Vacuum pump capable of achieving multiple vacuum degrees

A vacuum pump and vacuum degree technology, which is applied to the components of the pumping device for elastic fluid, pump, pump control and other directions, can solve the problems of complex power transmission shafting, large number of bearings, increase of failure points, etc., to reduce equipment The cost of investment and operation, the high efficiency of mechanical transmission, and the effect of improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

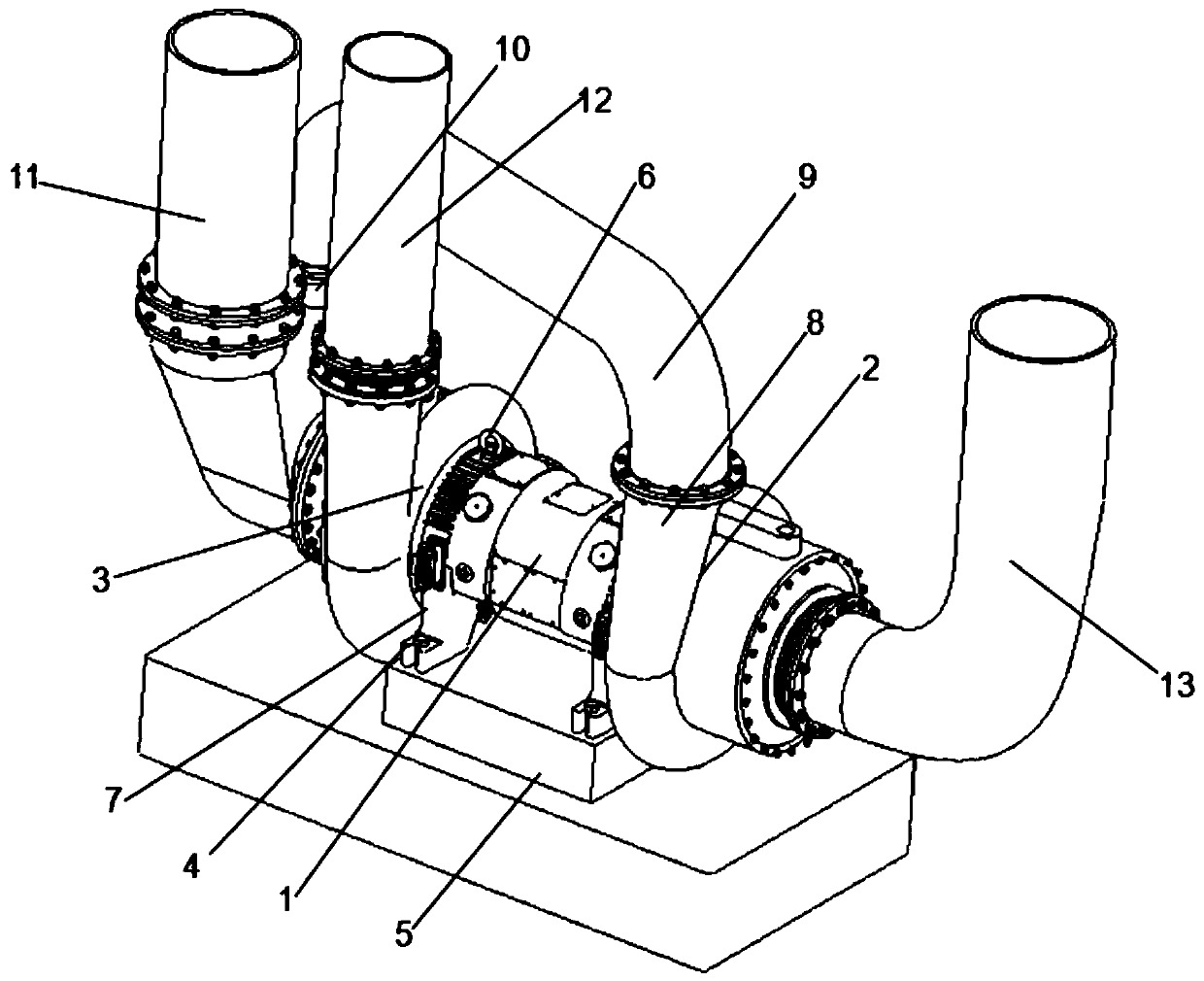

