Patents

Literature

70results about How to "Play a reassuring role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

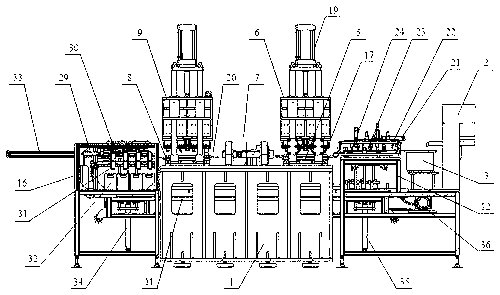

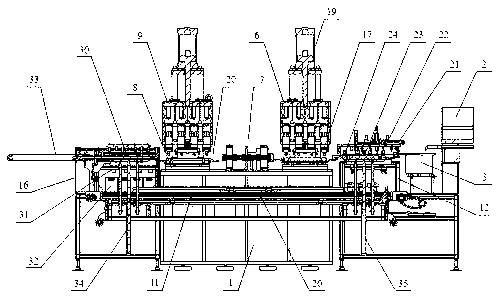

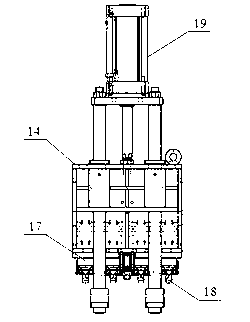

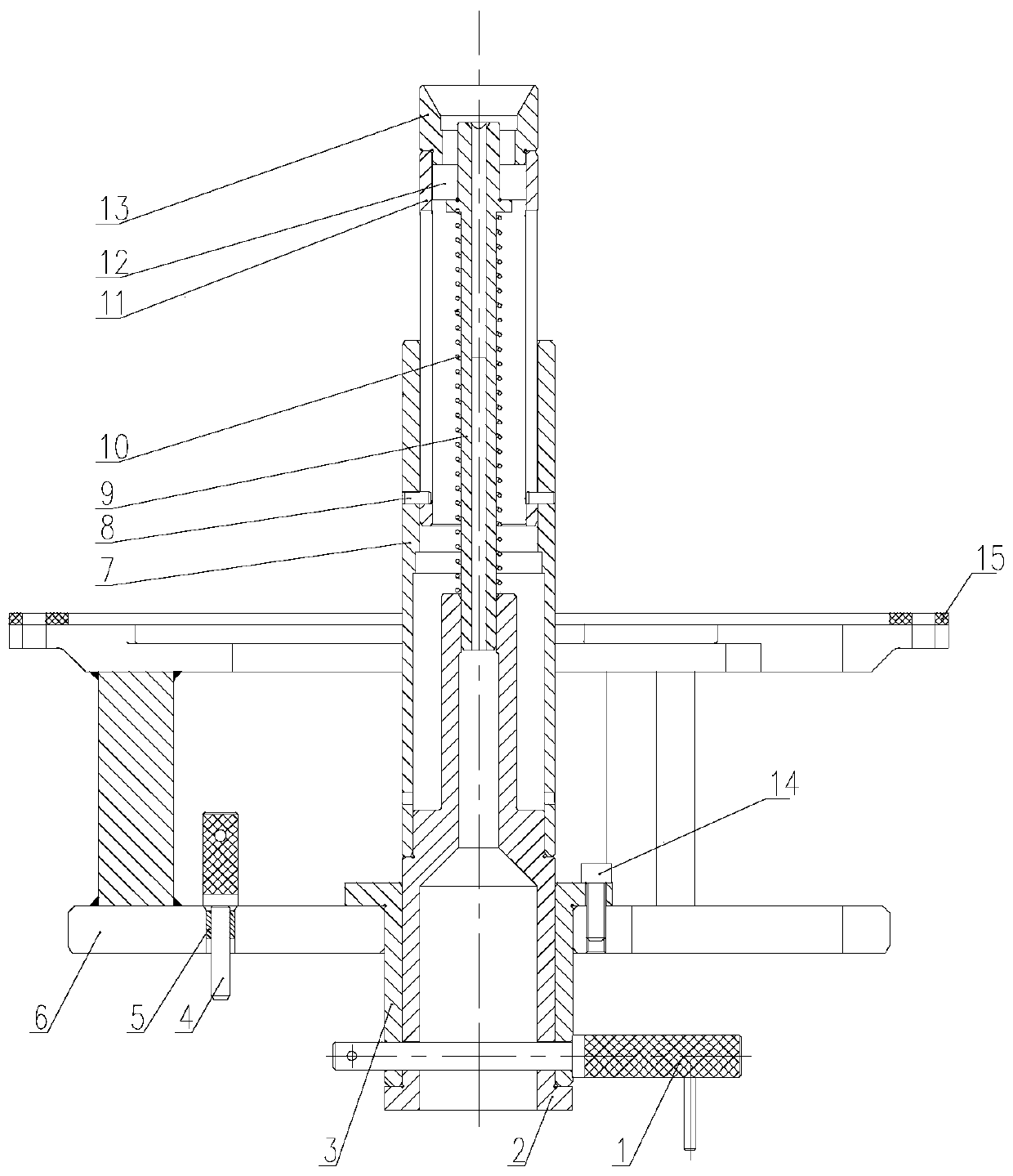

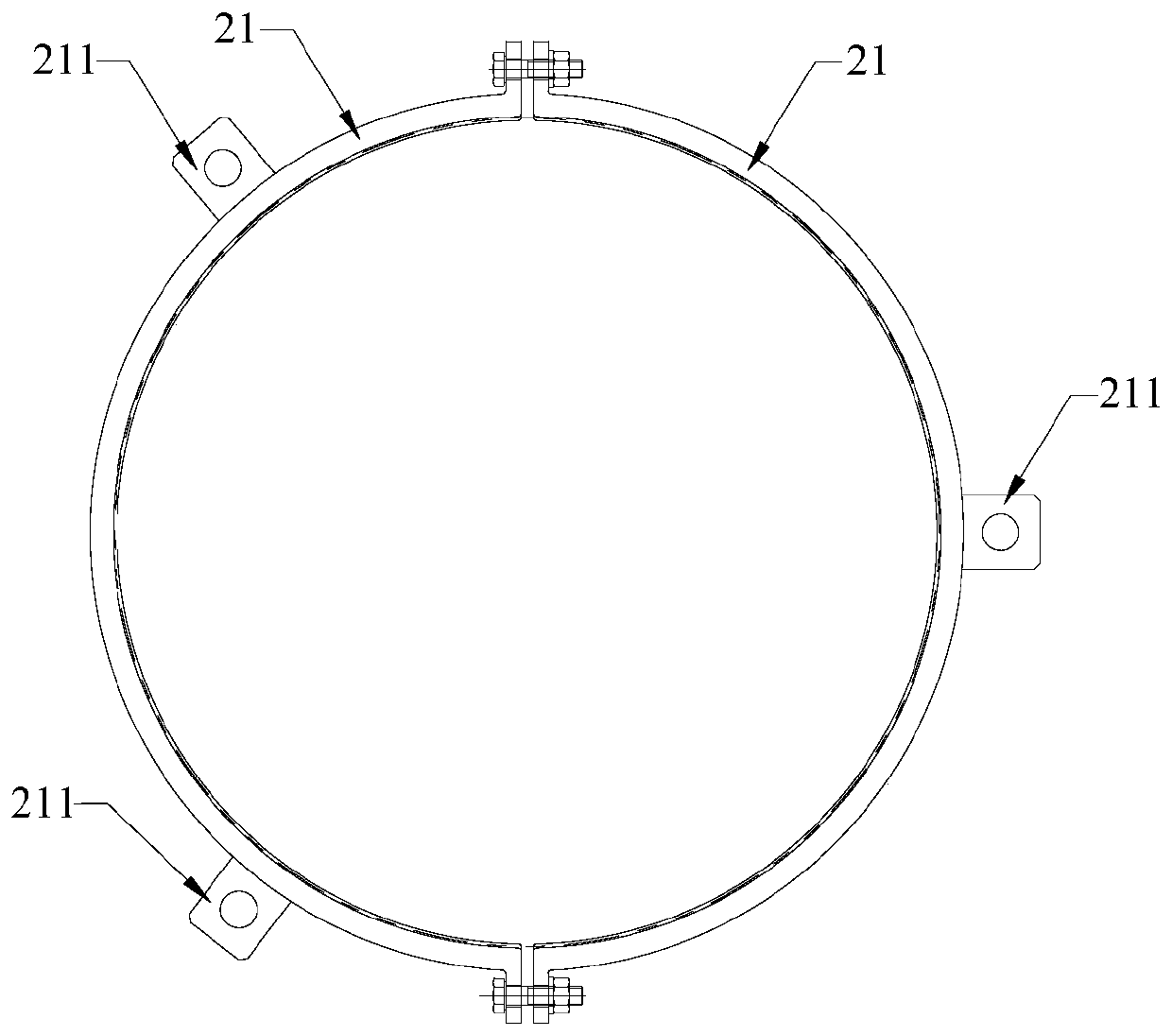

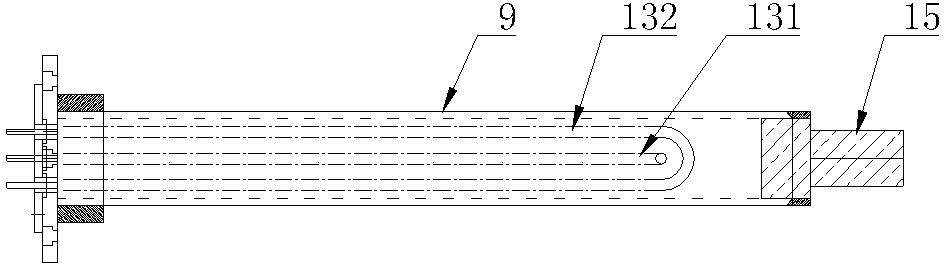

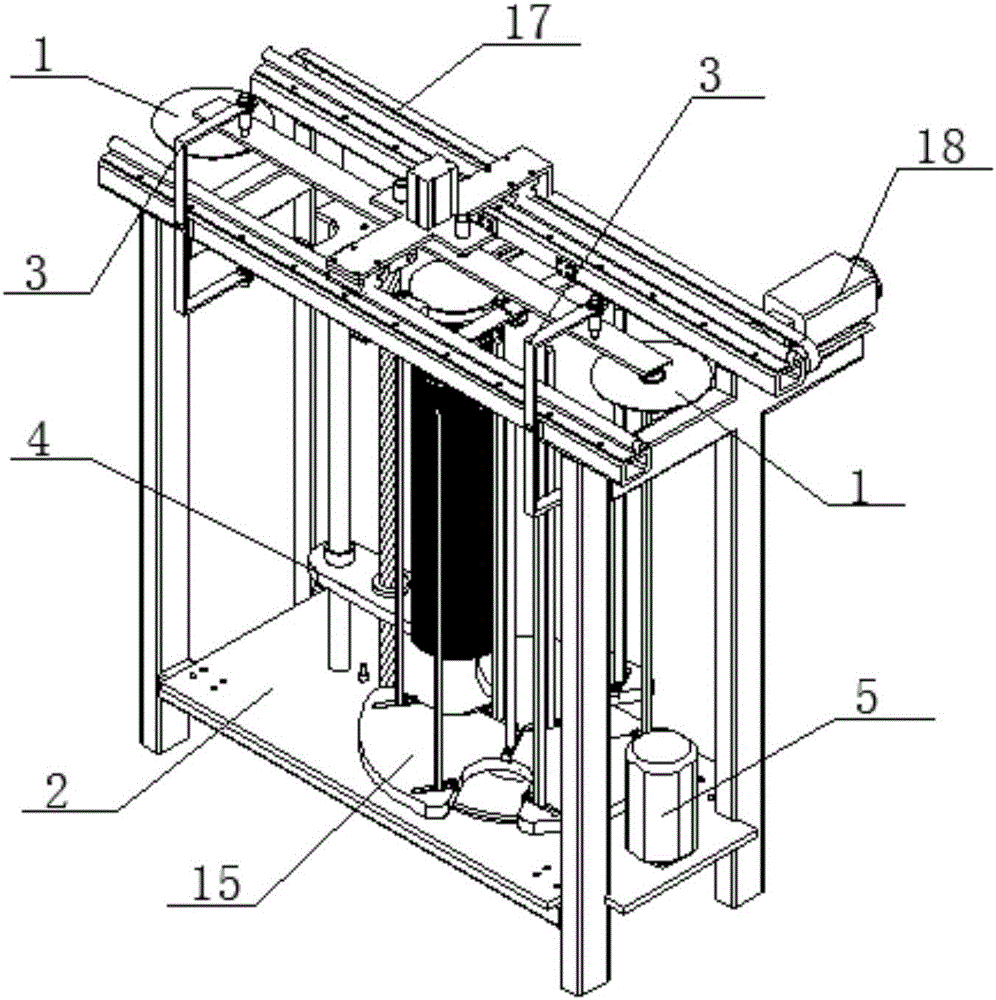

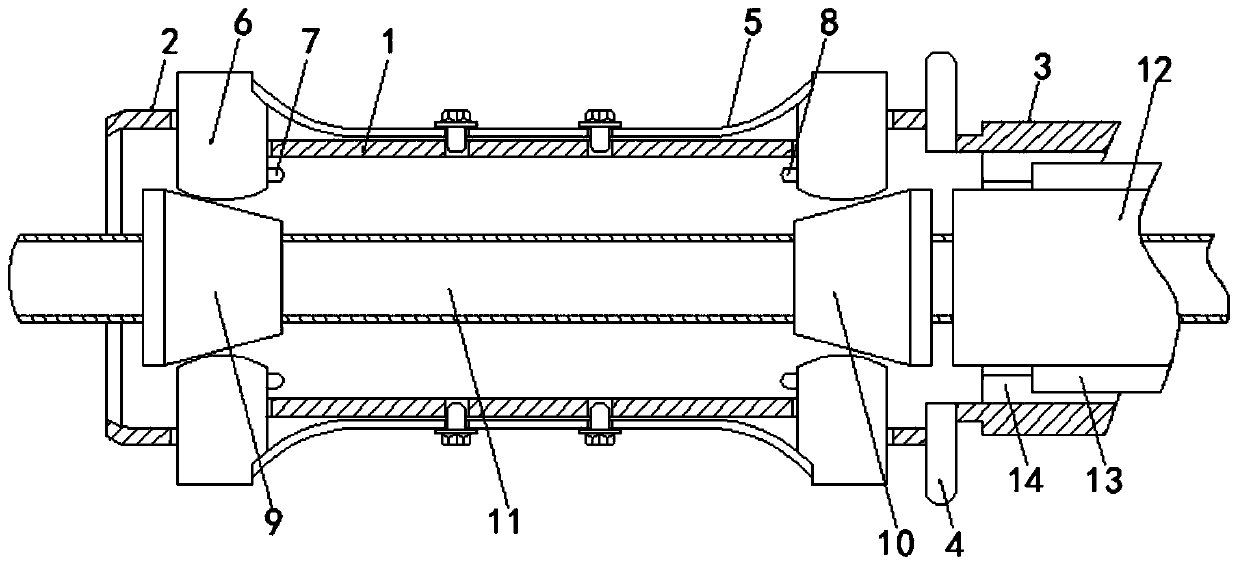

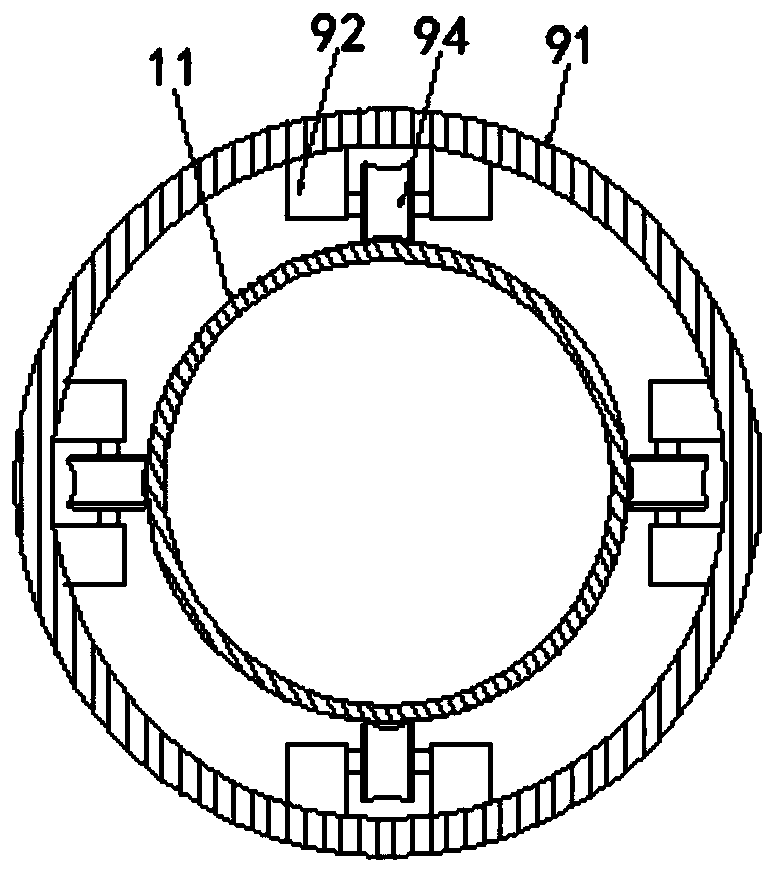

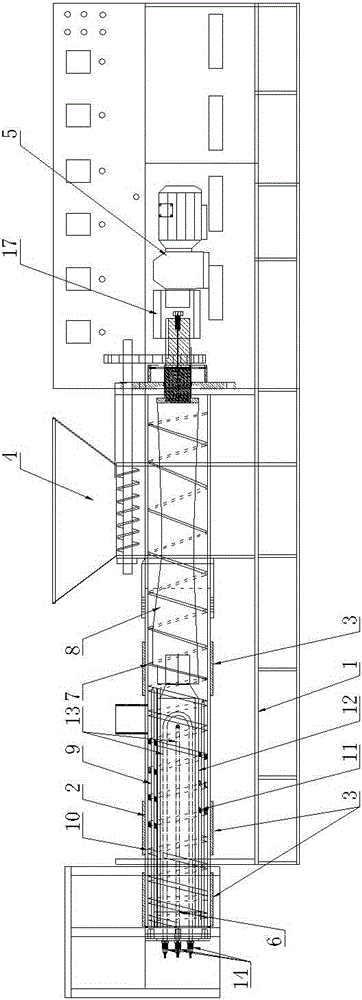

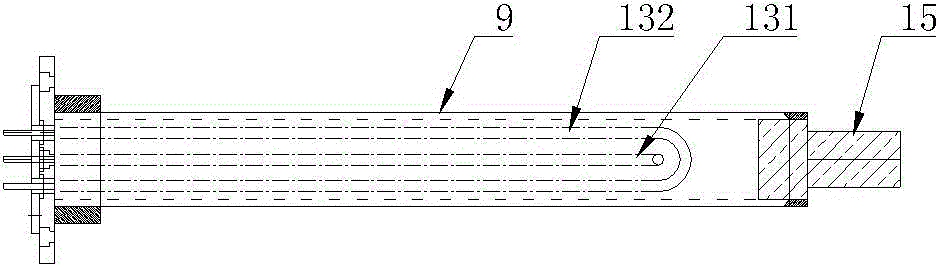

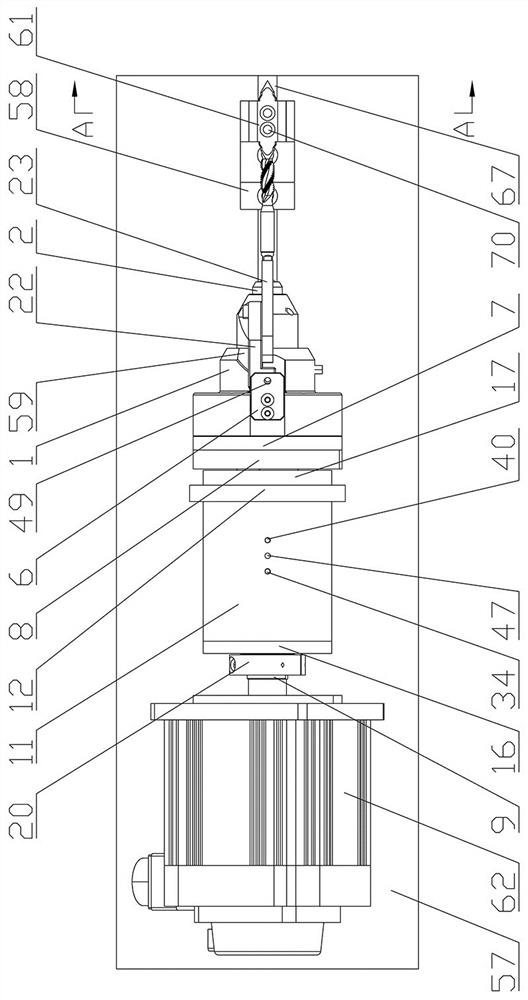

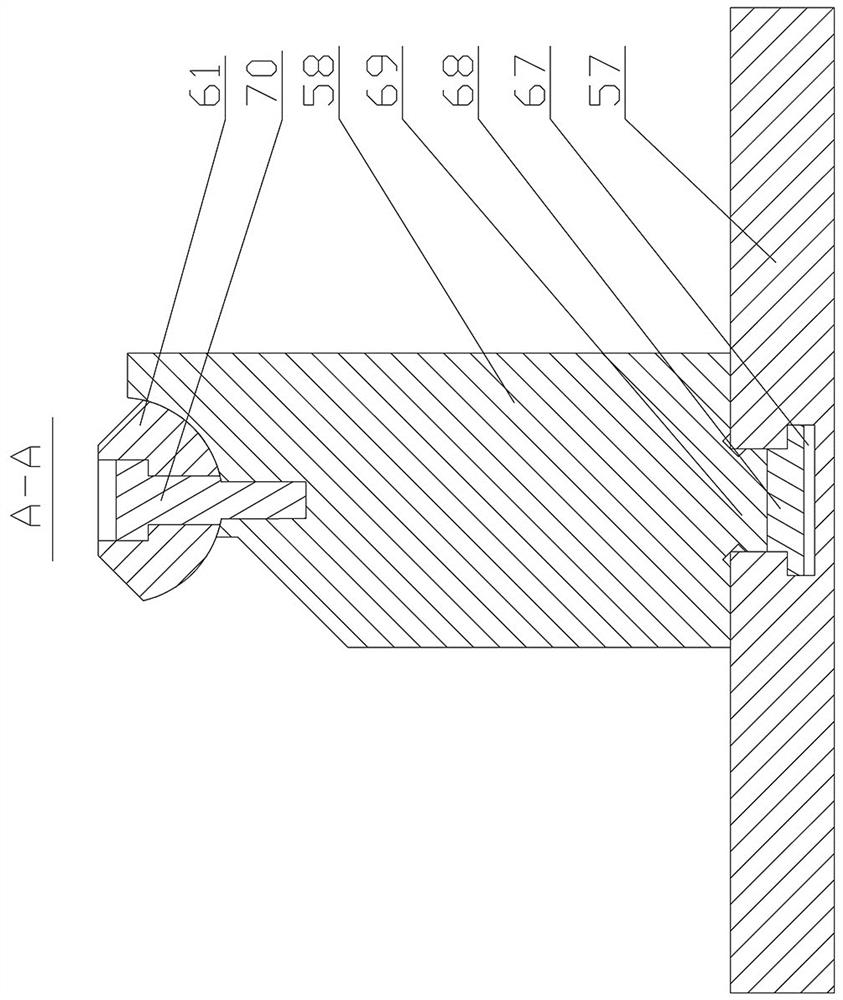

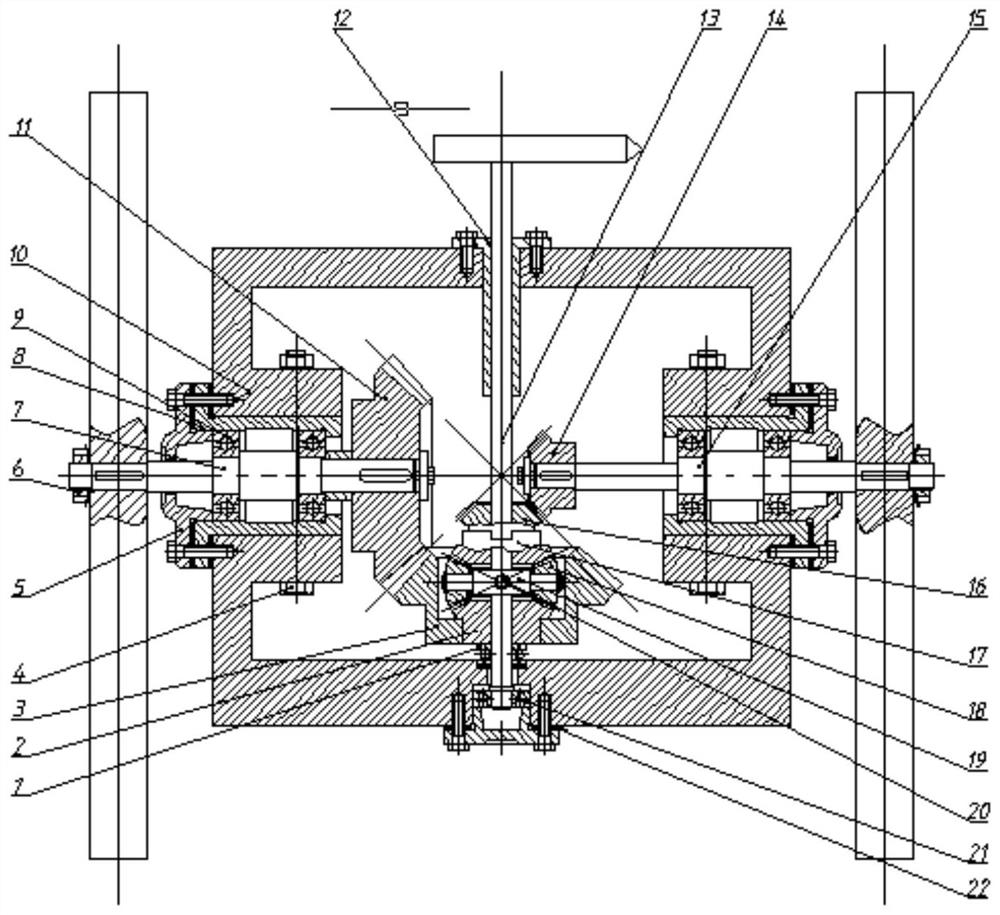

Multi-station electrolysis precise grinding automatic machine

InactiveCN103273402AReduce lossGuaranteed machining accuracyGrinding machinesGrinding work supportsElectrolysisEngineering

The invention relates to a multi-station electrolysis precise grinding automatic machine, and belongs to devices for conducting full-automatic grinding machining on the inner surface and the outer surface of a shaver net. The multi-station electrolysis precise grinding automatic machine adopts a follow clamp of a ship-plate type structure, can automatically feed and discharge materials, can conduct simultaneous operations at eight stations, uses an electrolytic action and an electric conduction grinding wheel with mechanical grinding capacity to conduct machining on the shaver net, greatly improves work efficiency, machining stability and accuracy, reduces losses of the grinding wheel and saves production cost. Machining on the front face and the back face of a machined piece can be achieved on one machine through a turnover device. Electrolytic machining is carried out on the machined piece through the electrode power supply electric conduction mode, the soft sheet connection electric conduction mode, the floating steel ring electric conduction mode and the insulation sleeve insulation electric conduction mode. Zirconia ceramics are made into a base to serve as a support due to the characteristics of insulation, abrasion resistance and high temperature resistance of the zirconia ceramics, and the centering effects of the machining position of the machined piece are achieved. An air-tight seal is adopted to prevent the situation that electrolytes spill out or atomize so as to enter a main grinding shaft box to abrade parts when the grinding wheel conducts grinding.

