Patents

Literature

31results about How to "Solve conductive problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

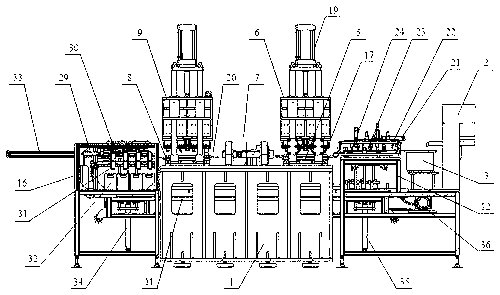

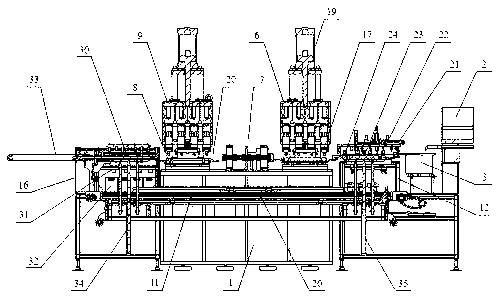

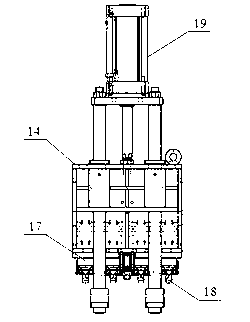

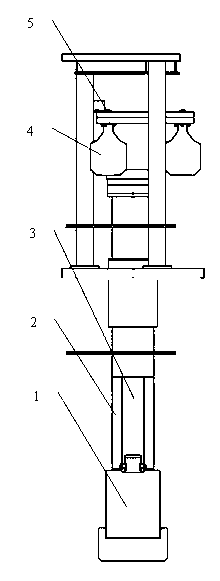

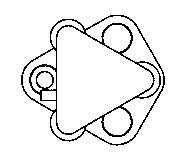

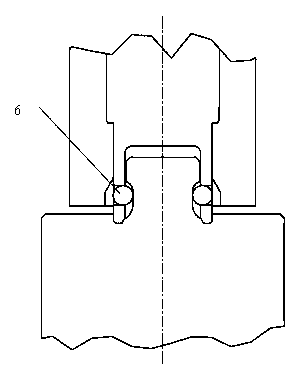

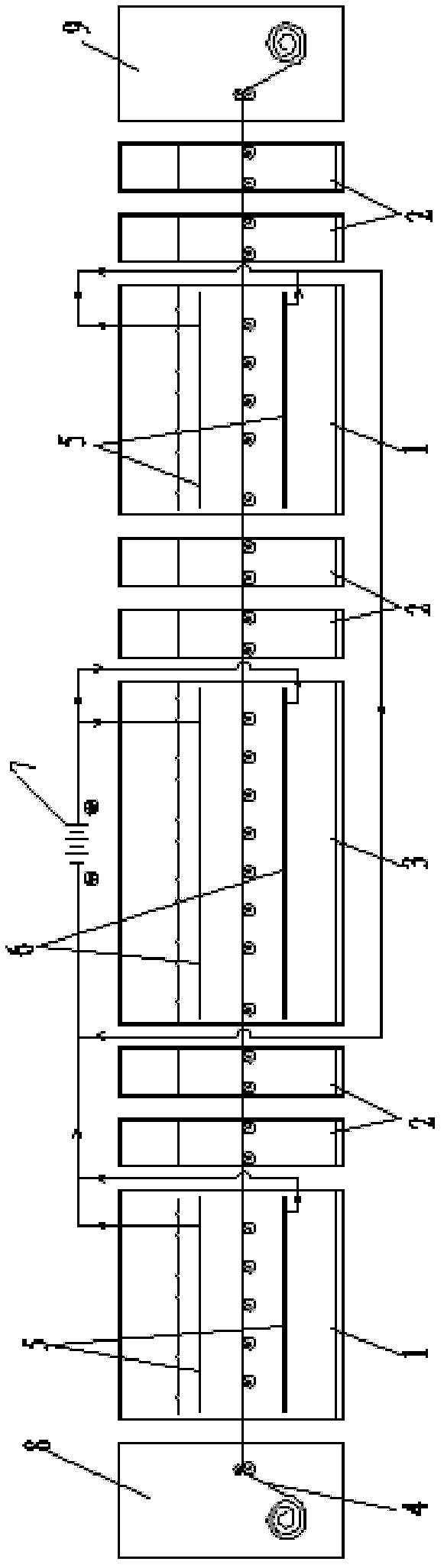

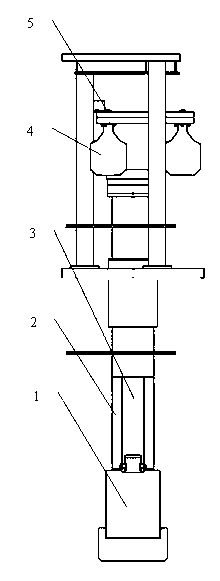

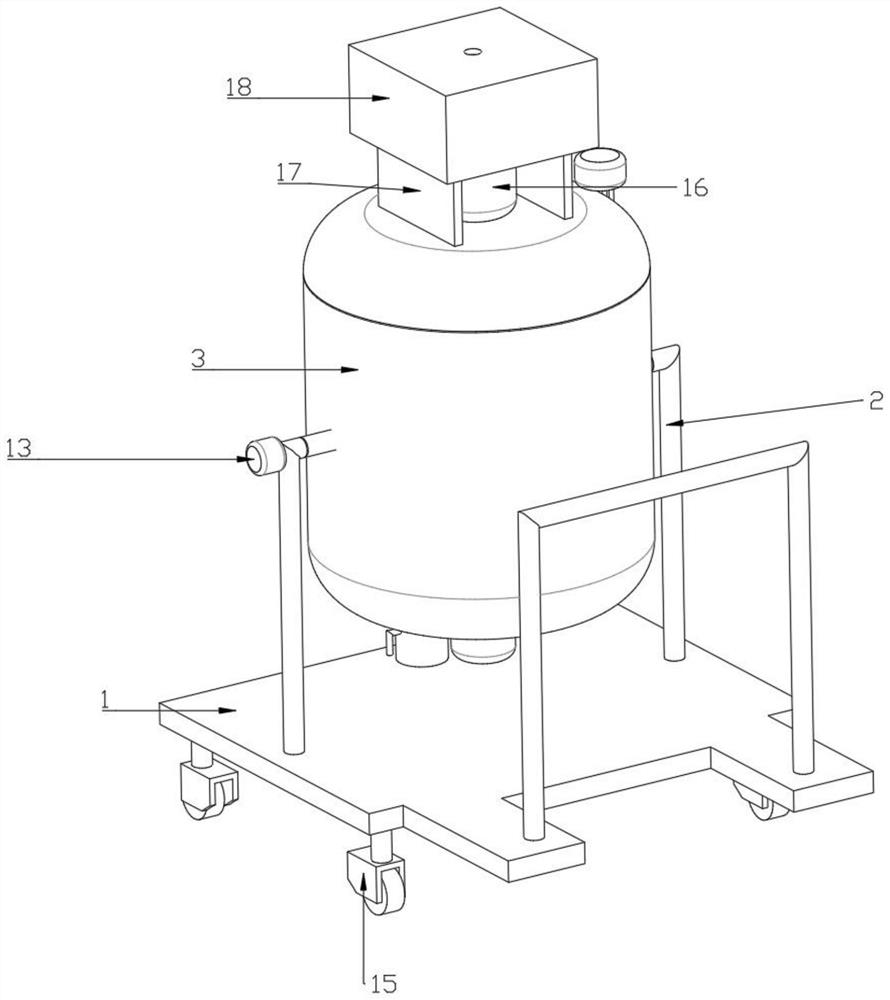

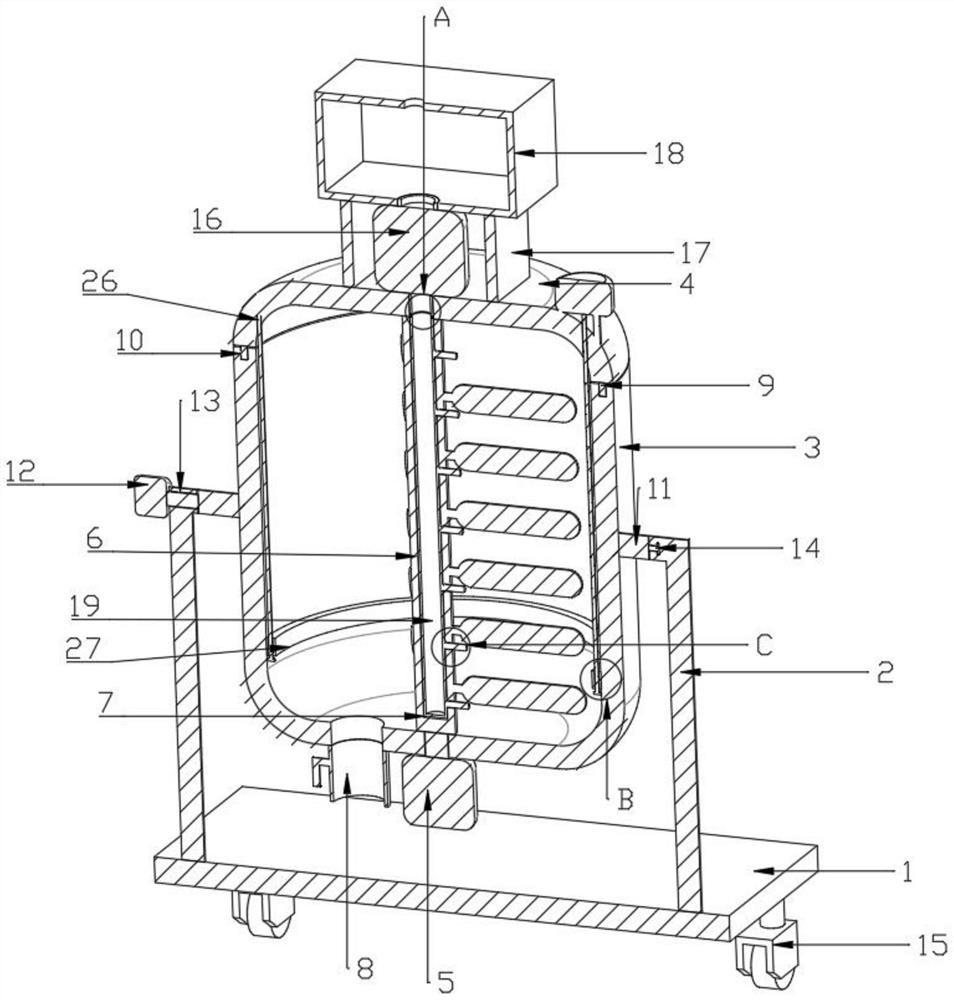

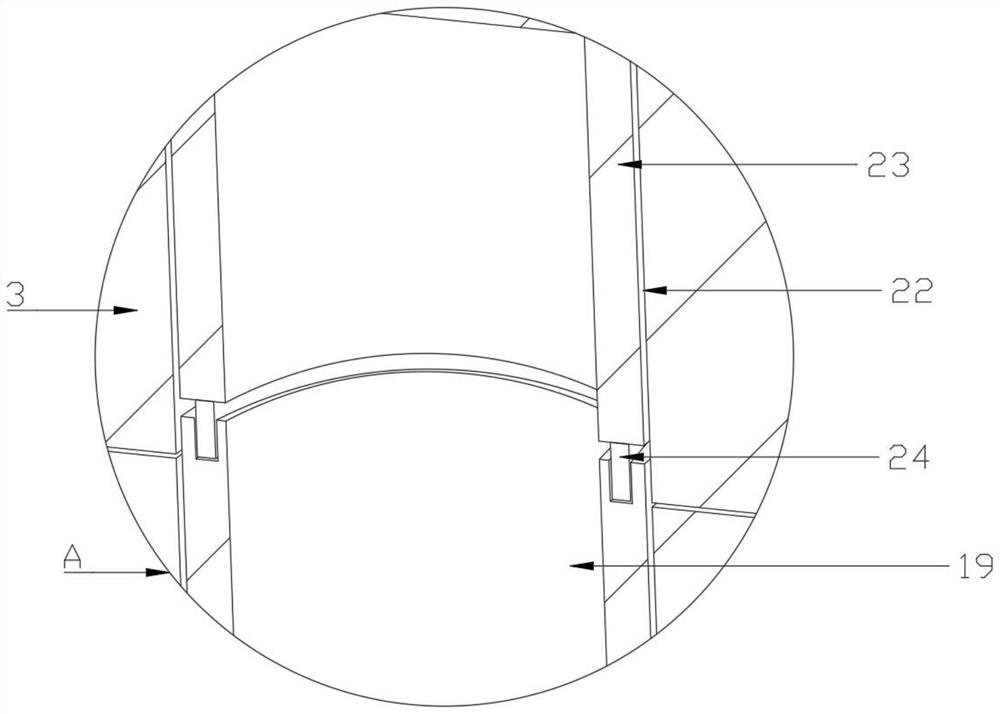

Multi-station electrolysis precise grinding automatic machine

InactiveCN103273402AReduce lossGuaranteed machining accuracyGrinding machinesGrinding work supportsElectrolysisEngineering

