Bamboo product production equipment

A technology for production equipment and bamboo products, which is applied in the direction of mechanical equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of bamboo cutting with different diameters, different sizes of bamboo strips, and small diameters of bamboo tubes, etc., to achieve Reduced handling, simple structure, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

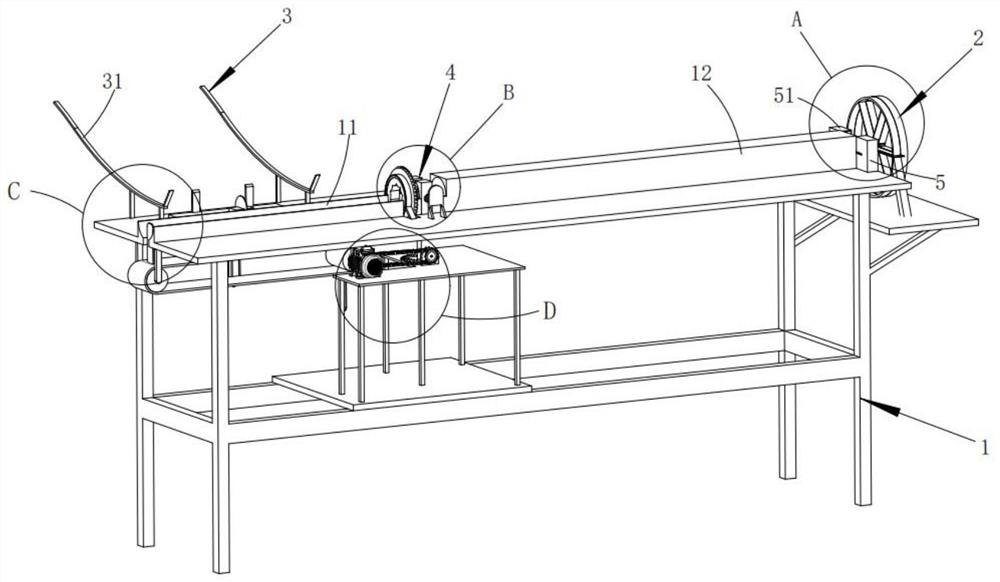

[0044] Such as Figure 1 to Figure 5 As shown, the invention provides a kind of bamboo product production equipment, comprising:

[0045] Equipment platform 1, this equipment platform 1 is provided with the feeding chute 11 and the feeding pipe 12 that are arranged along its length direction and are transitionally connected;