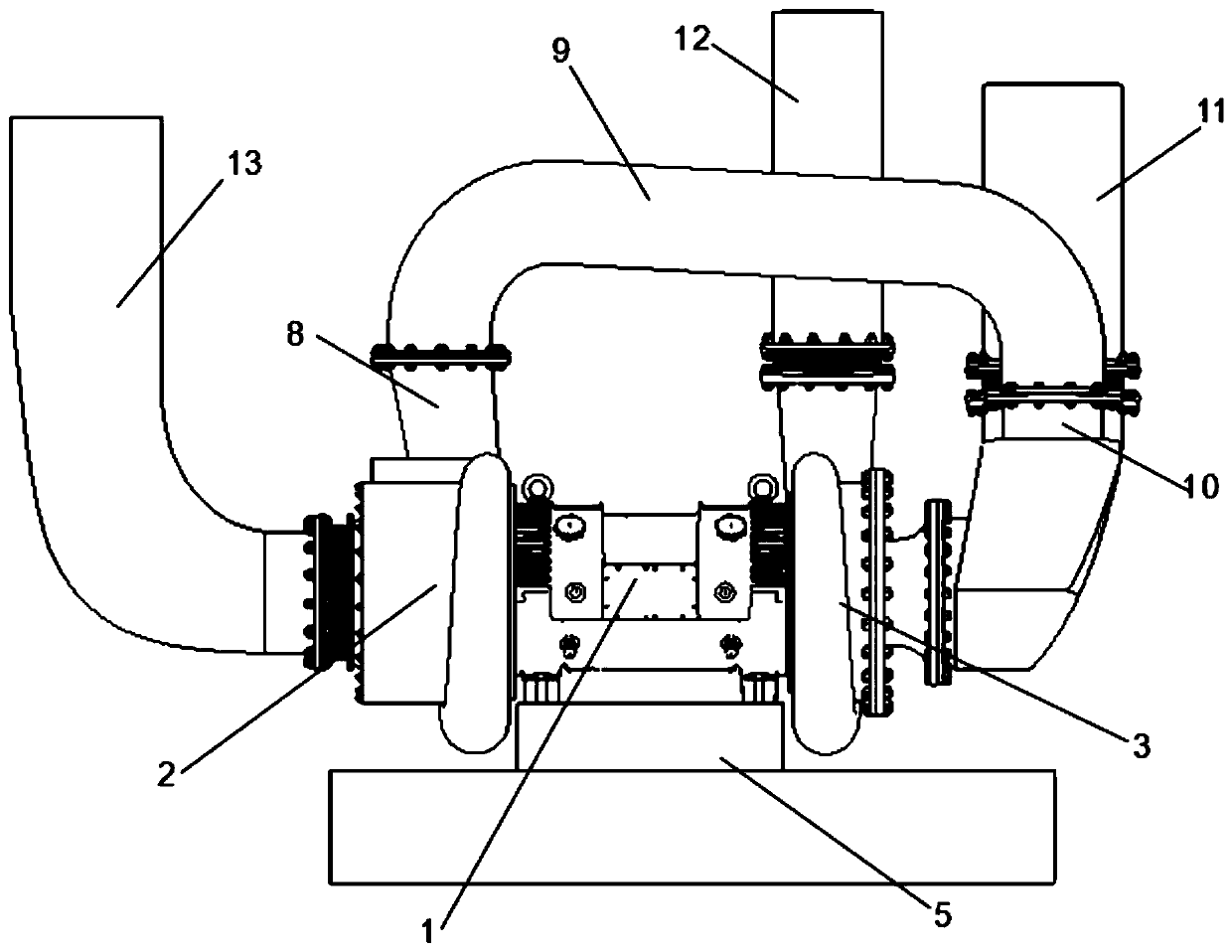

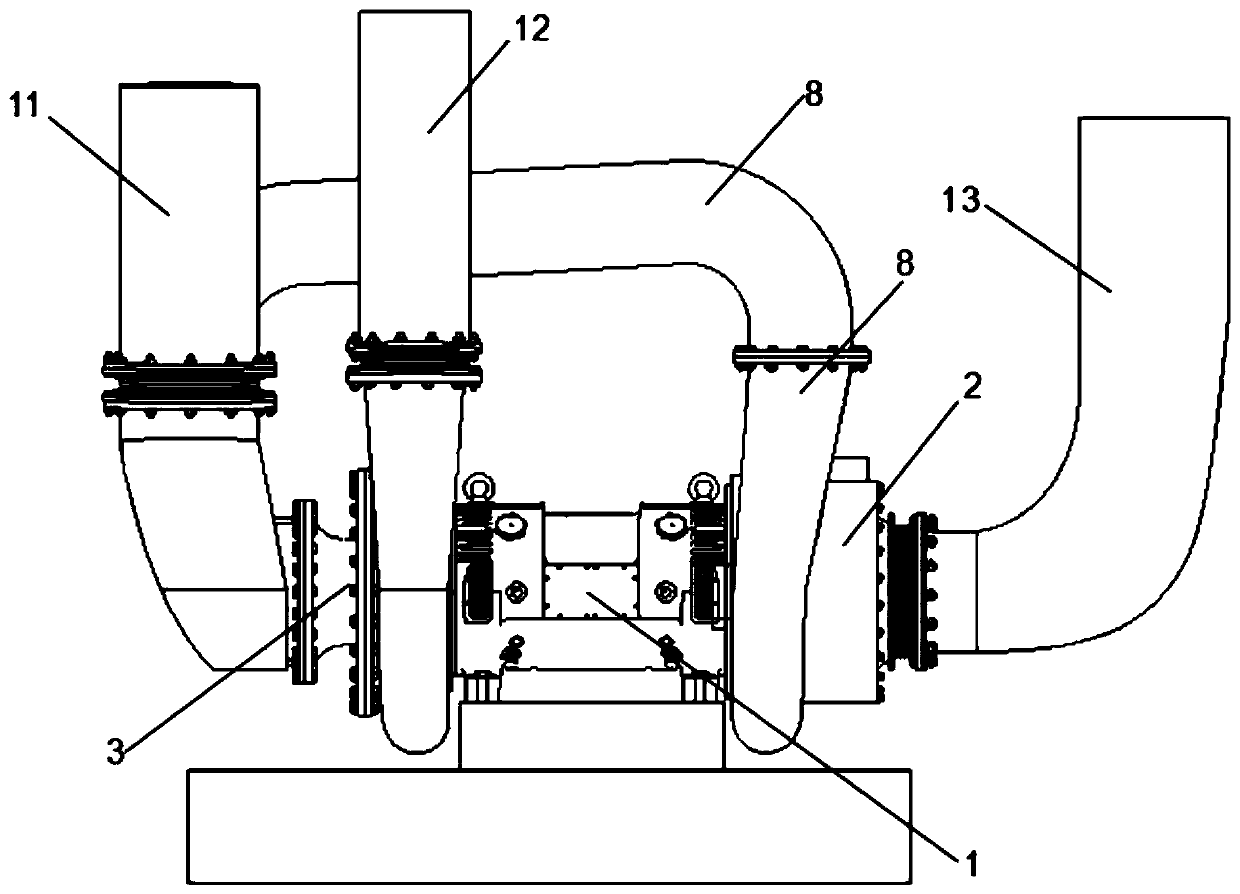

[0033] Embodiment: a kind of vacuum pump that can realize multi-vacuum degree.

[0034] refer to Figure 1 to Figure 8 As shown, a vacuum pump that can realize multiple vacuum degrees includes a base 5 on which a high-speed biaxial drive motor 1, a first vacuum pump body 2 and a second vacuum pump body 3 are installed, and the high-speed biaxial drive motor 1 is provided with four support blocks 7, and each support block 7 is provided with a connecting groove 4, and the support block 7 is fixed on the groove 4 through a connecting piece, and then connected to the base 5 through bolts, which can ensure high-speed double The stability of the shaft drive motor 1 in the working process, the output speed of the high-speed dual-axis drive motor is greater than 10000r / min, and two hoisting rings 6 are arranged side by side above the outer shell of the high-speed dual-axis drive motor 1, which is convenient for the movement of the whole machine and Installation; the first vacuum pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com