Owner:DALIAN JIADEHENG SCI & TECH

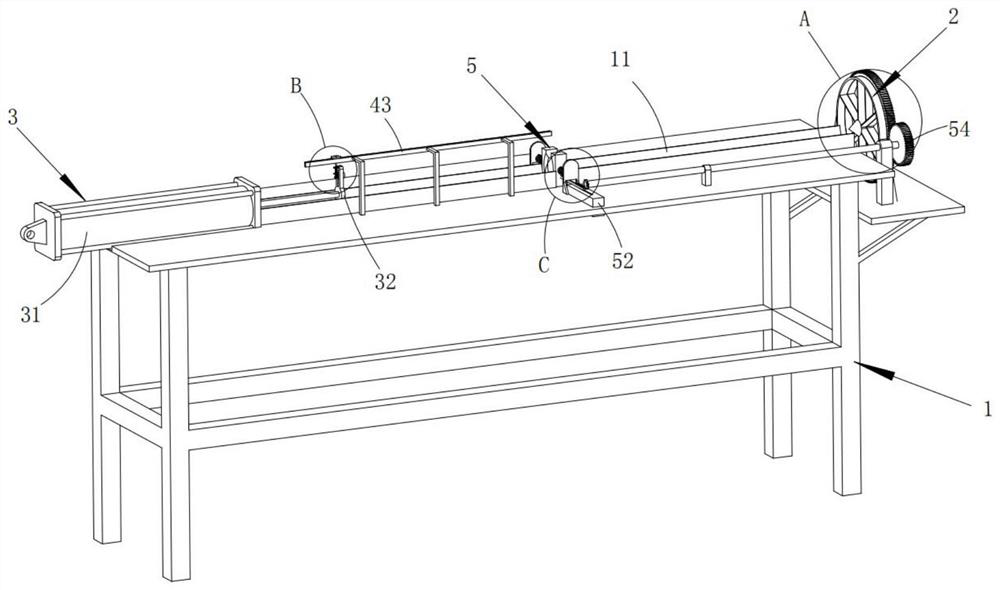

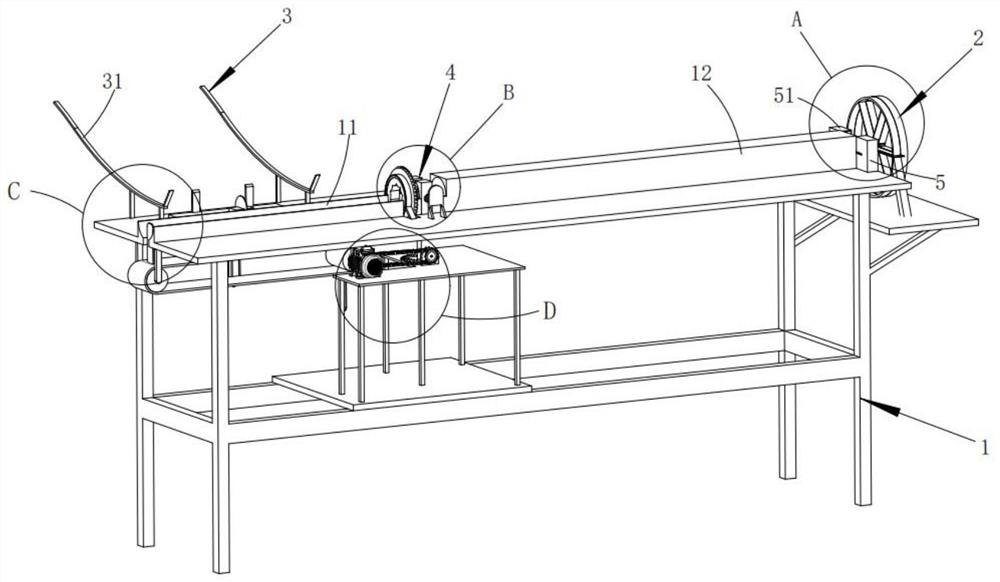

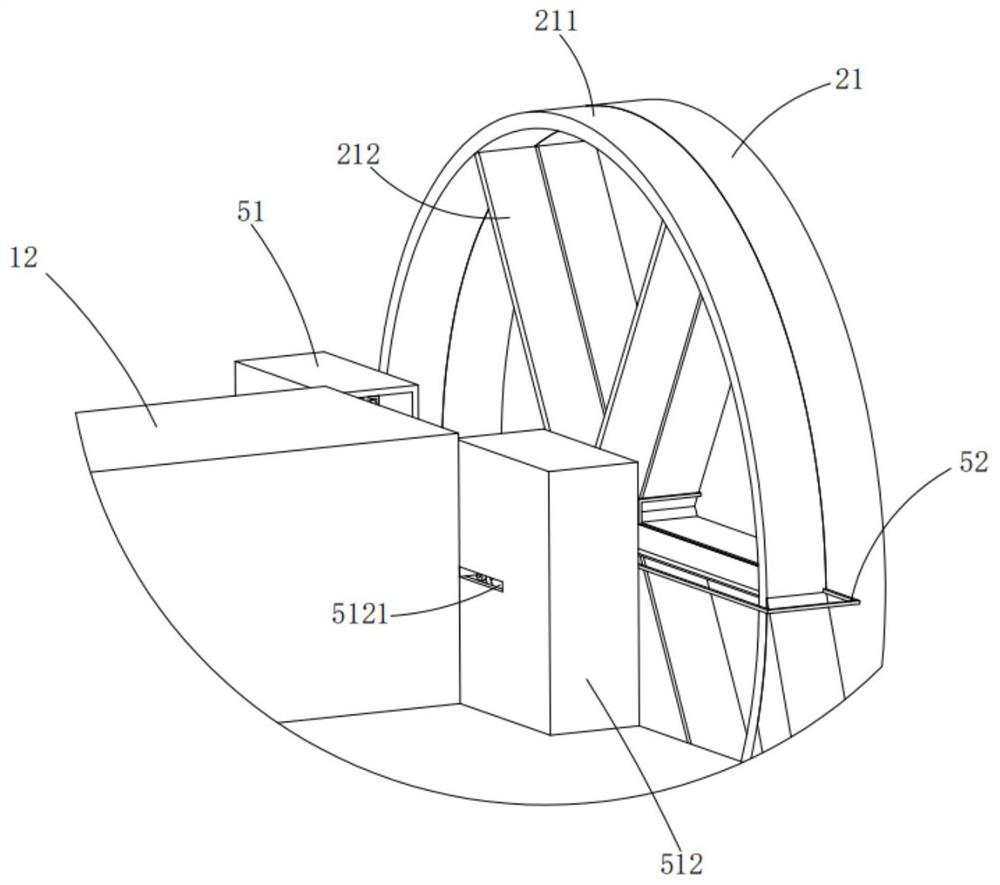

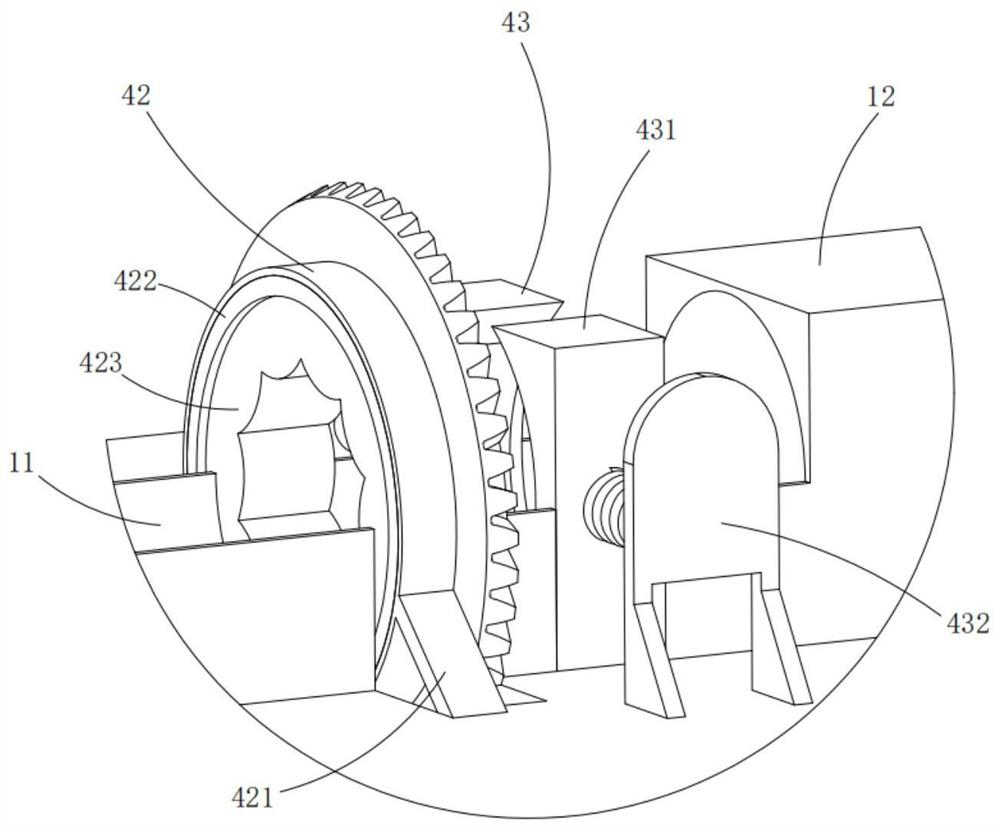

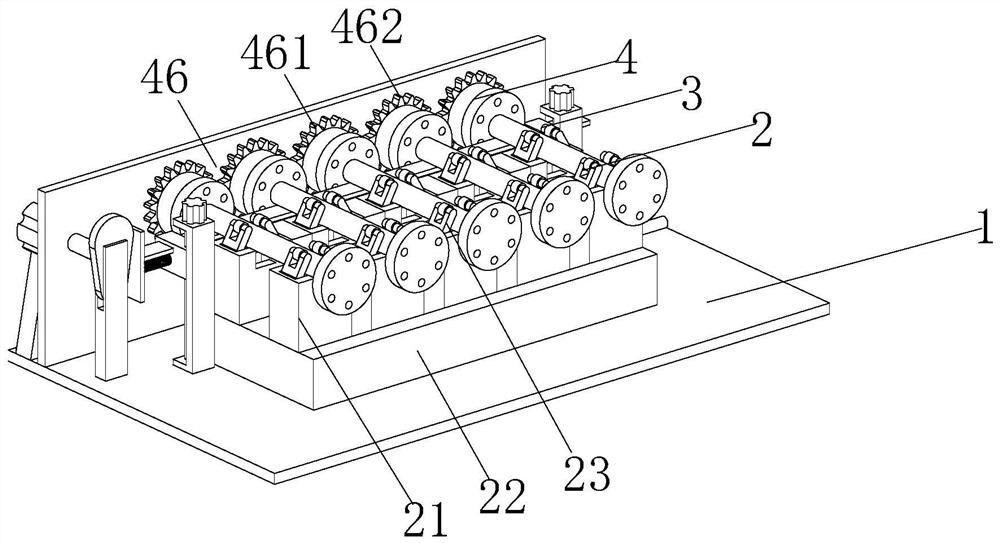

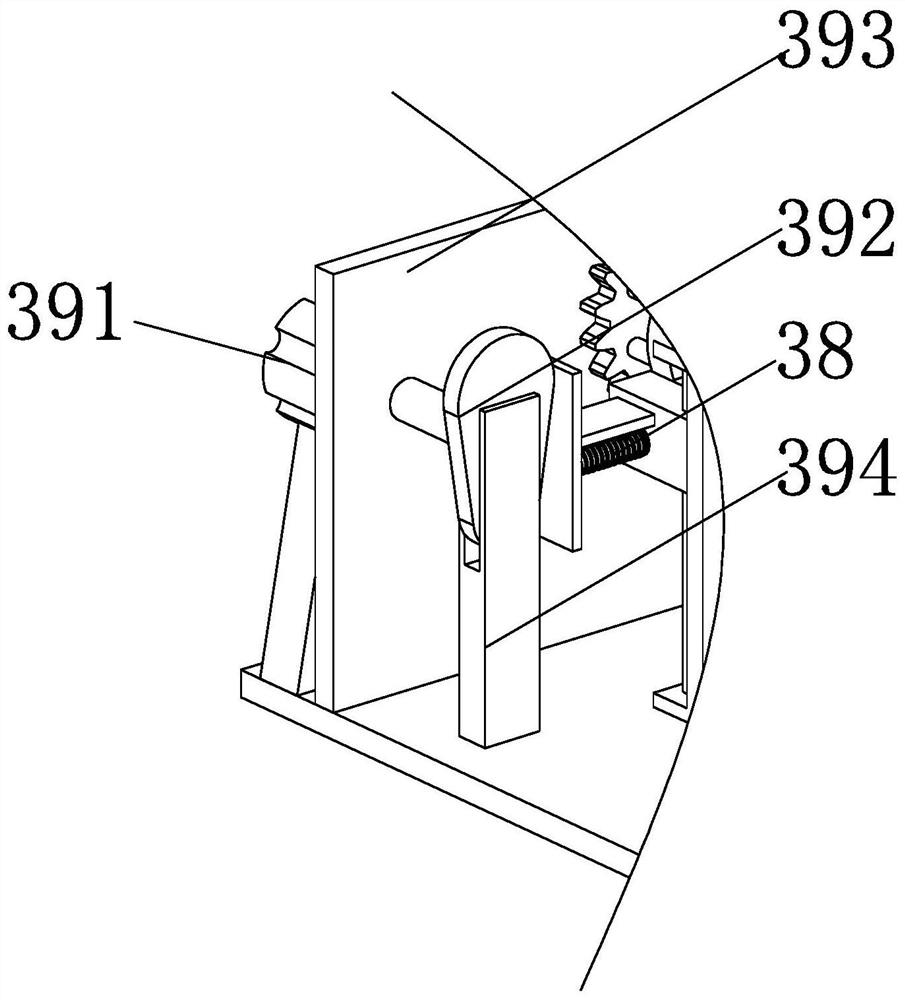

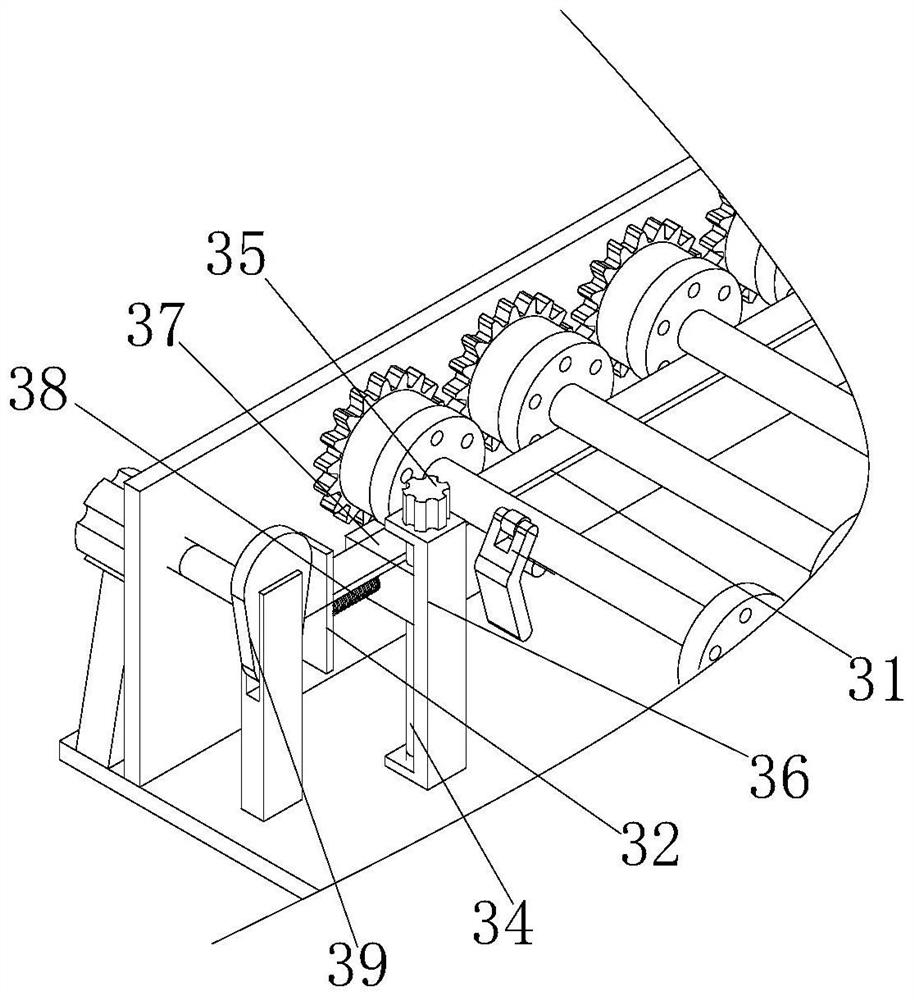

Automatic bamboo slicing machine

ActiveCN111873086AFragment GuaranteeReduce processingMulti-purpose machinesCane mechanical workingEngineeringPower apparatus

The invention provides an automatic bamboo slicing machine which comprises a workbench, a cutting device, a power device, a pressing device and a grinding device. The workbench is provided with a material conveying tank; the cutting device comprises cutter assemblies; the power device comprises a driving assembly, a pushing assembly and a guiding assembly; the pressing device comprises a pressingassembly, a control assembly and a transmission assembly a; and the grinding device comprises grinding assemblies, limiting assemblies, a transmission assembly b and a transmission assembly c. According to the automatic bamboo slicing machine, the two grinding assemblies are symmetrically arranged on the two sides of the material conveying tank in a sliding manner, the two cutter assemblies whichcoincide front and back and rotate are installed at the tail end of the material conveying tank, thin bamboos abut against the grinding assemblies when passing through the material conveying tank, andthe two cutter assemblies coincide for slicing; and thick bamboos abut against the grinding assemblies when passing through the material conveying tank, then the cutter assemblies are driven by the transmission assembly b and the transmission assembly c to rotate, then the two sets of cutter assemblies are staggered for slicing, and the technical problem that in the prior art, the bamboos with different thicknesses can only be sliced into single sizes, and consequently the sizes of bamboo chips are different is solved.

Owner:阜阳汇中芯自动化技术有限公司

Surface cutting-off device for log treatment

ActiveCN109366662APlay a reassuring roleReduce occupancyTree debarkingBark-zones/chip/dust/waste removalEngineeringAutomatic processing

The invention relates to the technical field of wood treatment, and discloses a surface cutting-off device for log treatment. The device comprises a base, two pairs of first hinge bases are hinged tothe upper portion of the base, telescopic devices are fixedly arranged on the first hinge bases, second hinge bases are fixedly arranged at the driving tail ends of the telescopic devices, a pipe bodyis hinged to the second hinge bases, and a feeding port is integrally formed in the front end of the pipe body. According to the surface cutting-off device for log treatment, the designed pipe body can play a certain centering role, a log can be rapidly peeled and subjected to surface treatment by the aid of an annular crushing knife, then the log is cut into cylinders with the equal diameter, moreover, automatic discharging of chips can be achieved in the cutting process, and external automatic feeding equipment is combined to achieve the purpose of automatic processing, so that the occupation of labor force is effectively reduced; and the device is simple to use and operate, high in efficiency and easy to carry and arrange, so that the quite high practicability is achieved.

