Continuous chipping process for bamboo tubes

A bamboo tube and fragment technology, which is applied in the directions of manufacturing tools, sugar cane machining, grinding workpiece supports, etc., can solve the problems of decreased production efficiency and different sizes of bamboo chips, and achieves the effect of simple structure, high fragmentation efficiency and ingenious design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

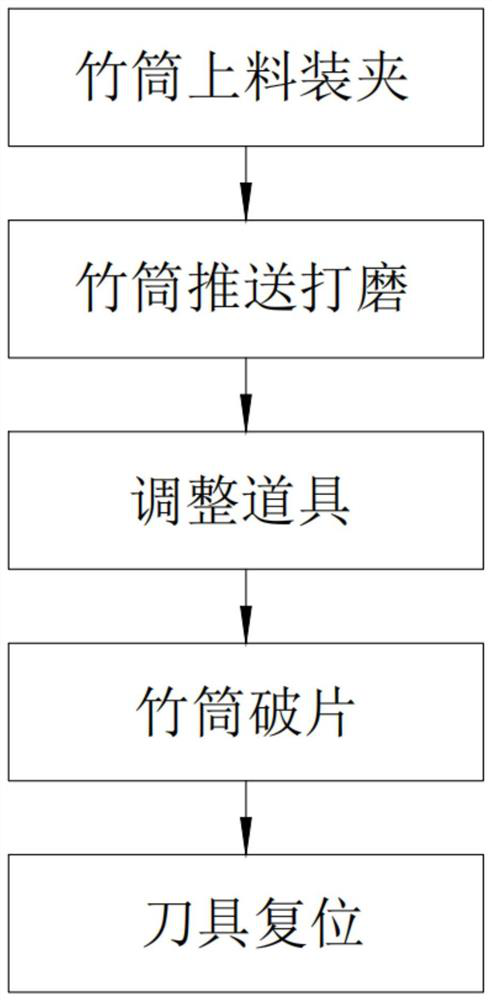

[0044] Such as figure 1 Shown, a kind of continuous fragmentation technology of bamboo tube comprises the following steps:

[0045] Step 1: The bamboo tube is loaded and clamped, the feeding wheel assembly is rotated to bring the bamboo tube at the end of the blanking track to the receiving tank, and the end of the bamboo tube is fixed by pressing the assembly;

[0046]Step 2: The bamboo tube is pushed and polished. After step 1, the moving component pushes the bamboo tube forward, and the control component drives the pressing component and the bamboo tube to rotate through the transmission component a. At the same time, the bamboo tube and the moving component pass through two sets of between the clamps;

[0047] Step 3: Adjust the cutter, and carry out at the same time as step 2. When the bamboo tube passes through the two sets of clamping blocks, the two sets of clamping blocks move outward at the same time according to the outer diameter of the bamboo tube by a correspond...

Embodiment 2

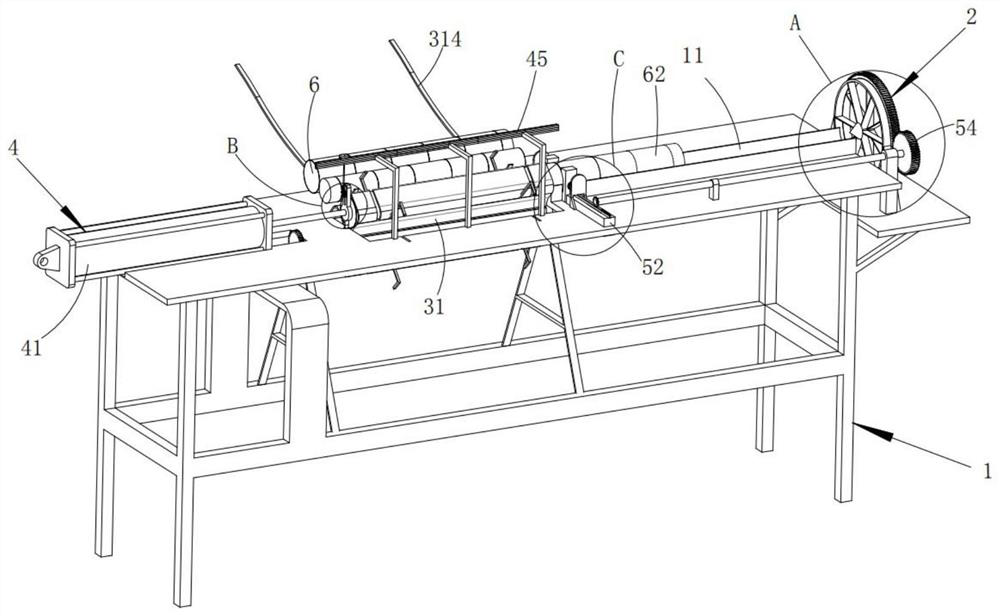

[0060] The invention also provides a bamboo tube continuous fragmentation device

[0061] Such as Figure 2 to Figure 7 Shown, a kind of bamboo tube continuous fragmentation equipment comprises:

