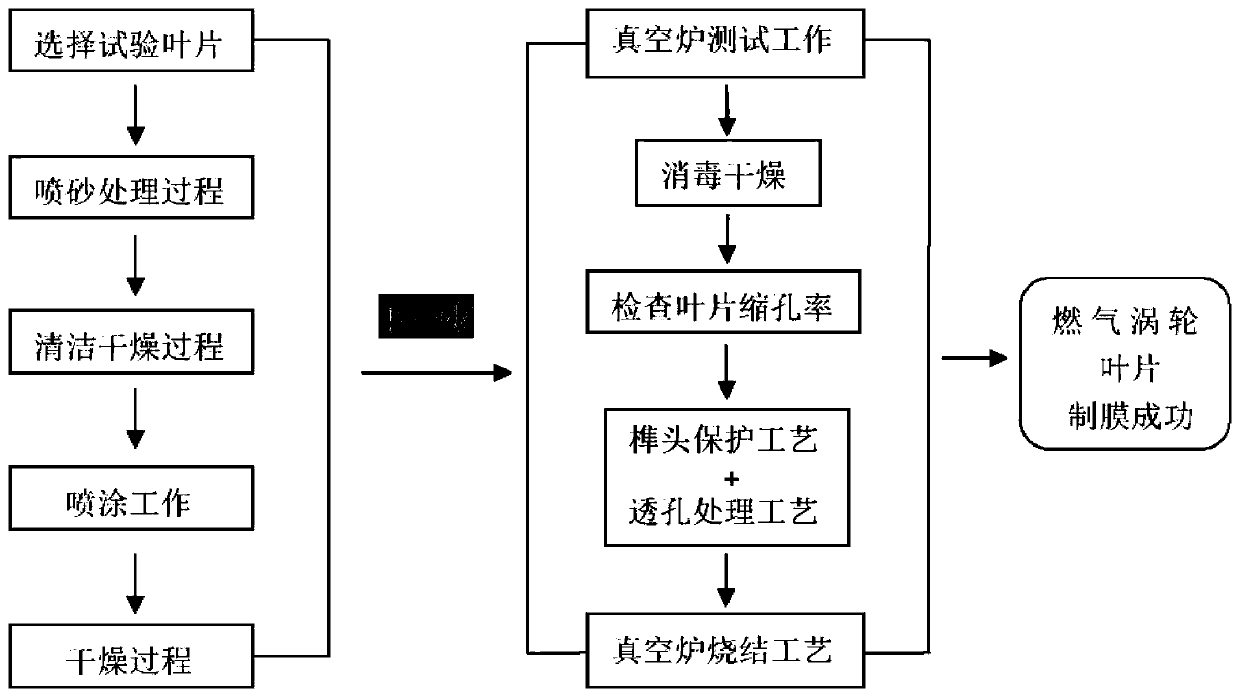

Gas turbine blade graphene coating thin film and preparation method thereof

InactiveCN111254429AHigh temperature ablation resistanceAntioxidantHeat inorganic powder coatingGraphene coatingTurbine blade

The invention relates to a gas turbine blade graphene coating thin film and a preparation method thereof. By means of the method, after a gas turbine blade is subjected to sand blasting, blow drying,cleaning, high-temperature disinfection drying and process optimization, the gas turbine blade is placed on a mold and is automatically sprayed by spraying equipment through graphene coating slurry, spraying is accumulatively carried out three times, finally vacuum sintering is carried out, and the graphene coating thin film is formed. The gas turbine blade graphene coating thin film prepared through the preparation method of the gas turbine blade graphene coating thin film has the advantages of being resistant to high temperature ablation, resistant to oxidization, resistant to wear and resistant to flushing. Engines of a certain type of a certain institution of AECC Zhuzhou are subjected to long-time test run verification, and a decisive effect is achieved on prolonging the service lifeof the aero-engine.

Owner:远科秦皇岛节能环保科技开发有限公司

Rubber lining gate valve

InactiveCN109386622AEasy to controlImprove machining accuracySlide valveValve housingsEngineeringSlurry