Owner:泰和县祥峰木艺制品有限公司

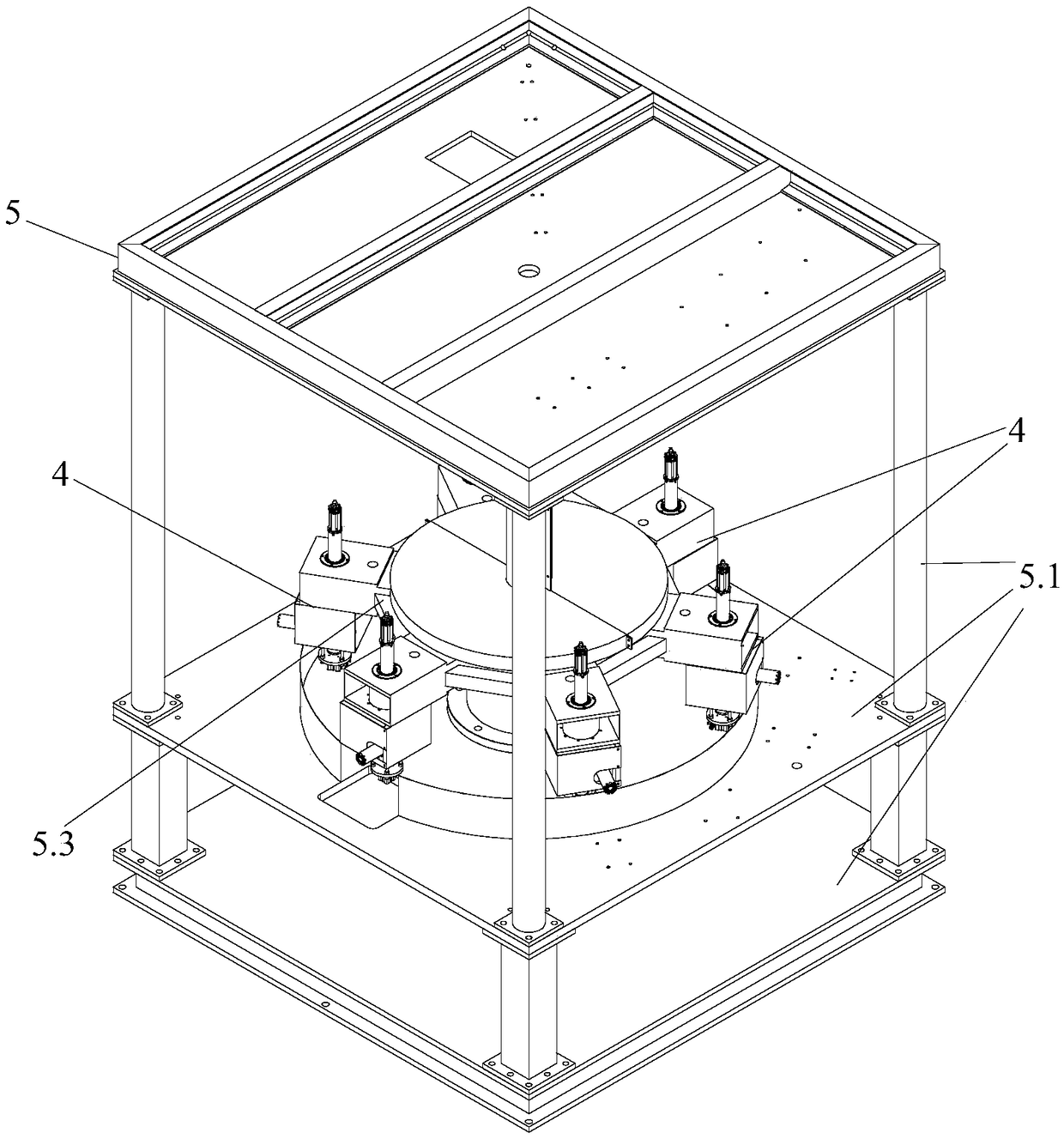

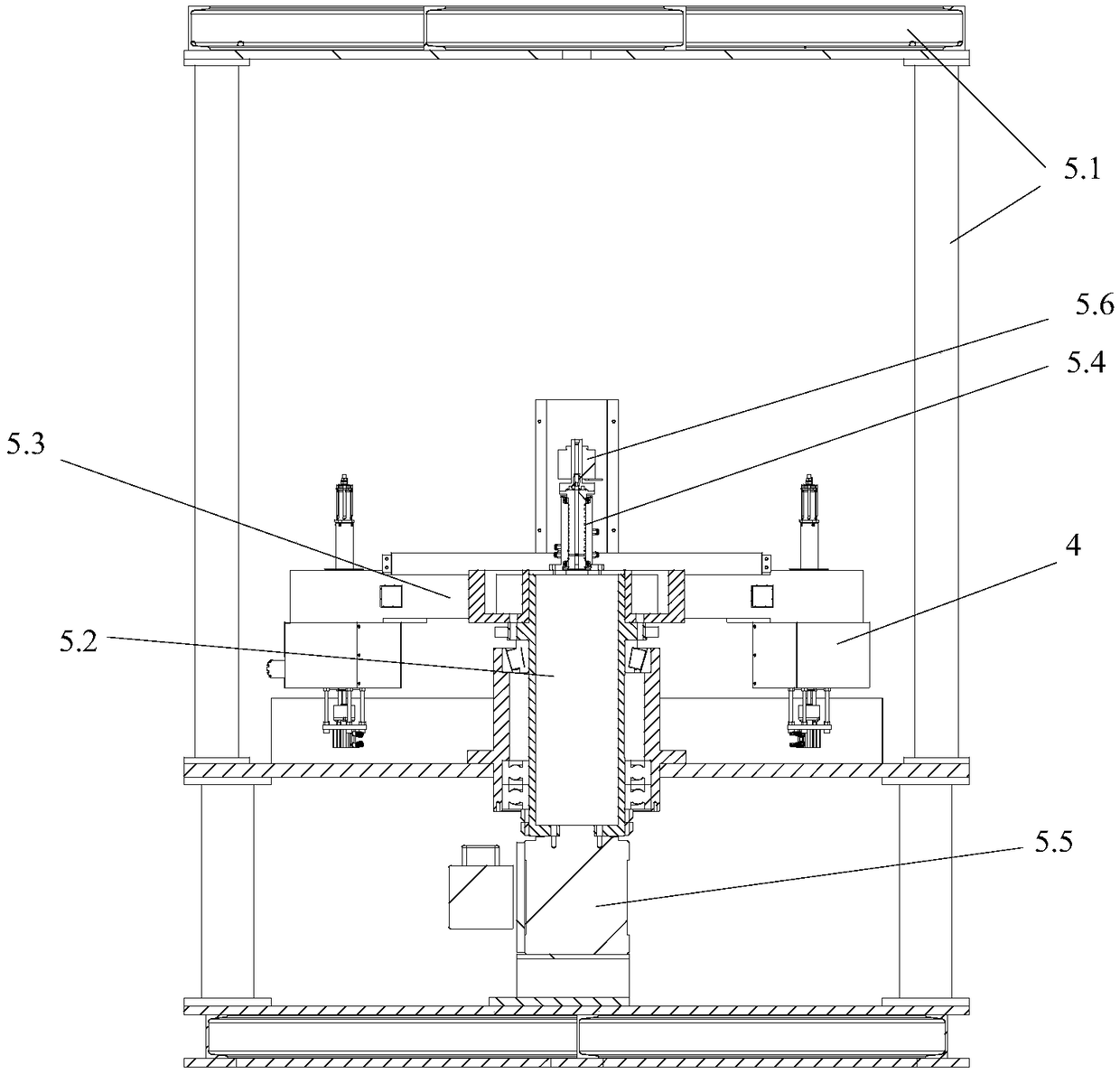

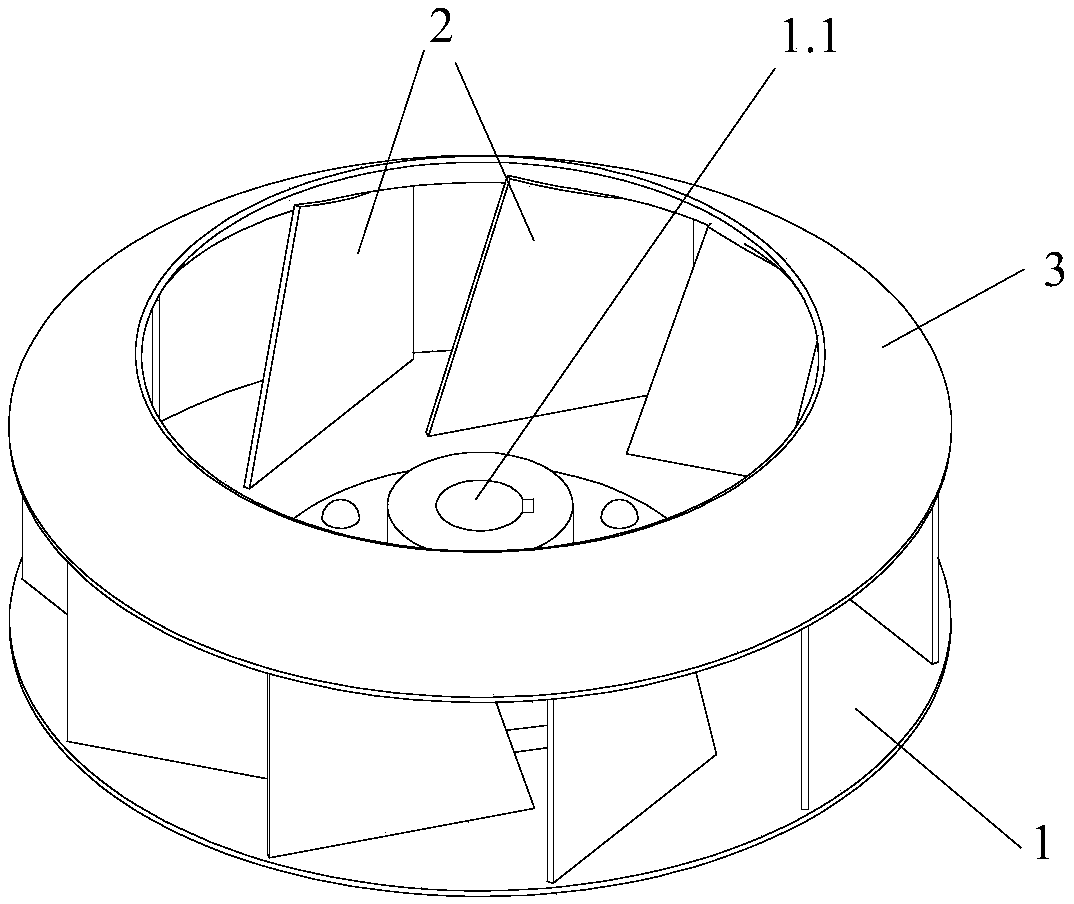

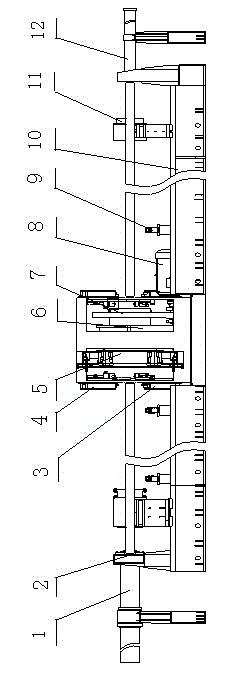

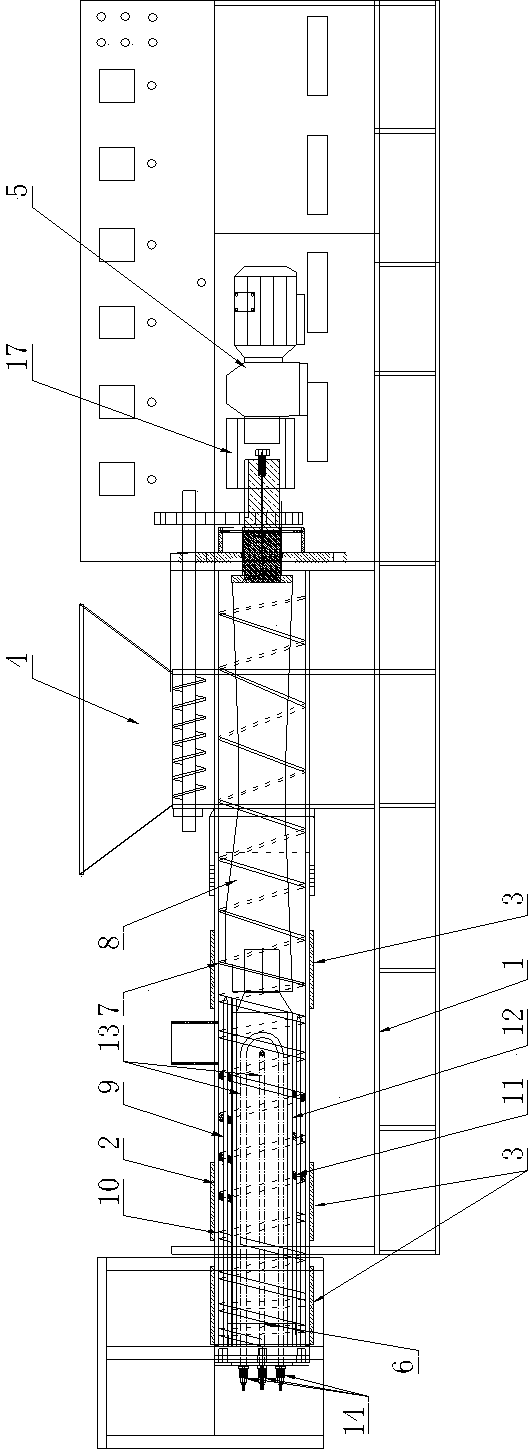

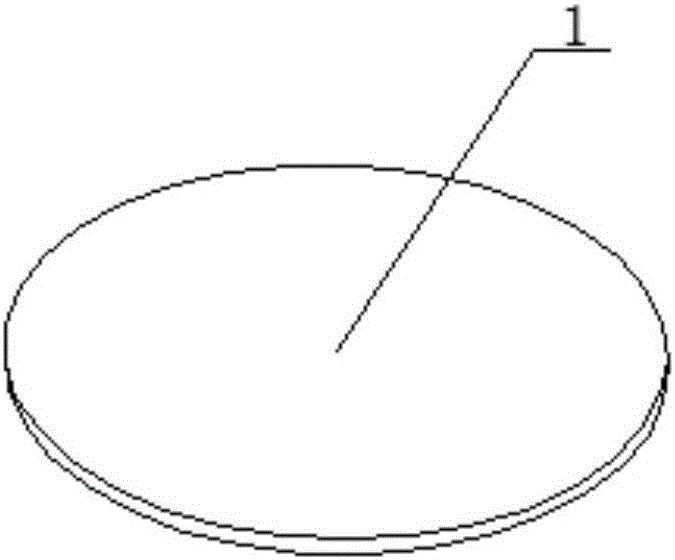

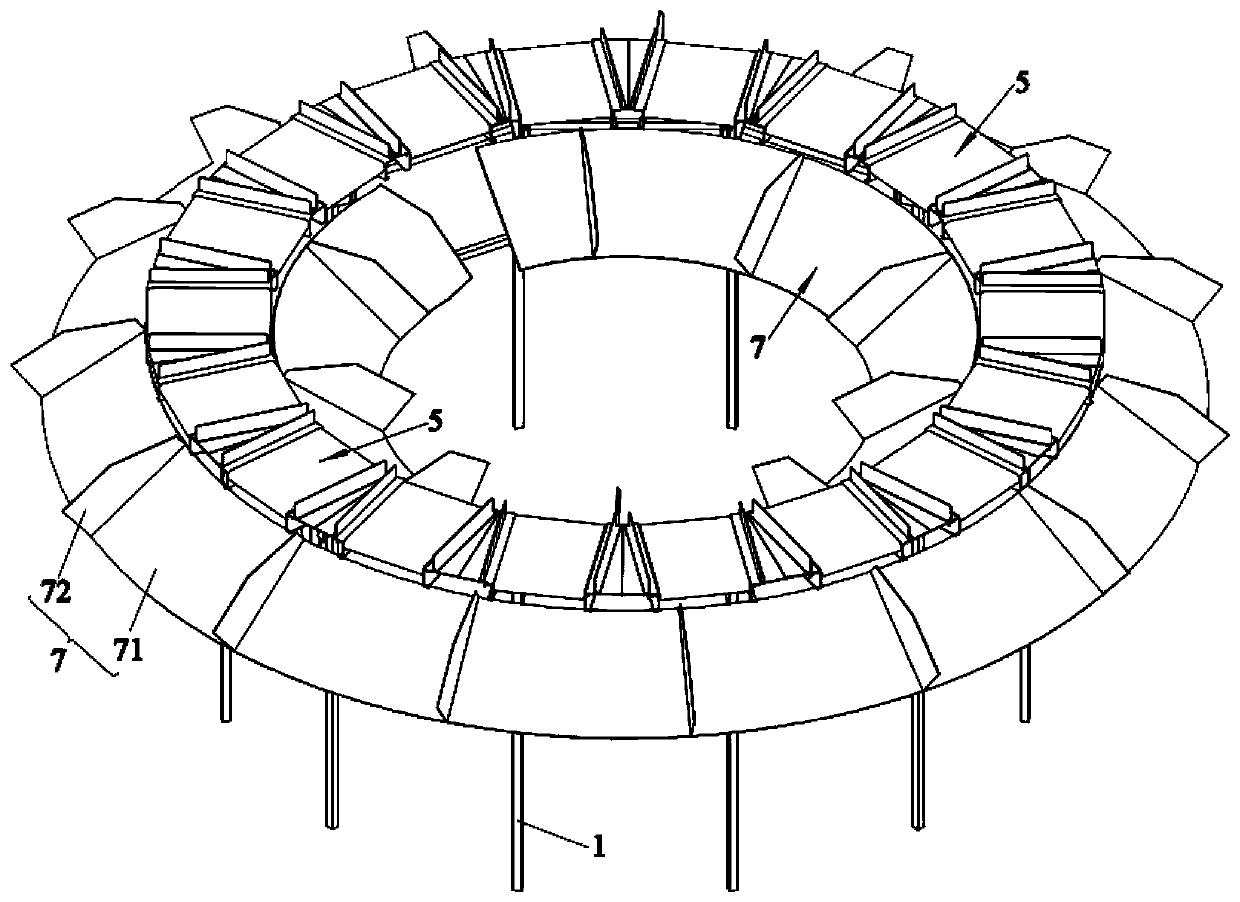

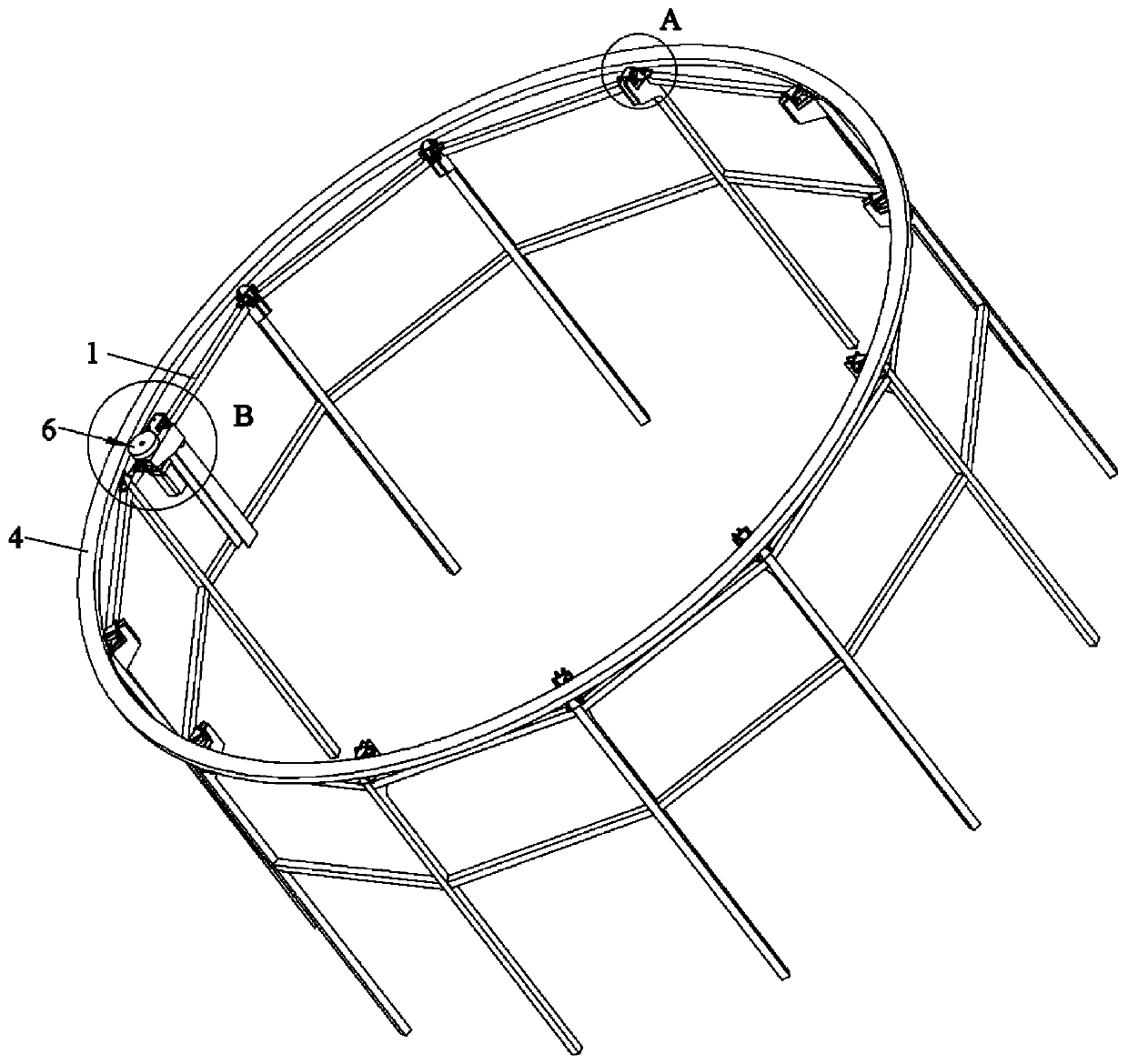

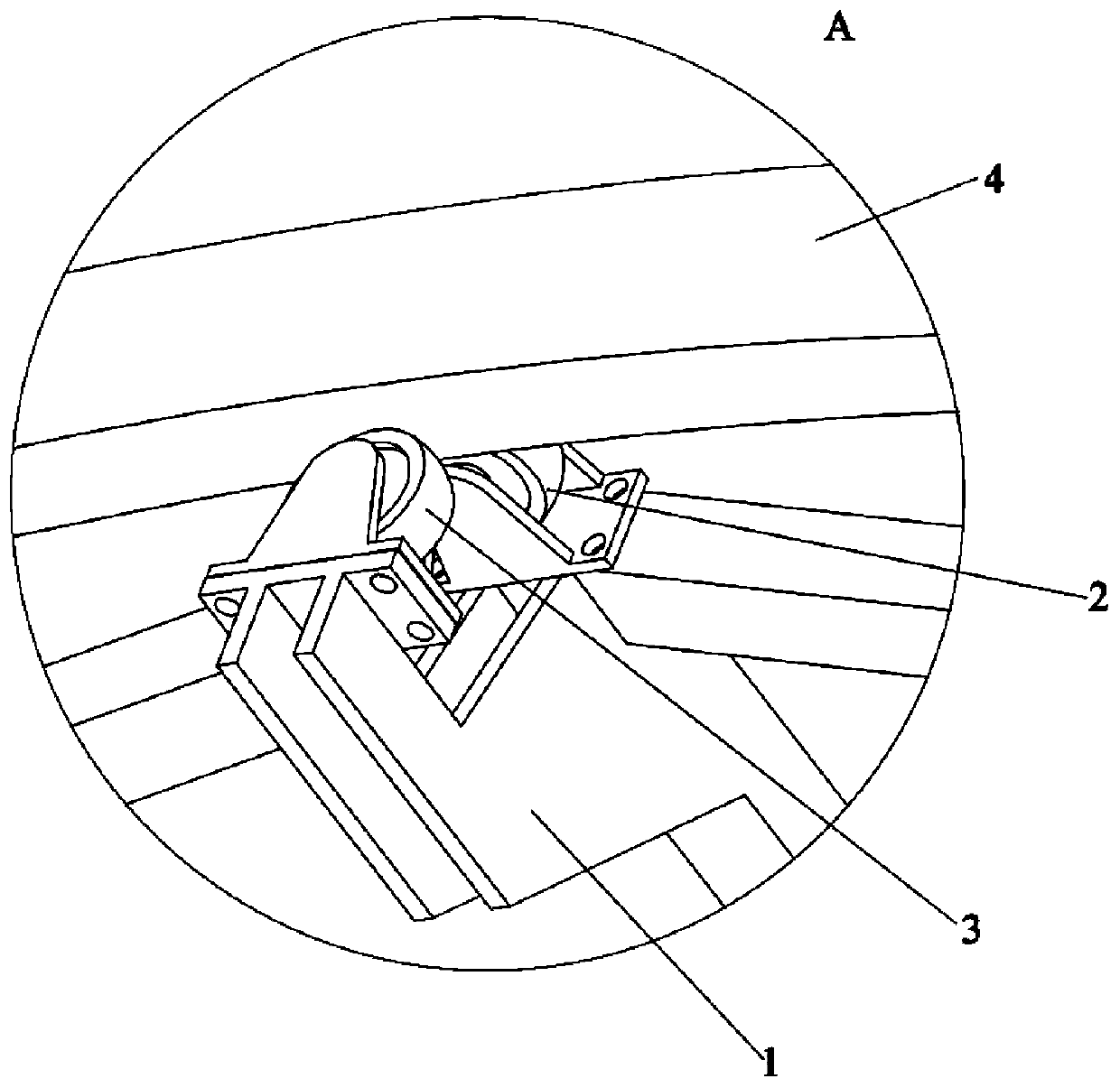

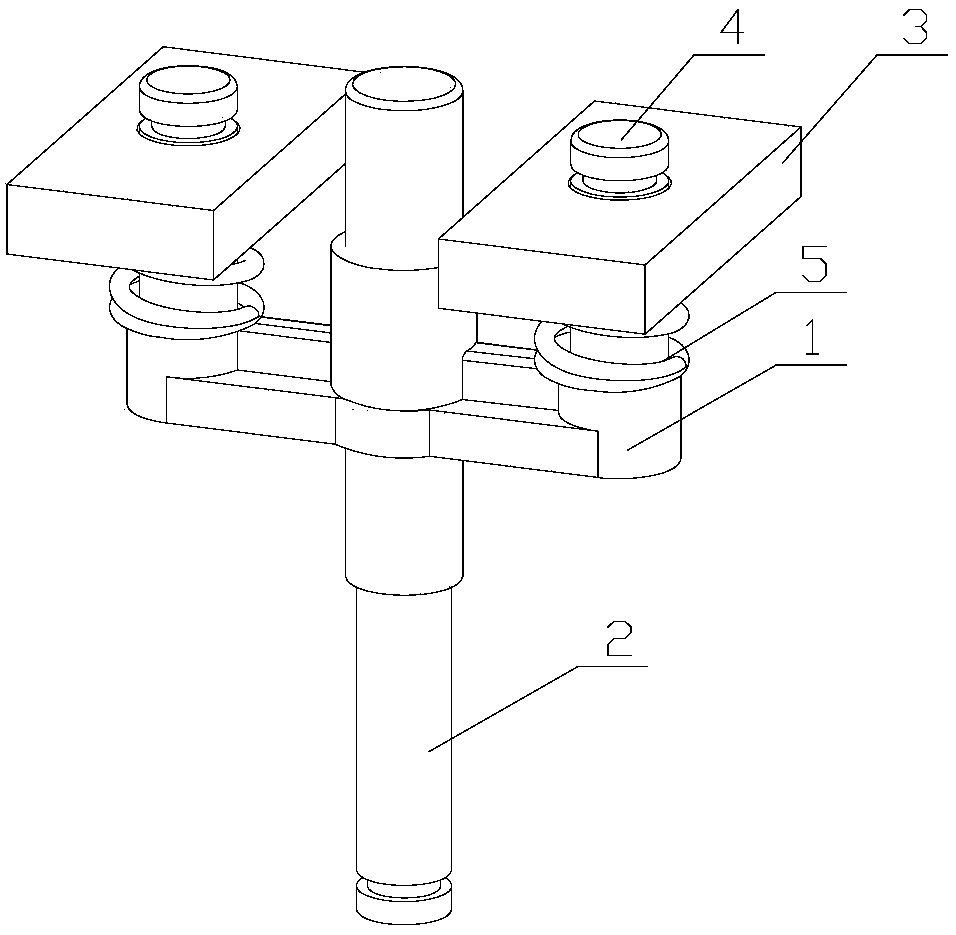

Multi-station full-automatic welding equipment for fan impeller machining

PendingCN109262189ASolve efficiency problemsImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesImpellerWork in process

The invention provides multi-station full-automatic welding equipment for fan impeller machining. The multi-station full-automatic welding equipment comprises chassis positioning mechanisms, a main frame mechanism, a blade and chassis assembling positioning mechanism located at a second machining station, a first welding mechanism used for welding blades and a chassis at a second machining station, a top cover feeding mechanism located at a third machining station, a second welding mechanism used for conducting spot welding on top covers and the blades on the third machining station, a turningmechanism located on a fifth machining station, a third welding mechanism used for conducting all welding on the turned top cover welding semi-finished products and turned blade welding semi-finishedproducts on the fifth machining station, so that a fan impeller finished product is obtained and a discharging mechanism. The chassis positioning mechanisms are separately connected with the main frame mechanism. According to production demands, full-automatic welding can be conducted on the fan impeller to replace a traditional manual welding technology, and therefore welding efficiency, weldingquality and welding precision are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

