Self-centering floating driving device

A driving device and self-centering technology, which is applied to the accessories of tool holders, tailstock/top, metal processing equipment, etc., can solve the problems of large clamping accuracy deviation, low clamping reliability, poor controllability, etc., to achieve Reduce the failure rate, reduce bumping and clamping time, and have the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0041] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of front, rear, top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the description.

[0042] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

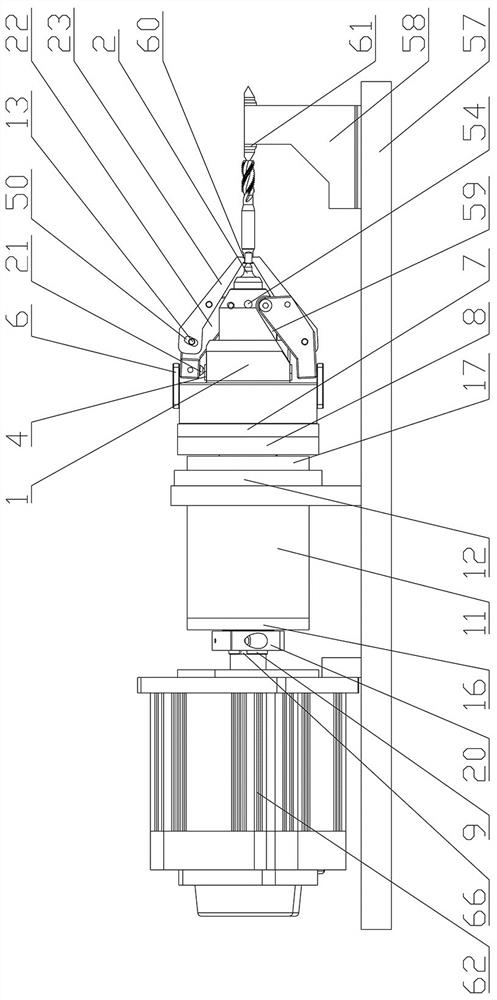

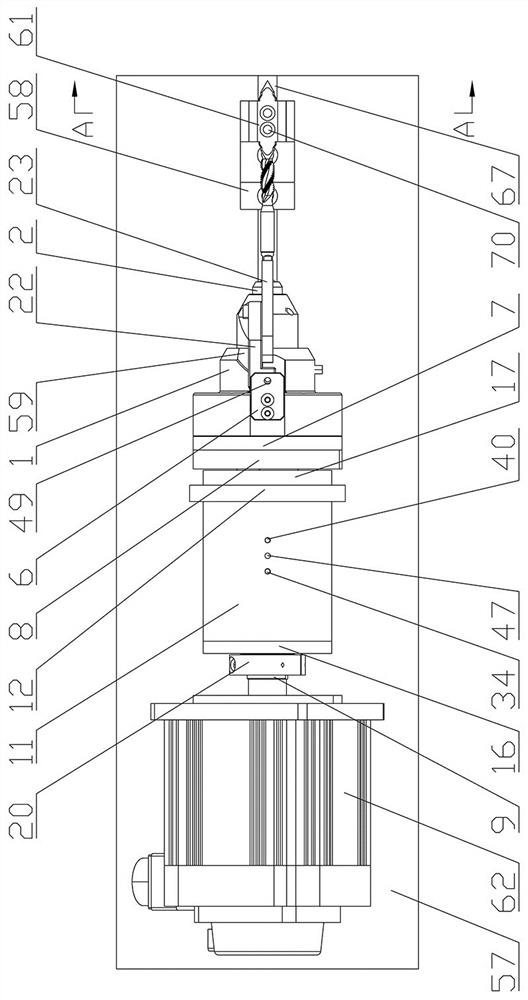

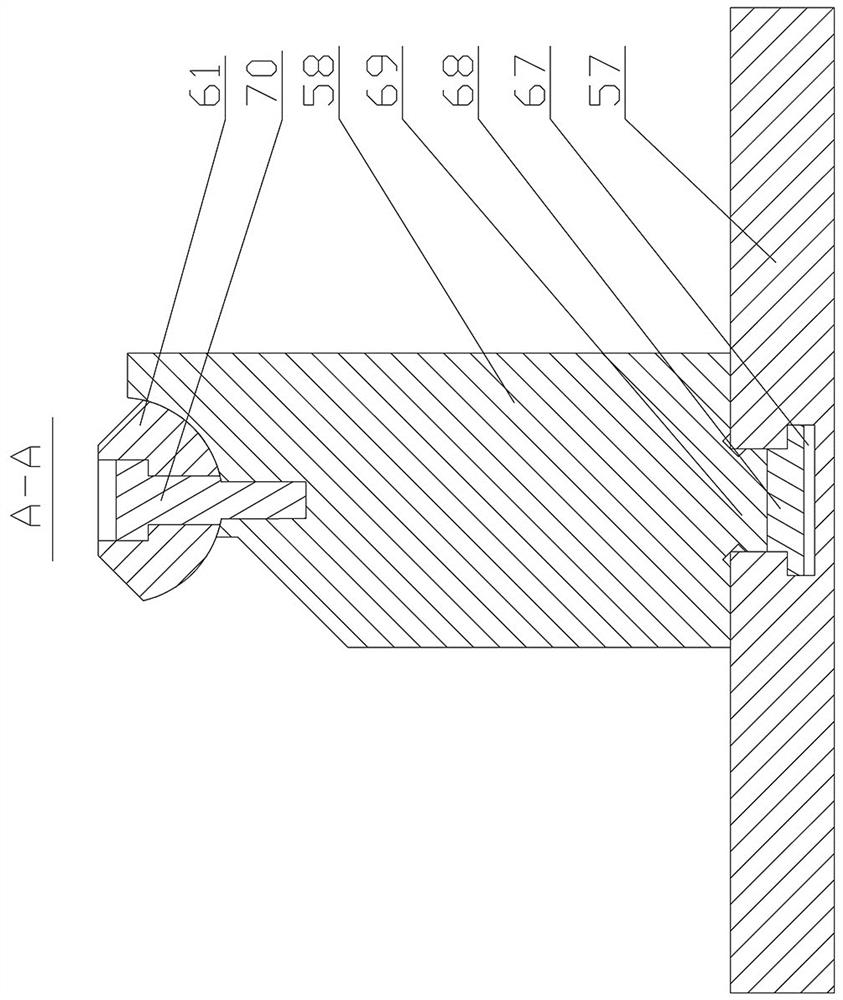

[0043] as attached Figures 1 to 15 As shown, the self-centering floating driving device includes a chuck body 1, a top 2, a jaw assembly, a main piston 3, a secondary piston 4, a base 57, a tailstock 58 and a driving device, and the base 57 is provided with a chuck body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com