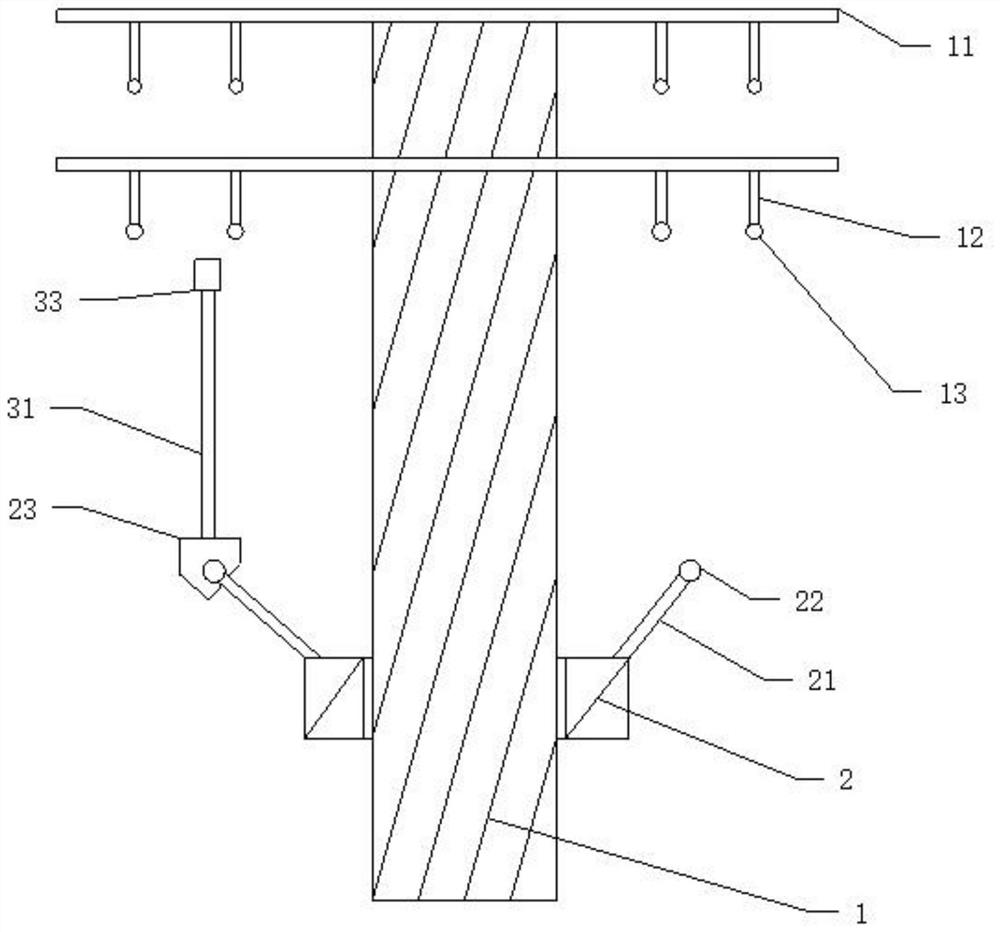

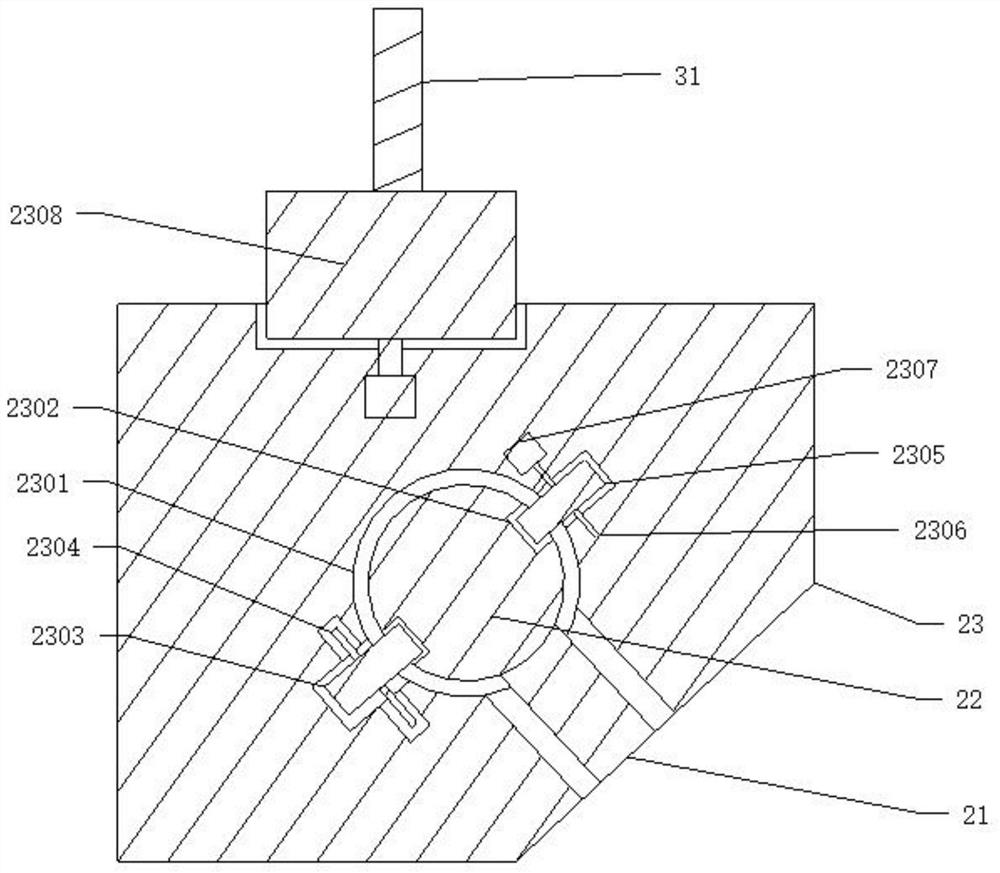

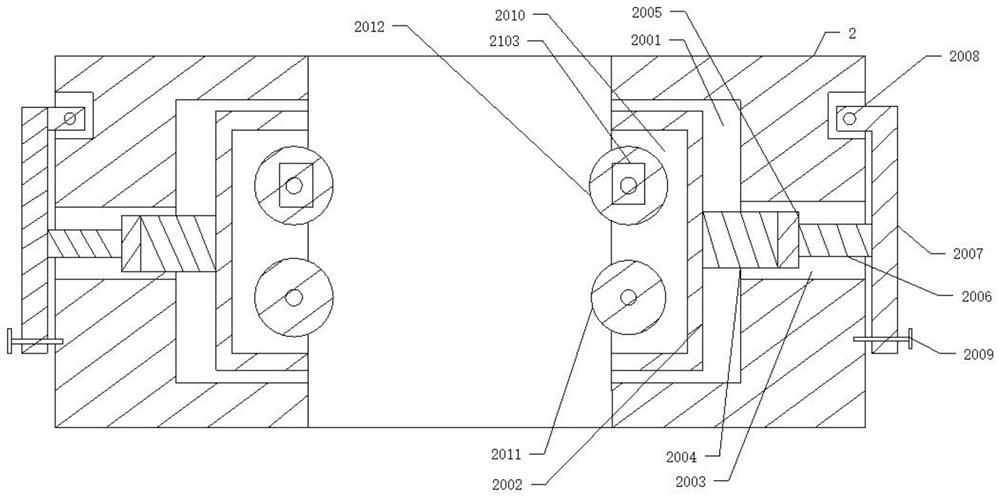

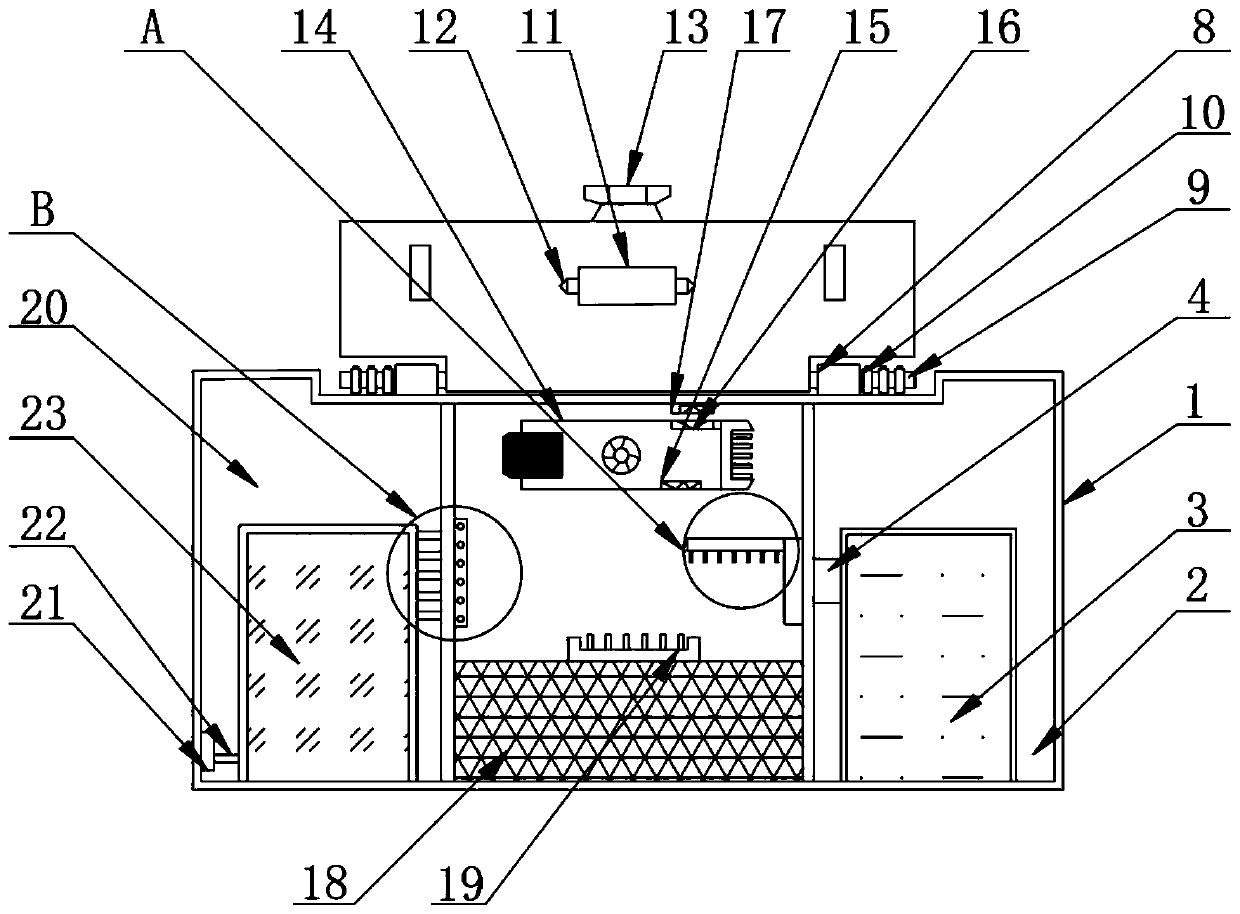

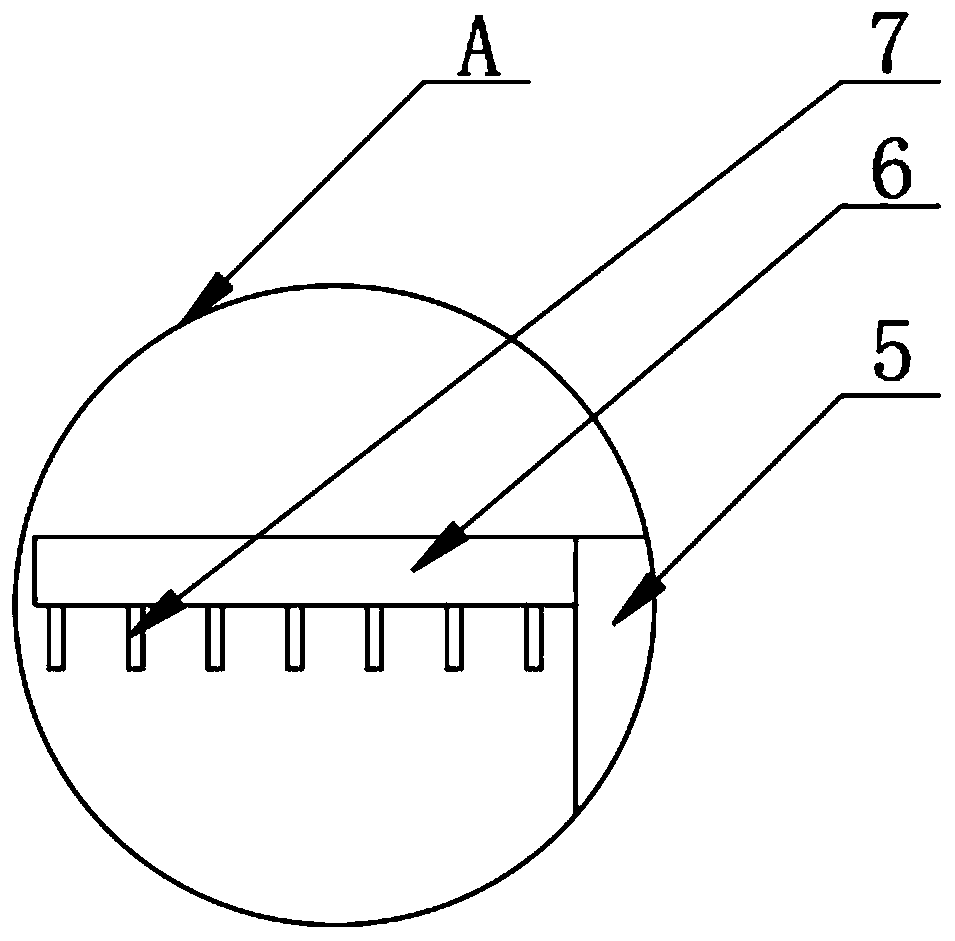

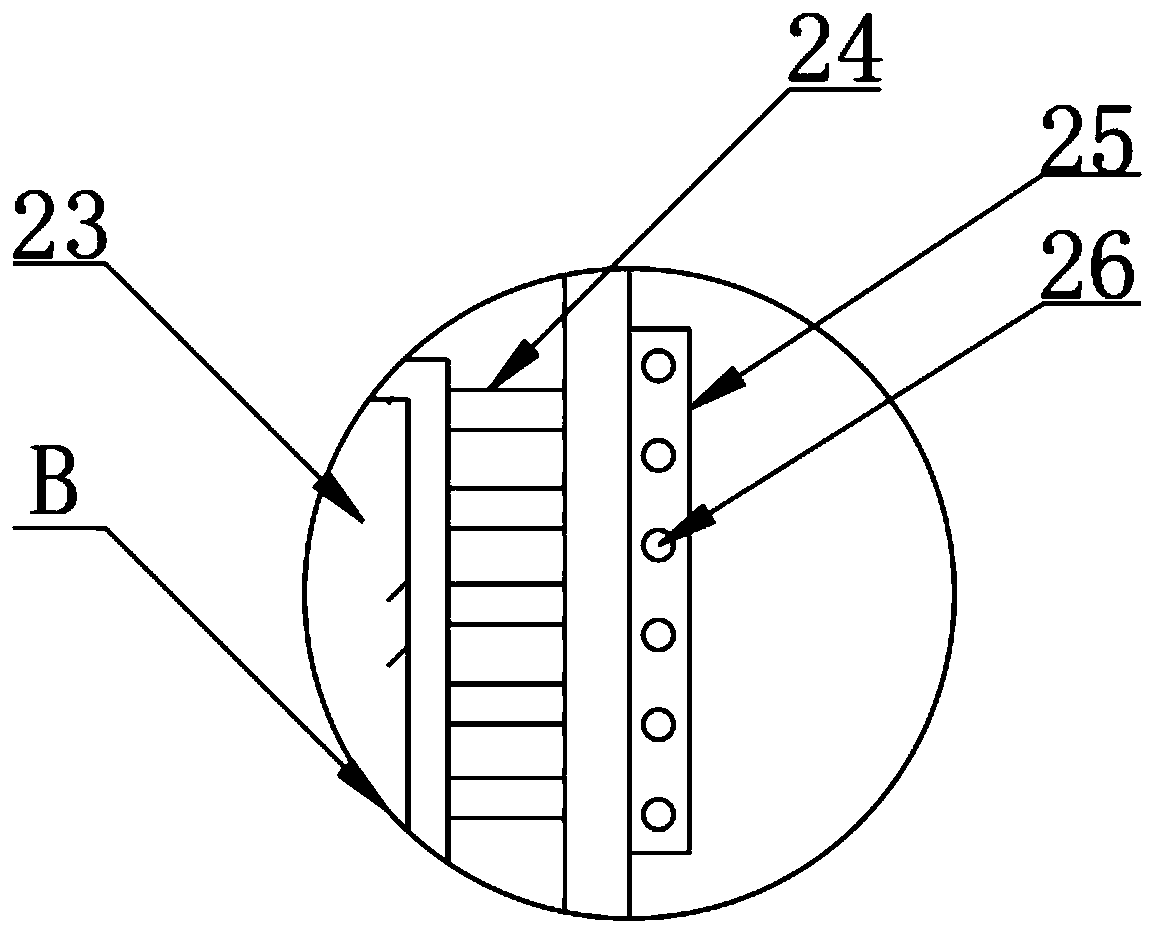

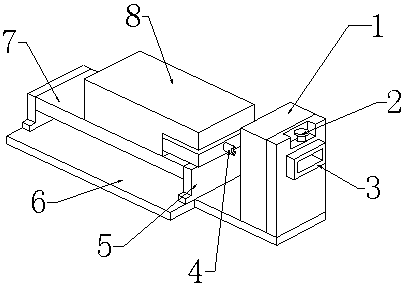

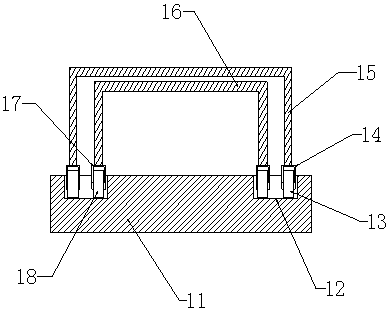

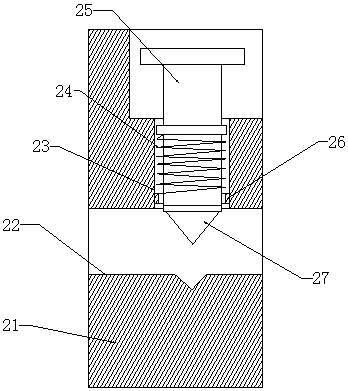

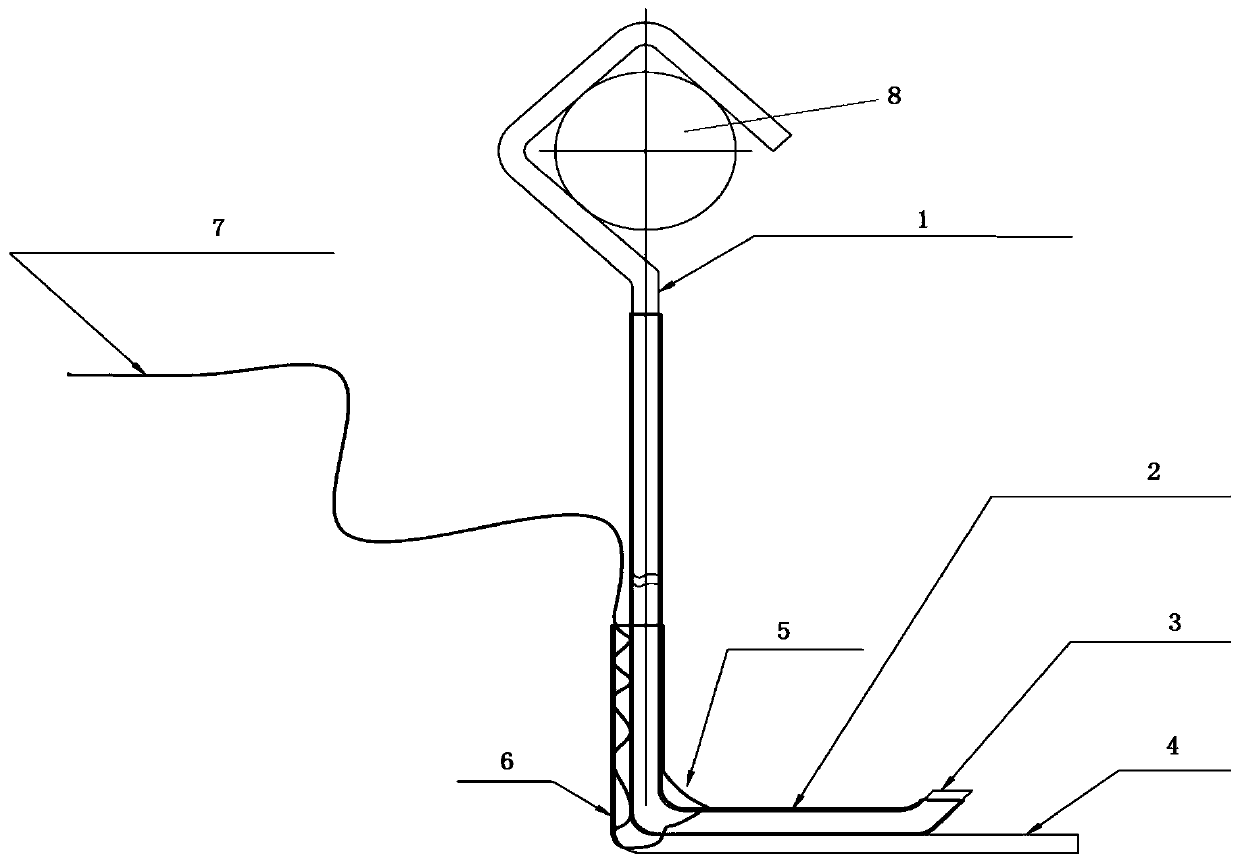

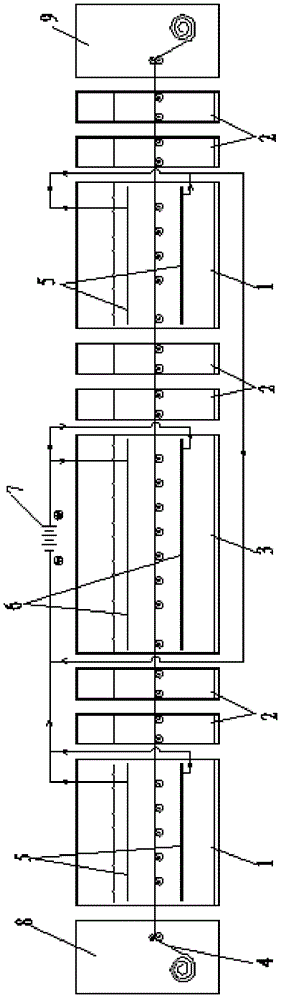

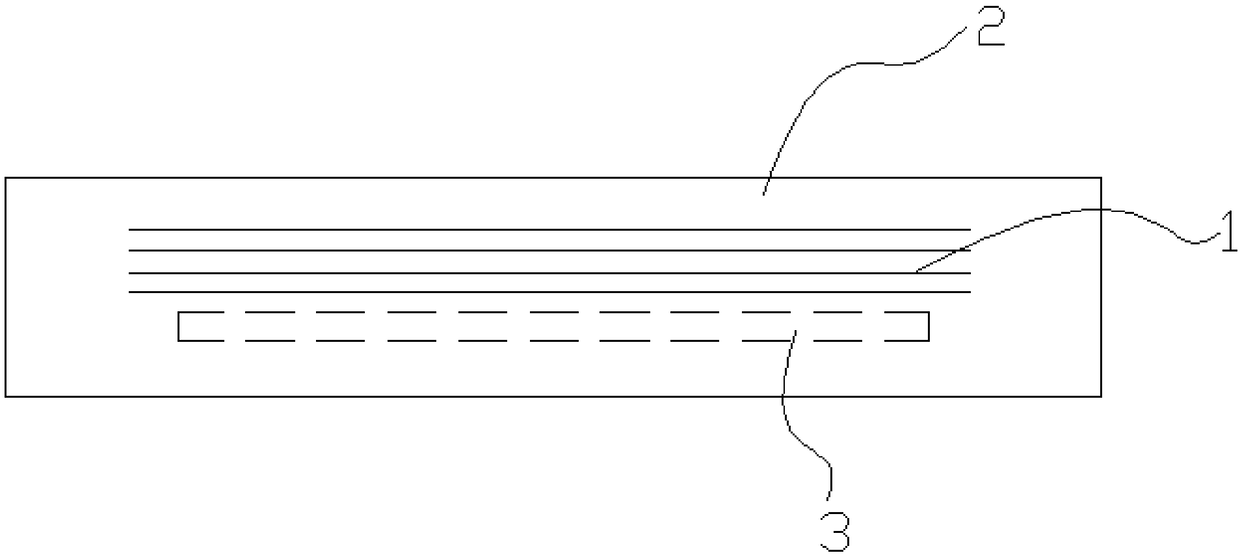

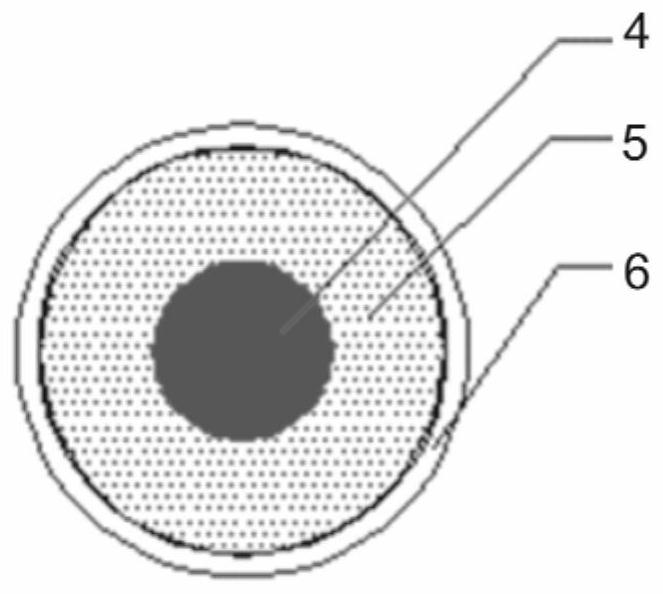

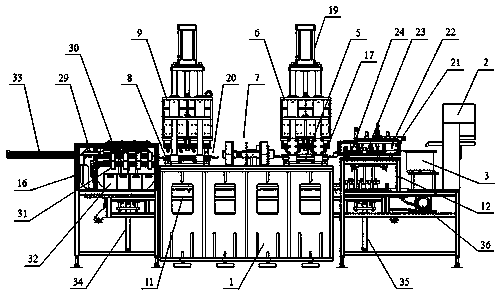

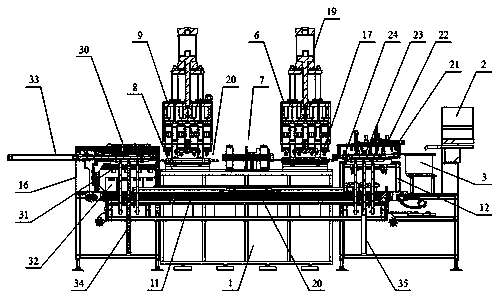

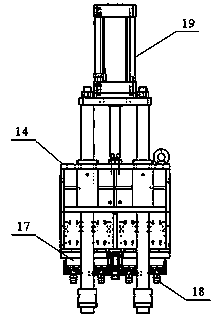

The invention relates to a multi-station electrolysis precise grinding automatic machine, and belongs to devices for conducting full-automatic grinding machining on the inner surface and the outer surface of a shaver net. The multi-station electrolysis precise grinding automatic machine adopts a follow clamp of a ship-plate type structure, can automatically feed and discharge materials, can conduct simultaneous operations at eight stations, uses an electrolytic action and an electric conduction grinding wheel with mechanical grinding capacity to conduct machining on the shaver net, greatly improves work efficiency, machining stability and accuracy, reduces losses of the grinding wheel and saves production cost. Machining on the front face and the back face of a machined piece can be achieved on one machine through a turnover device. Electrolytic machining is carried out on the machined piece through the electrode power supply electric conduction mode, the soft sheet connection electric conduction mode, the floating steel ring electric conduction mode and the insulation sleeve insulation electric conduction mode. Zirconia ceramics are made into a base to serve as a support due to the characteristics of insulation, abrasion resistance and high temperature resistance of the zirconia ceramics, and the centering effects of the machining position of the machined piece are achieved. An air-tight seal is adopted to prevent the situation that electrolytes spill out or atomize so as to enter a main grinding shaft box to abrade parts when the grinding wheel conducts grinding.