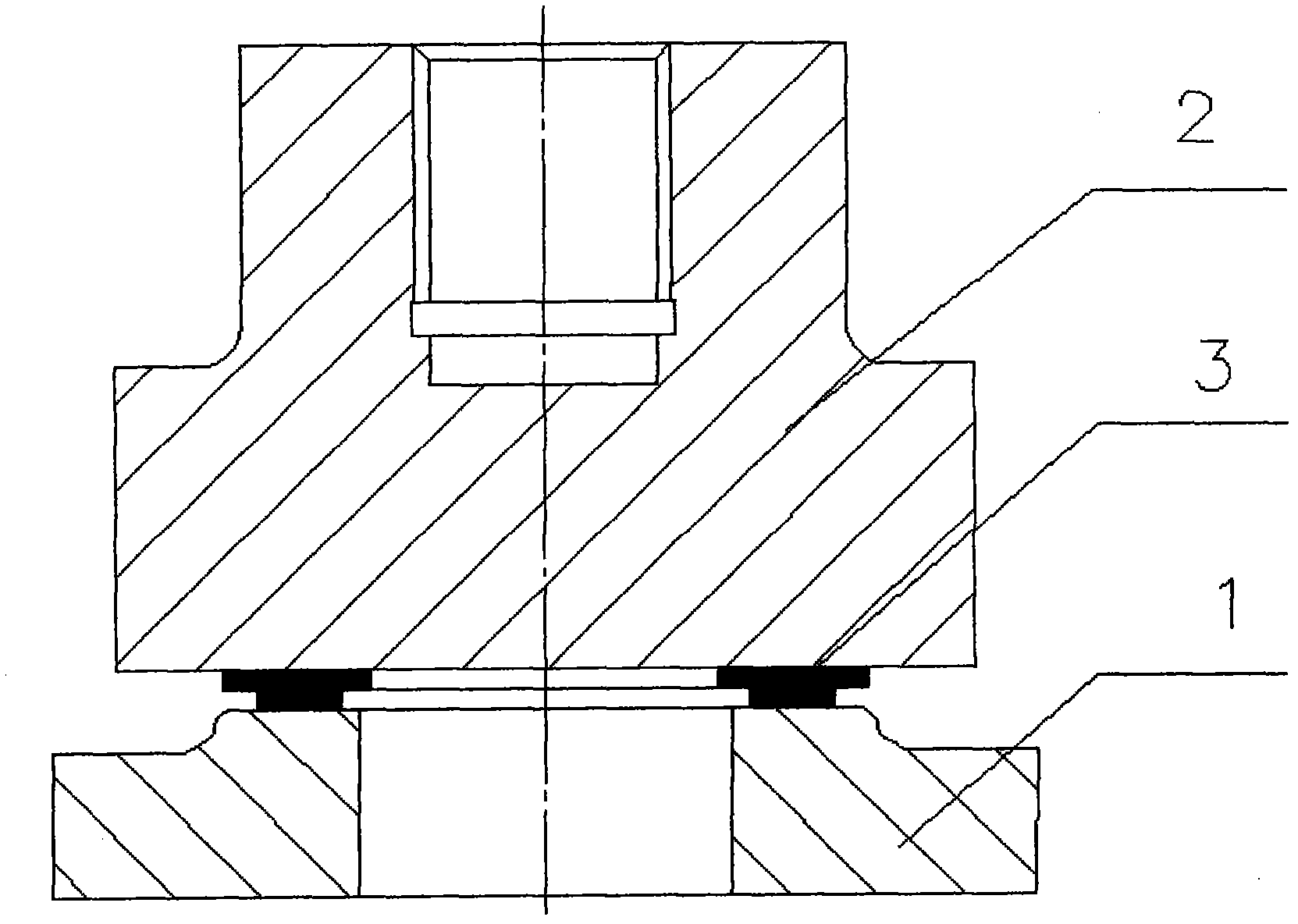

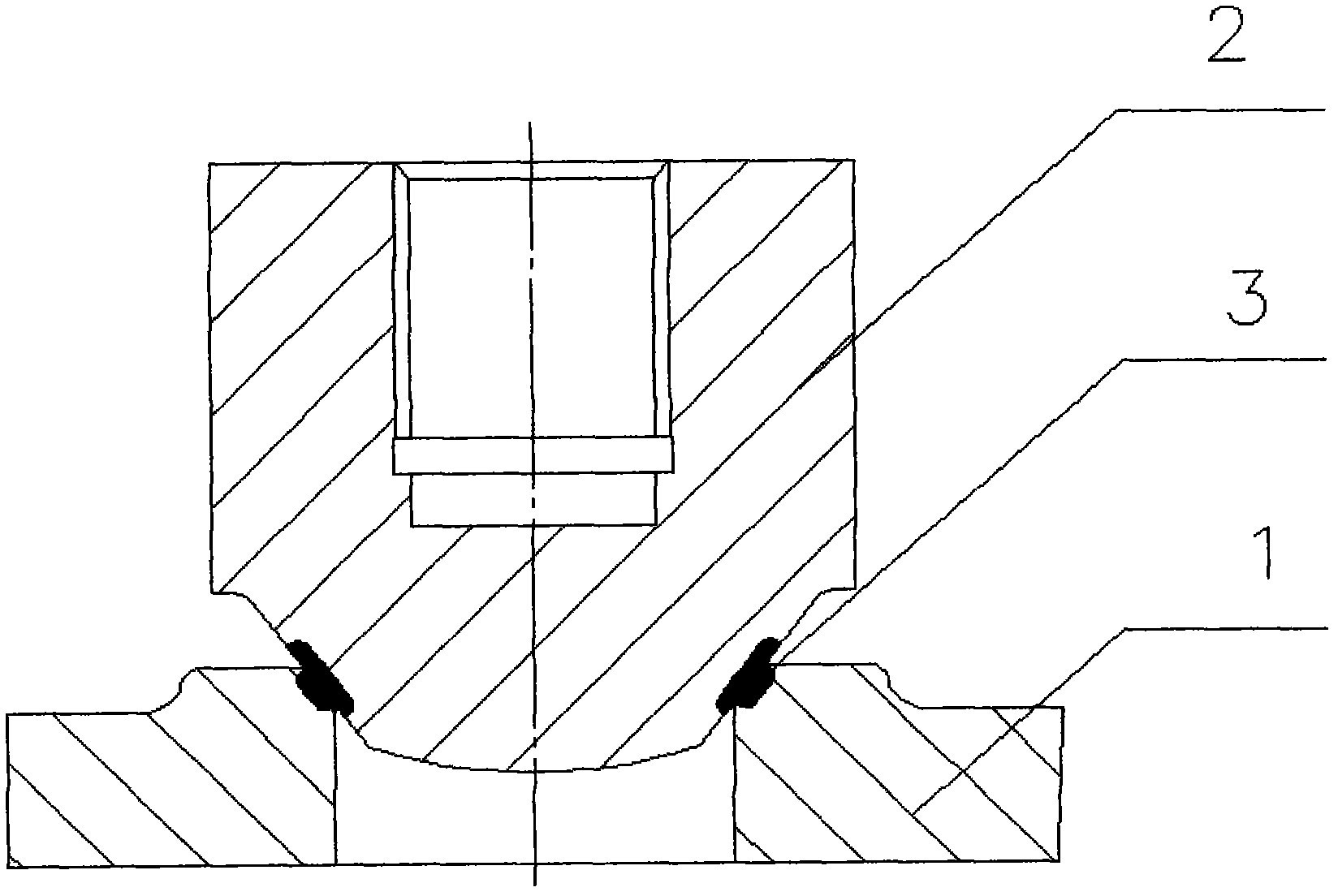

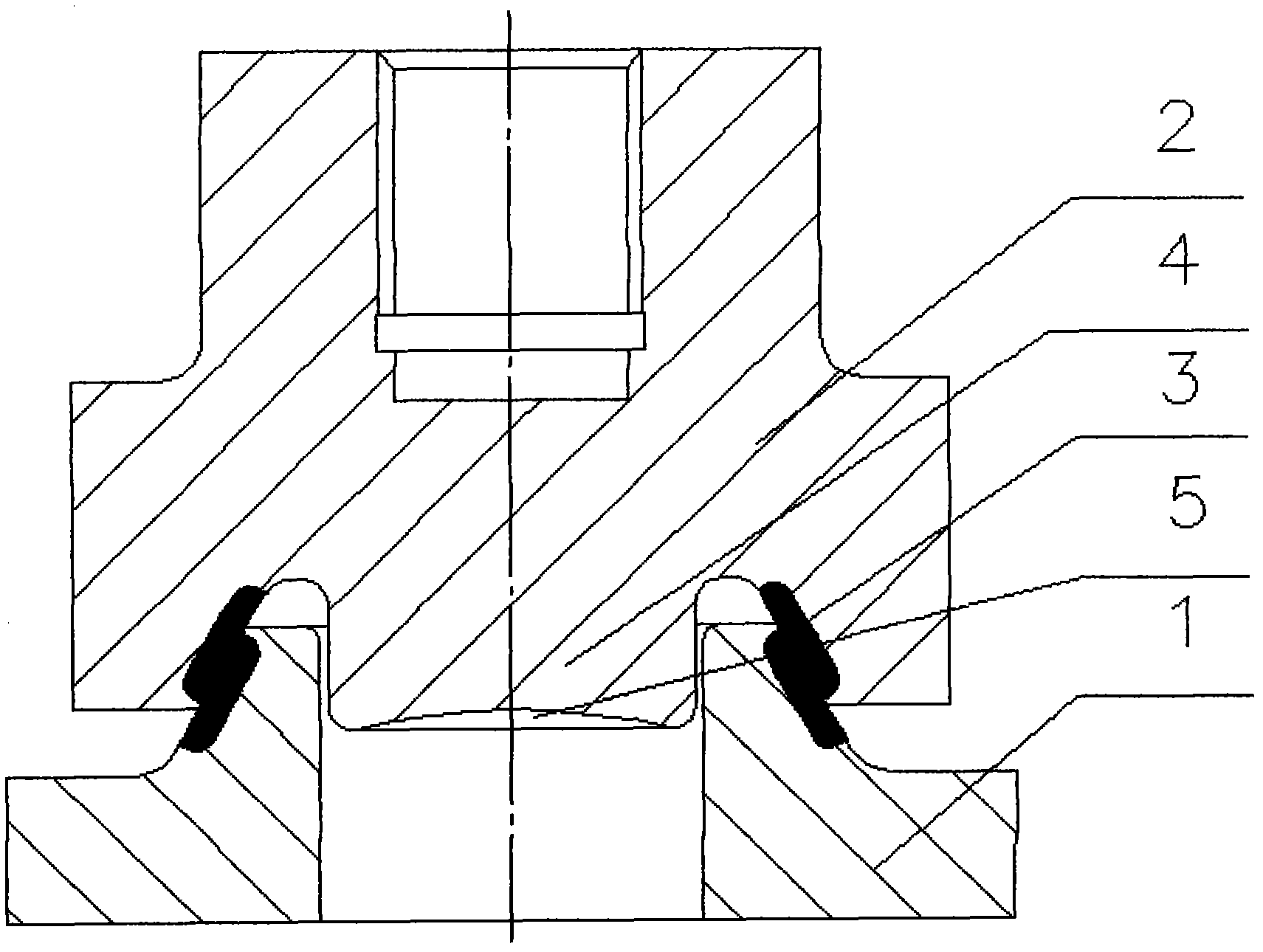

Erosion-prevention stop valve seal pair

The invention relates to an erosion-prevention stop valve seal pair which comprises a valve seat and a valve clack which are corresponding to each other; the seal surface of the valve seat is an outer conical surface; the seal surface of the valve clack is an inner conical surface which is matched with the outer conical surface; the center of the valve seat is provided with a valve seat hole; thecentral part of the inner conical surface of the valve clack is provided with a column structure which can insert in the valve seat hole; the lower end surface of the column structure is set into an arc-shaped concave surface and lower than the seal surface of the valve clack. According to the invention, on the basis of keeping the original seal effect of the stop valve seal pair, the erosion andcorrosion of a medium to the seal surface is relieved, thus the seal ring is always protected, the seal effect is more reliable, and the erosion-prevention stop valve seal pair is especially suitablefor the flow rate control of high-temperature high-pressure gas media.

Owner:SUNGO VALVES GRP CO LTD

Tool for turning excircle of transmission shaft universal joint fork and method for positioning and centering universal joint fork

ActiveCN102211283ASimple structureEasy to useAuxillary equipmentPositioning apparatusUniversal jointDrive shaft

The invention discloses a tool for turning the excircle of a transmission shaft universal joint fork. The tool comprises a connecting flange and a tailstock center which are arranged on an external machine tool, wherein the connecting flange is connected with a V-shaped block; a V-shaped groove in press fit with the two lug parts of the universal joint fork is formed on the V-shaped block; one end of the tailstock center is provided with a centering part matched with an inner nest of the universal joint fork; and a press center matched with a central nest of the universal joint fork is convexly arranged in the center of the centering part. The centering part is matched with the inner nest, so that the inner nest with relatively high blank quality can be used as a centering standard to achieve a better centering effect; and the press center is matched with the central nest of the universal joint fork, so that the universal joint fork can be firmly pressed on the V-shaped block through the press center. The invention also discloses a method for positioning and centering the universal joint fork by using the tool for turning the excircle of the transmission shaft universal joint fork. The better centering effect can be achieved; meanwhile, press operation is simple and convenient, and work efficiency is improved.

Owner:XUCHANG YUANDONG DRIVE SHAFT

Thin-walled part slider type vehicle clamp

InactiveCN104308576APlay a reassuring roleWork clamping meansPositioning apparatusCircular discCircular cone

The invention relates to a thin-walled part slider type vehicle clamp, wherein a right nut, a right cone, right sliders, a support plate, a right lining, a left cone, left sliders, a disc and a left nut sleeve a mandrel from right to left in sequence; the support plate and the disc are fixedly connected by a connecting rod; a right guide plate is arranged on each right slider; the right sliders are in sliding fit with the support plate through the right guide plates; each right slider comprises two small sliders which are connected by a spring; the plurality of right sliders are arranged along the circular conical surface of the right cone; the support plate is fixed on the mandrel by the right lining; the disc is fixed on the mandrel; the plurality of left sliders are arranged along the circular conical surface of the left cone on the disc; a left guide plate is arranged on each left slider; each left slider comprises two small sliders which are connected by a spring. The thin-walled part slider type vehicle clamp disclosed by the invention can clamp thin-walled part workpieces conveniently.

Owner:蒋飞雪

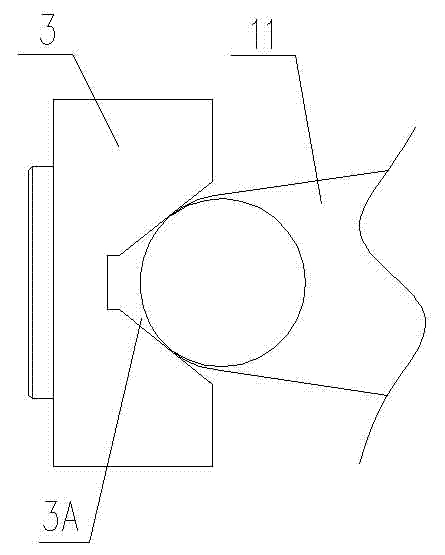

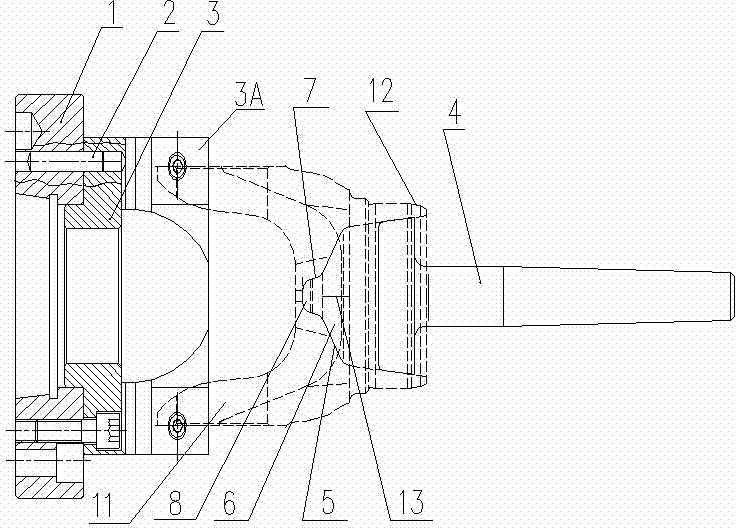

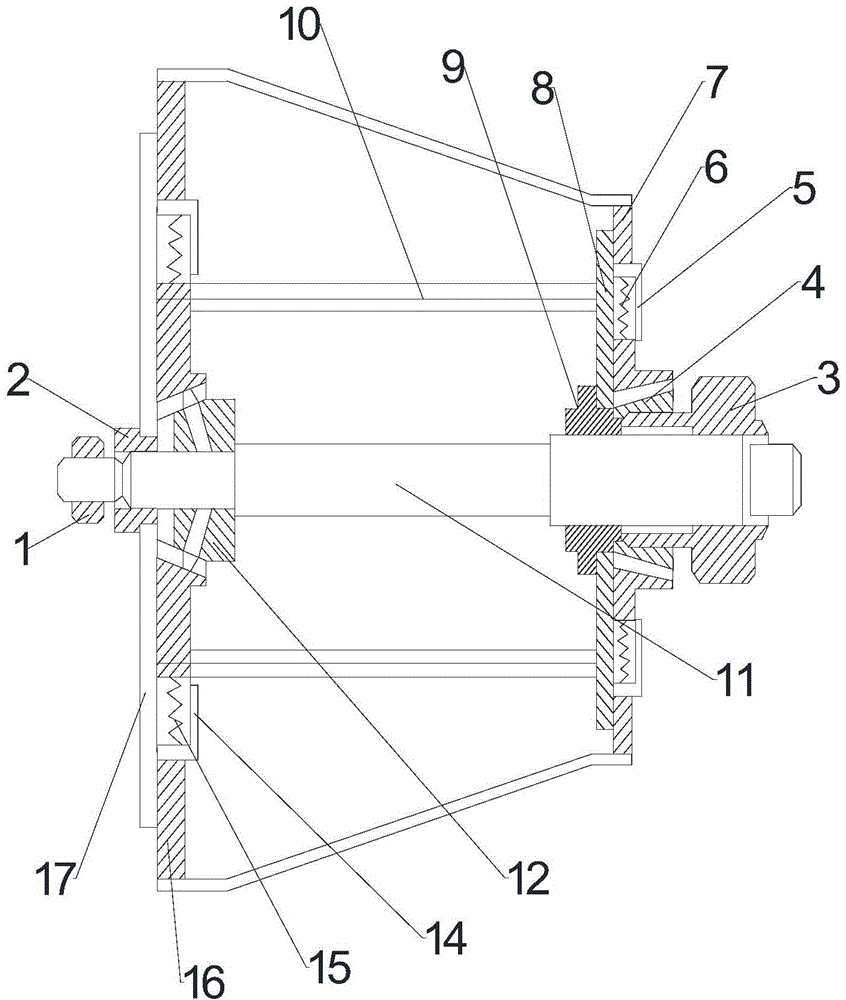

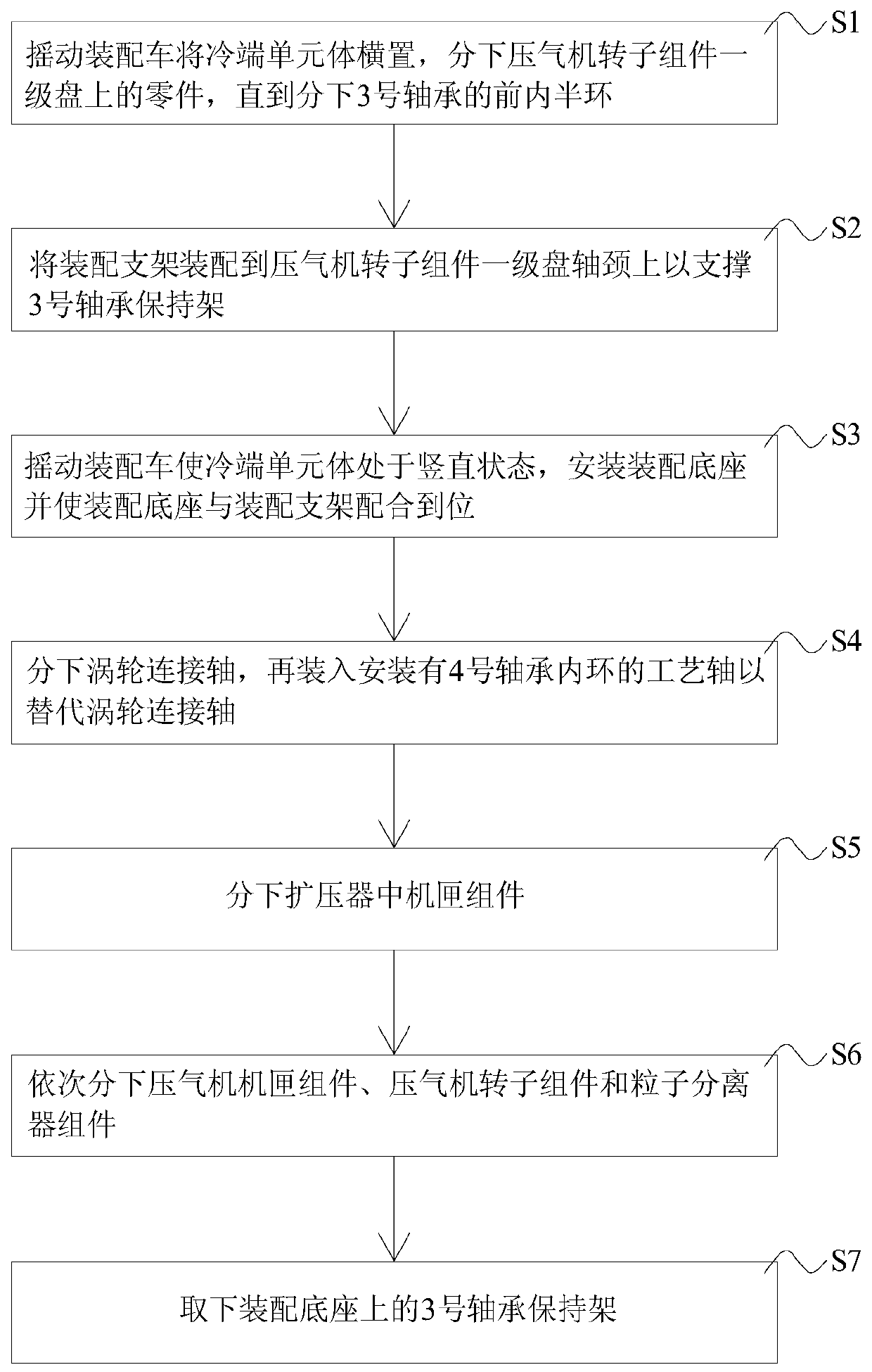

Disassembling method of cold-end unit body

ActiveCN110497169APlay a reassuring roleCentering effect maintainedMetal working apparatusTurbineCenter effect

The invention discloses a disassembling method of a cold-end unit body. According to the disassembling method of the cold-end unit body, a third bearing retainer is supported by an assembling bracketand an assembling base sequentially, thus, a third bearing can maintain the centering effect in the disassembling process, after a turbine connecting shaft is disassembled, a process shaft provided with a fourth bearing inner ring is used for replacing the turbine connecting shaft, therefore, the fourth bearing can maintain the centering effect, then a casing assembly in a diffuser, a compressor casing assembly, a compressor rotor assembly and a particle separator assembly are disassembled in sequence, and finally the third bearing retainer on the assembling base is taken down. According to the disassembling method of the cold-end unit body, the third bearing and the forth bearing maintain the centering effect in the entire disassembling process, the problems of rotor jamming, rotor and stator axial abrasion and falling-off of the third bearing retainer are avoided in the disassembling process, the reliability, stability and safety of the disassembling process are improved, and the scientific research and production progresses are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