The invention relates to a rubber lining gate valve. The rubber lining gate valve comprises a valve body, a gate plate, a valve rod, a bracket and a hand wheel. The valve body is mainly formed by connecting a left valve body part and a right valve body part which are of a symmetric structure through bolts, wearproof rubber layers are integrally vulcanized on a channel of the left valve body part,a channel of the right valve body part and an end surface of a flange, U-shaped steps are arranged at channel ports of opposite end surfaces of the left valve body part and right valve body part respectively, a U-shaped sealing base is mounted in a U-shaped sealing groove formed by connecting the U-shaped steps on the two sides, and the U-shaped sealing base and the U-shaped outer end face of thegate plate are matched with each other to form a sealing pair. Transverse sealing grooves are respectively formed in the end faces of the left valve body part and right valve body part at the upper end of the U-shaped sealing groove respectively, rubber sealing strips which are in sealing fit with the planes of the two sides of the gate plate are mounted in the transverse sealing grooves in the two sides respectively, and transverse metal scraping blades which are in contact with the planes of the two sides of the gate plate are embedded in the rubber sealing strips. The machining precision ofthe valve body is high, and the valve body has the advantages of great erosion resistance, good wearing resistance, excellent corrosion resistance, superior sealing performance and the like and is applicable to a control valve of a pipeline containing abrasive and corrosive slurry.

