Solidified mud soil and construction waste recycled aggregate composite inorganic material and molding method thereof

A technology of construction waste and recycled aggregates, applied in construction, soil protection, roads, etc., can solve the problems of less than 10% comprehensive utilization rate, large cultivated land occupation, environmental pollution, etc., to promote urbanization process and reduce project cost , The effect of saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

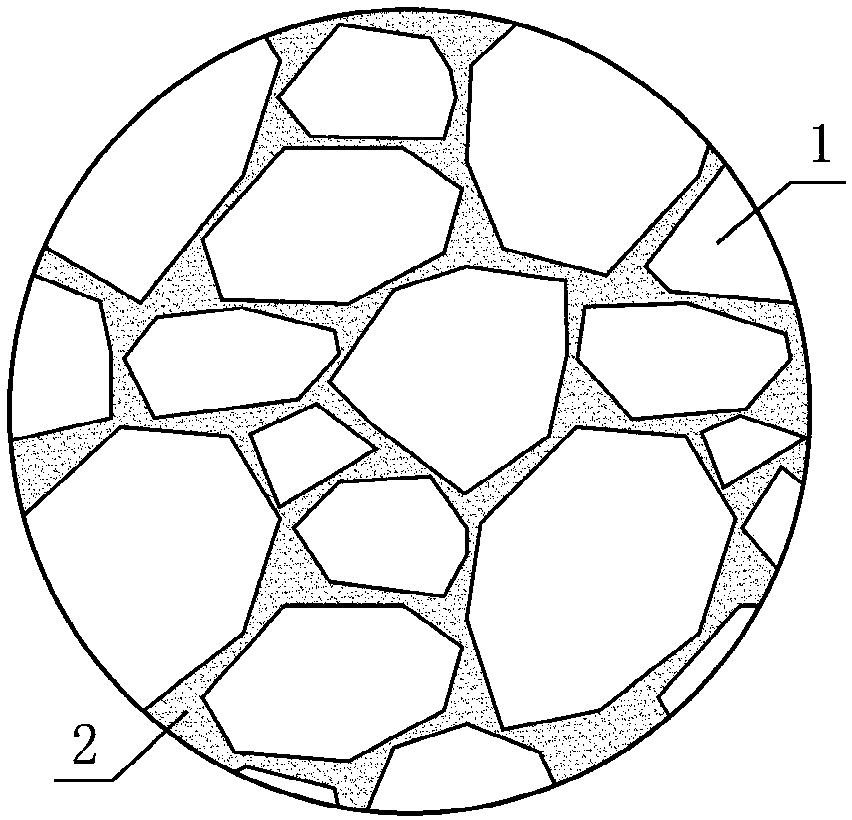

Image

Examples

Embodiment Construction

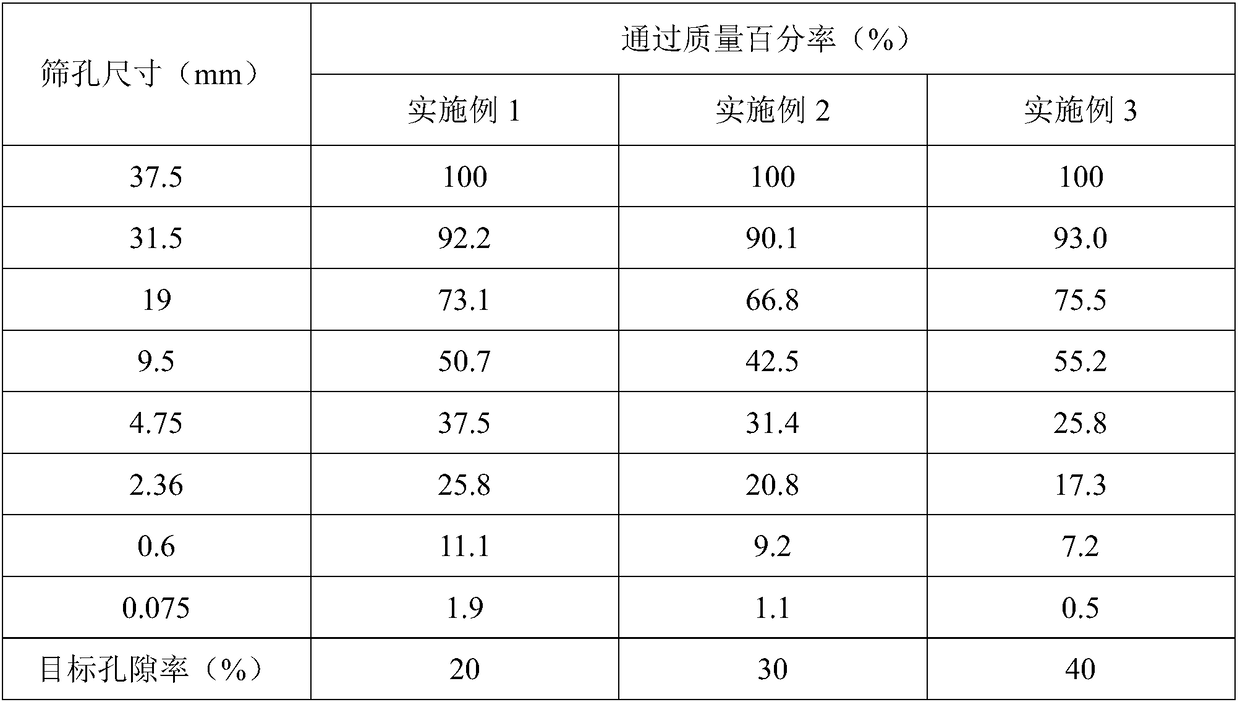

[0030] The present invention will be described in further detail below by specific embodiment:

[0031] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