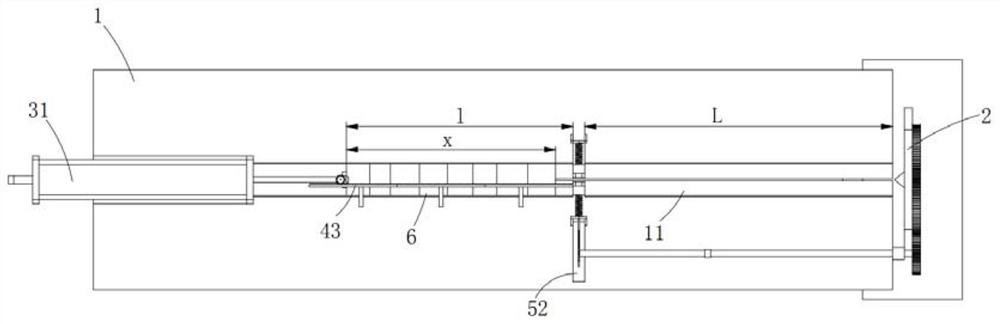

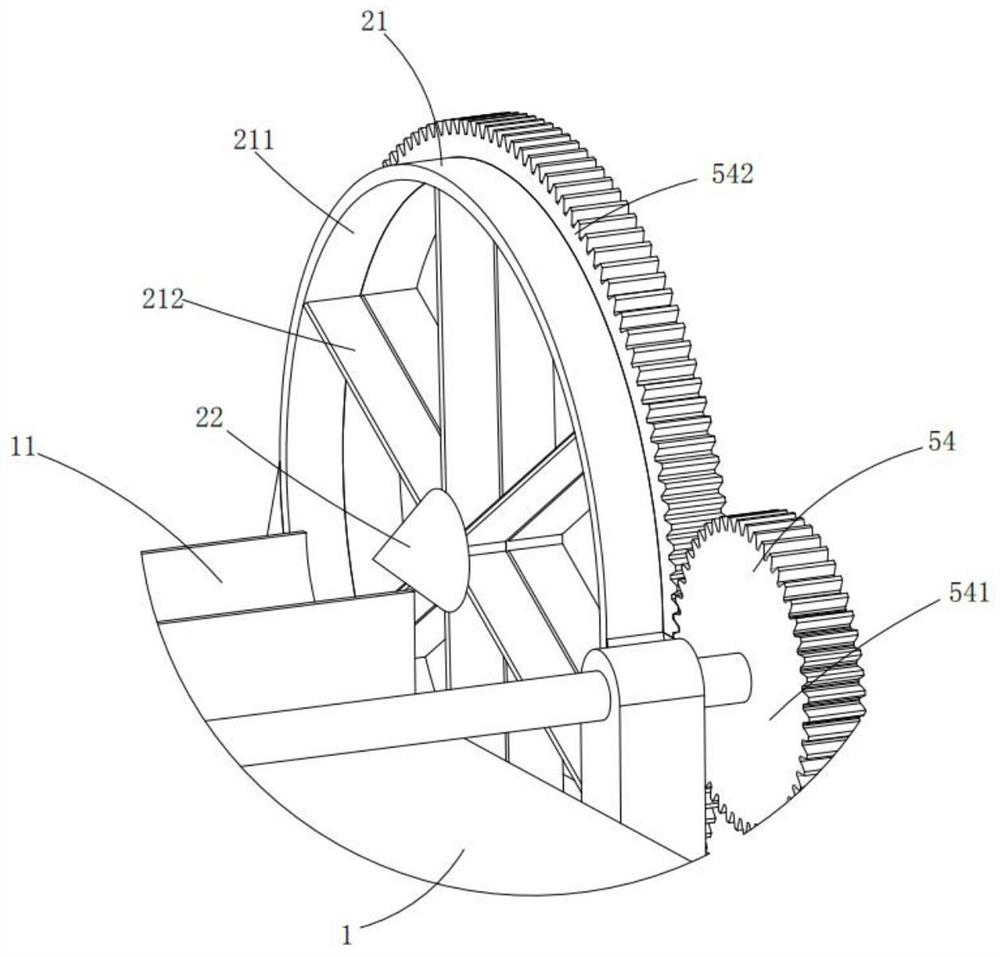

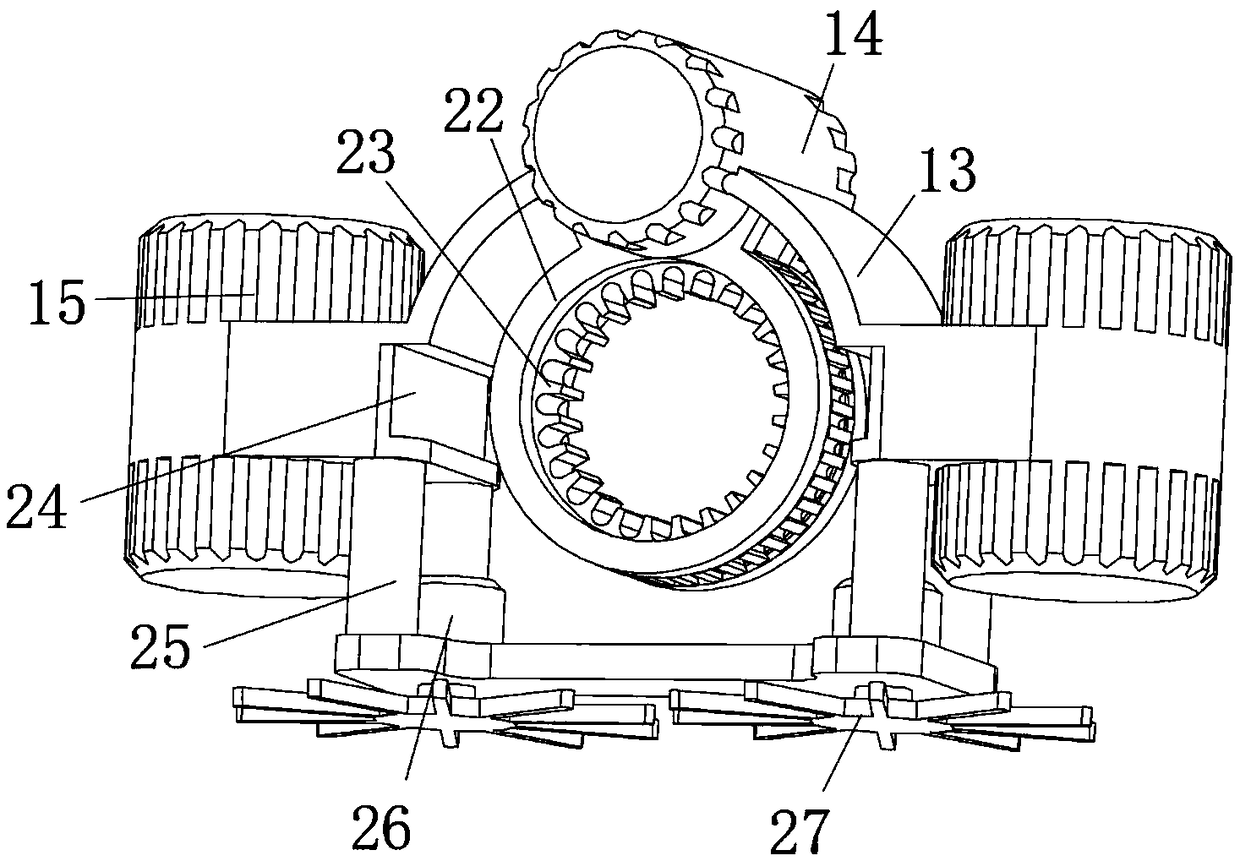

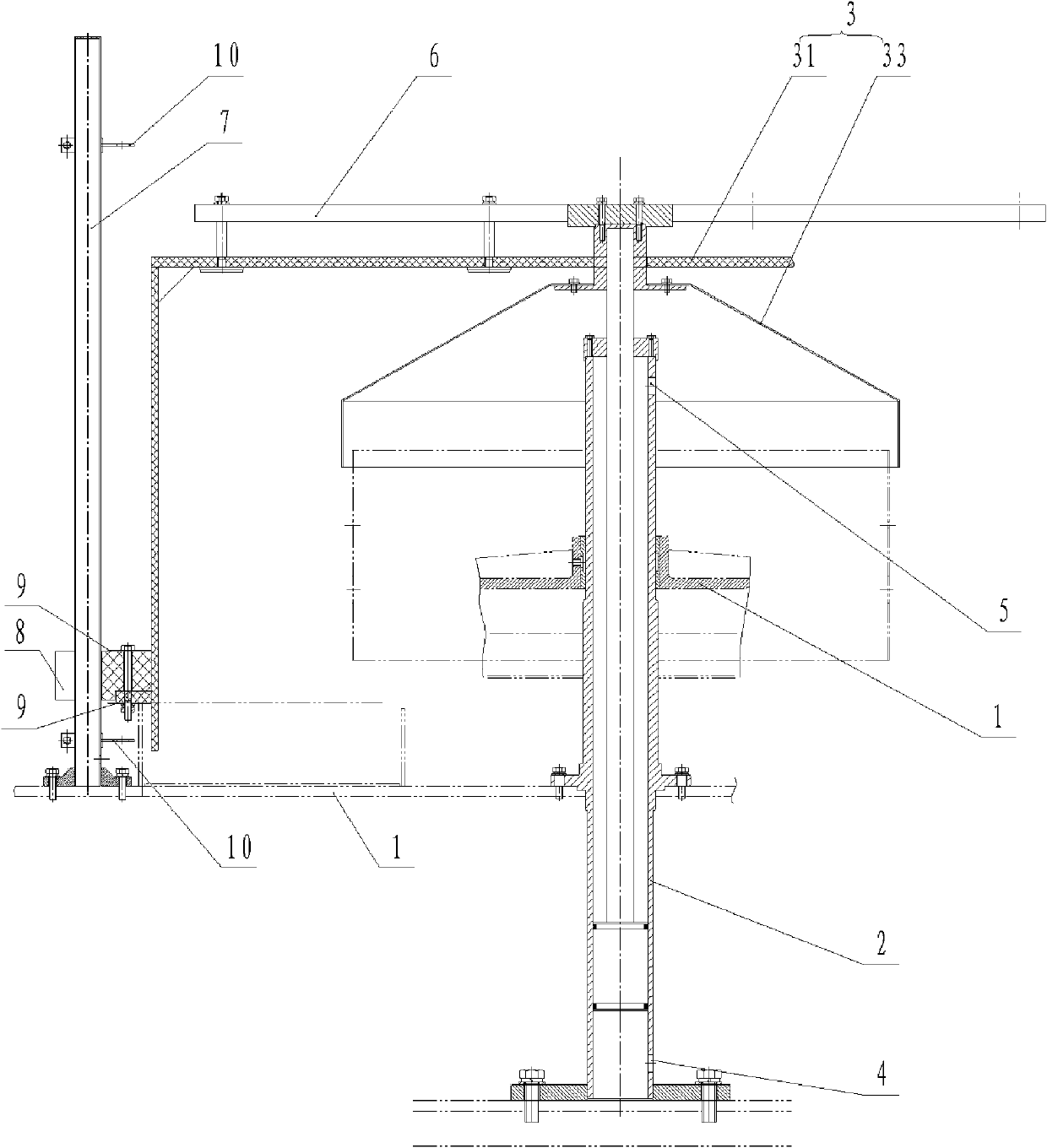

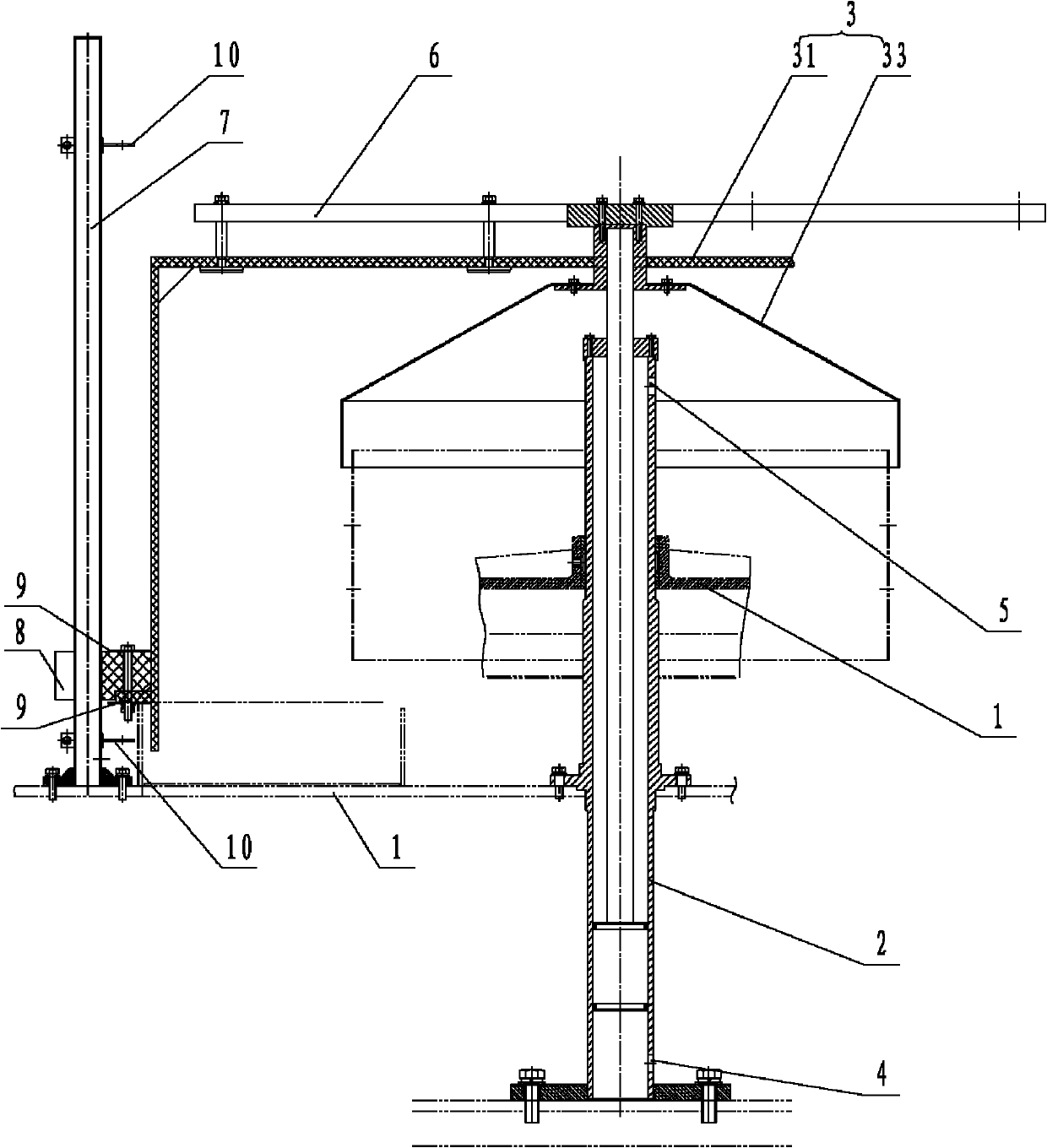

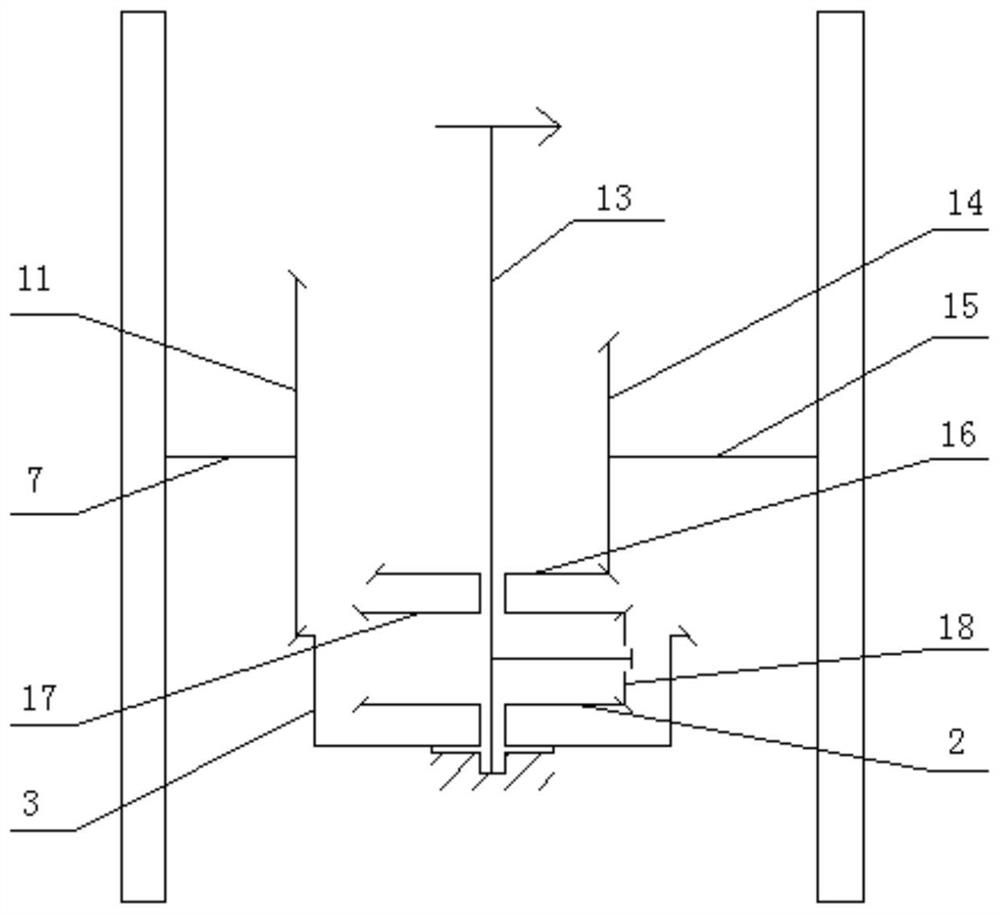

Horizontal type planet powerful spinning machine with four spinning rollers

A horizontal type planet powerful spinning machine with four spinning rollers is applied to the press working industry and comprises a main motion oil cylinder, a main motion sliding block, a front and back center frame, a material return device, a planet four-wheel spinning device, a supporting bearing block, a transmission device, a main motor, a supporting frame, a lathe bed, a tail ejection device and a tail ejection oil cylinder. The main motion oil cylinder is connected with the main motion sliding block, the front and back center frame and the material return device are connected with the planet four-wheel spinning device, the supporting bearing block is connected with the transmission device and mounted on the lathe bed, the transmission device is connected with the main motor, and the tail ejection device is connected with the tail ejection oil cylinder. Multiple adjustable material supporting devices are arranged on the lathe bed of the spinning machine, so that tube blanks are prevented from deforming due to self weight, a centering mechanism is arranged at the front end of the tail ejection device and plays a role in centering a core die, a planetary rotating device can conduct stepless speed regulation under dragging of a DC machine, the oil cylinders at the front end and the rear end synchronously move in the axial direction for stepless speed regulation, and four spinning rollers of a four-spinning-roller rigidity synchronizer adjust the feed distance and iso-wall thickness spinning of the spinning machine mechanically and synchronously.

Owner:扬州中旋机械科技有限公司

Plastic extruder

The invention provides a plastic extruder, which can solve the problems that a traditional plastic extruder cannot stir raw materials sufficiently, and the power consumption of a motor is large. With the plastic extruder, the extrusion quality is ensured, and the production cost is reduced. A feeding device is arranged on a machine barrel; an external heating device is arranged on the periphery of the machine barrel in sections; screw blades extending along the axial direction is arranged on the periphery of a screw. The plastic extruder is characterized in that the screw comprises a feeding section screw rod and a discharge section screw rod connected with each other in the axial connection; the feeding section screw rod is coupled to an output shaft of a drive motor; one end of the discharge section screw rod is connected with the feeding section screw rod while the other end of the discharge section screw rod is connected with an extrusion die of the discharge hole section of the machine barrel; the discharge section screw rod is in the shape of a hollow barrel; a screw blade extending along the axial direction is arranged on the outer periphery of the feeding section screw rod; screw blades which are in the same direction as the screw blade at the outer periphery of the feeding section screw rod are arranged on the outer periphery and the inner periphery of the hollow barrel-shaped discharge section screw rod; the screw blade at the outer periphery of the feeding section screw rod and the screw blade at the outer periphery of the discharge section screw rod are connected to form a whole body.

Owner:常熟市绿草根机械制造有限公司

Automatic feeding mechanism of double punching machines

ActiveCN105710248AAvoid damagePlay a reassuring roleMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention discloses an automatic feeding mechanism of double punching machines. The automatic feeding mechanism comprises a frame, a loading mechanism, a taking mechanism and a main controller, and is characterized by further comprising two punching machines, two thickness measurers and blank detection positioning mechanisms; the metal thickness detectors and the loading mechanism are both fixed on the frame; the taking mechanism is positioned rightly above the loading mechanism; the two ends of the frame are respectively connected with the two punching machines; the punching machines are provided with the blank detection positioning mechanisms; the metal thickness detectors are positioned in the middle positions of the punching machines and the loading mechanism; the metal thickness detectors can detect the thickness of blanks sucked on the taking mechanism so as to judge the number of the sucked blanks; and in the process of the taking mechanism conveying the blanks to the punching machines, the number of the blanks is detected to prevent the damage of molds. In addition, when the blanks are put in the molds, photoelectric detectors on the punching machines can detect if the blanks are placed precisely, so that such problems as mold damage and punching safety are further guaranteed.

Owner:ZHEJIANG UNIV OF TECH

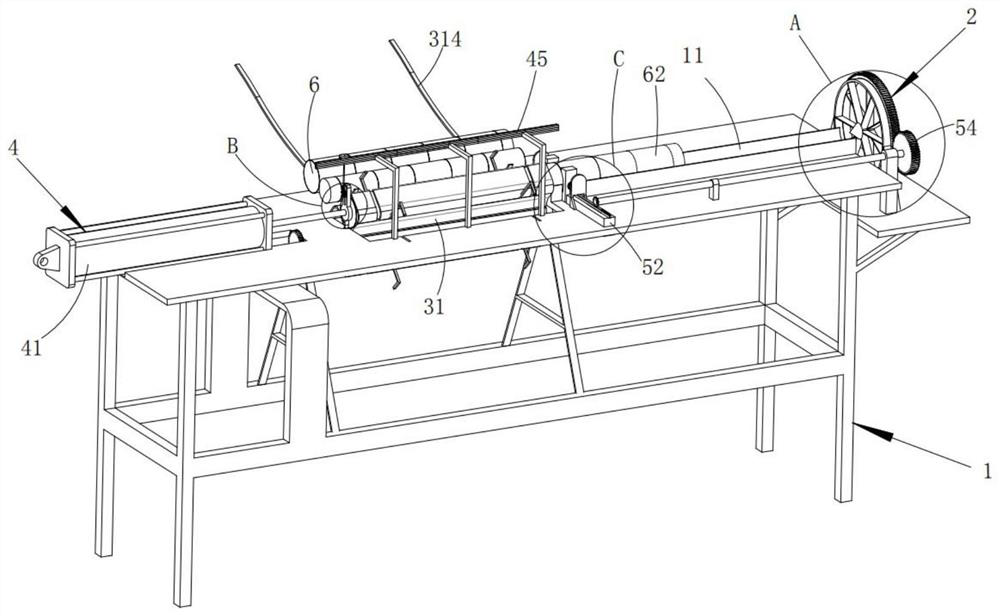

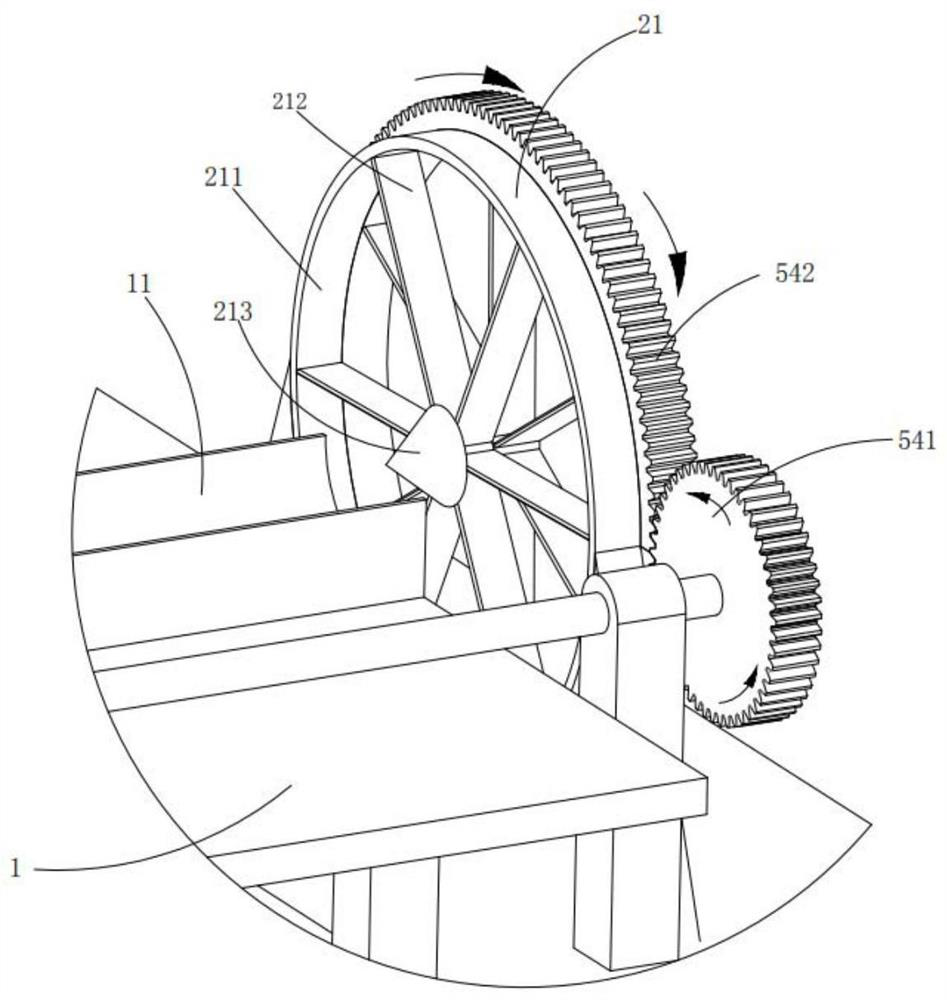

Bamboo product production equipment

ActiveCN111873087AReduce processingIncrease productivityWood splittingRevolution surface grinding machinesManufacturing engineeringMechanical engineering

The invention provides bamboo product production equipment which comprises an equipment platform, a slitting device, a feeding device, a grinding device and a detecting device. The equipment platformis provided with a material conveying tank and a material conveying pipe; the slitting device comprises a cutter assembly; the feeding device comprises a discharging rail and a slitting assembly; thegrinding device comprises a conveying belt pushing assembly, a rotating assembly, a grinding assembly and a power assembly, the detecting device comprises a limiting assembly and a stirring assembly,the slitting assembly slits bamboos into bamboo tubes with the same length and conveys the bamboo tubes into the material conveying tank, and the conveying belt pushing assembly pushes the bamboo tubes to be ground through the grinding device and then make contact with the limiting assembly; and the limiting assembly moves outwards according to the diameter of the bamboo tubes and drives the cutter assembly to rotate through the stirring assembly, the cutter assembly rotates to slit when the bamboo tubes have the large diameter, the slitting assembly coincide to slit when the bamboo tubes havethe small diameter, and the technical problem that in the prior art, the bamboos with different diameters cannot be correspondingly slit, and consequently the sizes of bamboo canes are different is solved.

Owner:山东龙图家居股份有限公司

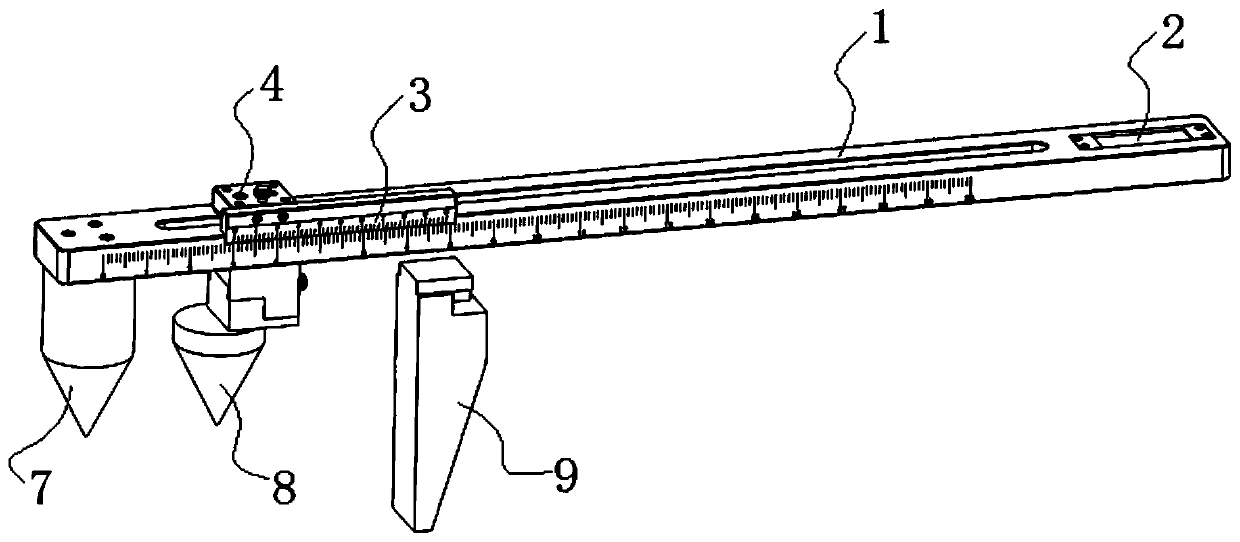

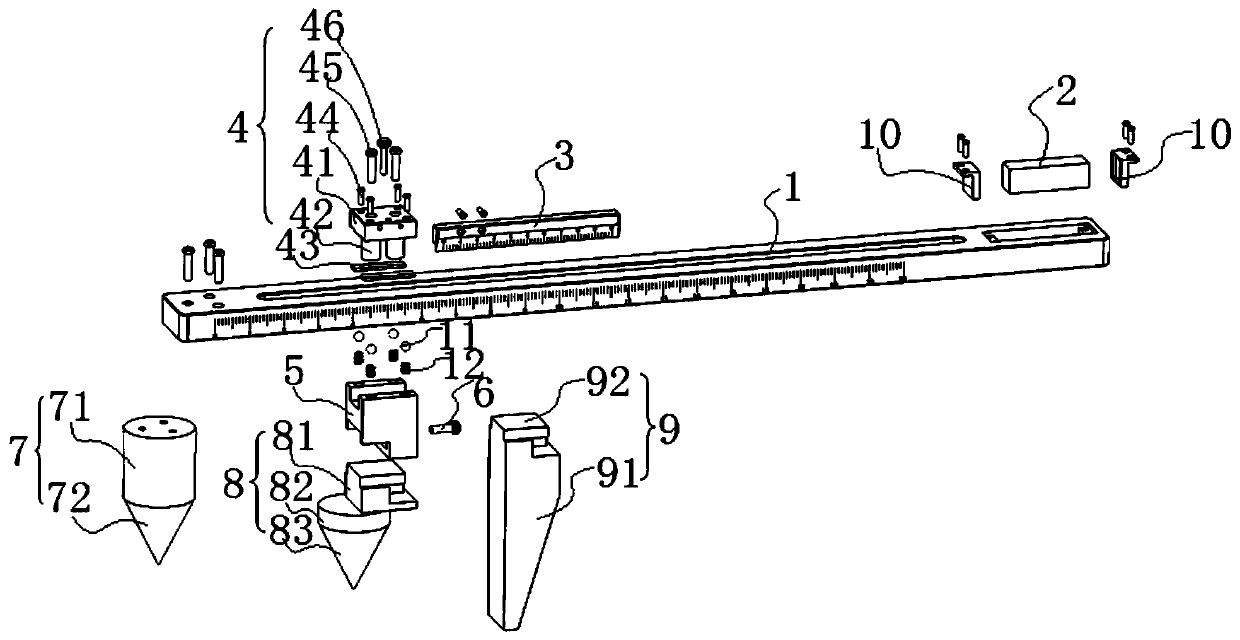

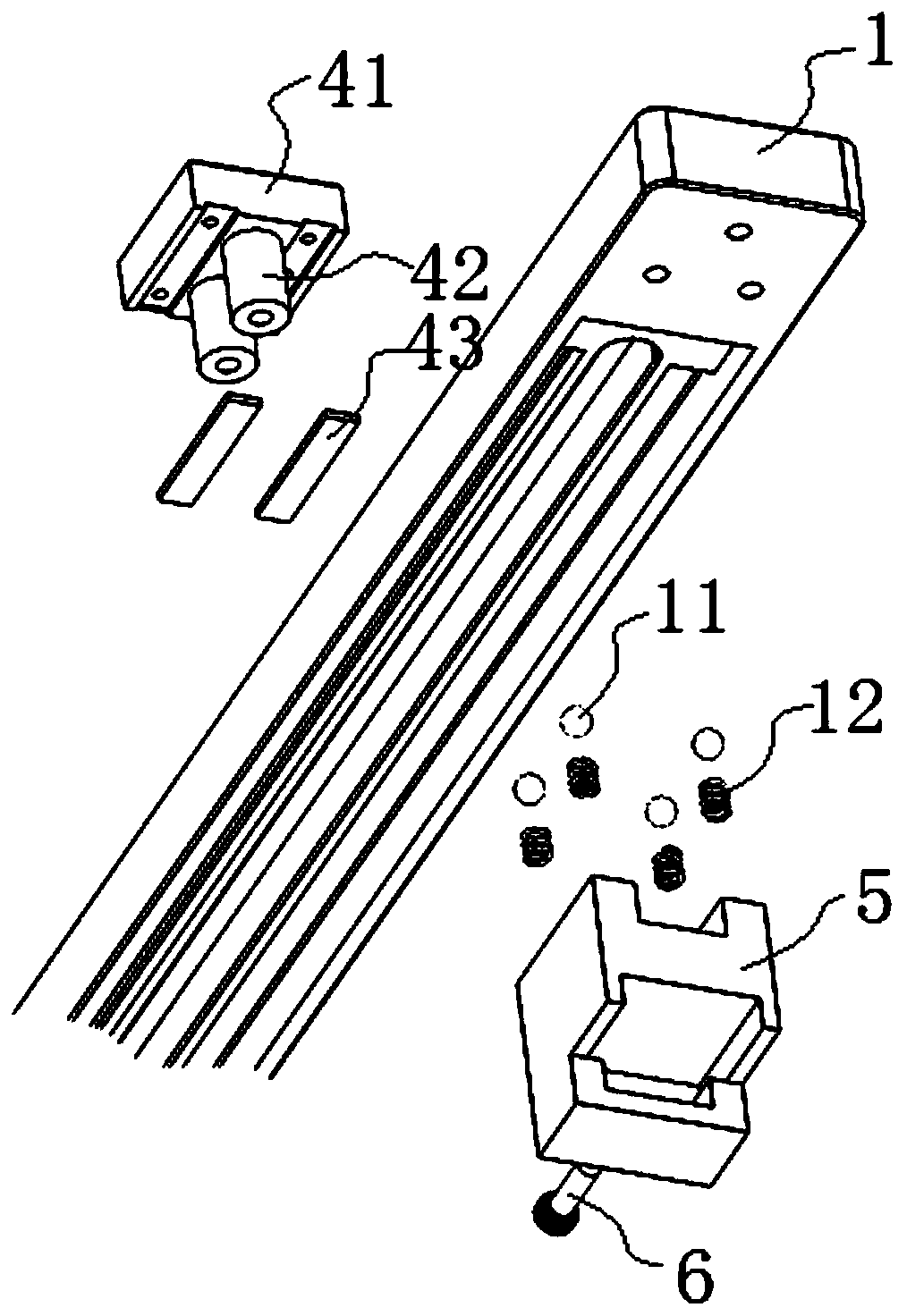

Vernier caliper used for hole distance measurement

ActiveCN110296641AQuick measurementPlay a reassuring roleSlide gaugesMechanical clearance measurementsVernier scaleEngineering

The invention provides a vernier caliper used for hole distance measurement. The vernier caliper comprises a main ruler, wherein the main ruler is provided with a gradienter used for detecting the level condition of the main ruler; the lower surface of the main ruler is provided with a fixed caliper inserted into one to-be-measured hole of a workpiece; the main ruler is provided with a sliding seat in a sliding way; the side surface of the sliding seat is provided with a vernier; and the bottom of the sliding seat is provided with a sliding caliper component which is inserted into the other to-be-measured hole of the workpiece or fit to the to-be-measured surface of the workpiece and can slide along the main ruler. The above vernier caliper used for hole distance measurement can quickly and accurately position the center of a circle of the to-be-measured hole so as to quickly detect an interval between two holes and an interval between a hole and a surface. The vernier caliper has theadvantages of being simple in structure, convenient in operation, accurate in measurement and the like.