[0062] An equipment platform 1, the equipment platform 1 is provided with a feeding chute 11 arranged along its length direction;

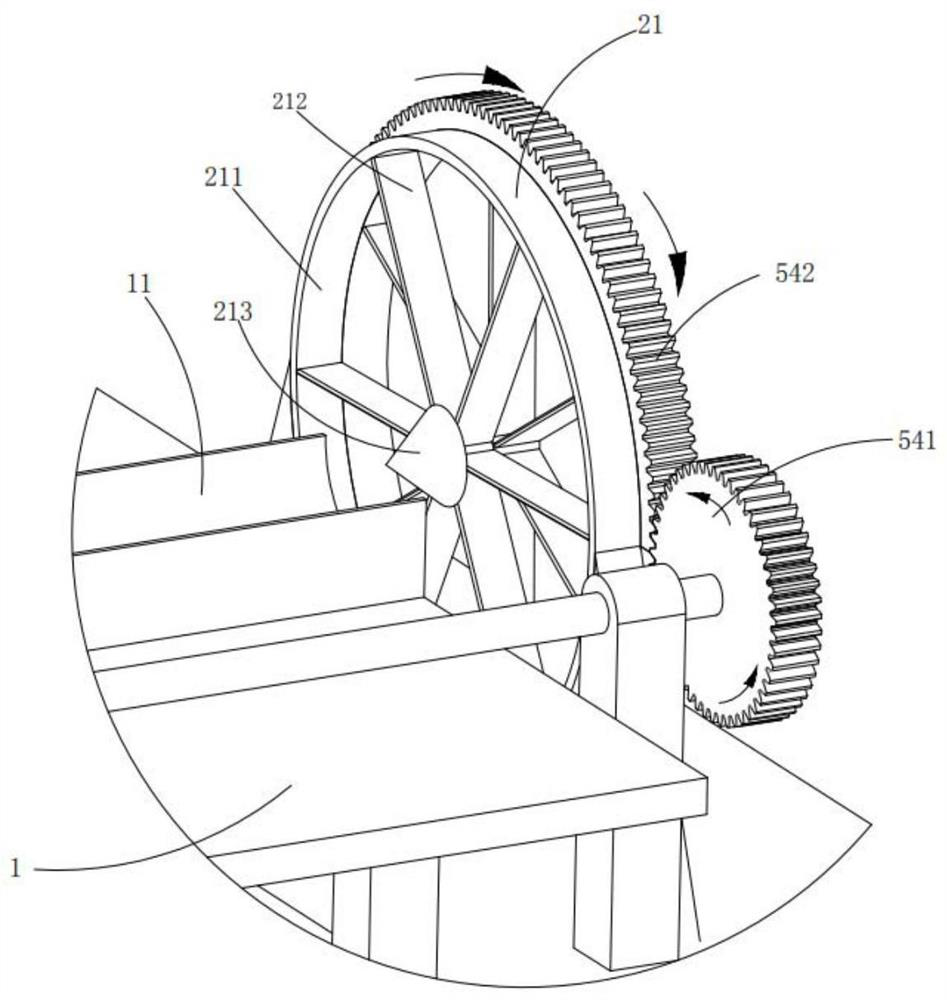

[0063] Slitting device 2, said cutting device 2 includes two groups of cutter assemblies 21 arranged at one end of said feeding chute 11 and arranged coaxially, and the two groups of cutter assemblies 21 are rotatably connected;

[0064] The feeding device 3, the feeding device 3 includes a feeding wheel assembly 31 arranged along the length direction of the equipment platform 1 and rotatably mounted on the other end of the feeding trough 11 relative to the cutter assembly 21, the upper The material runner assembly 31 includes a number of circular arrays set on the shaft and aligned with the material delivery chute 11 receiving chute 311, an arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com