Owner:DALIAN JIADEHENG SCI & TECH

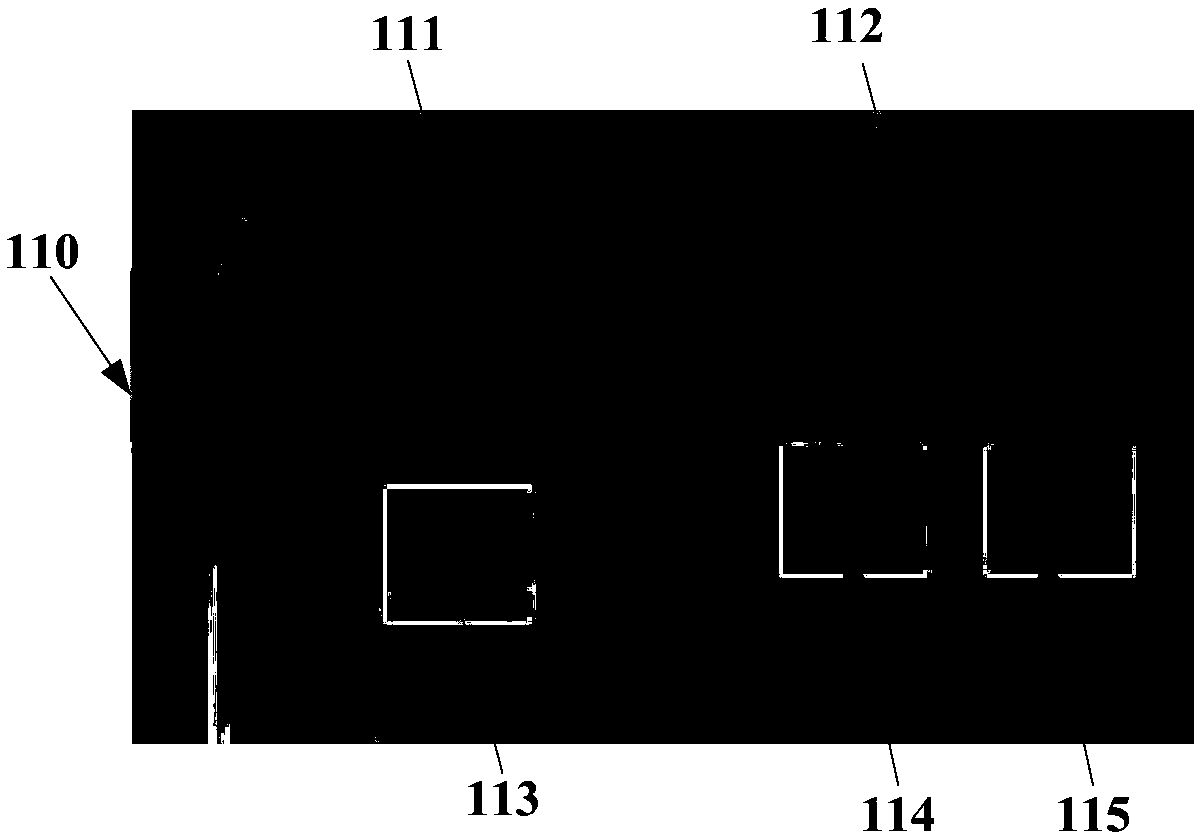

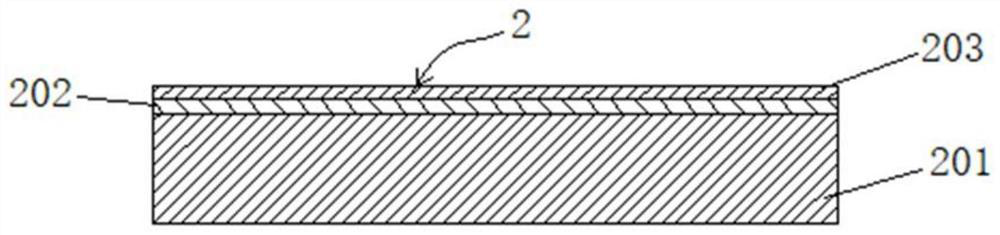

Metal housing and manufacturing method thereof

PendingCN108076608ANot prone to wear and oxidationLow conductivityMolten spray coatingVacuum evaporation coatingElectricityUltrasonic welding

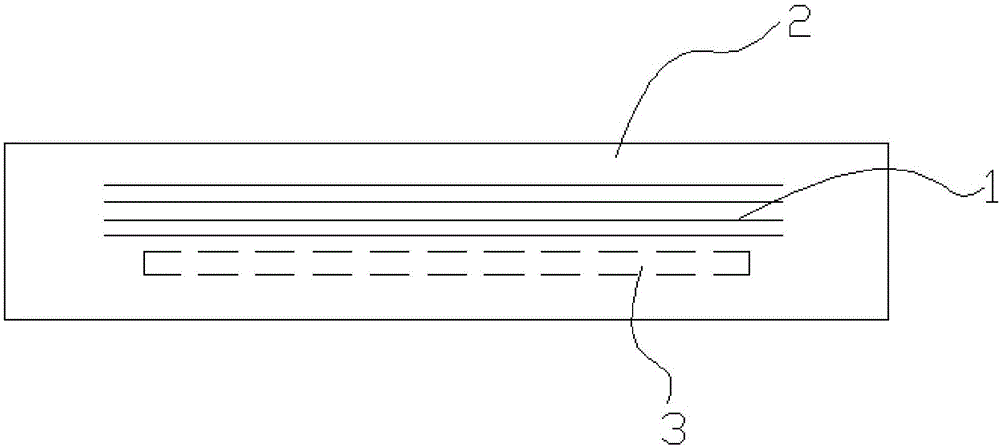

The invention discloses a metal housing and a manufacturing method thereof. According to the invention, a metal thin layer is deposited in an electrical connection contact area on a shell of the metalhousing, and the abrasion resistance and corrosion resistance of the metal thin layer are higher than that of a metal base material adopted by the shell, so that the metal thin layer is exposed at anelectrical connection contact in the actual using process, the high abrasion resistance and high corrosion resistance of the metal thin layer can avoid repeated friction between the electrical connection contact and a metal elastic piece on a mainboard of electrical equipment to generate particles, and thus the conductivity of the electrical connection contact is avoided from being affected by oxidation and accumulation of the particles. Compared with a mode of fixing a metal sheet on the electrical connection contact through laser welding, ultrasonic welding or screws in the prior art, the deposited metal thin layer in the embodiment of the invention is not limited by the space of an inner cavity of the shell and can be implemented on any sizes of electrical connection contacts, so thatthe embodiment of the invention can fundamentally solve a conductive problem of the electrical connection contact on the metal housing.

