Multi-station electrolysis precise grinding automatic machine

A precision grinding, automatic machine technology, applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding machines, etc., can solve the problems of large electrode loss, slow processing progress, large grinding wheel wear, etc., to save production costs, The effect of ensuring machining accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

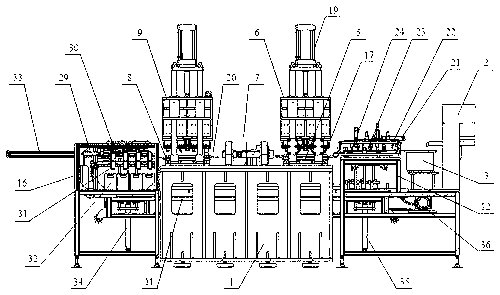

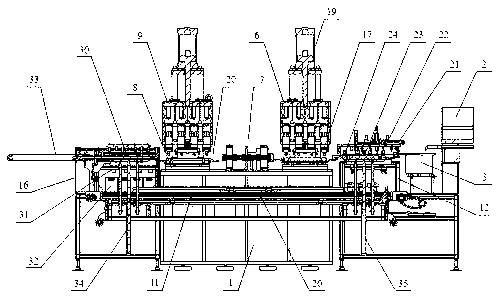

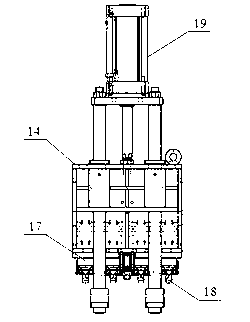

[0028] Such as Figure 1-Figure 17As shown, the multi-station electrolytic precision grinding automatic machine includes a main box 1, an automatic feeding device 4, a first support power supply workbench 5, a first grinding headstock 6, a turning device 7, and a second support power supply workbench 8. The second grinding spindle box 9 and the automatic feeding device 10, the automatic feeding device bracket 12 and the automatic feeding device bracket 16 are fixedly connected to both sides of the main machine box 1, the storage bin 2, the vibrating plate 3, and the transmission rod Cylinder 21, positioning frame cylinder 23, rising cylinder 35 and conveyor belt motor 25 are fixedly connected on the automatic feeding device support 12, and transmission pull rod 22 and positioning frame 24 are respectively fixedly connected on transmission pull rod cylinder 21 and positioning frame cylinder 23, can be in The reciprocating motion is performed on the support 12 of the automatic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com