Owner:YANKUANG DONGHUA HEAVY IND CO LTD +1

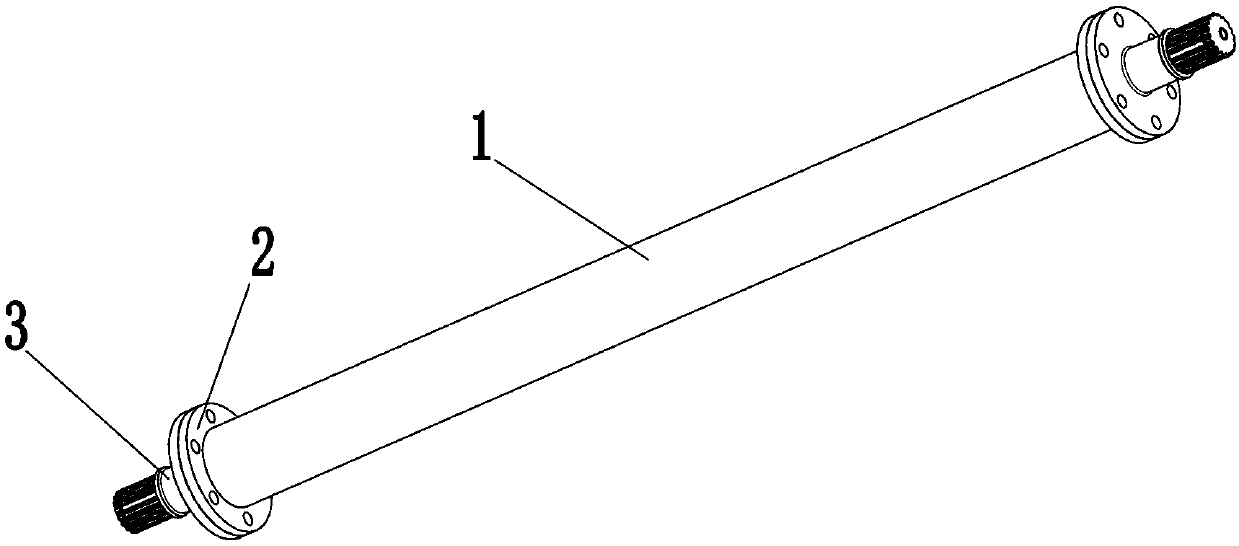

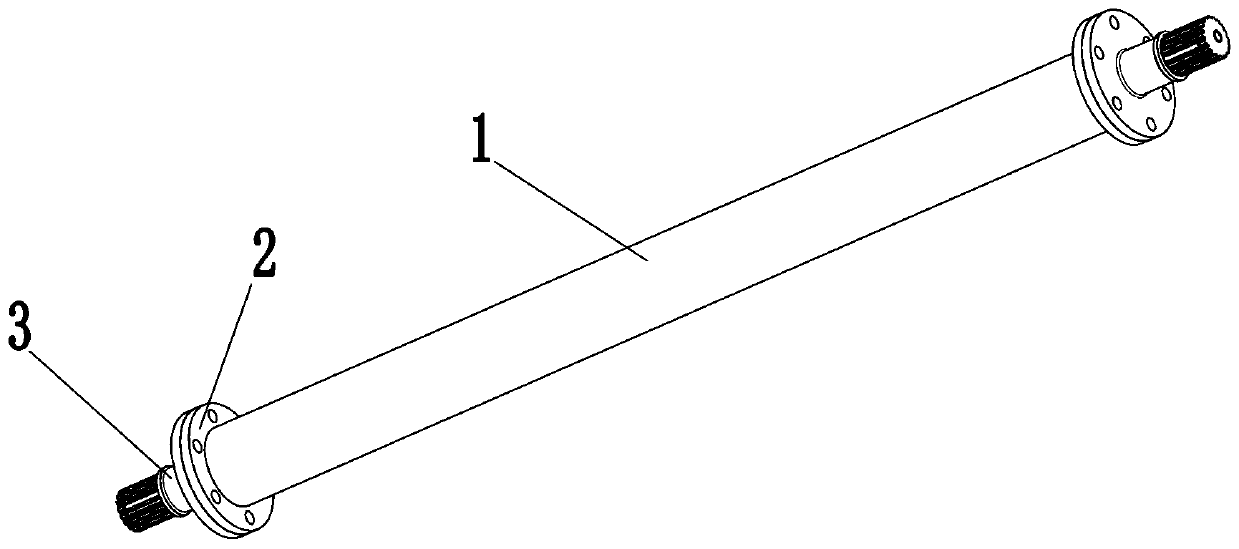

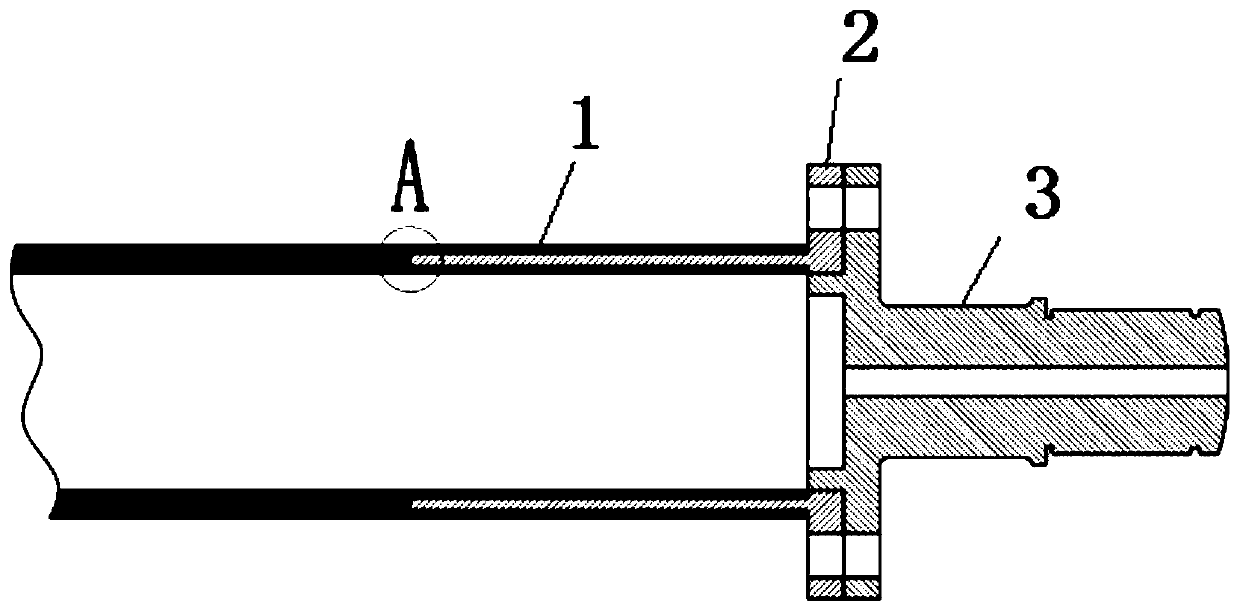

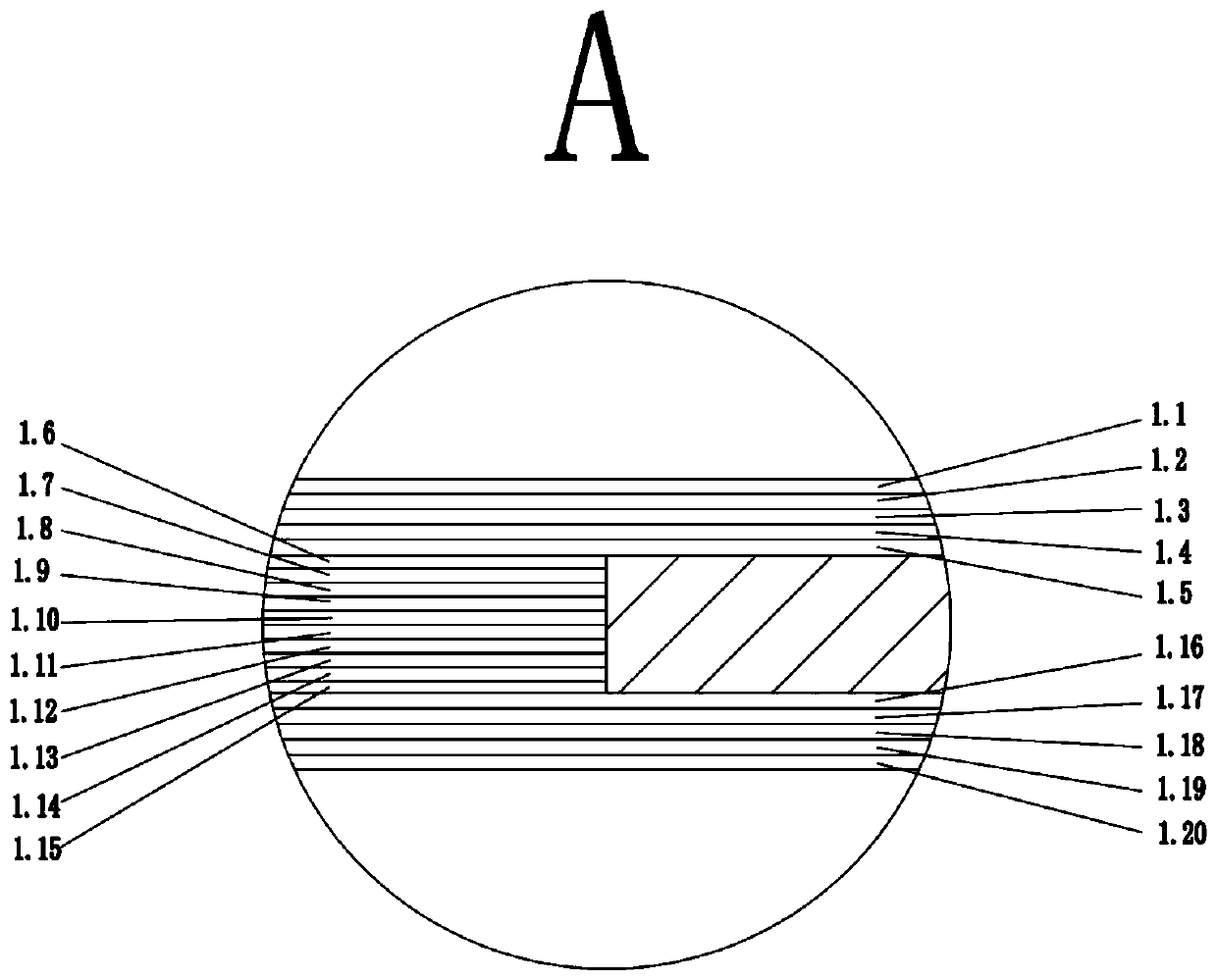

Method for forming and preparing carbon fiber drive shaft for college students' formula car

The invention relates to a method for forming and preparing a carbon fiber drive shaft for a college students' formula car. Carbon fiber prepregs are used for winding a mandrel, after the mandrel is connected with connecting ends, winding is preformed continuously. The mandrel is removed by solidification after winding, spline ends are connected to form an integral shaft, a carbon fiber shaft bodyis formed by symmetrical angle layering in three stages, the metal connection ends are divided into flange edges and internal and external gluing parts, the spline ends are divided into flange edgesand spline parts, and the carbon fiber shaft body and the metal connection ends are in a double-lapped connection and mechanical connection mode, and the metal connection ends and the spline ends arefixed by bolts passing through the holes of the flange edges. The drive shaft can be used for various purposes by replacing the spline ends, has high durability and high fiber content, the connectionstrength between the metal connection end and the carbon fiber shaft body is high, the mass of the drive shaft is low, the rotational inertia is small and the natural frequency is high.

Owner:WUHAN UNIV OF TECH

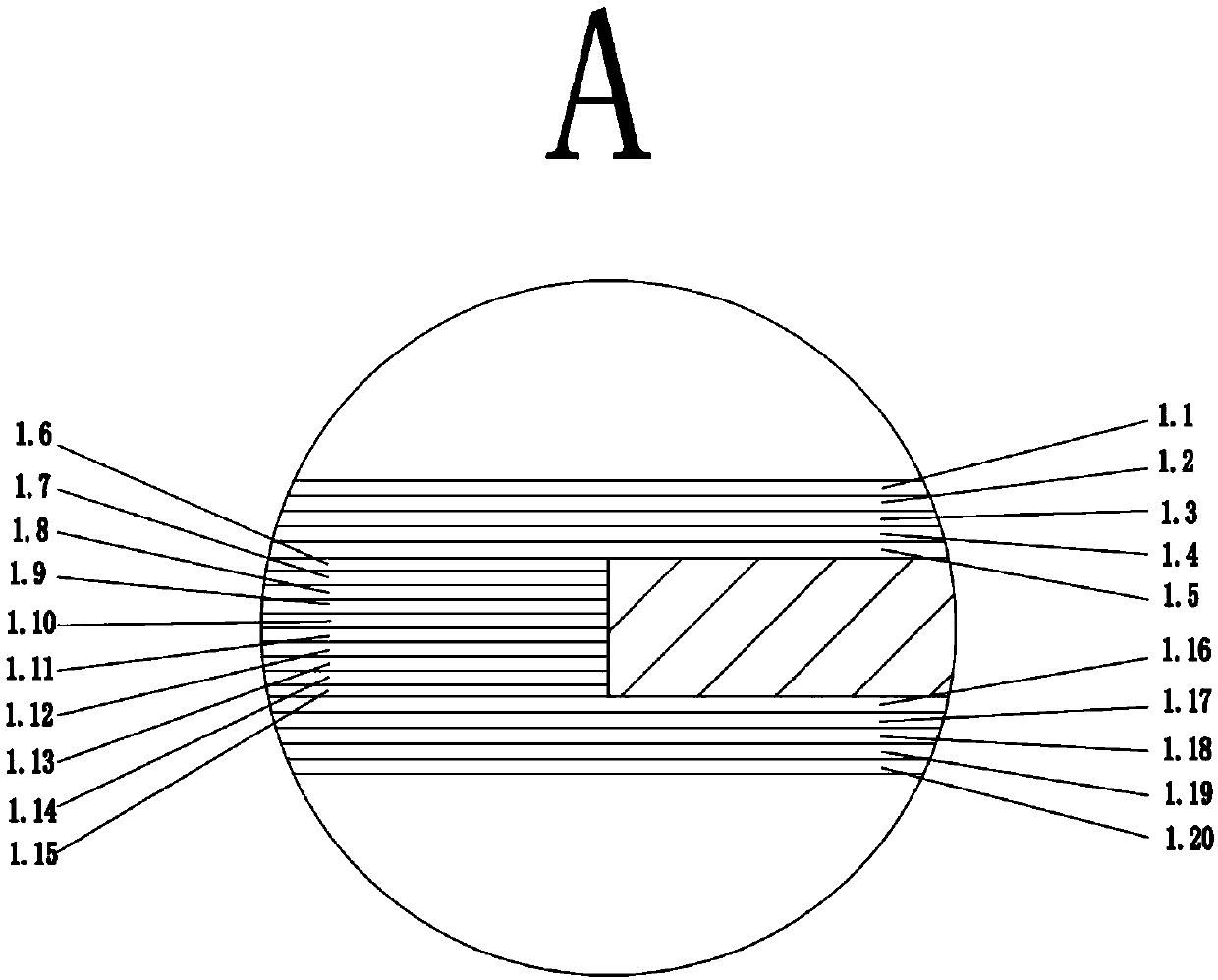

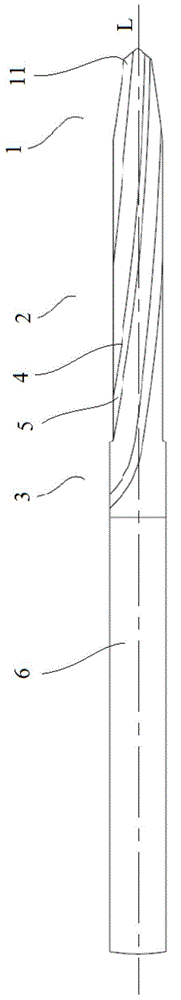

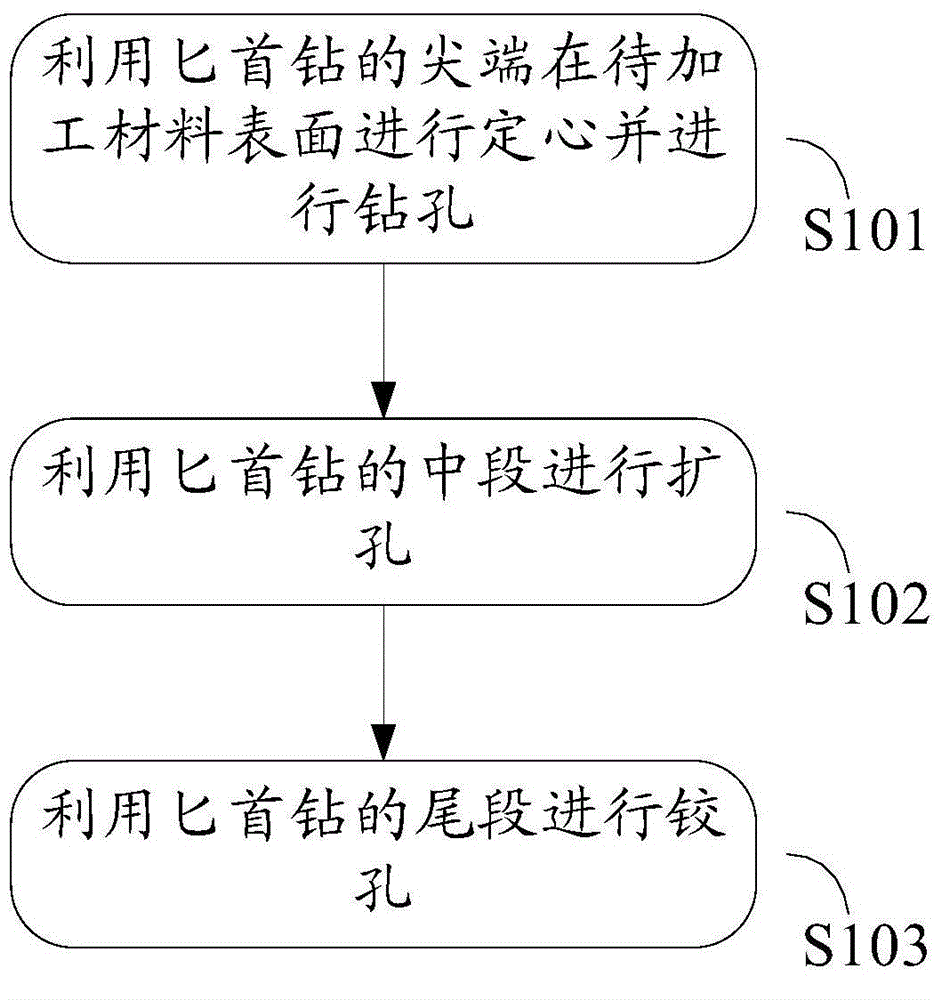

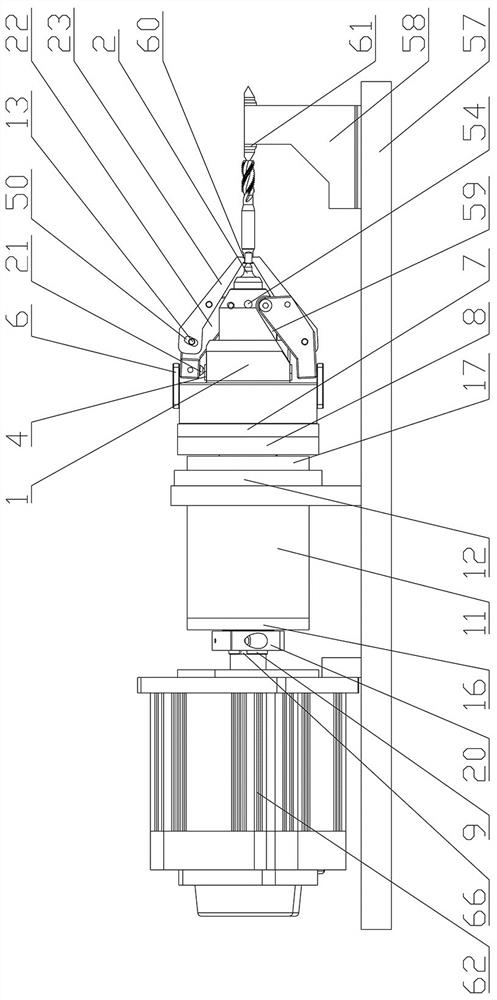

Dagger drill and method for hole processing

InactiveCN106334816AReduce risk of processing delaminationQuality improvementTransportation and packagingTrepanning drillsEngineeringDrill

The invention provides a dagger drill on one hand. The dagger drill comprises a head segment (1), a tail segment (3), and a middle segment (2) for connecting the head segment (1) and the tail segment (3). A continuous blade (4) is arranged around an axis direction (L) of the dagger drill from the head segment (1), the middle segment (2) to the tail segment (3); the end head of the head segment (1) forms a tip (11); and the diameter of the blade (4) is gradually increased from the first segment (1) to the middle segment (2). The invention also provides a method for hole processing on the other hand. According to the dagger drill and the method for hole processing provided by the invention, the improvement of the processing efficiency, the reduction of the layering risk of hole processing, and the improvement of the quality of a hole can be realized at least.