[0032] The explanation for raw material used in each embodiment of the present invention is as follows:

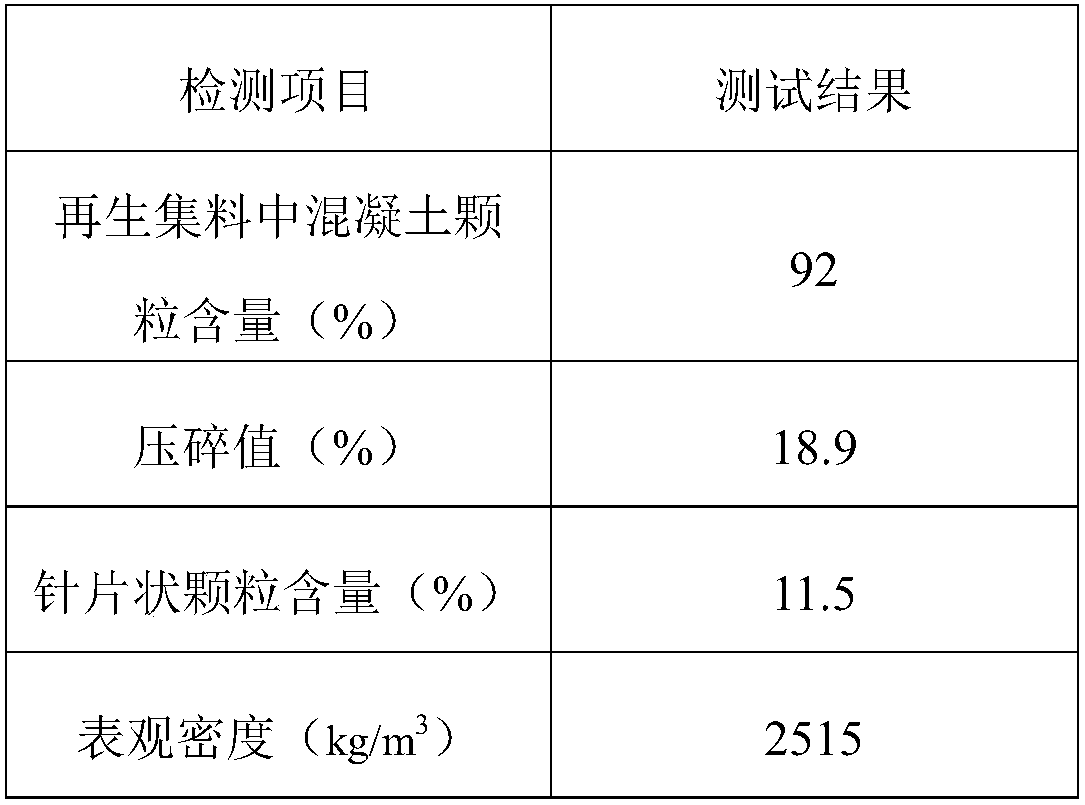

[0033] Recycled construction waste material: It is obtained from construction waste disposal plants that have undergone primary crushing and sorting, and is made by secondary crushing and screening in the laboratory; it meets the requirements of the industry standard DB13(J)T155.

[0034] Engineering waste mud: It is taken from the mud produced at the construction site of bored piles; the mud can represent dredging filling, underground diaphragm wall, bored piles, trenchless horizontal directional drilling, mud-water balanced pipe jacking, mud-water pressurized For the mud produced during the constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com