Owner:HUAWEI MACHINERY

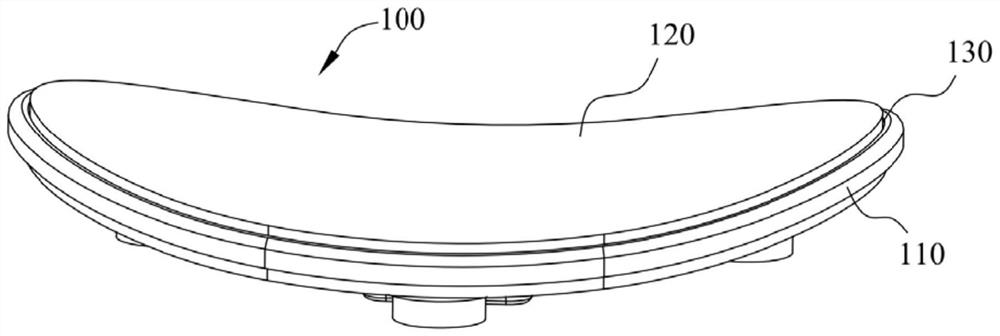

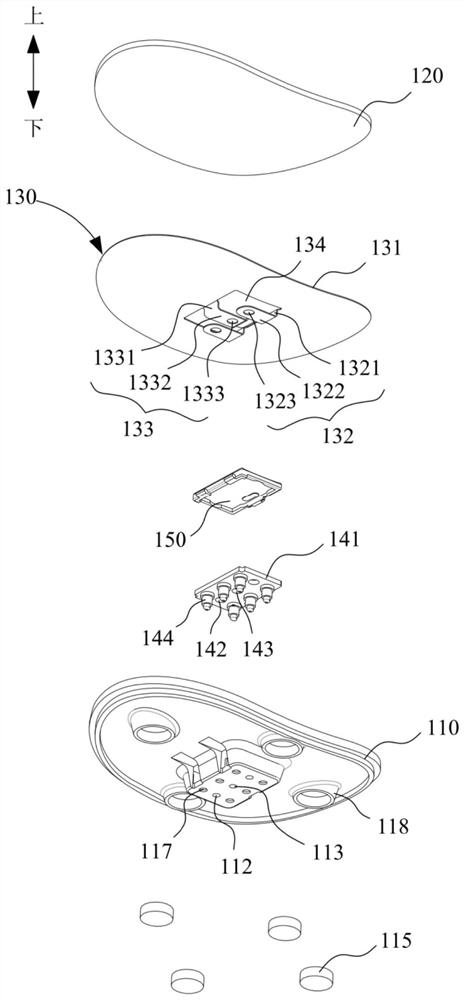

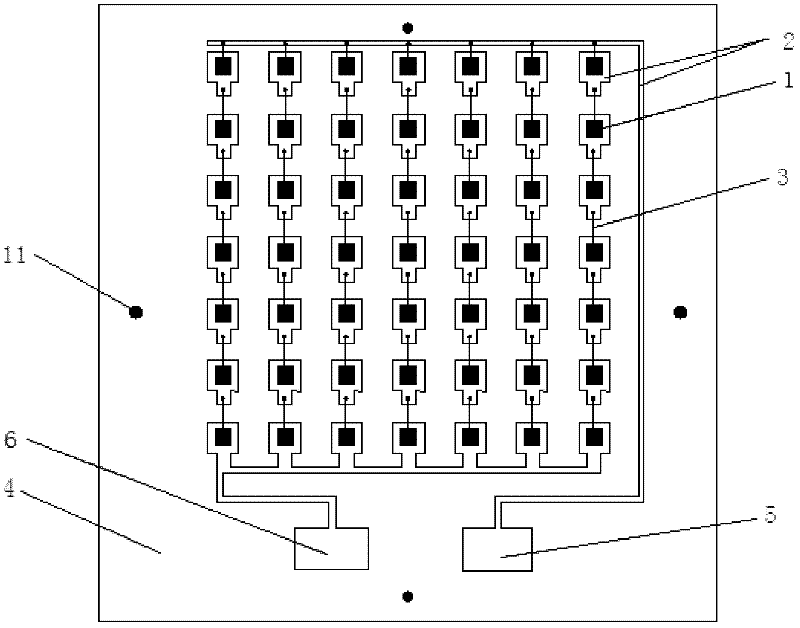

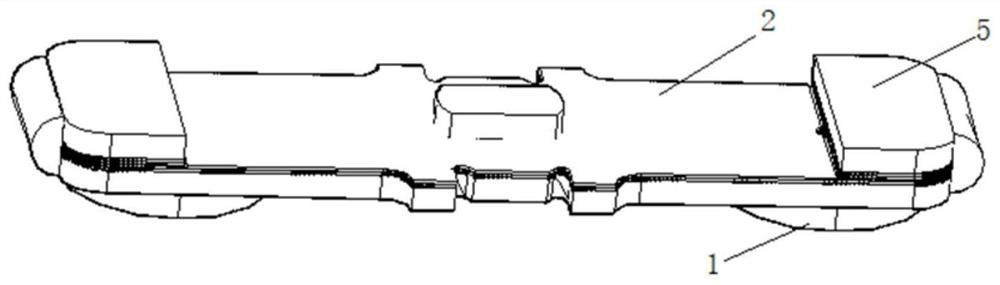

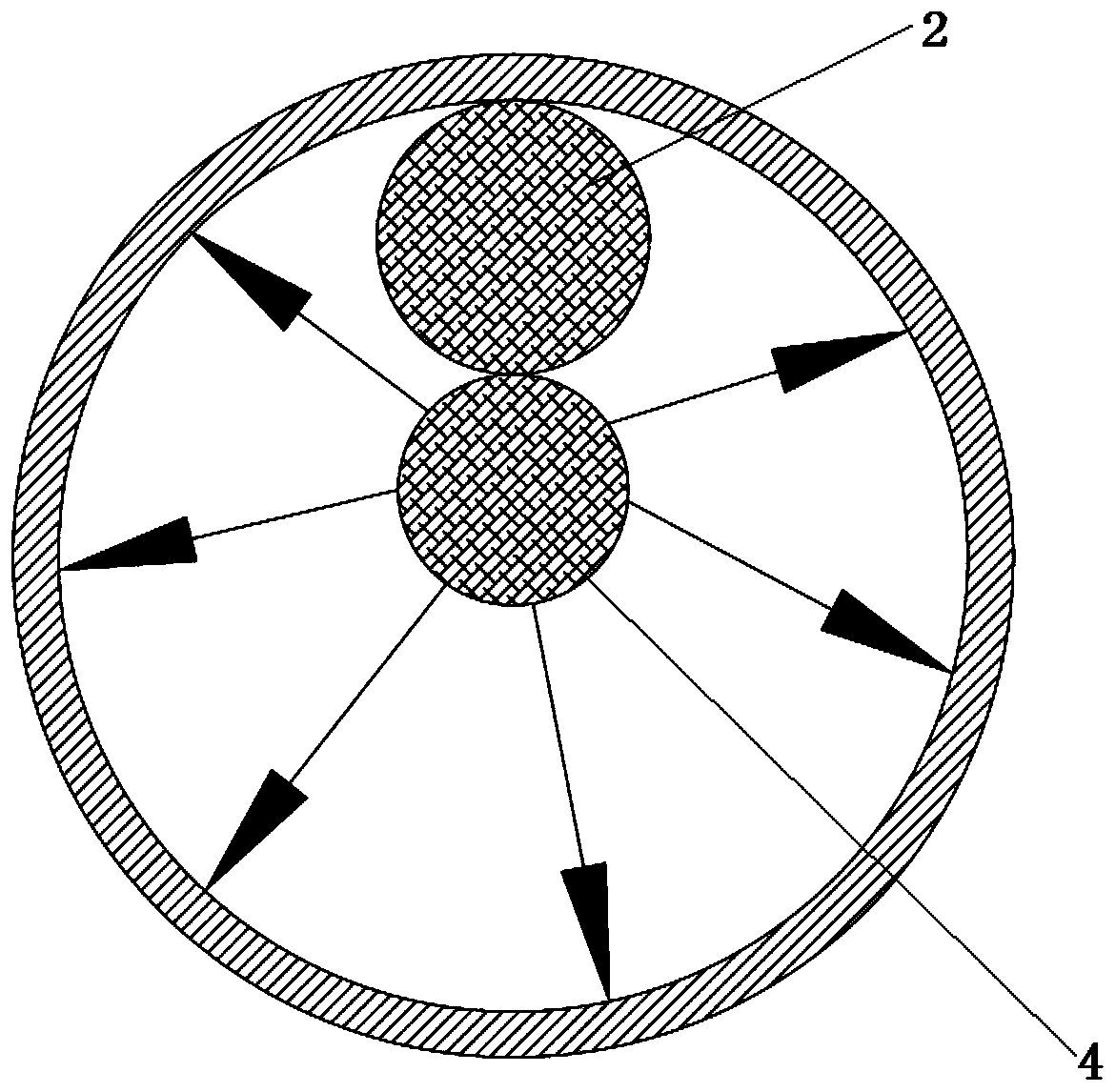

Electrode assembly, massage head, neck massager and wearable massage equipment

ActiveCN112023253AGood light transmissionReduced radiation shieldingLight therapyExternal electrodesMetallic electrodeMedicine

The invention discloses an electrode assembly, a massage head, a neck massager and wearable massage equipment. The electrode assembly comprises a carrier, a non-metal electrode slice and a conductingfilm, wherein the non-metal electrode slice is arranged on the carrier and used for making contact with the skin of the human body; the conducting film is arranged between the carrier and the non-metal electrode slice; and the conducting film is attached to the non-metal electrode slice and electrically connected with the non-metal electrode slice so as to connect a power supply to the non-metal electrode slice. According to the electrode assembly in the embodiment of the invention, the non-metal electrode slice is adopted, and the conducting film is arranged between the carrier and the non-metal electrode slice to conduct electricity to the non-metal electrode slice, so that the problem of electricity conduction of the non-metal electrode slice can be solved; and due to adoption of the non-metal electrode slice, the light transmittance of the electrode assembly can be improved, the ray shielding property of the electrode assembly can be reduced, and the function expansibility of equipment such as the massage head, the neck massager and the wearable massage equipment provided with the electrode assembly can be improved.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

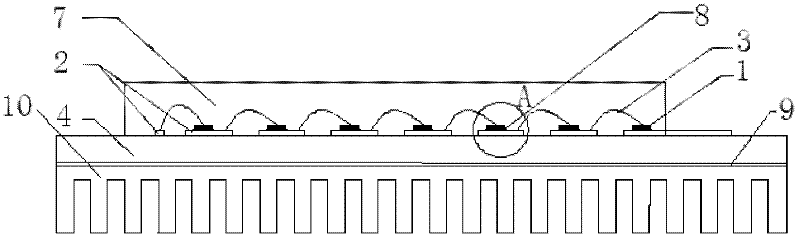

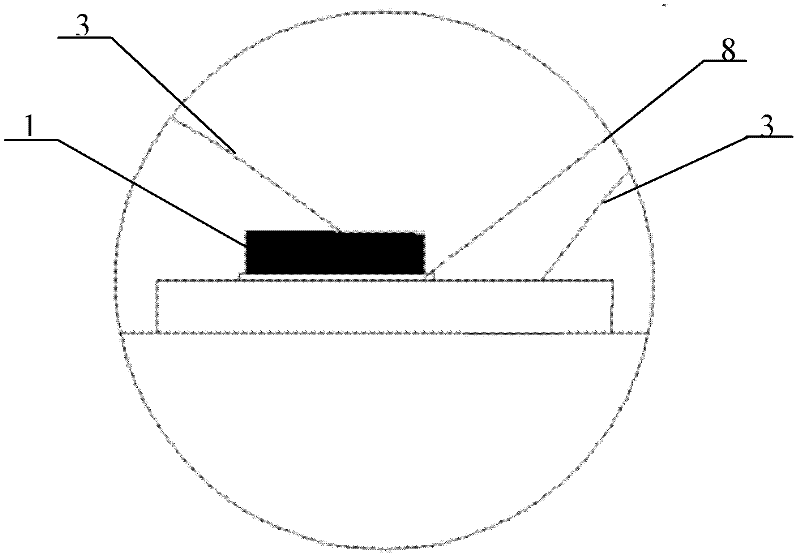

LED encapsulated by ceramic substrate in integrated mode

InactiveCN102244189AImprove cooling effectReduce thermal contact resistanceSolid-state devicesSemiconductor devicesColloidThermal contact

The invention discloses a light-emitting diode (LED) encapsulated by a ceramic substrate in an integrated mode, which comprises a ceramic substrate, wherein a circuit and a circuit positive electrode and a circuit negative electrode at both ends of the circuit are arranged on the metalized front side of the ceramic substrate; a metal base for connecting chips is arranged on the circuit; the chips and the metal base are connected by an eutectic layer; the metal base is connected with the adjacent chip by a connection wire; and fluorescent powder colloid is wrapped on the chips. In the LED encapsulated by the ceramic substrate in an integrated mode, thermal contact resistance is reduced by the application of the high-heat conduction ceramic substrate and the application of the eutectic technology and metalized technology, so that the radiating performance of a high-power integrated encapsulation LED light source is improved greatly.

Owner:IRICO

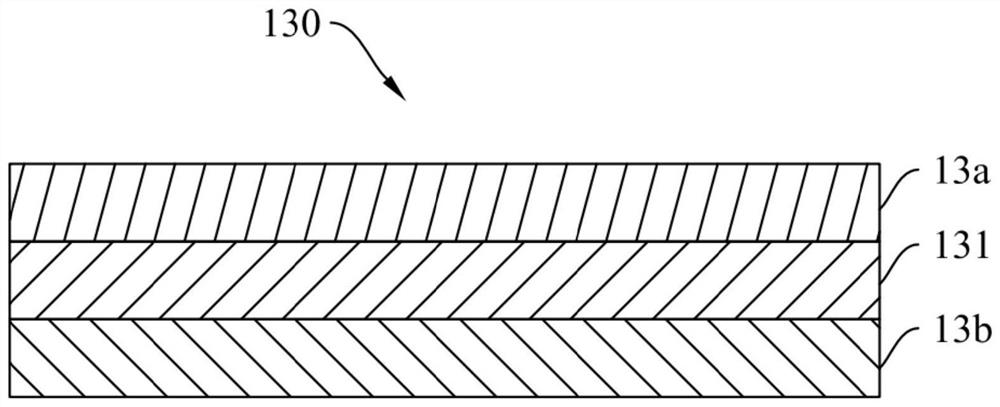

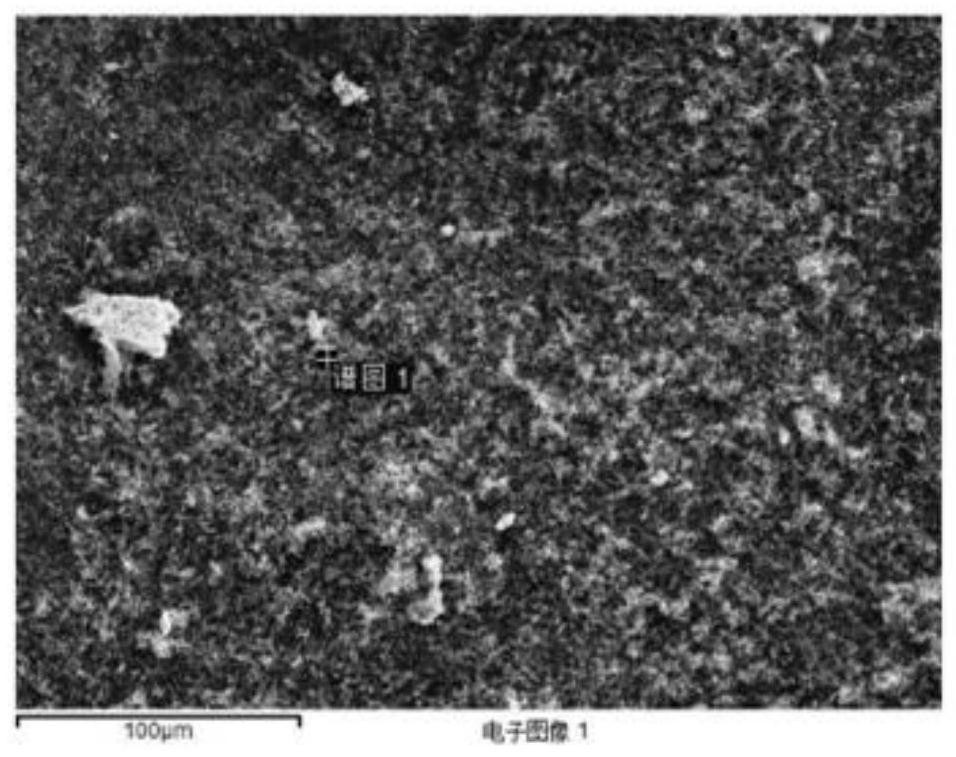

Neodymium-iron-boron magnetic steel with coating and preparation methods thereof

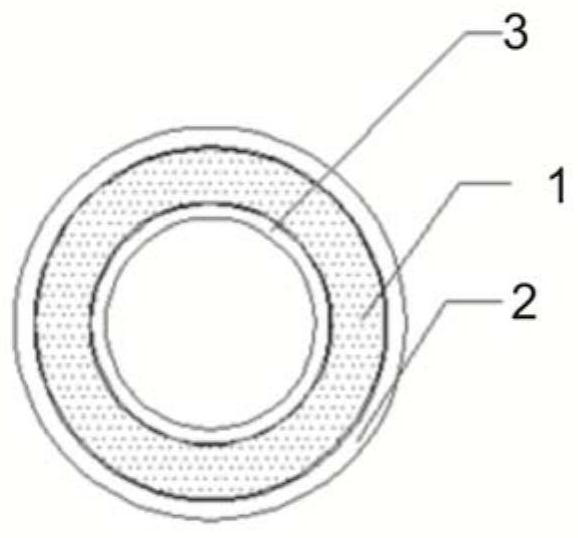

InactiveCN102166873AGood insulation performanceSolve conductive problemsMolten spray coatingLayered productsPolytetrafluoroethyleneThermal spraying

The invention provides neodymium-iron-boron magnetic steel with a coating. The neodymium-iron-boron magnetic steel comprises a neodymium-iron-boron substrate and the coating arranged on the surface of the neodymium-iron-boron substrate, wherein the coating is formed by a fluorine coating taking polytetrafluoroethylene as substrate resin, and the content of tetrafluoroethylene in the fluorine coating is over 75 weight percent. The invention also provides two preparation methods of the neodymium-iron-boron magnetic steel with the coating. The coating of the neodymium-iron-boron magnetic steel is prepared by a thermal spraying process or a coating and baking process respectively. The surface coating of the neodymium-iron-boron magnetic steel is prepared from the fluorine coating taking the polytetrafluoroethylene as the substrate resin, so that the neodymium-iron-boron magnetic steel has high insulating property, the problem of electric conduction of the neodymium-iron-boron magnetic steel can be effectively solved, and eddy-current loss is reduced; meanwhile, the neodymium-iron-boron magnetic steel has high corrosion resistance and high-temperature stability, is not corroded by an external environment, and can stably work in the process that an electric motor is operated.