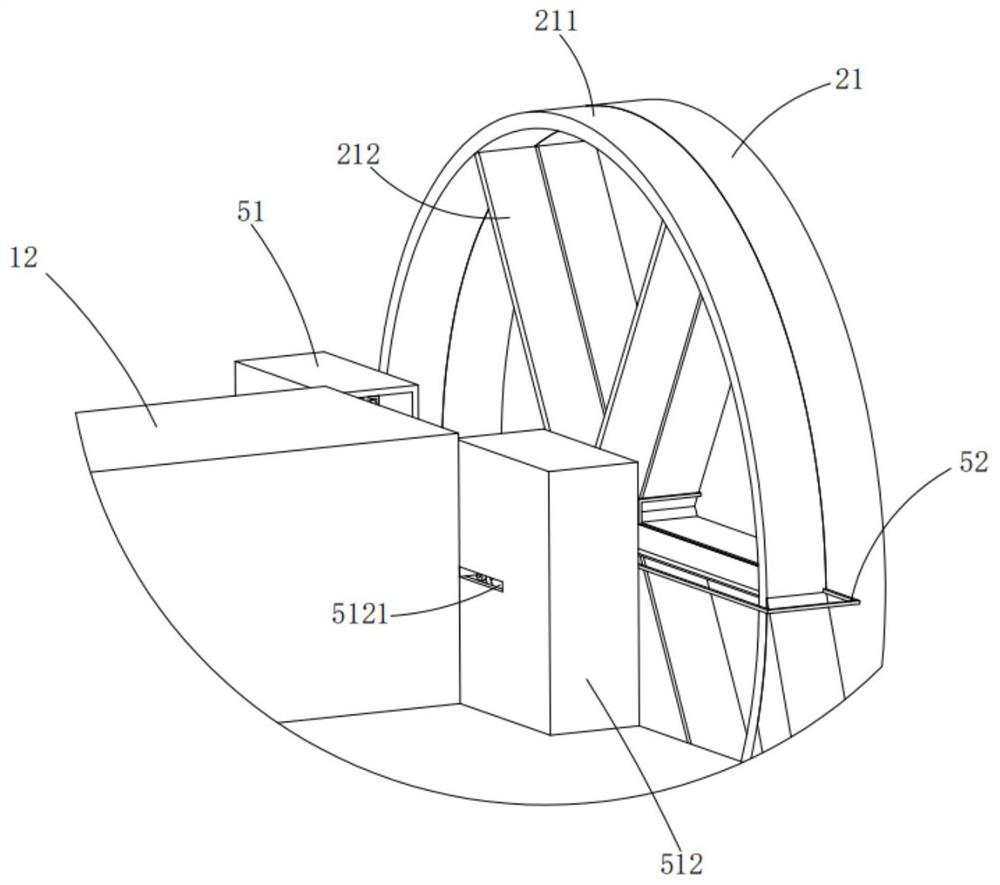

[0046] Cutting device 2, said cutting device 2 includes two groups of cutter assemblies 21 arranged at one end of said feeding pipe 12 and coaxially arranged, and the two groups of cutter assemblies 21 are rotatably connected;

[0047] The feeding device 3, the feeding device 3 includes a blanking track 31 arranged at one end of the chute 11 opposite to the cutter assembly 21 and located on one side of the chute 11, and a blanking track 31 arranged on the side of the chute 11. Between the end of the material track 31 and the chute 11, the slitting assembly 32 that can be turned over and misplaced with the end of the falling material track 31;

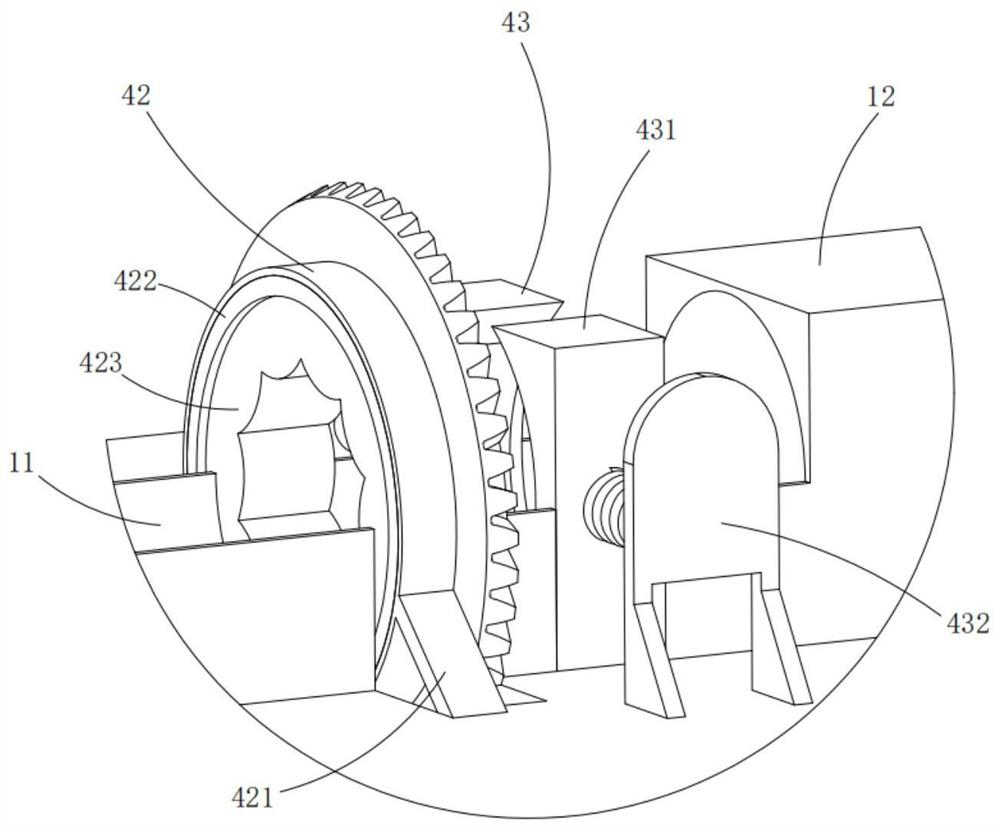

[0048] Gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com