Dagger drill and method for hole processing

A hole processing and dagger technology, applied in metal processing equipment, drilling/drilling equipment, components of boring machines/drilling machines, etc., can solve the problems of low efficiency, increase the risk of delamination, increase the risk of hole quality, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

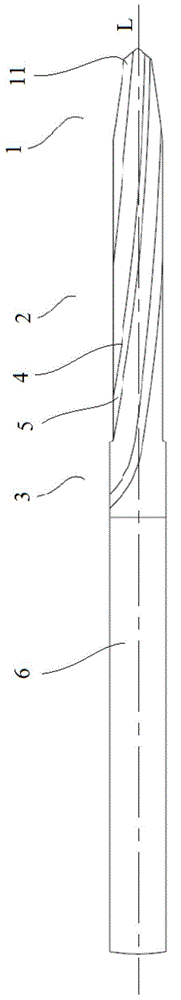

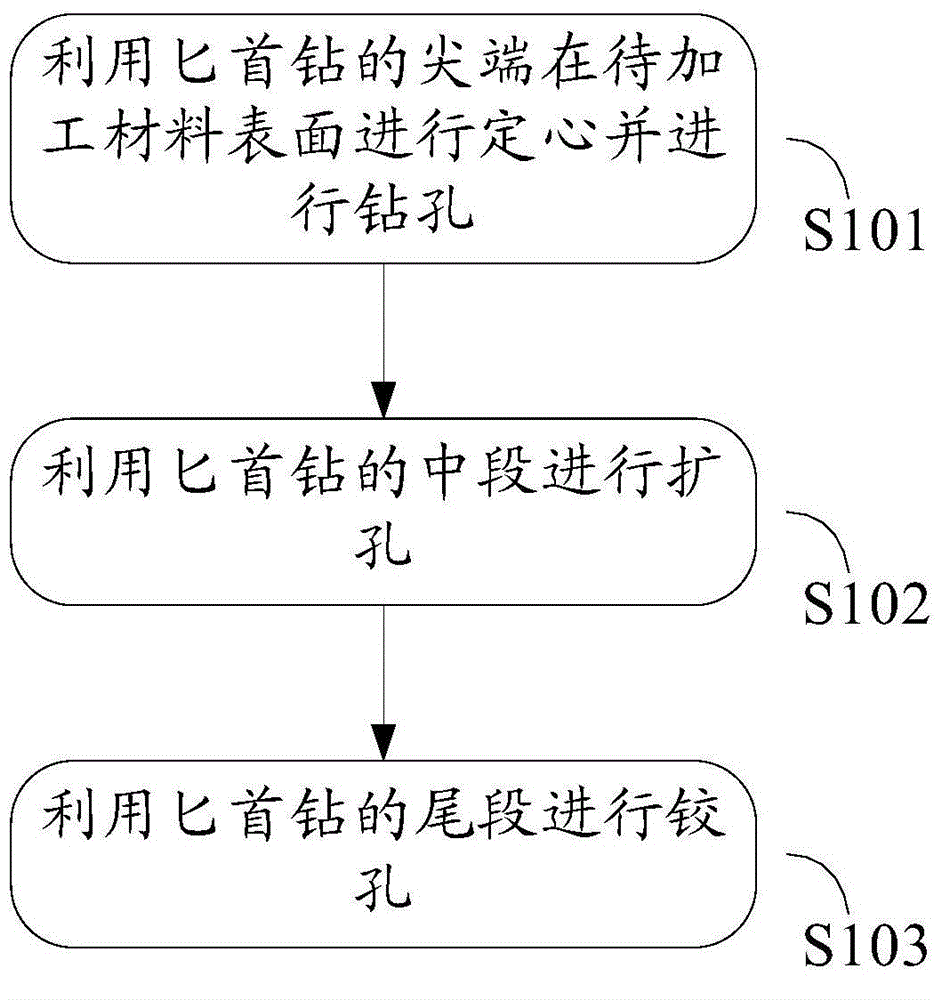

[0023] The invention will now be described with reference to the accompanying drawings. like figure 1 Shown is the structural representation of an embodiment of the dagger drill of the present invention. The dagger drill includes a first section 1, a middle section 2 and a tail section 3, wherein the middle section 2 connects the first section 1 and the tail section 3, that is, the dagger drill is a continuous forming member.

[0024] More specifically, a continuous cutting edge 4 is provided around the axis direction L of the dagger drill from the first section 1 , the middle section 2 to the tail section 3 . That is to say, the blade 4 extends continuously on the above-mentioned three sections, and is arranged around the axis direction L of the dagger drill, so as to form figure 1 In the helically extended shape shown, drilling cutting is performed with the cutting edge 4 of this shape.

[0025] In addition, the end of the first section 1 can be configured as a tip 11 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com