Owner:BYD CO LTD

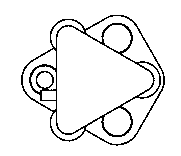

Conductive automatic clamping device for electrode of electric slag furnace

The invention provides a conductive automatic clamping device for an electrode of an electric slag furnace. The conductive automatic clamping device is characterized by comprising an auxiliary electrode, a conductive material rod, a fixing shaft, thin film air cylinders, a fixing board and a marble, wherein the conductive material rod is connected to the auxiliary electrode through the marble; the fixing shaft and the fixing board are fixedly arranged on a furnace head bracket; the fixing shaft is arranged on the outer side of the conductive material rod; and a vertical moving sleeve consistsof the conducive material rod and the three thin film air cylinders. The conductive automatic clamping device provided by the invention has the advantages that the device for automatically locking bymeans of using the three thin film air cylinders as power to drive a water cooling inner sleeve material rod to slide a ceramic ball group is designed. The conduction problem, caused by large lockingcontact current (40000 A) of a large-size consumable electrode and the conductive material rod of the 120-t electric slag furnace, can be solved.

Owner:SUZHOU ZHENWU ELECTRIC FURNACE +1

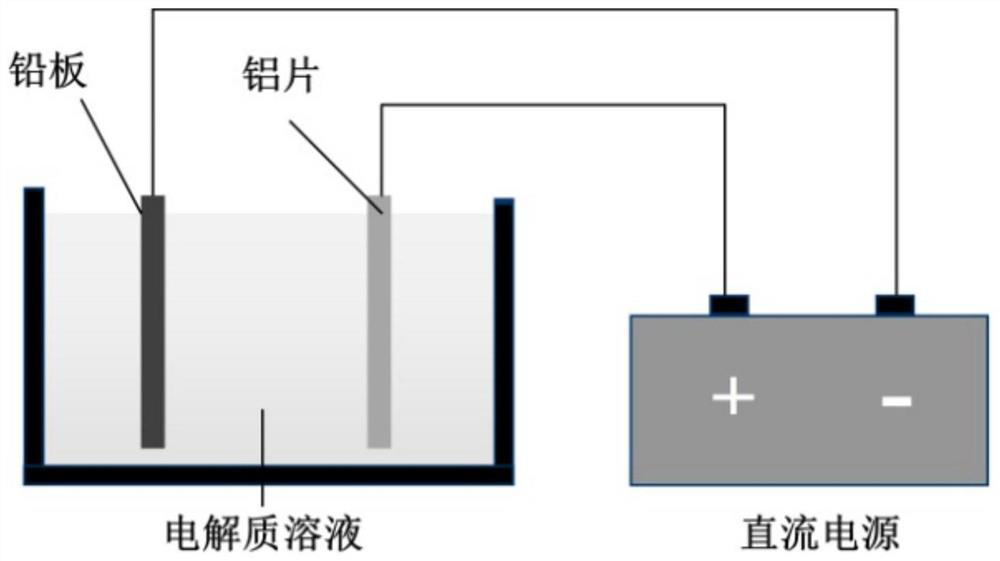

Continuous-electroplating liquid conduction apparatus and continuous liquid electroplating method

The invention discloses a continuous-electroplating liquid conduction apparatus. The apparatus comprises a conduction tank, a water washing tank and an electroplating tank which are sequentially arranged, a member for plating sequentially traverses through the conduction tank, the water washing tank and the electroplating tank to form a continuous electroplating line, first pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the conduction tank, second pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the electroplating tank, a power supply is also arranged, the first pole plates are electrically connected with the negative pole of the power supply, and the second pole plates are electrically connected with the positive pole of the power supply; and an electrolyte having a depth higher than the height of the first pole plates is filled in the conduction tank, and an electroplating liquid higher than the second pole plates is filled in the electroplating tank. The apparatus and the method solve an electroplating uniformity problem, and can also solve an electroplating surface damage problem.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Copper supporting piece, preparation method thereof and electrical assembly

The invention provides a copper supporting piece and a preparation method thereof and an electrical component, the copper supporting piece comprises a first metal layer, a second metal layer and a middle metal layer, the first metal layer and the second metal layer are made of pure copper, copper alloy or composite copper, the middle metal layer is made of iron or low-carbon steel, and the three layers are compounded into a whole to form a layered composite material strip. The thickness of the first metal layer is larger than that of the second metal layer, and the first metal layer wraps the side edge of the layered composite material belt, so that the middle metal layer is not exposed in the air; the first metal layer serves as a welding surface, the middle metal layer serves as a non-welding surface, and the welding surface is provided with a through hole penetrating through the thickness direction of the layered composite material belt. According to the invention, the problems of mechanism clamping, easy tilting of an arc striking angle, welding creeping points and poor deslagging and exhausting caused by rusting of the electrical component are effectively solved, so that the temperature rise of an electrical product is reduced, the electrical life of the electrical product is prolonged, the welding process is shortened, the quality of the electrical component is greatly improved, the use amount of high-valence copper is reduced, and the method is suitable for batch production.