Owner:永嘉县信诚科技服务有限公司

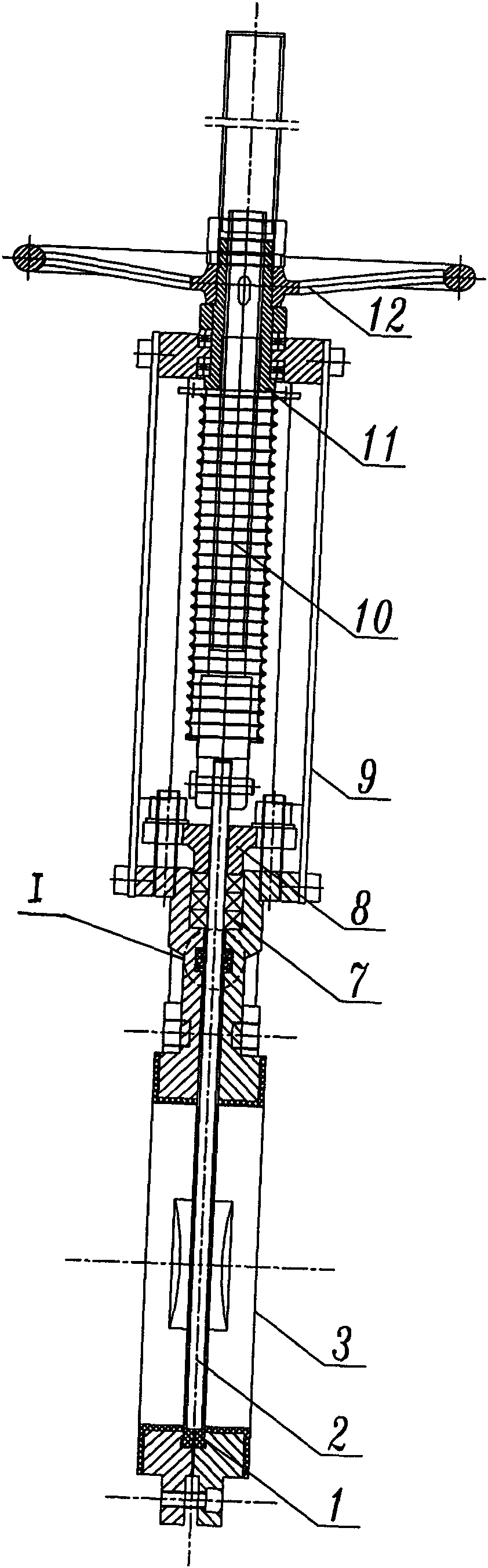

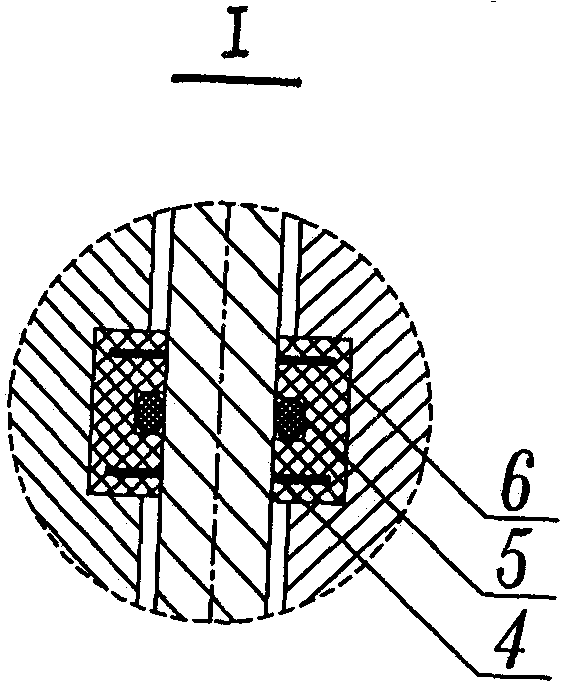

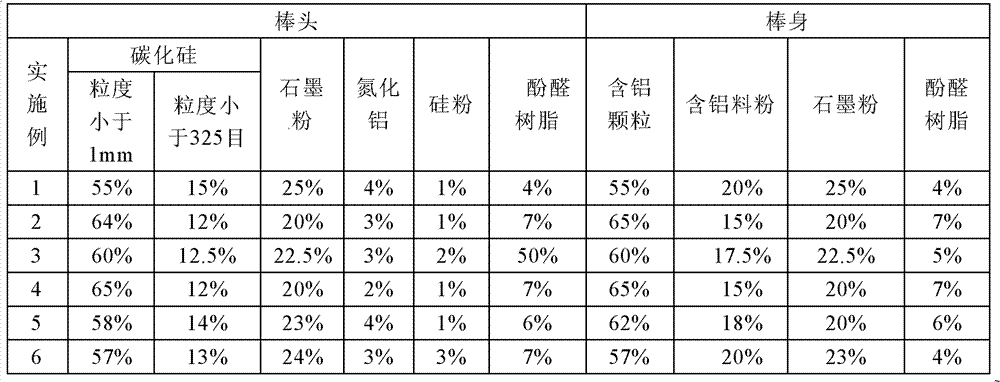

Monolithic stopper used for continuous casting, and preparation method thereof

ActiveCN102896309AStrong resistance to slag erosionImproved thermal shock stabilityMelt-holding vesselsSlagGraphite

The invention relates to a monolithic stopper used for continuous casting, and a preparation method of the monolithic stopper; the monolithic stopper comprises a stopper head and a stopper body, wherein the stopper head comprises the following components by mass percent: 55-65% of SiC particles with the particle size less than or equal to 1mm, 12-15% of SiC powder with the particle size less than or equal to 325 meshes, 20-25% of graphite powder with the particle size less than or equal to 325 meshes, 2-4% of AlN powder with the particle size less than or equal to 325 meshes, 1-3% of Si powder with the particle size less than or equal to 325 meshes and 4-7% of phenolic resin; and the stopper body comprises the following components by mass percent: 55-65% of aluminum-containing raw material particles with the particle size less than or equal to 1mm, 15-20% of aluminum-containing raw material powder with the particle size less than or equal to 325 meshes, 20-25% of graphite powder with the particle size less than or equal to 325 meshes and 4-7% of phenolic resin. The monolithic stopper used for continuous casting has the characteristics of being high in slag erosion resistance, good in thermal shock stability, and high in strength, having anti-scouring performance and high temperature resistance, and the like, and has the service life more than 12h, thus meeting the multi-furnace continuous casting performance requirement and the product quality requirement.

Owner:BAOSHAN IRON & STEEL CO LTD

Ecological slope protection method applied to sand gravel side slope

InactiveCN112726637ARealize ecological reinforcementIncrease mud contentExcavationsRevegetationSoil science

The invention relates to the technical field of environmental protection engineering, in particular to an ecological slope protection method applied to a sand gravel side slope. The ecological slope protection method applied to the sand gravel side slope comprises the steps of side slope soil pretreatment, mixed grass seed preparation, preparation of a composite ecological base material, spray seeding of the composite ecological base material, side slope maintenance and the like. Quantitative slow-release fertilizer, spray-seeding soil and water are mixed into thin slurry to be sprayed to a slope body, the mud content and fertility of a sand gravel matrix are improved, soil is improved, and the water content of the soil is increased; mixed sowing is performed by using a planting system in which pioneer vegetation and long-term vegetation are organically combined, so that the slope vegetation recovery capability is further improved; and through spray seeding of the composite ecological base material with certain thickness for fixing sand, retaining water, increasing fertility and promoting growth, the water-heat-fertilizer-gas effect of the original soil is improved while the surface of the sand gravel side slope is reinforced, the side slope is quickly regreened, the side slope is stabilized, and water and soil loss is reduced.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

A revetment structure combined with plastic sheet piles and concrete

ActiveCN104695380BCombination structure is stableFast constructionBreakwatersQuaysEngineeringRevetment

The invention relates to a revetment structure composed of plastic steel plate piles and concrete. The revetment structure comprises plastic steel plate piles and a concrete coping, wherein the plastic steel plate piles are connected through a connector having two mutually matched ends; the concrete coping is preformed and can be stably buckled with the upper ends of the plate piles. The revetment structure can be used for revetments of rivers or lakes, is safe and stable, high in construction speed, low in construction cost, environment-friendly and pollution-free, less in influence on the surrounding environment, and long in durability, can be further used for resisting the seepage of embankments and dike bodies of rivers and protecting dams.

Owner:海盐汇祥新型建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com