Owner:KUANG CHI INST OF ADVANCED TECH +1

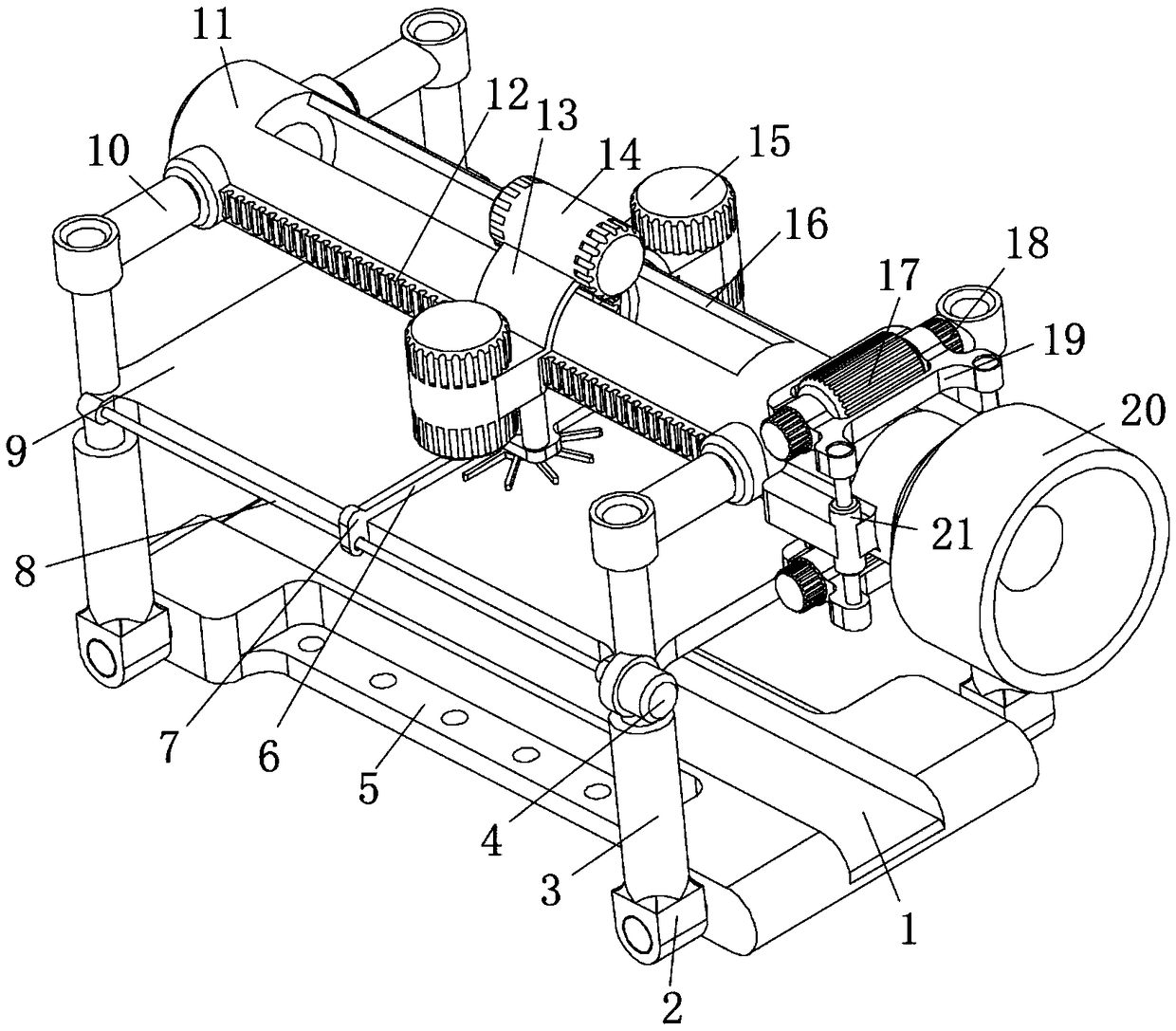

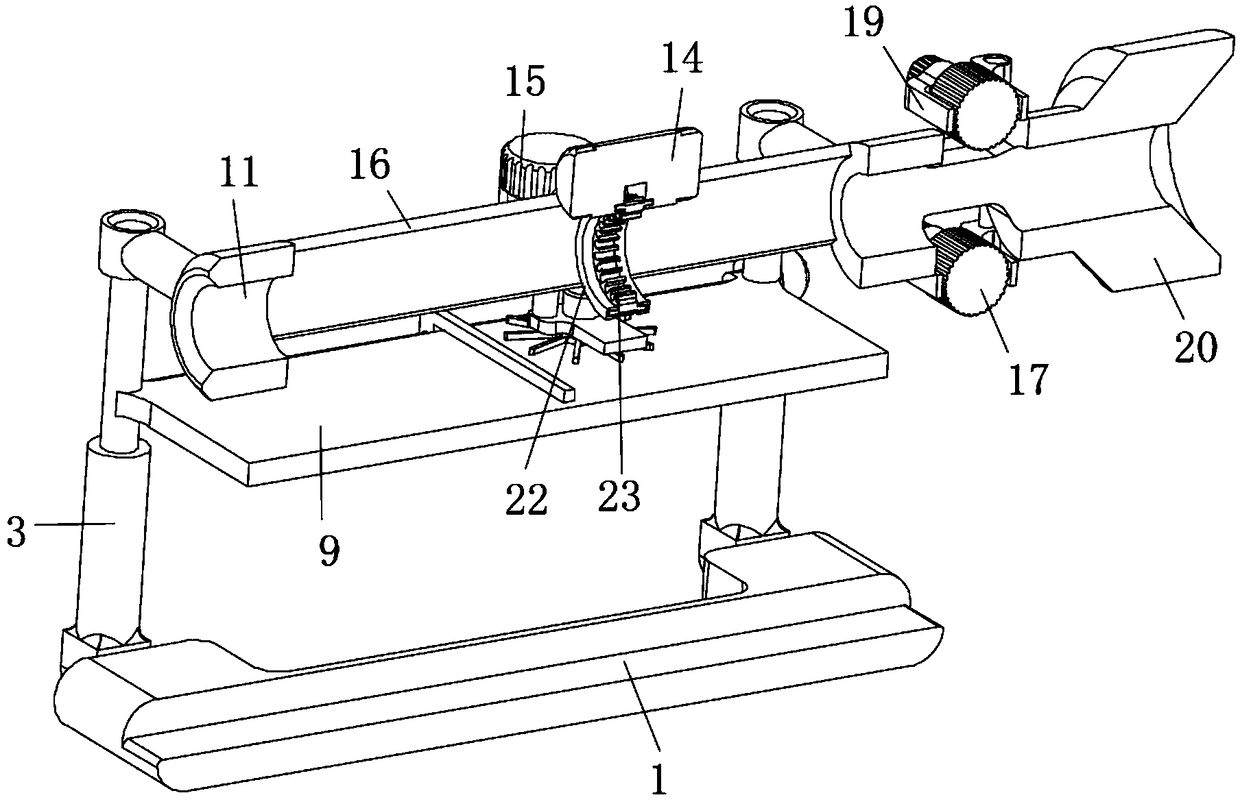

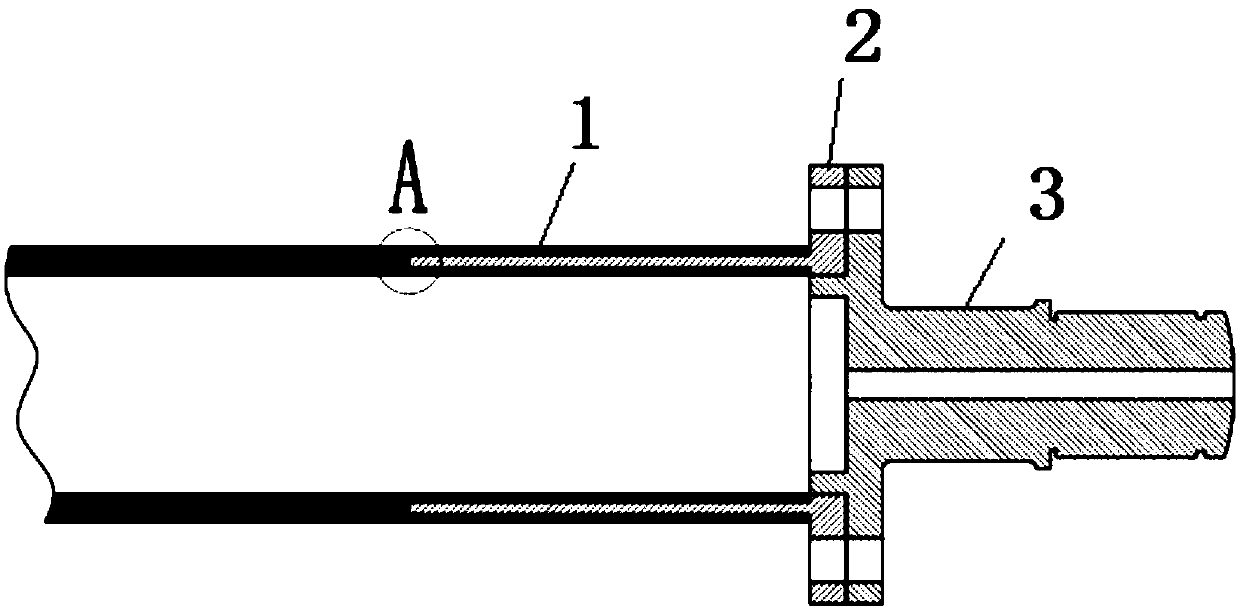

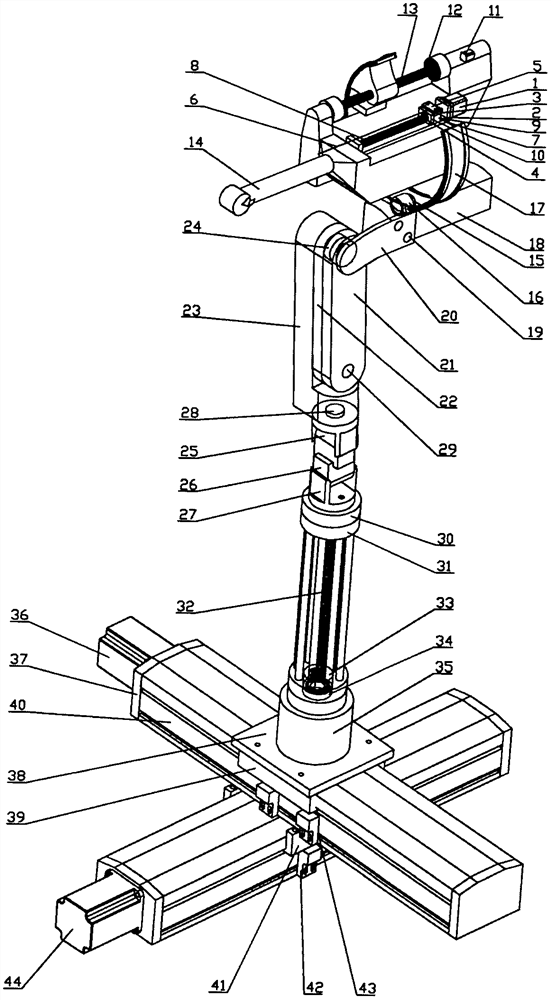

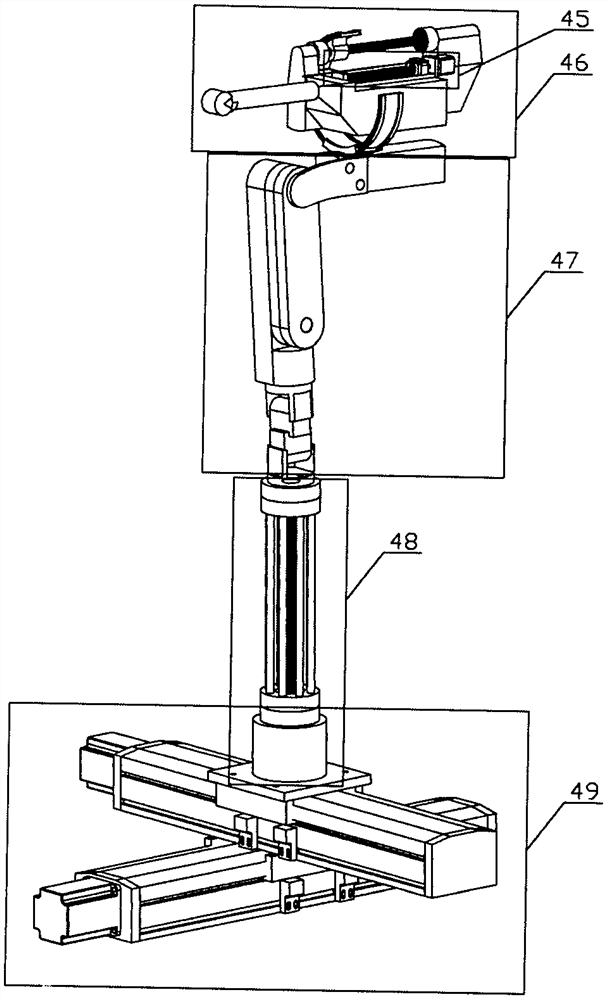

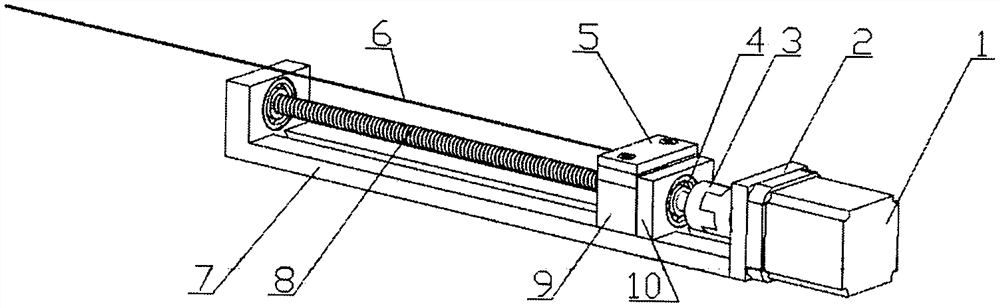

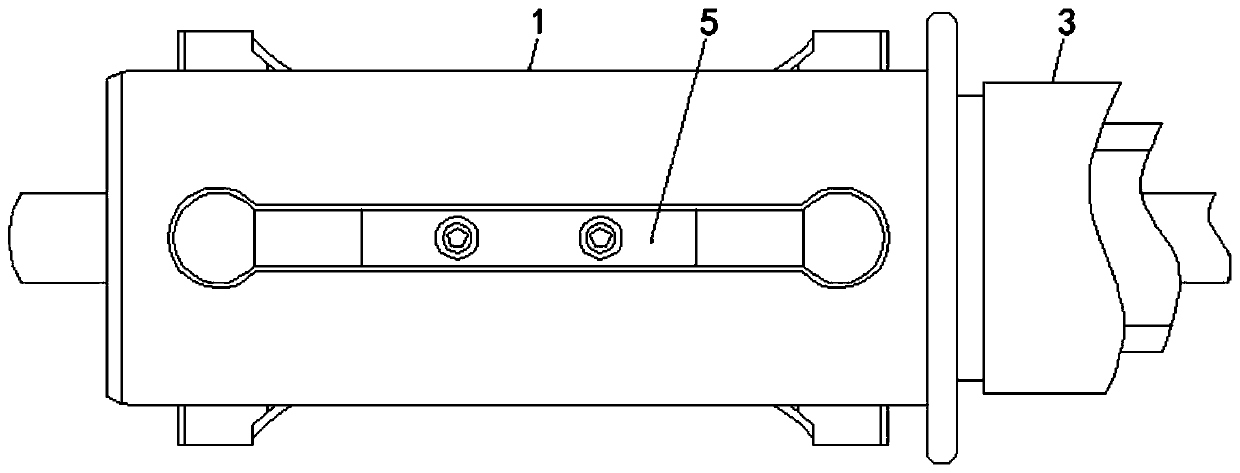

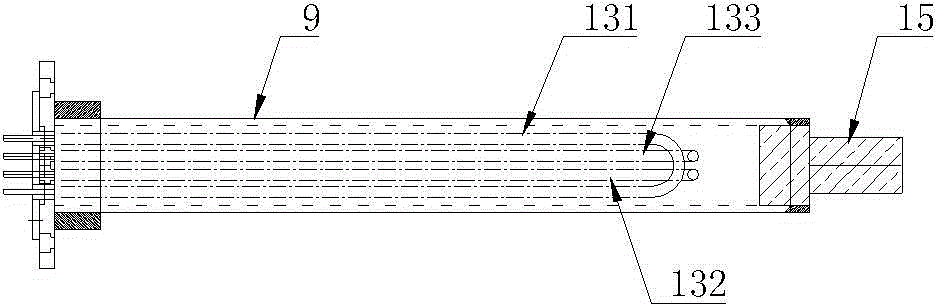

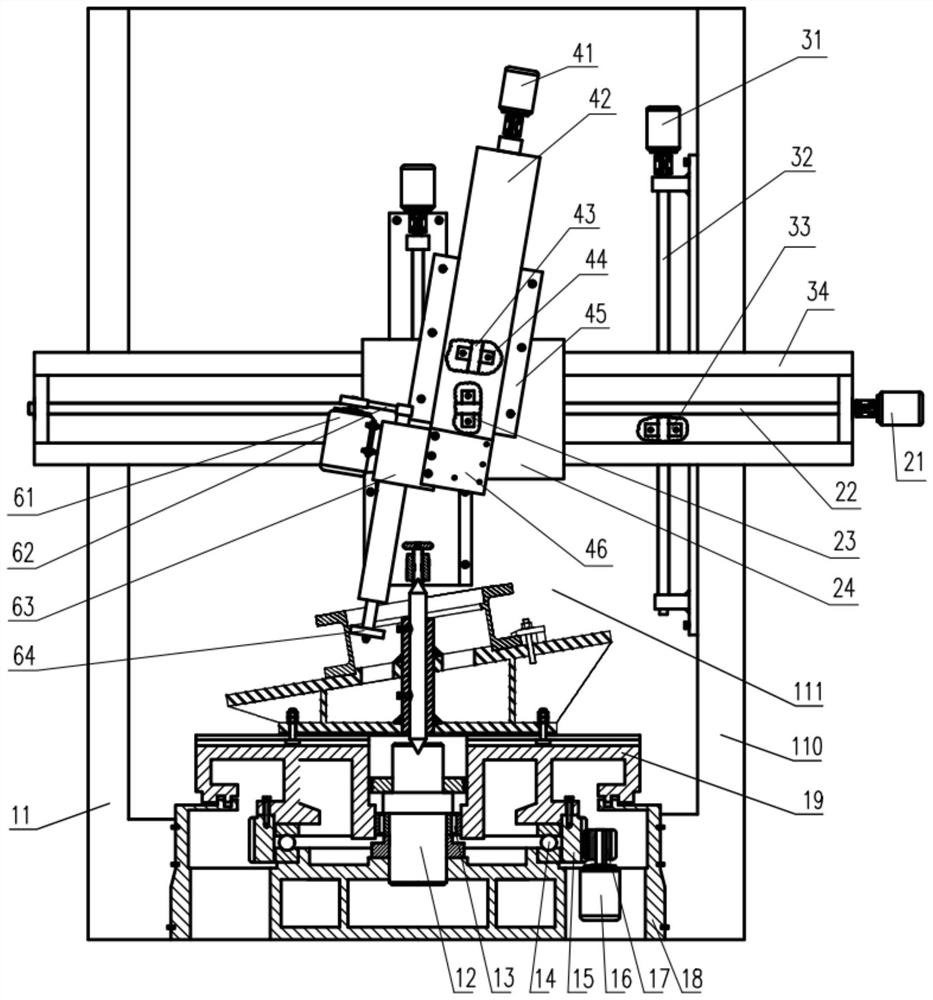

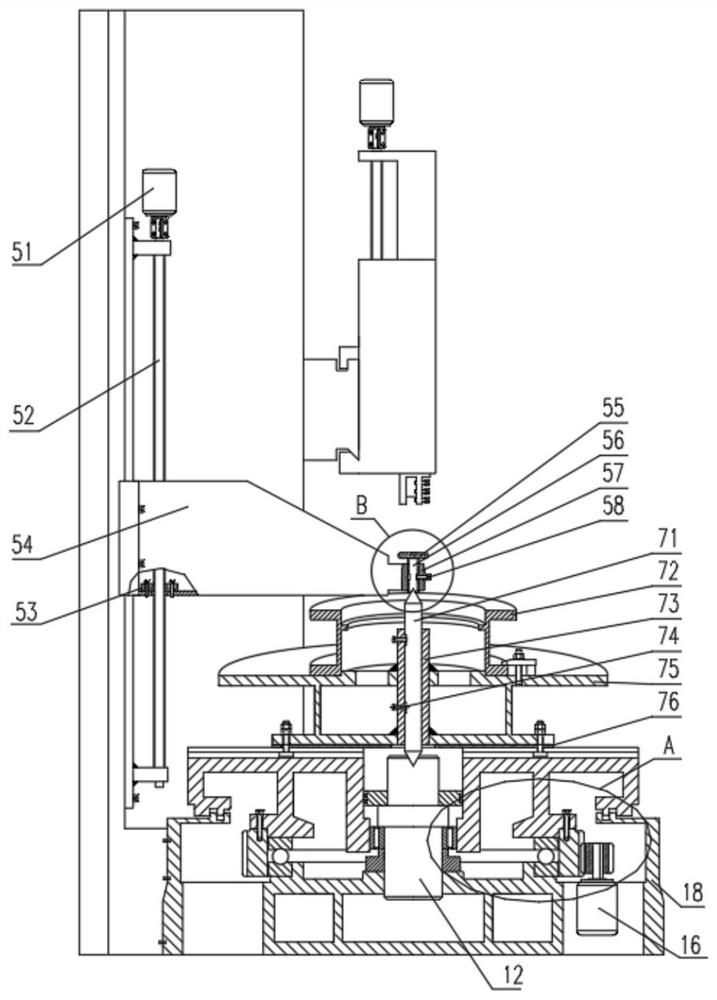

Prostate puncture surgical robot based on ultrasonic image navigation

PendingCN114209400AAchieve axial rotationImprove the inconvenienceUltrasonic/sonic/infrasonic diagnosticsSurgical needlesReoperative surgeryNeedle insertion

The invention discloses a prostate puncture surgical robot based on ultrasonic image navigation. The prostate puncture surgical robot comprises a seven-degree-of-freedom pose adjusting mechanism and a three-degree-of-freedom supporting frame mechanism. Wherein the posture adjusting mechanism comprises a posture adjusting module capable of realizing accurate positioning, a probe adjusting module for controlling the probe to automatically position, rotate and feed, and an end effector for realizing a puncture function. The posture adjusting module adopts a multi-joint coupling algorithm to control a remote center motion point, two rotating plates are restrained through rotation to form a connecting rod mechanism, and the angle between the two rotating plates is changed through driving of a holder motor, so that virtual fixation of the remote center motion point is achieved. The supporting frame mechanism for achieving large-range movement of the pose adjusting mechanism in the space comprises a moving module for achieving X-axis and Y-axis movement and a lifting module for achieving Z-axis up-down lifting. Under ultrasonic image navigation, automatic rotary feeding and pose adjustment of the ultrasonic probe can be achieved, accurate positioning is carried out, a large-range prostate scanning view can be obtained, the biopsy tissue sampling range can be expanded, meanwhile, automatic needle insertion of a puncture needle can be achieved, fatigue of doctors can be effectively relieved, and the working efficiency of the doctors is improved. And the surgical precision, the surgical efficiency and the surgical safety are improved to a certain extent.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Resistivity variation principle based optical centering deviation detecting device

The invention discloses a resistivity variation principle based optical centering deviation detecting device and relates to the technical field of optical centering. The resistivity variation principle based optical centering deviation detecting device comprises a shell; an inlet end and an outlet end are respectively fixedly connected to the left side and the right side of the shell; a baffle isfixedly connected between the shell and the outlet end; four spring sheets are flexibly connected to the outer side of the shell; centering blocks are flexibly connected to the left ends and the rightends of the spring sheets; a light source is flexibly connected to the inner side of each centering block at the left end; and a photoresistance is flexibly connected to the inner side of each centering block at the right side. The height of the light source and the height of the photoresistance are on the same straight line; a material penetrates an inlet positioning mechanism and an outlet positioning mechanism, an outer ring contacts the centering blocks to drive the centering blocks to move when the material shifts and the light source and the photoresistance are not on the same straightline at the moment; whether the material inclines can be detected by utilizing the resistivity variation of the photoresistance; and accuracy and stability of the detection result of the device is improved.

Owner:涌淳半导体无锡有限公司

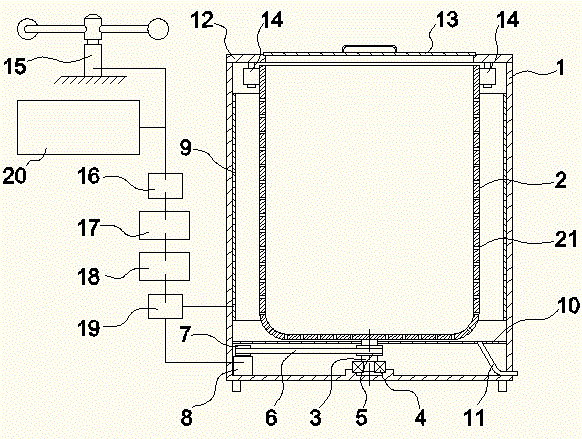

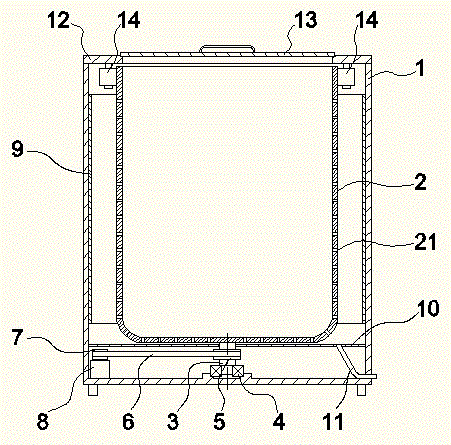

Protective device for cleaning machine

ActiveCN102000686ACompact structureEasy to installCleaning processes and apparatusMechanical engineeringEngineering

The invention discloses a protective device for a cleaning machine. The protective device comprises a stand and a protective cover, wherein the protective cover is connected with the output end of a lifting driving cylinder; and the lifting driving cylinder is arranged on the stand. The protective device for the cleaning machine of the invention has the advantages of simple and compact structure and low cost; the lifting speed of the protective cover is controlled by the extension speed of a piston rod of the driving cylinder, and conveniently and quickly controlled and adjusted; and the protective device is convenient to mount and works safely and reliably.

Owner:TRUKING TECH LTD

plastic extruder

The invention provides a plastic extruder, which can solve the problems of insufficient mixing of raw materials and high power consumption of a motor in a traditional plastic extruder, ensure extrusion quality and reduce production cost. The barrel is provided with a feeding device, and the external heating device is installed on the outer periphery of the barrel in sections, and the outer periphery of the screw is provided with helical blades extending in the axial direction. The screw in the feed section, the screw in the feed section is connected to the output shaft of the drive motor, one end of the screw in the discharge section is connected to the screw in the feed section, and the other end is connected to the extrusion die at the discharge port of the barrel, the screw in the discharge section is in the shape of Hollow cylindrical, the outer periphery of the screw in the feeding section is provided with helical blades extending in the axial direction, and the outer and inner peripheries of the hollow cylindrical screw in the discharging section are provided with spiral blades in the same direction as the outer periphery of the screw in the feeding section. The helical blade, the helical blade on the outer periphery of the screw rod in the feeding section is connected with the helical blade on the outer periphery of the screw rod in the discharging section.

Owner:常熟市绿草根机械制造有限公司

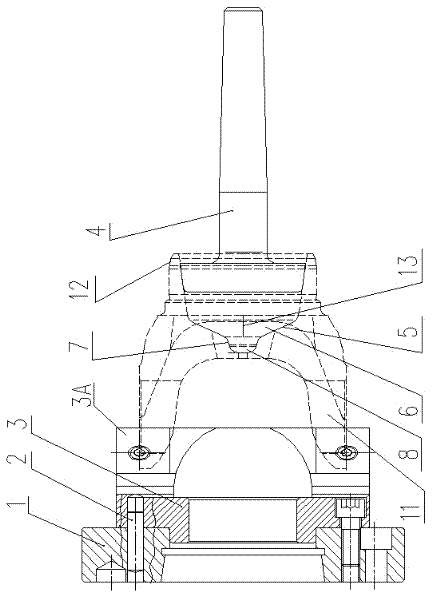

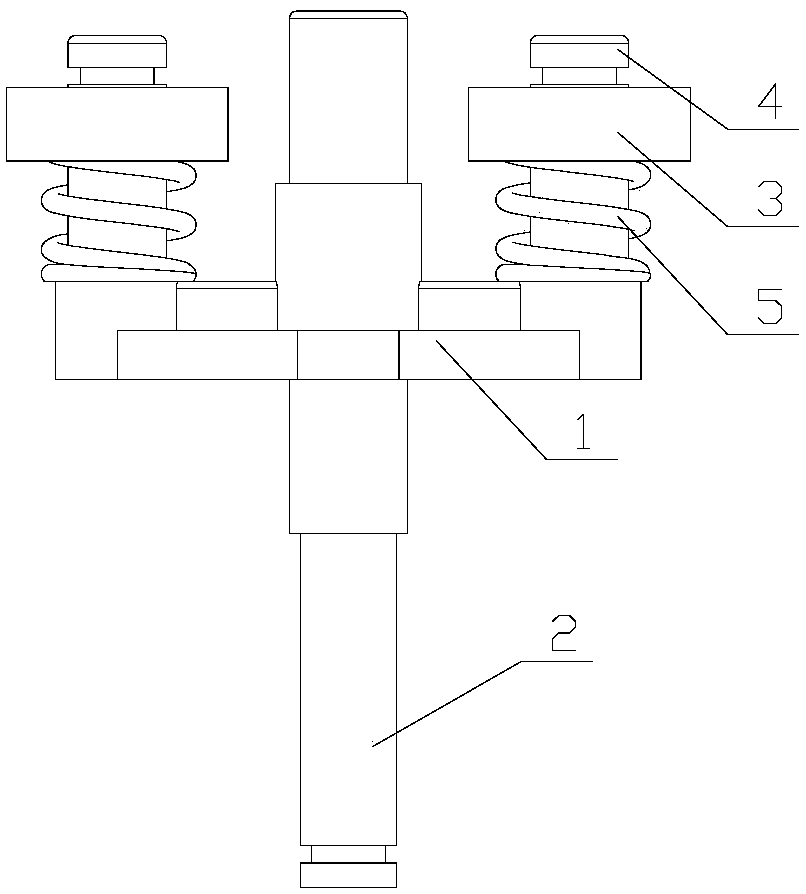

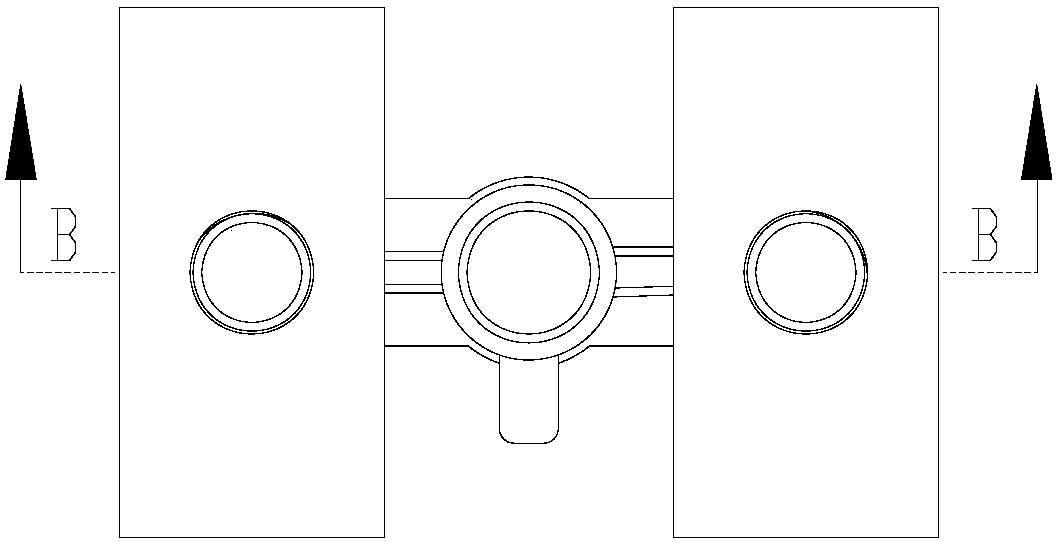

Self-centering floating driving device

ActiveCN113894307APlay a reassuring roleRealize high-precision clamping and positioning functionTailstocks/centresChucksEngineeringTailstock

The invention relates to the technical field of clamps, in particular to a self-centering floating driving device which comprises a chuck body, a tip, a clamping jaw assembly, a main piston, an auxiliary piston, a base, a tailstock and a driving device body. The self-centering floating driving device provided by the invention has a reasonable and compact structure, the driving device drives the main piston to move leftwards, one end of a to-be-machined workpiece is placed to abut against the right end of the tip, the tip achieves a centering effect on the to-be-machined workpiece, and then, the main piston moves rightwards; since each clamping jaw is hinged and connected to the outer side of the chuck body, so that the clamping jaws can float according to the specification of a workpiece to be machined in the clamping process; finally, the workpiece to be machined is clamped under the effect of a reset elastic piece, the clamping position can be automatically adjusted, over-positioning of the clamping jaws is avoided, and high-precision clamping positioning is achieved; and the connecting plate can be prevented from deviating in the process of rotating along with the chuck body through the limiting groove, the stability of the self-centering floating driving device in use is enhanced. The self-centering floating driving device has the advantages of small clamping precision deviation, multi-procedure one-time clamping capability, positioning accuracy, stability and high efficiency.