Owner:温州宏丰特种材料有限公司

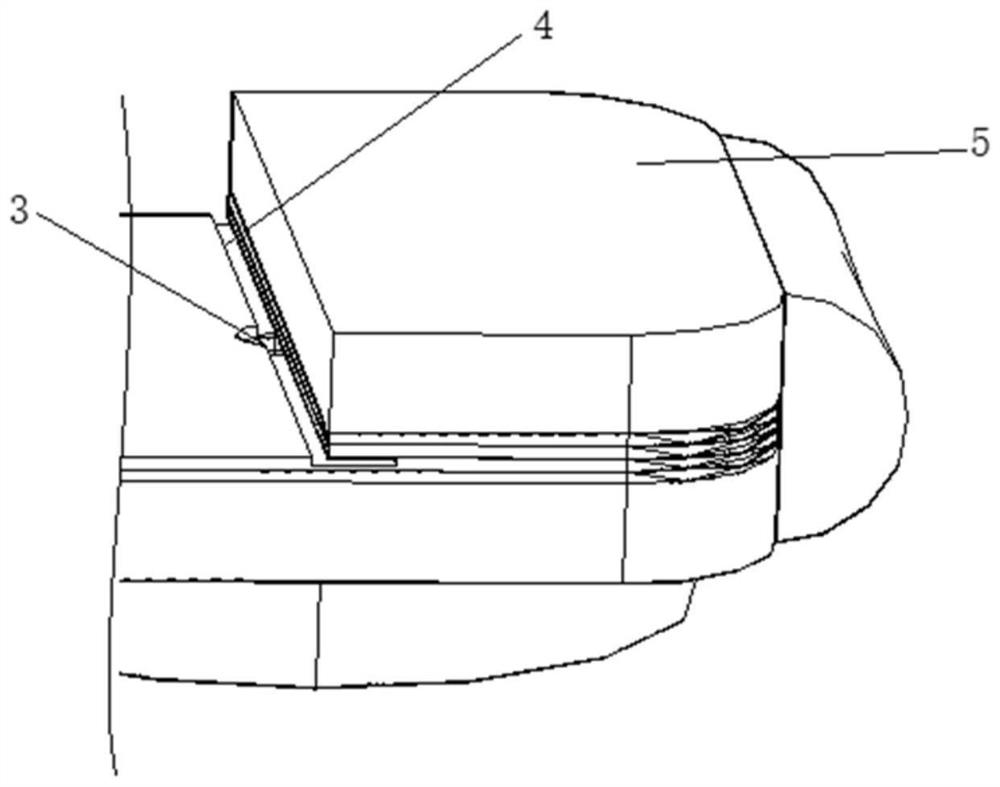

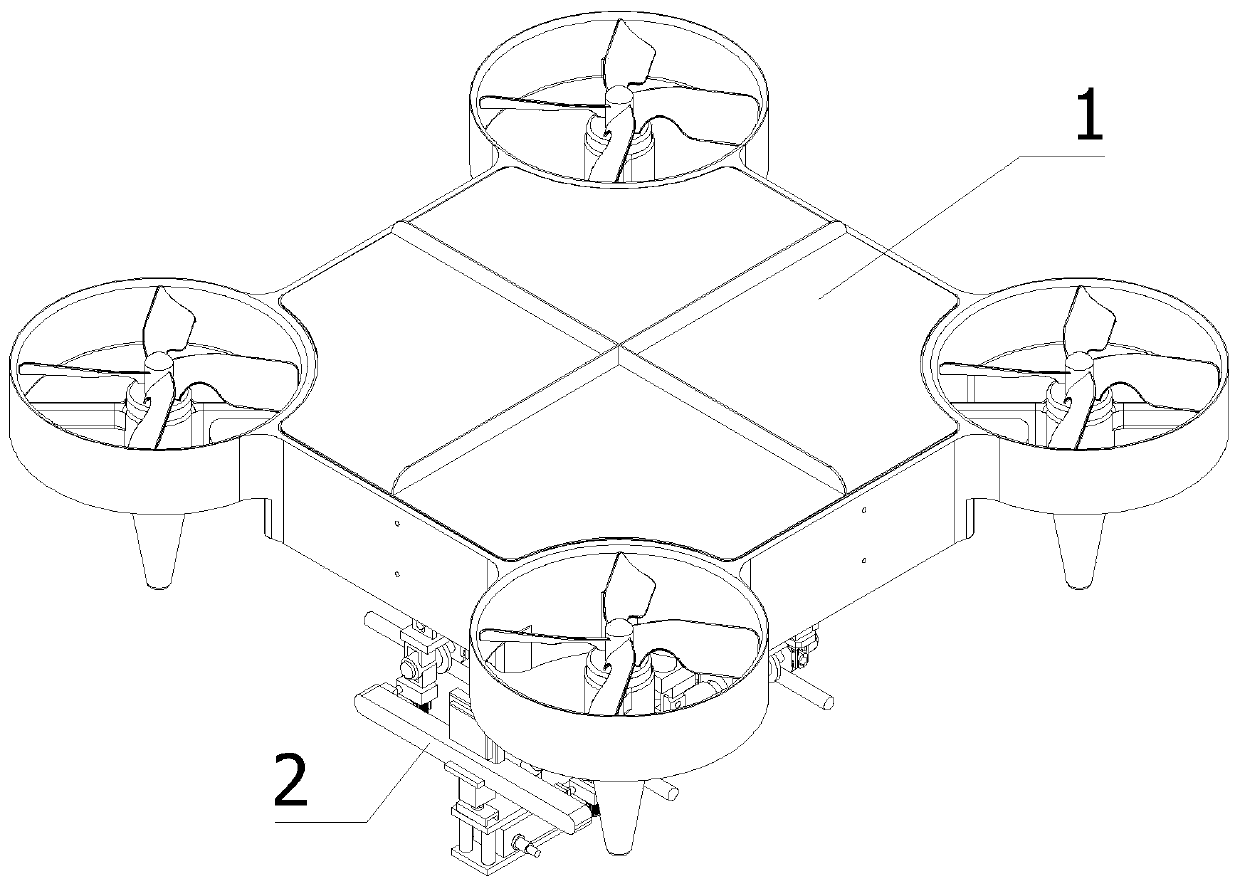

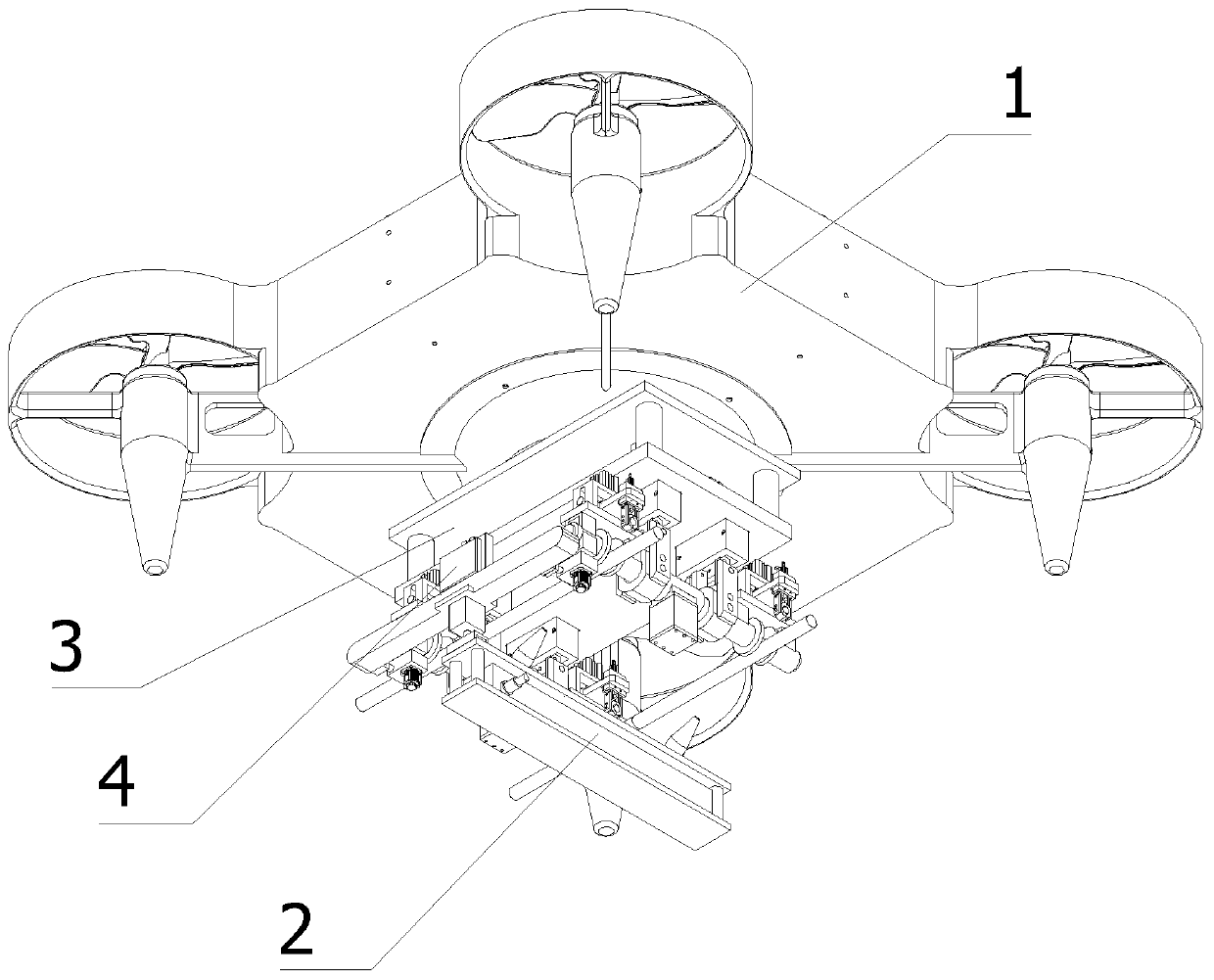

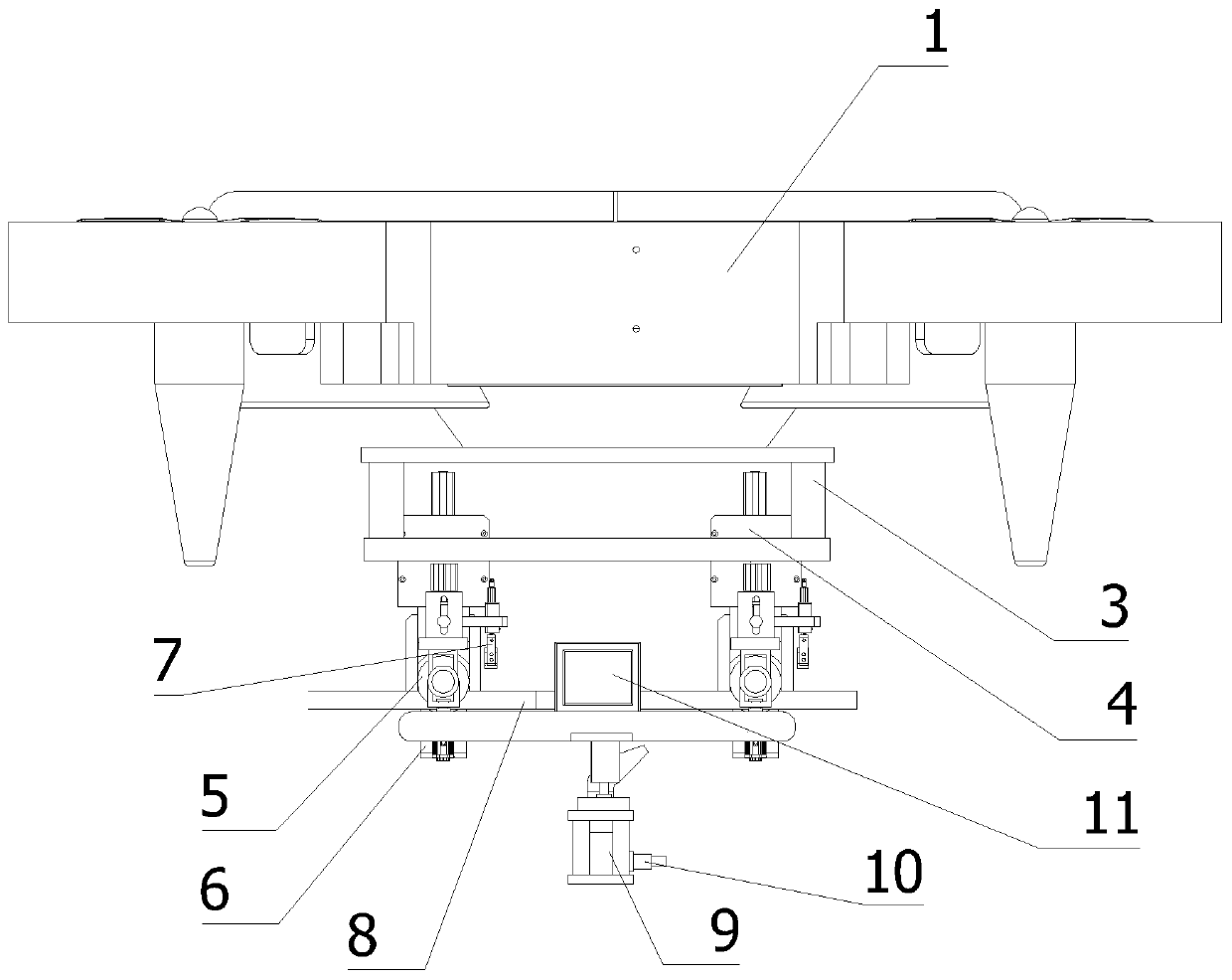

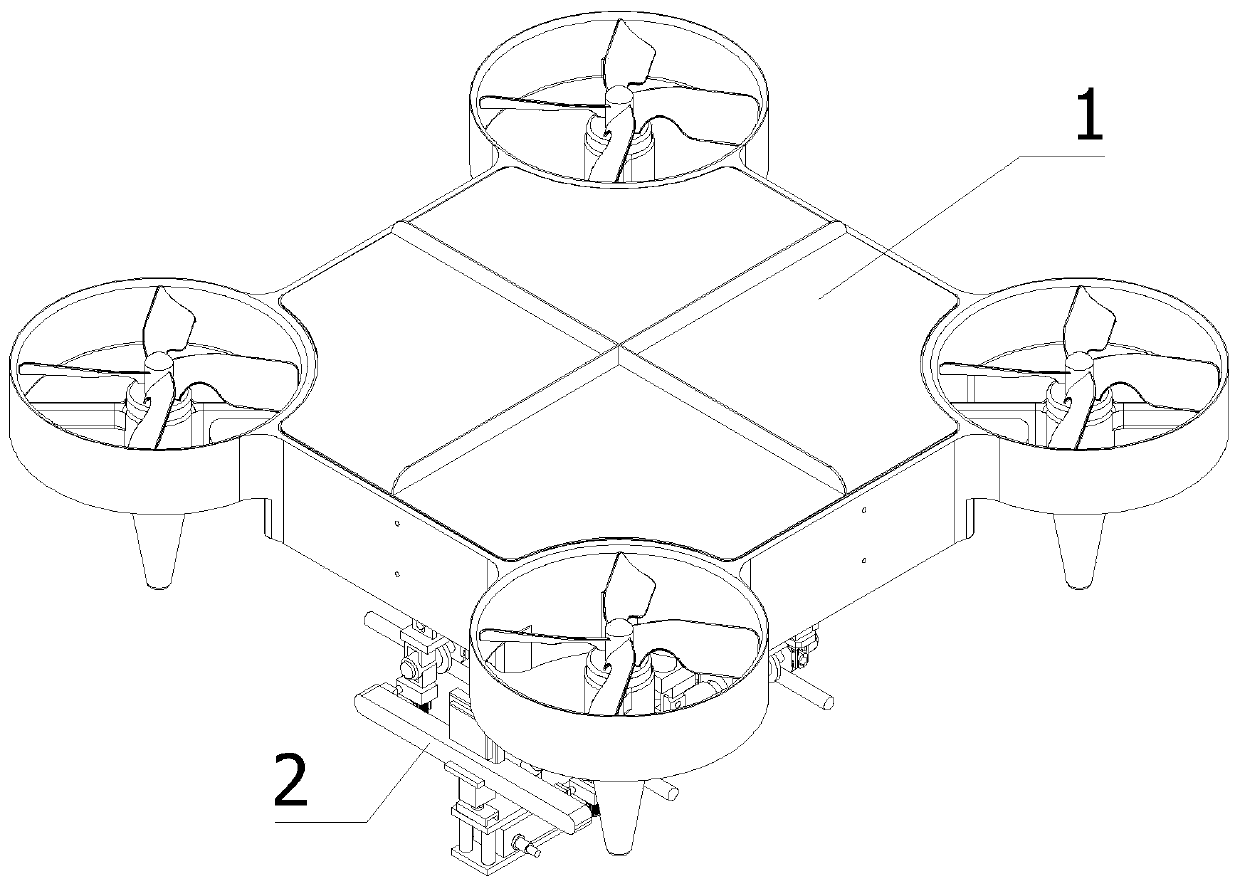

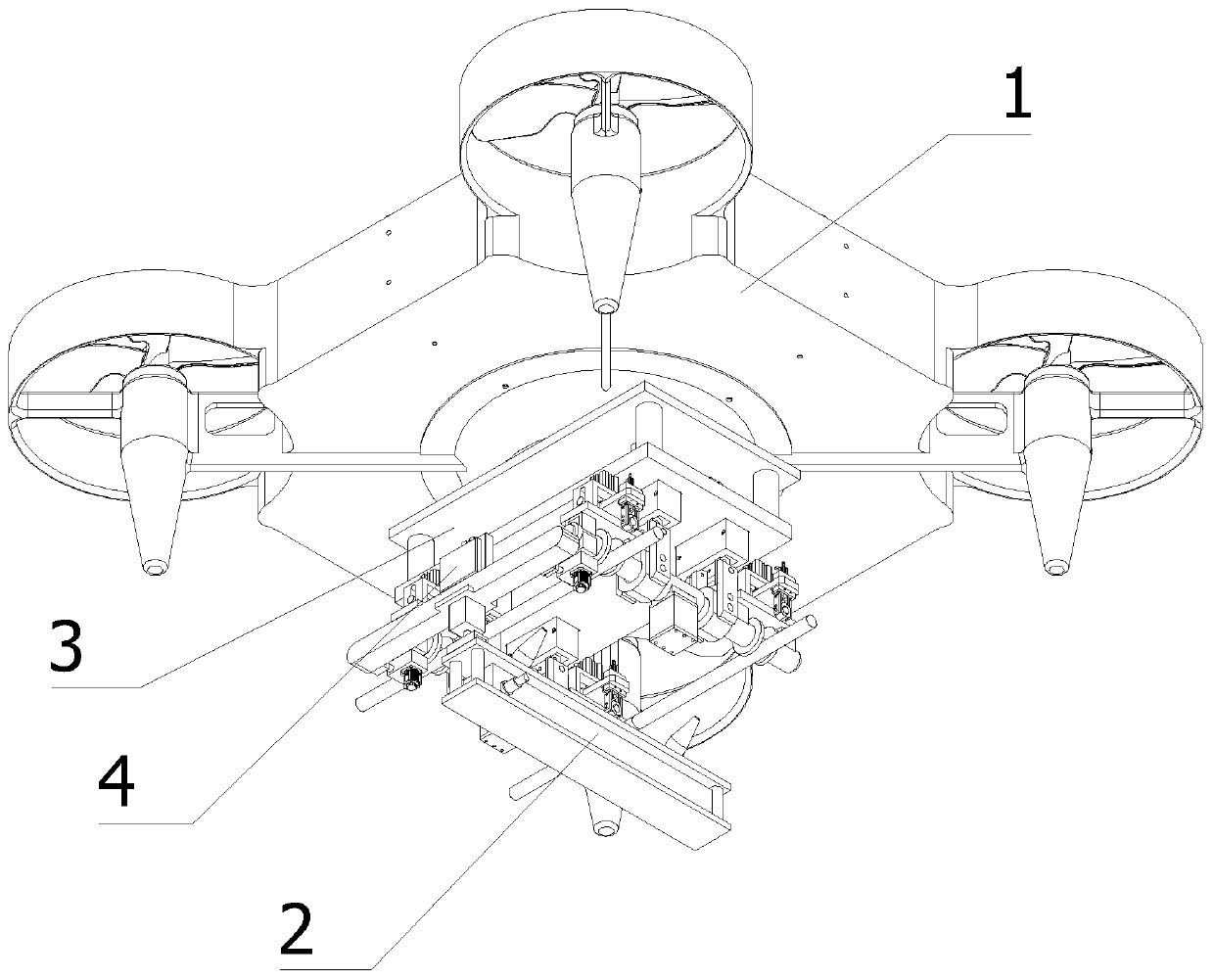

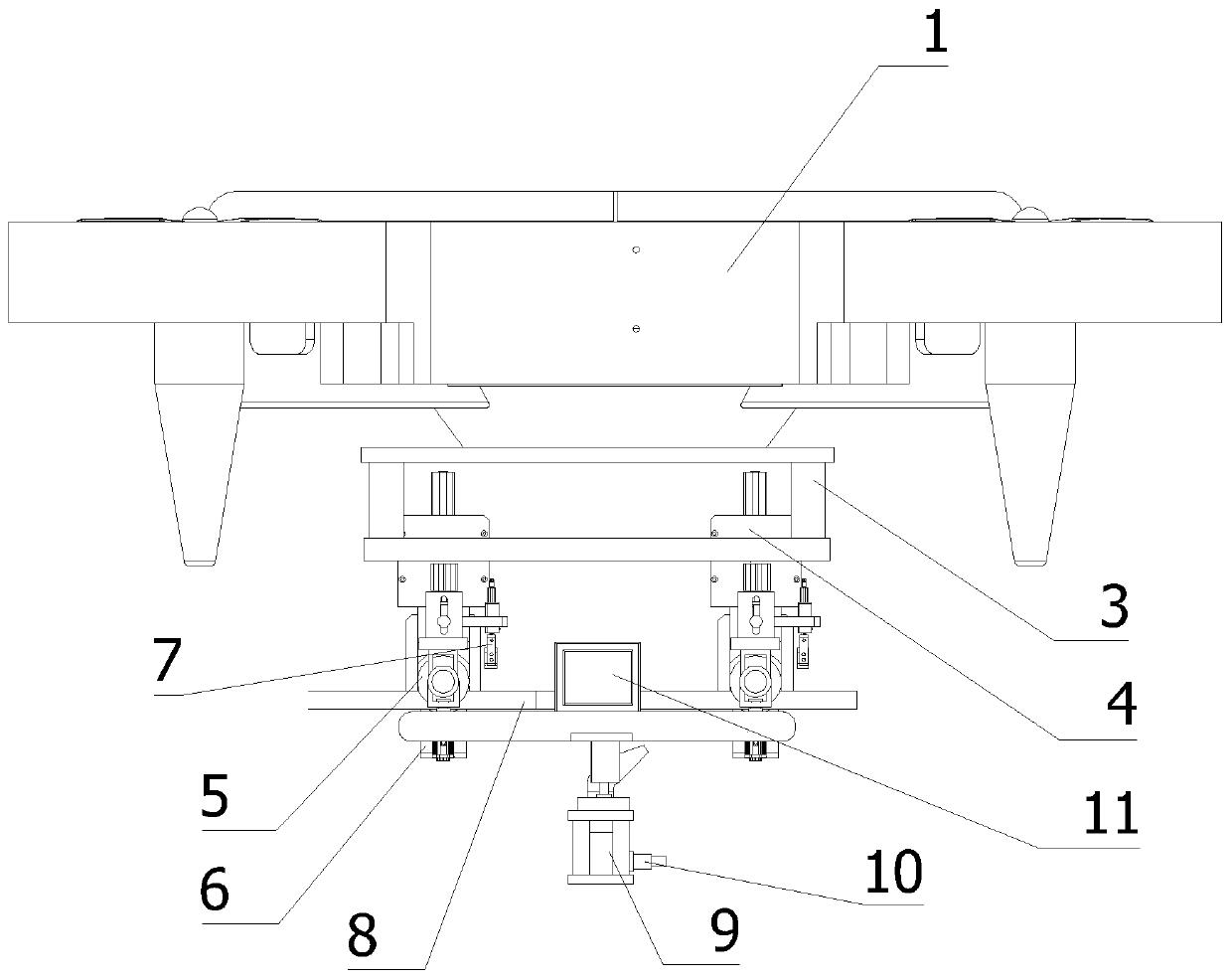

Power grid remote control robot

InactiveCN111570371AEasy to cleanAvoid troubleMaterial analysis by electric/magnetic meansCleaning using liquidsWater storage tankRemote control

The invention relates to the field of high-voltage maintenance robots, in particular to a power grid remote control robot. The robot comprises an unmanned aerial vehicle and a cleaning robot, whereina loading frame is fixedly arranged at the bottom of the unmanned aerial vehicle, and an electric clamping mechanism is vertically arranged on the loading frame; the cleaning robot comprises two travelling assemblies, two overturning assemblies, two insulating column clamping assemblies, a connecting column, a cleaning assembly, a detection assembly and a controller, wherein each travelling assembly comprises two travelling wheels capable of moving on a cable, and the insulating column clamping assemblies comprise electric clamping jaws capable of clamping insulating columns and lifting mechanisms; and the overturning assemblies comprise mounting frames, first rotating mechanisms and second rotating mechanisms, the cleaning assembly comprises a water storage tank and water spraying nozzles, and the detection assembly comprises a camera. According to the power grid remote control robot, the cleaning robot can be brought to the high altitude for operation through the unmanned aerial vehicle, and the high-altitude insulating columns are automatically cleaned through the cleaning robot, so that the cleaning efficiency is improved, and danger caused by manual cleaning is avoided.

