Rubber lining gate valve

A gate valve and rubber lining technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems affecting the closing of the gate, wear of the sealing surface of the valve seat, easy adhesion of the slurry, etc., to improve the processing accuracy and sealing performance. Good, easy to control the effect of processing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

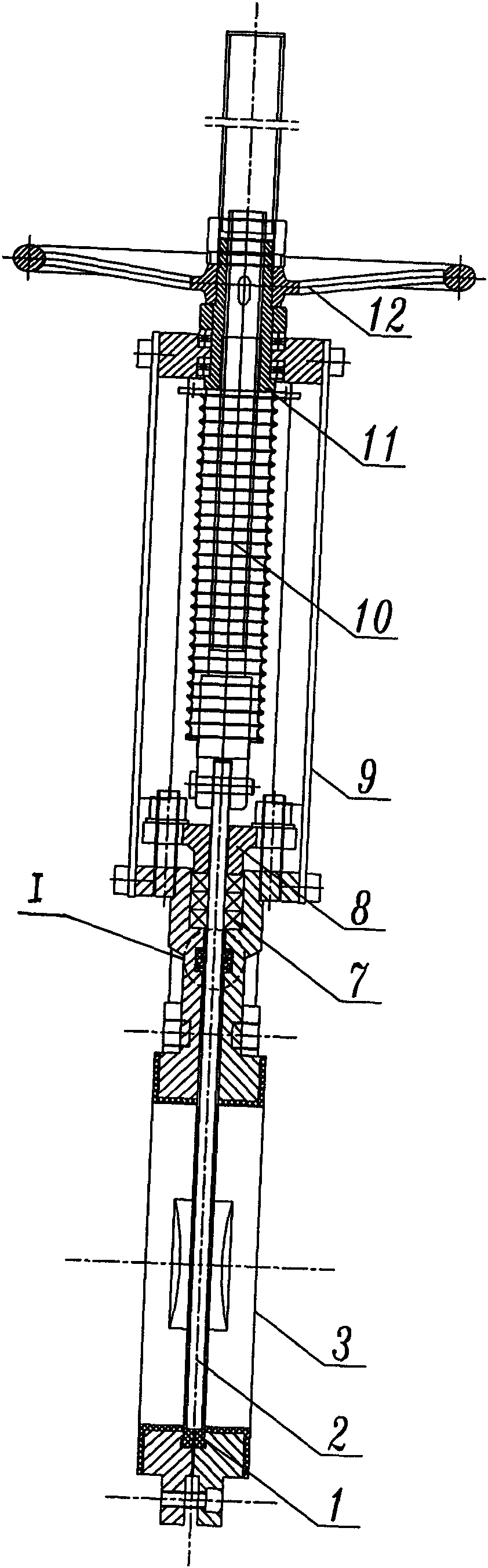

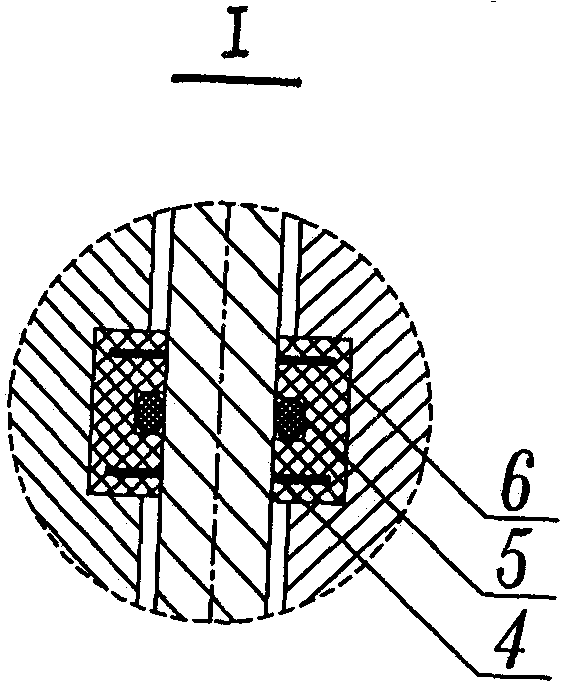

[0009] like figure 1 The shown rubber-lined gate valve includes a valve body 3, a gate plate 2, a valve stem 10, a bracket 9, and a hand wheel 12. The lower end of the valve stem 10 is fixedly connected to the upper end of the gate plate 2, and the upper end of the valve stem 10 is connected to The hand wheel 12 is threaded, and the packing gland 8 is pressed between the valve body 3 and the valve stem 10 to install the packing 7; The processing control of each surface of the cavity improves the matching accuracy between the gate 2 and the valve body 3, and the overall vulcanized wear-resistant rubber layer of the left valve body and the right valve body channel and the end face of the flange effectively protects the medium from scouring and the valve body 3. wear, improve the anti-scouring and wear-resistant performance of the valve body 3, U-shaped steps are respectively made on the channel openings of the opposite end faces of the left valve body and the right valve body, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com