Owner:ZHEJIANG WEIKE MACHINERY TECH

Efficient and energy-saving type drying machine

InactiveCN105780414AShorten drying timeReasonable structural designTextiles and paperSpin-dryersElectricityAgricultural engineering

The invention discloses an efficient and energy-saving type drying machine. The efficient and energy-saving type drying machine comprises a shell body and a drying bucket, wherein a rotary shaft is fixedly arranged at the center of the bottom of the outer side of the drying bucket; a first belt wheel is fixed on the rotary shaft; the first belt wheel is connected with a second belt wheel through a belt; the second belt wheel is fixed on an output shaft of a motor; a heating plate is arranged on an inner wall of the shell body; the motor and the heating plate are electrically connected with an electrifying switch; the electrifying switch is electrically connected with an inverter; the inverter is electrically connected with a storage battery; the storage battery is electrically connected with a charging controller; and the charging controller is electrically connected with a wind power generator and a solar battery. The efficient and energy-saving type drying machine disclosed by the invention adopts clean wind energy and solar energy as a working power supply, and clothes can be heated and dried when being dried by spinning, so that the airing time of the clothes is saved; and the efficient and energy-saving type drying machine is reasonable in structural design and easy to manufacture, and has the advantages of convenience for utilization, low cost, remarkable energy-saving effect and the like.

Owner:WUXI AOYUTE NEW TECH DEV

Automobile transmission shaft welding forming surface refinement treatment process

InactiveCN112548694AImprove grinding efficiencyImprove the rate of refinement processingRevolution surface grinding machinesGrinding drivesDrive shaftAutonomation

The invention provides an automobile transmission shaft welding forming surface refinement treatment process, and relates to the field of automobile part machining treatment. The automobile transmission shaft welding forming surface refinement treatment process comprises a bottom plate, clamping devices, grinding devices and fixing devices, wherein the clamping devices are fixedly arranged on thebottom plate, and the fixing devices are fixedly connected to the bottom plate; and the grinding devices are arranged on the bottom plate, and the grinding devices are located between the clamping devices and the fixing devices. According to the automobile transmission shaft welding forming surface refinement treatment process, automatic batch fine treatment of the surface of an automobile transmission shaft can be achieved, the fine treatment efficiency is improved, and the cost consumption is reduced; according to the automobile transmission shaft welding forming surface refinement treatmentprocess, the clamping stability of the automobile transmission shaft is improved in multiple modes; and secondly, according to the automobile transmission shaft welding forming surface refinement treatment process, by means of two grinding modes of rotation and left-right sliding, the grinding efficiency is improved.

Owner:深圳市安能石油化工有限公司

Device for machining sealing surfaces of valve body and valve plate of butterfly valve at high precision

PendingCN114670084APlay a central rolePlay a reassuring roleGrinding carriagesGrinding drivesBall bearingEngineering

The invention discloses a high-precision butterfly valve body and valve plate sealing face machining device which comprises a base, a workbench and a mounting frame fixedly connected to the front face and the back face of the base, and the workbench is rotationally connected with the base through a thrust ball bearing. According to the device, the main shaft and the workbench are fixed, the vertical shaft frame and the upper center are also fixed, no gap exists between the vertical shaft frame and the upper center, the inclination disc tool is fixed to the center shaft, a workpiece to be machined is fixed to the inclination disc tool, no gap exists obviously, and the rubber pad bears the weight of the workpiece to be machined; meanwhile, the center shaft has the aligning and centering effects, the whole tool part tightly floats on the workbench, the workbench rotates to drive the inclination disc tool and the workpiece to be machined to rotate so as to complete machining of the workpiece, in this way, deviation in the workpiece machining process can be effectively reduced, the sealing effect is more ideal in the pressure testing process after the workpiece is assembled, and the machining efficiency is improved. And the leakage problem is reduced.

Owner:张盛洪

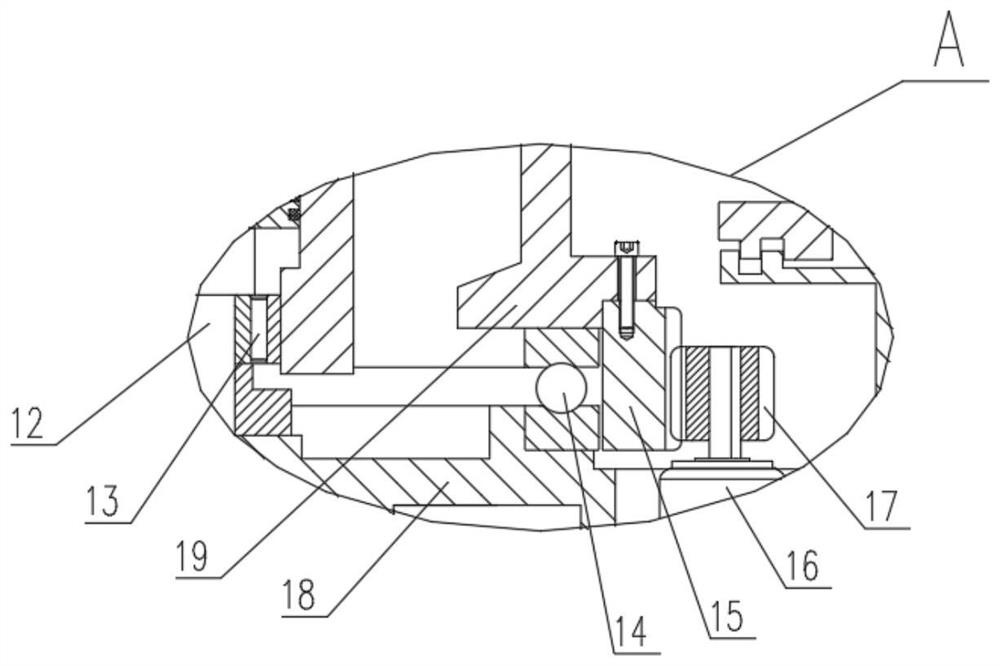

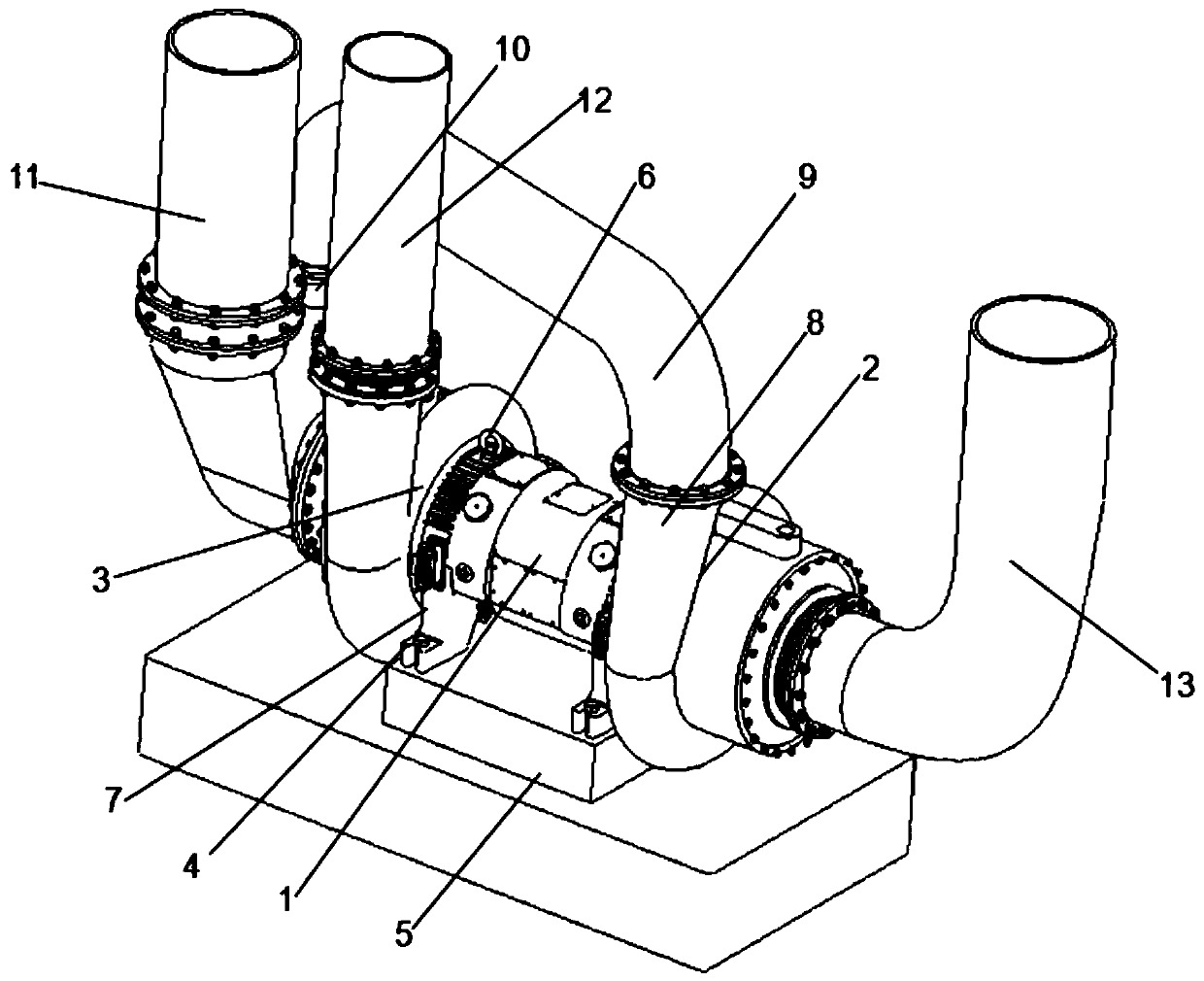

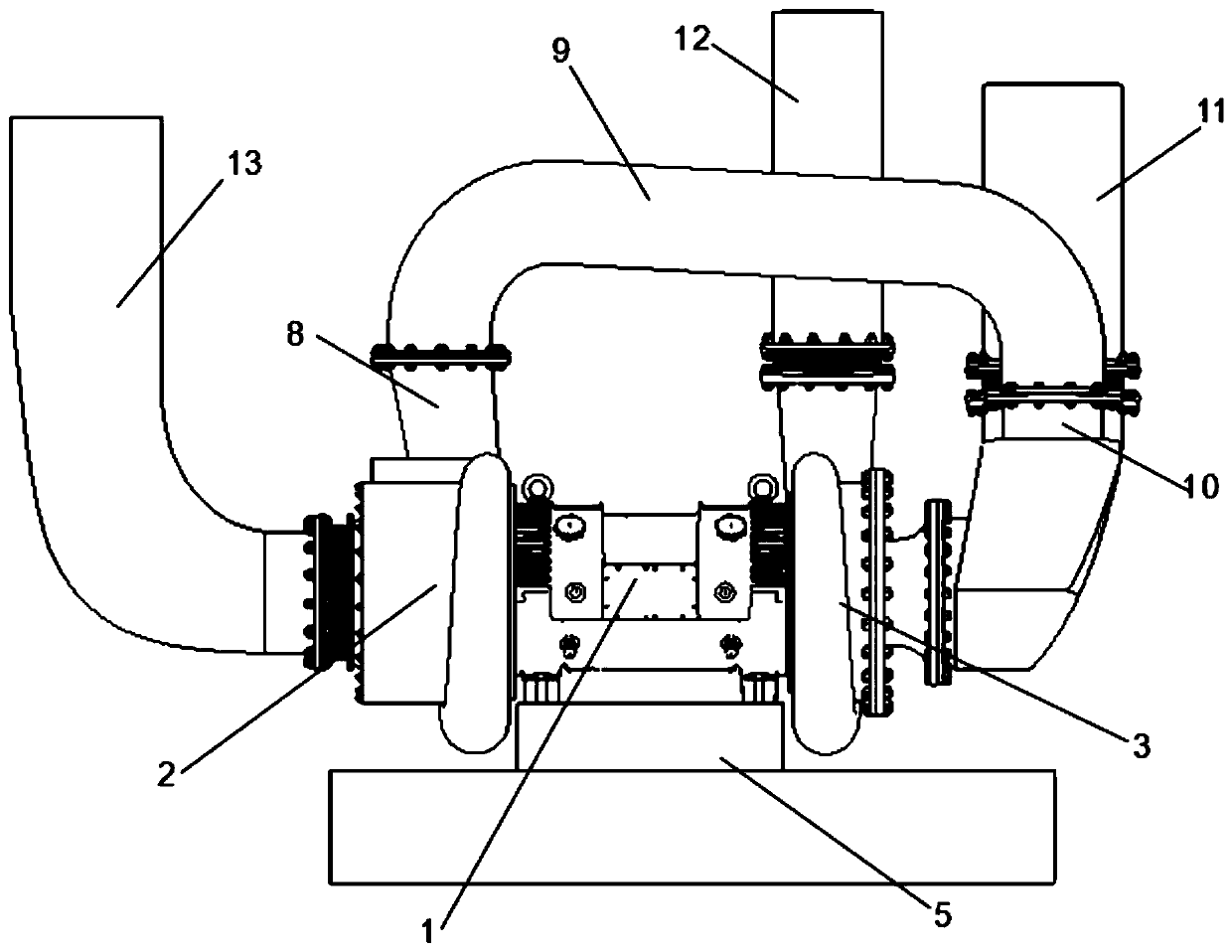

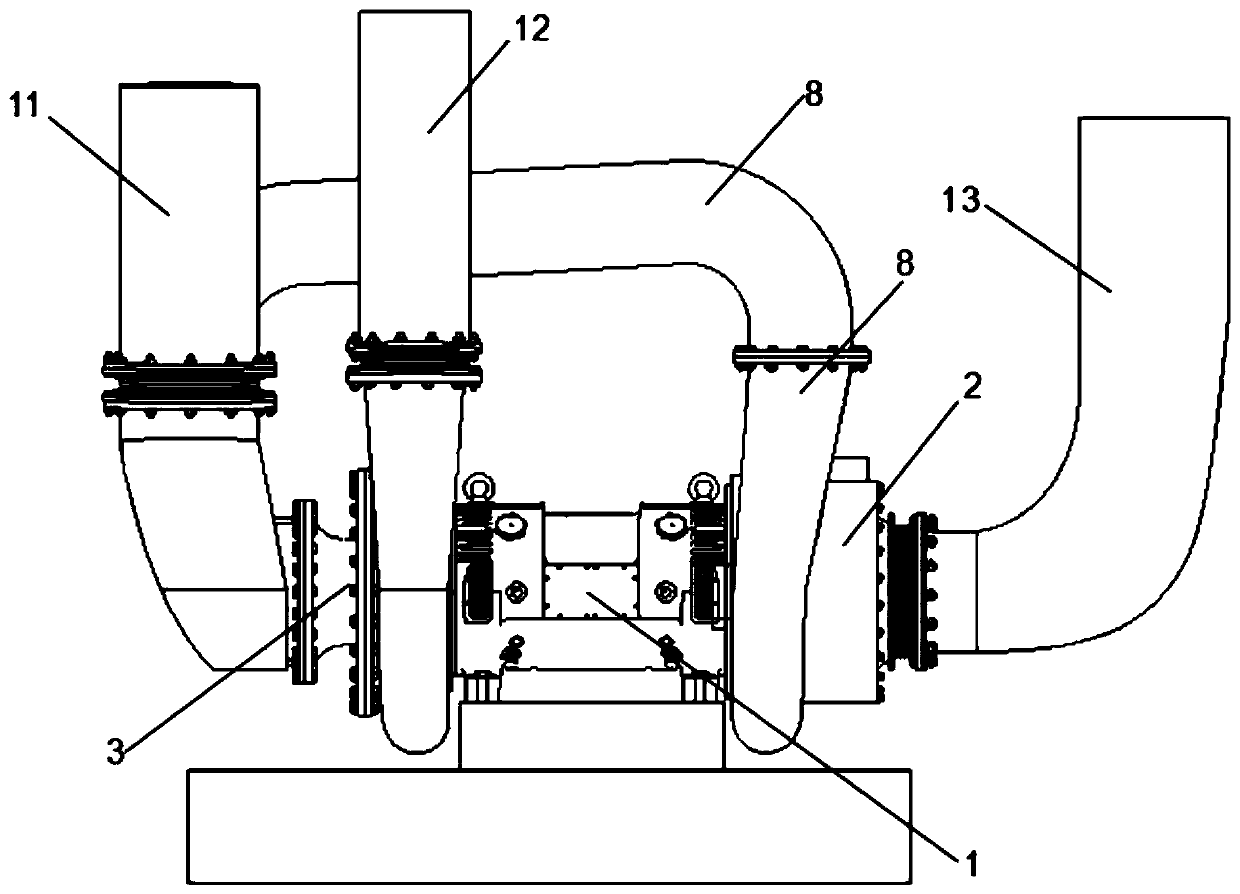

Vacuum pump capable of achieving multiple vacuum degrees

PendingCN110439827ASatisfy Multiple Vacuum PointsMeet needsPump componentsPump controlImpellerDrive motor

The invention provides a vacuum pump capable of achieving multiple vacuum degrees. The vacuum pump comprises a base, and the base is provided with a high speed double-shaft drive motor, a first vacuumpump body and a second vacuum pump body, wherein the first vacuum pump body and the second vacuum pump body are installed at the right and left ends of the high speed double-shaft drive motor symmetrically; output shafts at the right and left ends of the high speed double-shaft drive motor penetrate through outer shells of the first vacuum pump body and the second vacuum pump body separately, andare directly connected with impellers in the outer shells; and the second vacuum pump body is provided with a first air inlet and a second air inlet, wherein an exhaust port of a first vacuum pump onthe first vacuum pump body is connected with the first air inlet in the second vacuum pump body through a communicating pipe. According to the vacuum pump capable of achieving the multiple vacuum degrees, not only can the high vacuum degrees be achieved, but also the requirements of multiple vacuum points and different vacuum degrees in the industry can be met; and the purpose of replacing a plurality of machines with one machine is achieved, and the equipment investment and operating cost are reduced greatly.

Owner:珠海德智源科技有限公司

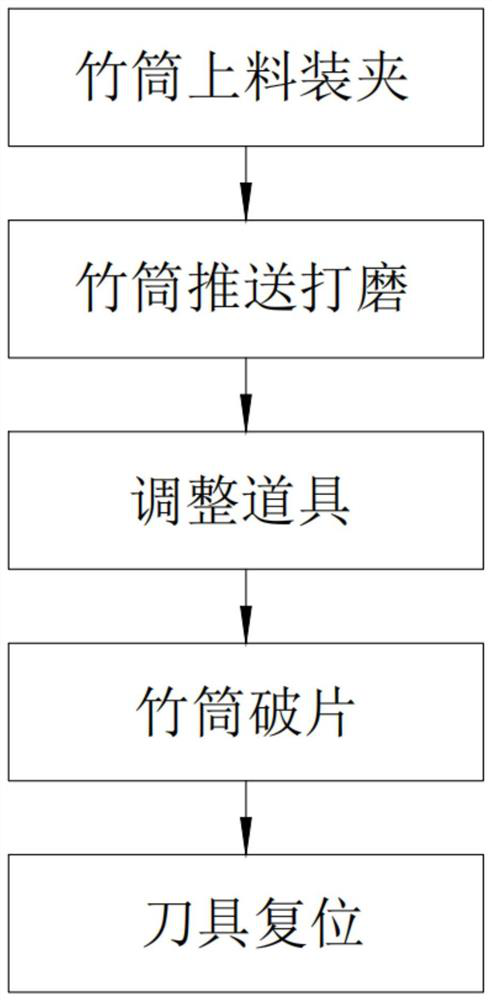

Continuous chipping process for bamboo tubes

ActiveCN111890498ASimple structureIngenious designWood splittingRevolution surface grinding machinesStructural engineeringMechanical engineering

The invention provides a continuous chipping process for bamboo tubes. The continuous chipping process comprises the following steps: feeding and clamping of the bamboo tubes, pushing and polishing ofthe bamboo tubes, adjustment of cutters, chipping of the bamboo tubes and reset of the cutters. A feeding rotating wheel rotates to roll the bamboo tubes into receiving grooves, the bamboo tubes arefixed by a pressing assembly, and a moving assembly pushes the bamboo tubes to move towards cutter assemblies. In the process, the bamboo tubes rotate under the action of a control assembly and pass through grinding assemblies, and the grinding assemblies drive the cutter assemblies to rotate correspondingly according to the outer diameters of the bamboo tubes. When the thick bamboo tubes pass, the cutter assemblies rotate, while when the thin bamboo tubes pass, the cutter assemblies do not rotate, and then the bamboo tubes are cut by the cutter assemblies. The technical problem of different sizes of bamboo chips cut from the thick and thin bamboo tubes in the prior art is solved.

Owner:阜阳汇中芯自动化技术有限公司

Heating type dryer

InactiveCN105780416ARealize dehydration and dryingShorten drying timeTextiles and paperSpin-dryersAgricultural engineeringElectric motor

The invention discloses a heating type dryer which comprises a shell and a drying barrel, wherein the tops of the shell and the drying barrel are both open; the drying barrel is arranged in the shell and is of a cylindrical shape; a rotary shaft is fixed at the center of the outer bottom of the drying barrel; a bearing is mounted on the rotary shaft and fixed at the inner bottom of the shell; a first belt wheel is fixed on the rotary shaft and connected with a second belt wheel through a belt; the second belt wheel is fixed on an output shaft of an electromotor; a heating plate is arranged on the inner wall of the shell; water-through holes are formed in the side wall and bottom of the drying barrel; and a drain pipe is arranged at the bottom of the shell. According to the heating type dryer disclosed by the invention, the clothes are heated and dried at the time of spin-drying, and the airing time of the clothes is saved; and the heating type dryer disclosed by the invention is reasonable in structural design and easy to produce and has the advantages of convenience in use, low cost and the like.

Owner:WUXI AOYUTE NEW TECH DEV

Swivel sorting machine

The invention relates the technical field of automatic sorting equipment, and discloses a swivel sorting machine. The sorting machine is characterized in that a plurality of supporting wheels are adopted to support a swivel, and a plurality of centering wheels are arranged, so that the swivel rotates around the circle center of a circle defined by the plurality of centering wheels, the centering of the swivel is achieved, a rotating shaft does not need to be arranged at the center area of the swivel, and a driving device does not need to be arranged at the center area of the swivel under the limit of the position of the rotating shaft. On the one side, grid mouths can be arranged both on the inner side and on the outer side of the swivel at the same time, the center area of the swivel is fully utilized to increase the quantity of the grid mouths, and a sorting cart is capable of doing two-way sorting to the inner side and the outer side of the swivel, and the sorting efficiency is improved obviously; and on the other hand, structures such as civil engineering pillars can be arranged at the center of the swivel, the requirements of the swivel sorting machine for distance between pillars are reduced, the overall arrangement is more flexible, and the adaptability is higher.

Owner:CHINA POST SCI & TECH

Movable contact structure for high power DC contactor

ActiveCN105551894BImprove reliabilityReduce volumeElectromagnetic relay detailsPlastic materialsEngineering

The invention provides a movable contact structure for a high-power DC contactor. The movable contact structure comprises two movable contact assemblies, a movable contact bracket and a reset push rod, wherein the two movable contact assemblies are symmetrically arranged at two sides of the reset push rod along the radial direction; and the movable contact assemblies, the reset push rod and the movable contact bracket are injected into a whole. According to the movable contact structure for the high-power DC contactor provided by the invention, the movable contact bracket is made of a high-strength plastic material; and the movable contact assemblies, the reset push rod and the movable contact bracket are injected into a whole to play a centering role, so that the consistency of actions of the movable contact assemblies is improved; and the reliability of the DC contactor is improved. Furthermore, two movable contact assemblies are arranged on one push rod, so that used parts are reduced; the space is saved; and the volume of the DC contactor is reduced.

Owner:常州市吉士电器有限公司

Vehicle pointing device based on differential gear train

The invention relates to a pointing device of a pure mechanical structure, in particular to a vehicle pointing device based on a differential gear train. In order to provide the pointing device which is of a pure mechanical structure and high in reliability, the pointing device comprises a box body and a center shaft which stretches into the box body from the top end of the box body and is provided with a pointing mark, and a wheel A shaft and a wheel B shaft stretch into the box body from the left side and the right side of the box body respectively. A first bevel gear, a second bevel gear, a third bevel gear, a fourth bevel gear, a fifth bevel gear, a sixth bevel gear and a planet gear are arranged in the box body; in the straight running process of the vehicle, the center shaft is stationary, and the pointing mark is stationary; when the vehicle turns, the planet wheel drives the center shaft to rotate in the opposite direction, the rotating angle is the same as the turning angle of the vehicle, the direction pointed by the mark is still unchanged, and finally the purpose of pointing in the given direction is achieved.

Owner:王彩艳

Molding and preparation method of carbon fiber transmission shaft for Formula Student racing car

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com