Owner:张恒

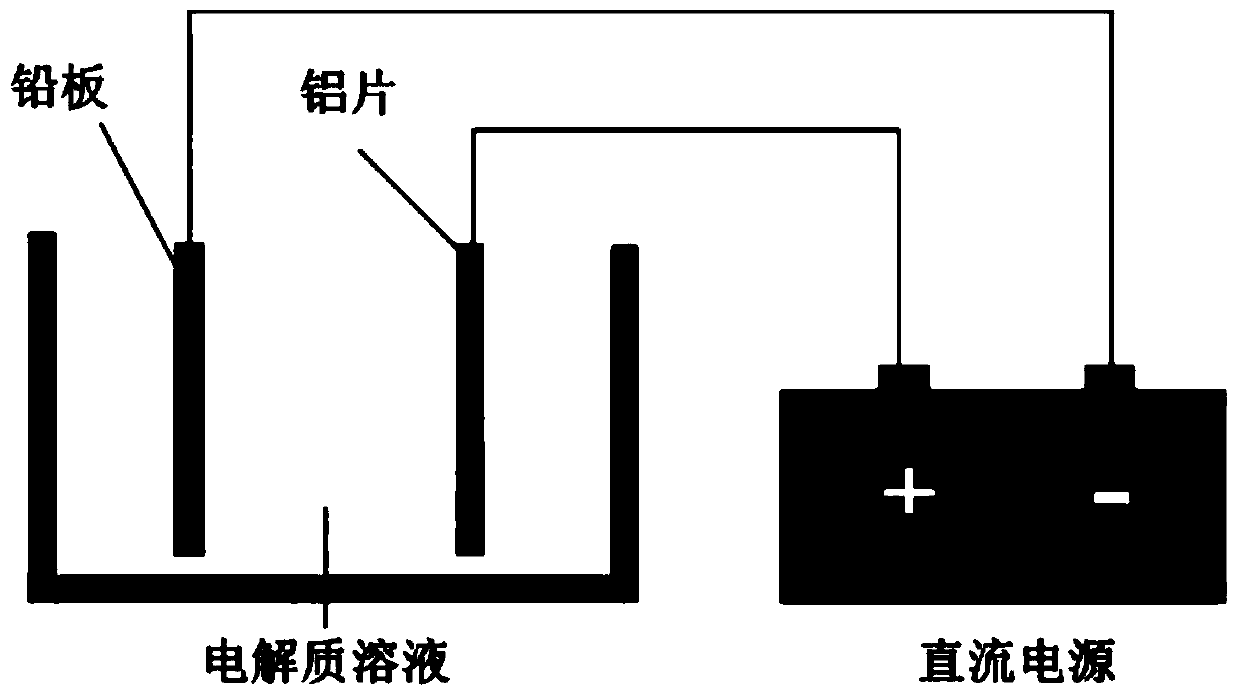

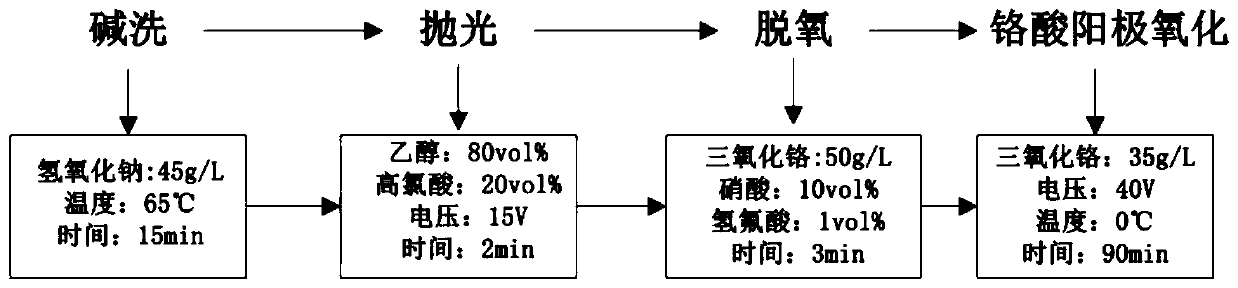

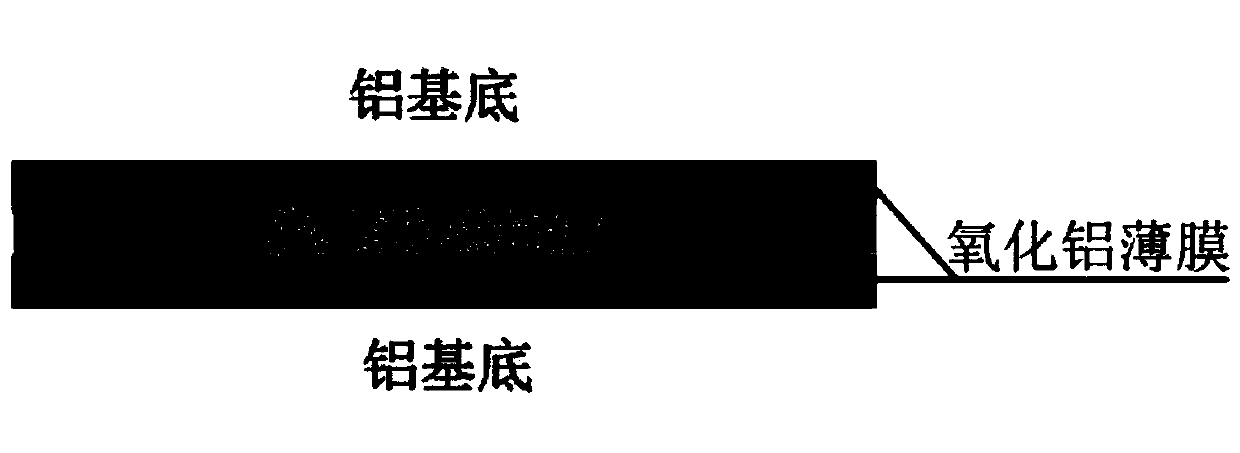

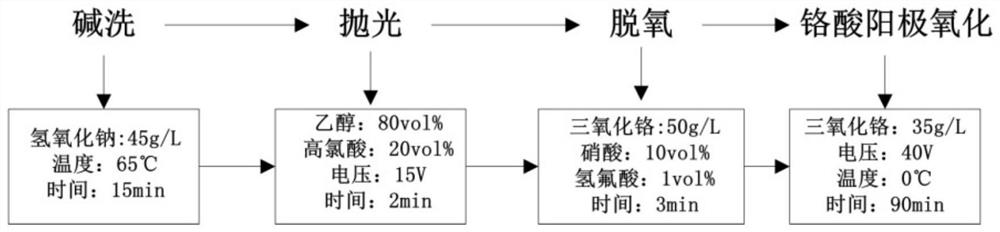

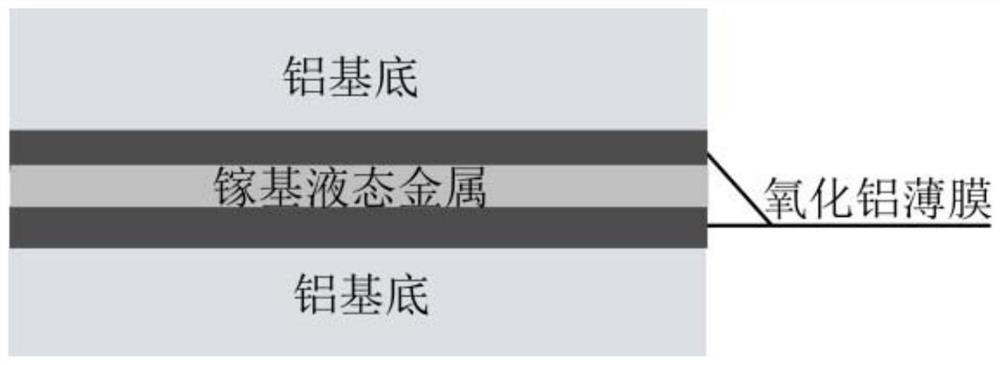

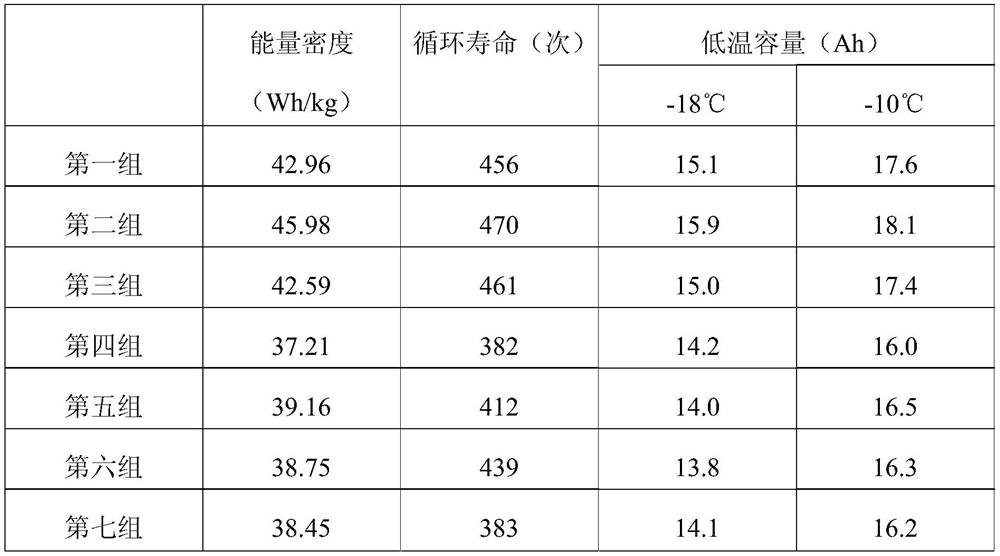

Method for strengthening interface heat transfer through applying gallium-based thermal interface material to aluminum substrate

ActiveCN110014718AImprove heat transfer performanceSolve conductive problemsAnodisationLaminationLiquid metalAluminum substrate

The invention discloses a method for strengthening interface heat transfer through applying a gallium-based thermal interface material to an aluminum substrate. The method comprises the following steps: (1) pretreating an aluminum sheet: submerging the aluminum sheet into an acetone solution, ethanol and water sequentially, and carrying out ultrasonic treatment for 10 to 25 minutes; (2) preparingan aluminum oxide film: subjecting the pretreated aluminum sheet to alkali washing, polishing, deoxidation and chromic acid anodizing, so as to prepare the aluminum oxide film; and (3) preparing a three-layer structure test sample: coating the surface of the aluminum oxide film of the aluminum sheet with gallium-based liquid-state metal, sequentially superposing the aluminum substrate, the aluminum oxide film, the gallium-based liquid-state metal, the aluminum oxide film and the aluminum substrate together, and carrying out preparing under the pressure of 4 MPa to 11 MPa. According to the method, interfacial heat transfer can be strengthened through applying a gallium-based liquid-state metal thermal interface material to the surface of the aluminum substrate for the first time, the blankin this field is filled up, and the problem of electric conduction present when the liquid-state metal thermal interface material is applied to a metallic solid interface is solved.

Owner:DALIAN MARITIME UNIVERSITY

Cleaning mechanism of power grid remote control robot

InactiveCN111570370AImprove efficiencyAvoid Conduction ProblemsCleaning using liquidsPower gridEngineering

Disclosed is a cleaning mechanism of a power grid remote control robot. The cleaning mechanism comprises two sets of walk components, two sets of overturning components, two sets of insulation columnclamping components, a connection column, a cleaning component, a detection component, and a controller; the connection column is arranged horizontally; the two sets of overturning components are disposed at both ends of the connection column, respectively; the two sets of walk components are horizontally mounted on output ends of the overturning components, respectively; each set of walk components comprises two walk wheels capable of moving on a cable; the insulation column clamping components are disposed beside the walk components in a lift manner; the insulation column clamping componentscomprise electric clamping jaws capable of clamping an insulation column and lift mechanisms; the lift mechanisms are fixedly mounted at the top ends of the walk components; and the electric clampingjaws are vertically and fixedly mounted on output ends of the lift mechanisms. The cleaning mechanism can automatically clean the insulation column, greatly improves the cleaning efficiency, and prevents the danger caused by manual cleaning.

Owner:张恒

Accurate cleaning mechanism of intelligent electric automatic cleaning robot

InactiveCN111632916AImprove cleaning efficiencyEasy to cleanCleaning using toolsCleaning using liquidsControl engineeringElectric machinery

The invention discloses an accurate cleaning mechanism of an intelligent electric automatic cleaning robot. The accurate cleaning mechanism comprises a telescopic arm, a cleaning mechanism and an insulating mechanism, wherein the telescopic arm comprises a plurality of connecting modules and a control base; the connecting modules are connected in series and arranged on the control base; the control base is used for controlling the swing direction and amplitude of the connecting modules; the cleaning mechanism comprises a cleaning head, a control module and a brushing mechanism; the control module is arranged at the top of the cleaning head; a fifth motor used for controlling and driving the cleaning head to rotate is arranged in the cleaning mechanism; and two cleaning clamp sleeves capable of swinging synchronously are arranged on the brushing mechanism. Through the telescopic arm, the position of the cleaning mechanism can be adjusted; through the cleaning clamp sleeves, the cleaningoperation on insulating columns can be achieved; and the cleaning efficiency can be greatly improved.

Owner:刘博

Storage type interface for computer hardware mainboard

PendingCN111506167AProtection interfaceGuaranteed cleanlinessDigital processing power distributionData transmissionTorsion spring

The invention discloses a storage type interface for a computer hardware mainboard, in particular to the field of computer hardware. The storage type interface comprises a computer body, a support, arotating shaft, a torsion spring, a slot, a buffer slot, a buckle fastener and a storage joint, a case right cavity is formed in the side face of an inner cavity of the computer body, a control box isfixedly installed at the bottom in the case right cavity, and a control rod is welded to the top of the side face of the control box. According to the invention, the adsorption device is arranged; the interface structure is changed, so that the interface can be prevented from being exposed outside for a long time; however, when the interface is used, the interface is always exposed outside for aperiod of time. In this way, a large amount of dust can still be accumulated in the interface for a long time, the adsorption device adsorbs the dust in the interface regularly at the moment, the problem that a large amount of dust is accumulated in the interface is avoided, the problem that the interface influences data transmission is solved, and therefore cleanliness of the interior of the interface is guaranteed, and meanwhile data transmission is rapid.

Owner:永州职业技术学院

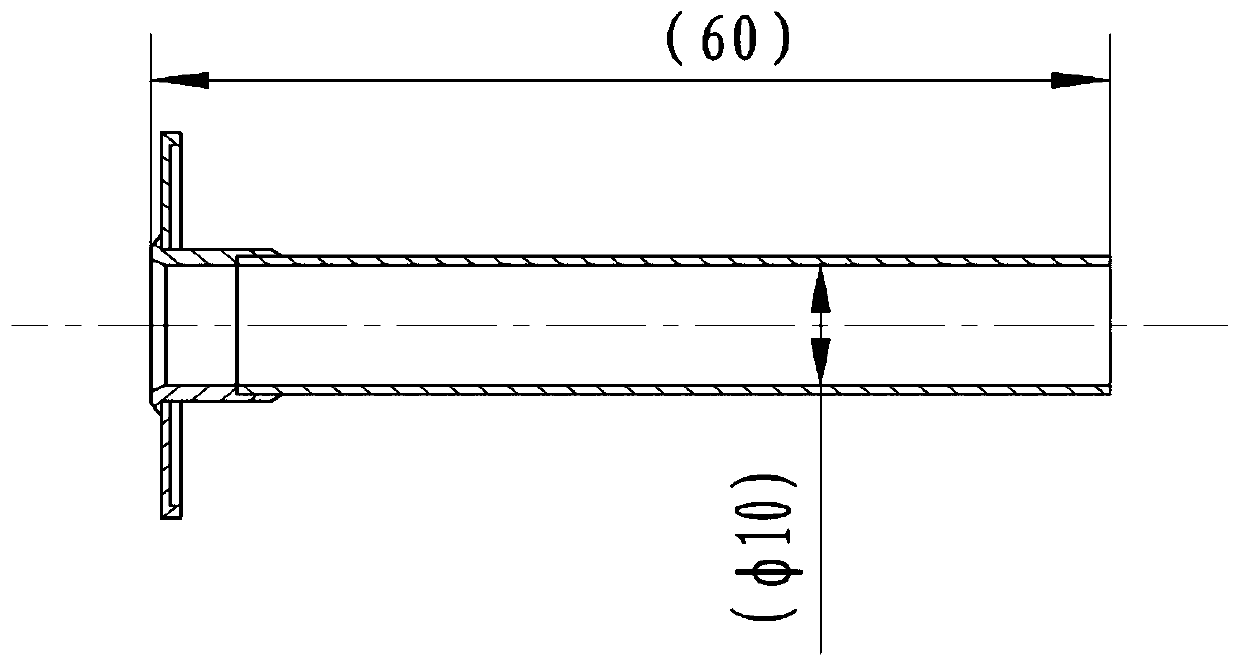

Motor wire end and outgoing wire twisting device

PendingCN107565769AAffect conductivitySolve conductive problemsManufacturing dynamo-electric machinesEngineeringOperational safety

The invention provides a motor wire end and outgoing wire twisting device, comprising rollers I, frame plate I, frame plate II, rollers II, a press rod, a cutter head, round-orifice posts, positioningbolts and pulleys. The motor wire end and outgoing wire twisting device has the advantages that the frame plate I is connected with the rollers I through mounting racks I, the frame plate II is connected with the rollers II through mounting racks II, a protective function is provided for wire twisting operation, and operational safety is enhanced; the press rod is arranged in a mounting hole, thecutter head is mounted on the lower end face of the press rod, a quick cutting function is provided for outgoing wires, cuts are neat, and next wire twisting is facilitated; the positioning bolts aremounted on the round-orifice posts, the pulleys are mounted in the round-orifice posts, a tension adjusting function is provided for the outgoing wires, and it is ensured that the outgoing wires aretensioned during twisting; the motor wire end and outgoing wire twisting device is convenient to use and operate, good in stability, and high in reliability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Novel corrosion resistance and tearing prevention pre-embedded coil of conveying belt

InactiveCN107521954AAddress water resistanceSolve corrosiveControl devices for conveyorsCopper platingTin plating

The invention proposes a novel corrosion-resistant and tear-proof pre-embedded coil for a conveyor belt, which includes a coil made of stainless steel wire, and a layer of conductive coating is provided on the surface of the stainless steel wire. The conductive plating layer is a copper plating layer, a zinc plating layer, a tin plating layer or a silver plating layer. The diameter of the stainless steel wire is 0.1-1.5mm, preferably 0.1mm. The coil is directly made of single or multiple strands of the stainless steel wire. The coil is braided into a round tube by a single stainless steel wire, and then the coil is made of the round tube. The invention has good electrical conductivity, corrosion resistance, high strength and impact resistance. Copper plating on the surface of the stainless steel wire not only solves the above problems, but also hardly increases the cost and does not require additional processing technology, so the promotion value is high.

