Erosion-prevention stop valve seal pair

A shut-off valve and sealing pair technology, which is applied to lift valves, valve devices, engine components, etc., can solve the problems of poor sealing effect and shortened service life of shut-off valves, reduce erosion and corrosion, increase production costs, and simplify the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

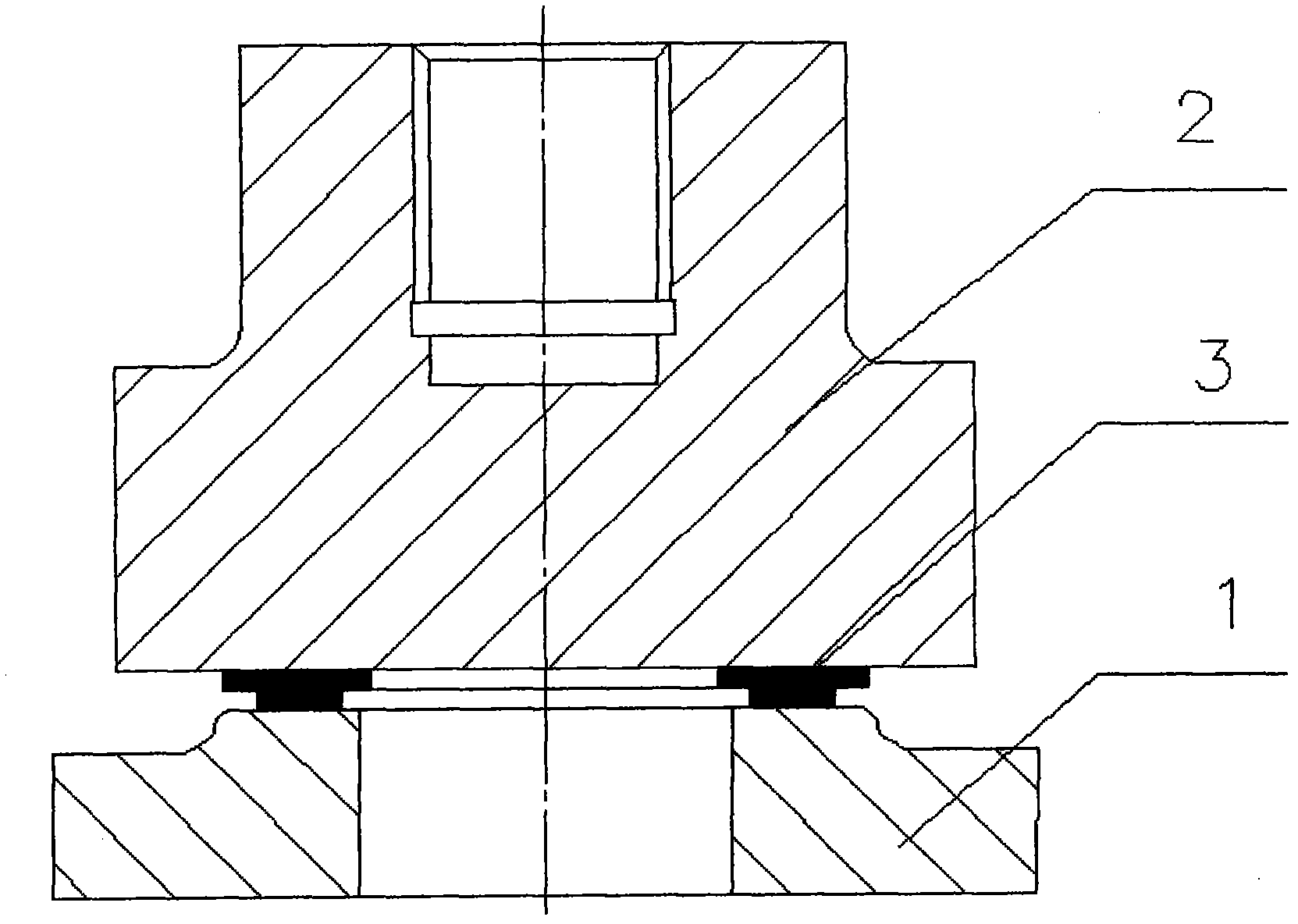

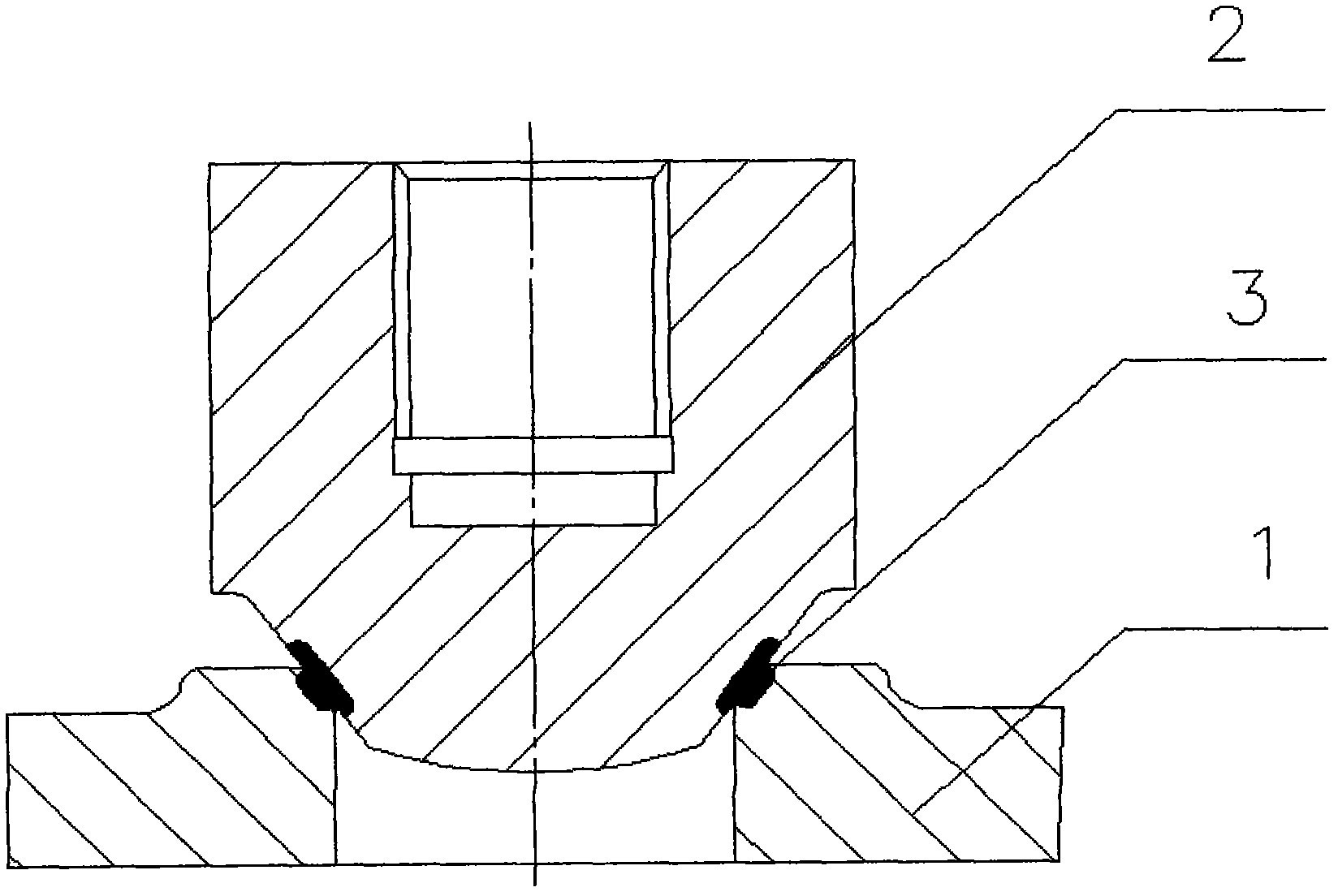

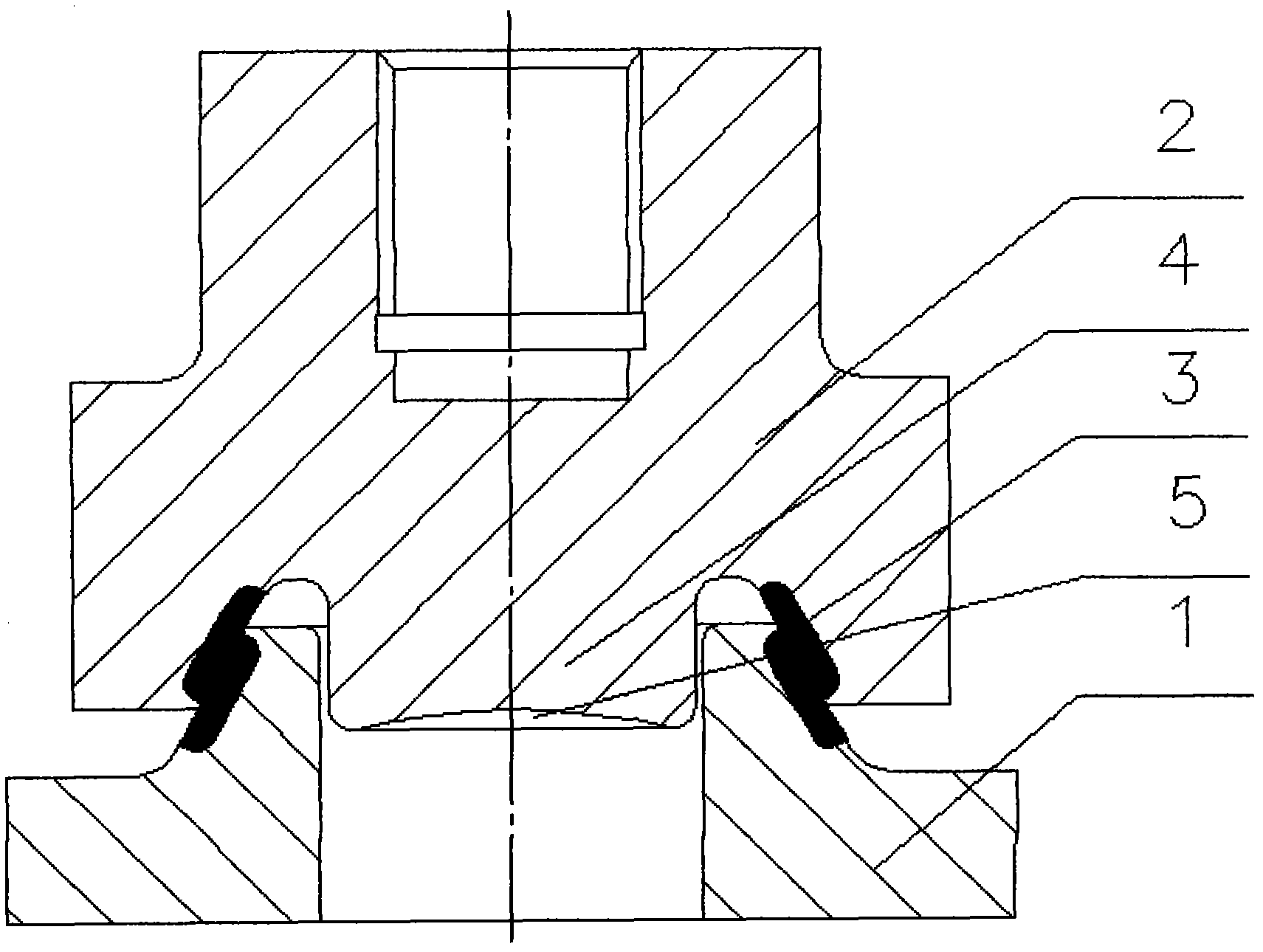

[0017] see image 3 and Figure 4 , the present invention provides a sealing pair of an anti-scour stop valve, including a valve seat 1 and a valve flap 2 corresponding to each other, a valve seat hole is provided in the center of the valve seat, and the sealing surface of the valve seat is an outer cone surface, The sealing surface of the valve disc is an inner cone surface matched with the outer cone surface. For the convenience of processing and improving the sealing effect of the sealing surface, the outer cone surface of the valve seat and the inner cone surface of the valve disc The valve seat hole and the valve seat hole can be arranged in a centrally symmetrical structure, and the installation method is preferably such that the centerlines of the three coincide with each other, so that the medium flowing out of the valve seat hole can evenly spread around.

[0018] In order to improve the sealing effect of the sealing pair of the shut-off valve, the outer conical surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com