Owner:杨建国

A Simple Fixture for Conduit Galvanized

The invention discloses a simple fixture for galvanizing a guide tube. The simple fixture comprises a first conducting wire, a second conducting wire and an auxiliary anode conducting wire, wherein the first conducting wire is connected with a cathode bar, the second conducting wire is connected with an anode bar, and the auxiliary anode conducting wire is connected with the second conducting wire; a hook section is formed on one end, which is connected with the cathode bar, of the first conducting wire, a right-angle bending section is formed on the other end of the first conducting wire, an upwarp is formed on the tail end of the right-angle bending section, and a first insulating layer is arranged on the outer side of the first conducting wire between the upwarp and the hook section; and the auxiliary anode conducting wire is in a right-angle bending shape and is connected with the right-angle bending section of the first conducting wire by virtue of a second insulating layer. The simple fixture has the advantages of simplicity, easiness in manufacturing, good conduction, simplicity and convenience in hanging and installation and simplicity in operation. The simple fixture is mainly composed of a stainless steel wire, a copper wire and an insulated rubber tape, and an auxiliary anode can be arranged just in the middle of an inner hole of the guide tube, so that the current distribution is uniform, and the coating quality is good. The inner hole and the outer surface are electroplated once, so that the coating uniformity is guaranteed, and the production efficiency is greatly improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Method for making anode tube of wet electrostatic precipitator by using non-metallic material

InactiveCN106552714BSolve conductive problemsEnsure continuityExternal electric electrostatic seperatorElectrode constructionsSand blastingMetallic materials

The invention relates to a method for preparing a wet-type electric precipitator anode tube from a nonmetallic material. The method comprises tube detection, sandblasting, cutting, tube processing, tube assembly welding, and tube bundle resistivity testing. An anode tube prepared through tube detection, sandblasting, cutting, tube processing, tube assembly welding and tube bundle resistivity testing can effectively solve the non-metallic material conductive problems and ensure that a water film and a grounding module are communicated in precipitator operation, and a grounding module lead is communicated with a grounding network so that charge enriched on the anode is released. The method has simple processes, realizes a low manufacturing cost and optimizes the use performances and life of the product. Through two glass sand blasting processes, roughness of the tube inner wall is uniform relative to those of other metal sand and other sand materials. Glass sand can prevent the wall roughness out of control and damage to the anode tube.

Owner:JIAXING HUANENG ENVIRONMENT PROTECTION EQUIP CO LTD

Continuous electroplating liquid conductive device and continuous liquid electroplating method

The invention discloses a continuous-electroplating liquid conduction apparatus. The apparatus comprises a conduction tank, a water washing tank and an electroplating tank which are sequentially arranged, a member for plating sequentially traverses through the conduction tank, the water washing tank and the electroplating tank to form a continuous electroplating line, first pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the conduction tank, second pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the electroplating tank, a power supply is also arranged, the first pole plates are electrically connected with the negative pole of the power supply, and the second pole plates are electrically connected with the positive pole of the power supply; and an electrolyte having a depth higher than the height of the first pole plates is filled in the conduction tank, and an electroplating liquid higher than the second pole plates is filled in the electroplating tank. The apparatus and the method solve an electroplating uniformity problem, and can also solve an electroplating surface damage problem.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Novel conveying belt corrosion resistant and impact resistant anti-tear embedded coil

InactiveCN108529168ASolve conductive problemsImprove corrosion resistanceConveyorsControl devices for conveyorsCopper platingCopper coating

Owner:杨建国

A Small Size Ring Heating Rod with High Heating Power

ActiveCN112118648BRealize simulationTo meet the requirements of heat insulationNuclear energy generationNuclear monitoringHeat flowHeater Rod

The invention relates to a small-sized annular heating rod with high heating power, comprising a heating rod inner casing, a heating rod outer casing and a ceramic insulating ring; the heating rod outer casing is covered outside the heating rod inner casing; the ceramic insulating ring is set Between the inner and outer shells of the heating rod to support the inner shell of the heating rod and the outer shell of the heating rod; the ceramic insulating ring is also provided with a plurality of heating holes distributed along the circumferential direction; the heating holes are provided with capillaries Heating wire. The beneficial effects of the present invention are as follows: the present invention can realize the simulation of fuel elements outside the pile, insert the heating wire into the ceramic insulating ring with a plurality of small holes, and change the previous heating wire, magnesium oxide insulation, stainless steel cladding, oxidation The four-layer structure design of the aluminum core block only uses the double-layer structure of the heating wire and the ceramic insulating ring to meet the requirements of heating and insulation in a small space and achieve a high heat flux density.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Multi-station electrolytic precision grinding automatic machine

InactiveCN103273402BReduce lossGuaranteed machining accuracyGrinding machinesGrinding work supportsElectrolysisTemperature resistance

The invention relates to a multi-station electrolysis precise grinding automatic machine, and belongs to devices for conducting full-automatic grinding machining on the inner surface and the outer surface of a shaver net. The multi-station electrolysis precise grinding automatic machine adopts a follow clamp of a ship-plate type structure, can automatically feed and discharge materials, can conduct simultaneous operations at eight stations, uses an electrolytic action and an electric conduction grinding wheel with mechanical grinding capacity to conduct machining on the shaver net, greatly improves work efficiency, machining stability and accuracy, reduces losses of the grinding wheel and saves production cost. Machining on the front face and the back face of a machined piece can be achieved on one machine through a turnover device. Electrolytic machining is carried out on the machined piece through the electrode power supply electric conduction mode, the soft sheet connection electric conduction mode, the floating steel ring electric conduction mode and the insulation sleeve insulation electric conduction mode. Zirconia ceramics are made into a base to serve as a support due to the characteristics of insulation, abrasion resistance and high temperature resistance of the zirconia ceramics, and the centering effects of the machining position of the machined piece are achieved. An air-tight seal is adopted to prevent the situation that electrolytes spill out or atomize so as to enter a main grinding shaft box to abrade parts when the grinding wheel conducts grinding.

Owner:DALIAN JIADEHENG SCI & TECH

Conductive automatic clamping device for electrode of electric slag furnace

Owner:SUZHOU ZHENWU ELECTRIC FURNACE +1

Conductor paste and preparation method thereof

PendingCN114388169AReduce silver contentAvoid frequentNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseElectrical conductor

The invention discloses conductor paste and a preparation method thereof. The conductor paste is prepared from the following raw materials in a concentration range: 70%-90% of silver, 1%-10% of terpineol, 1%-10% of ethyl cellulose, 1%-10% of a flame-retardant material, 0.1%-1% of copper oxide and 0.1%-1% of an active agent. While the silver content is reduced, the performance of the conductor slurry can be ensured not to be lost; the problem of tin beads can be effectively reduced, frequent generation of the tin beads is avoided, the thick film substrate is more durable, and the overall performance is improved; and the problem of electric conduction caused by increase of tin beads is avoided.

Owner:JIANGSU YUNYI ELECTRIC

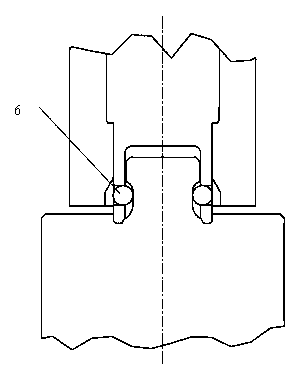

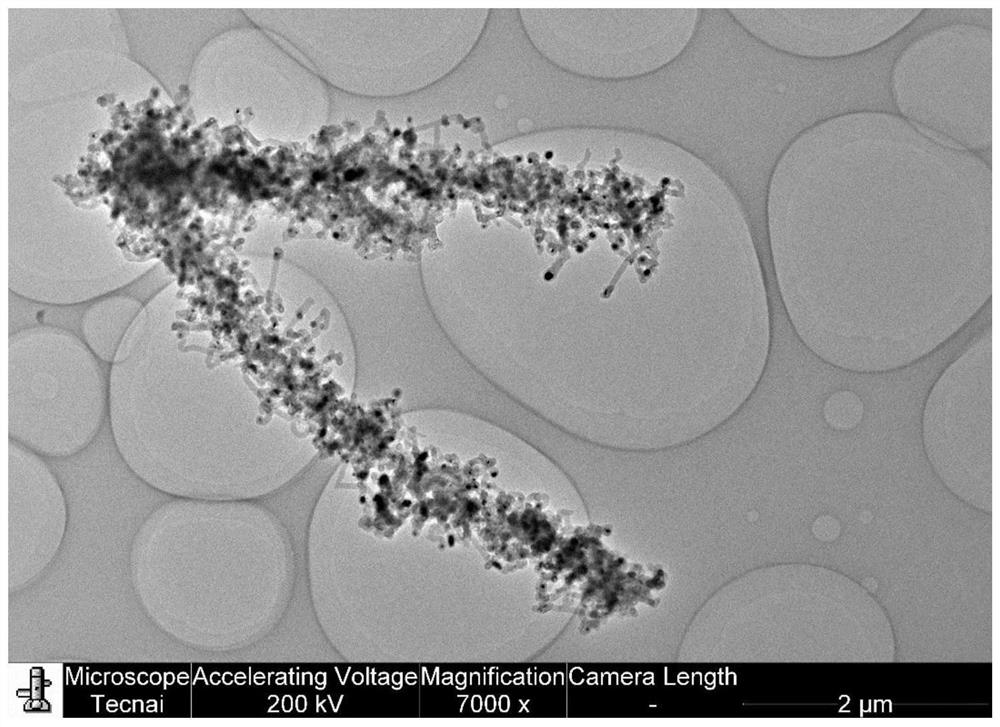

Preparation method of electrochemically active material

ActiveCN110323421BSolve conductive problemsRealize continuous productionMaterial nanotechnologyCell electrodesAir atmospherePhysical chemistry

Owner:SUZHOU FIRST ELEMENT NANO TECH

Movable silicon carbide smelting furnace

The invention relates to a movable carborundum smelting furnace. The movable carborundum smelting furnace comprises a furnace vehicle, a gas collecting tank and a track, wherein longitudinal bearing beams are arranged in a furnace vehicle chassis; bearing seats on the two sides of vehicle wheels are fixed to the bearing beams through bolts; insulation sleeves are arranged outside studs in a sleeving mode; insulation mats are arranged between the bearing seats and the bearing beams; and insulation mats are also arranged between gaskets and the bearing beam as well as between the gaskets and the bearing seats; each side seam is divided into a left part and a right part, wherein a side seam insulation mat is arranged between each left half part and each right half part, the shape of each side seam insulation mat is the same as the cross-sectional shape of each side seam; the left half parts and the right half parts are connected through bolts;, insulation sleeves are arranged outside studs in the sleeving mode; the insulation mats are also arranged between the spacers and the left half parts as well as between the spacers and the right half parts; and plugging board doors are arranged at the lower parts of the side seams. According to the movable carborundum smelting furnace disclosed by the invention, an insulation structure is designed, so that the problem of large electric loss of the movable carborundum smelting furnace is solved; the plugging board doors are designed on the lower parts of the side seams, so that the problems that the opening degree of a conventional lower discharge door is difficult to control, materials are liable to leak, and the smelting furnace is greatly affected due to heating deformation are solved.

Owner:宋克纯

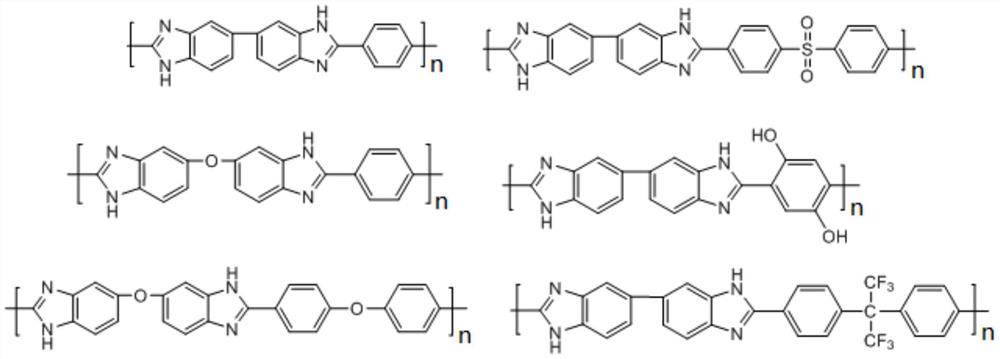

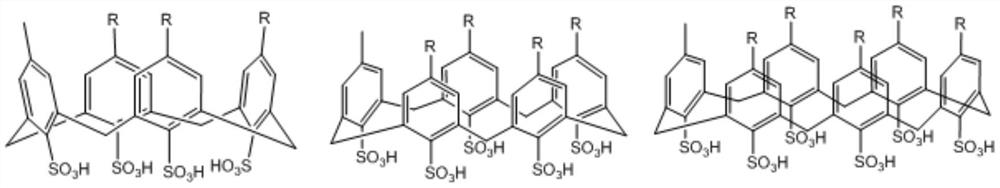

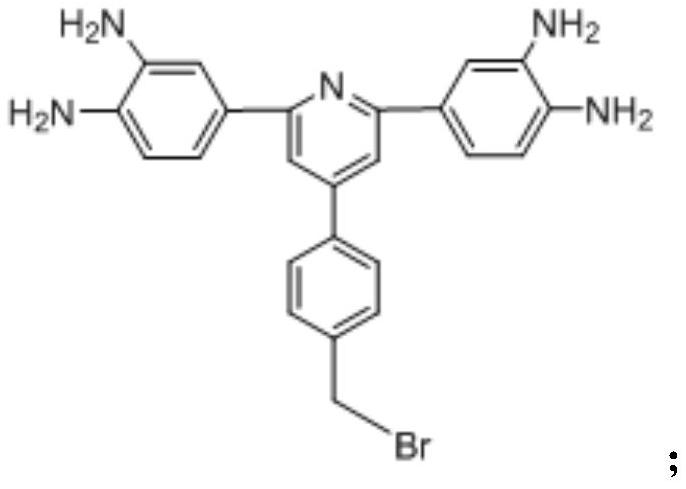

Sulfonated calixarene grafted polybenzimidazole proton exchange membrane material and preparation method thereof

ActiveCN111718503ATroubleshoot MigrationSolve conductive problemsFuel cellsPolymer scienceCalixarene

The invention discloses a sulfonated calixarene grafted polybenzimidazole proton exchange membrane material and a preparation method thereof. The structural formula of the proton exchange membrane material is shown in the specification, wherein n is an integer between 5000 and 10000. According to the invention, sulfonated calixarene is grafted to polybenzimidazole to design the proton exchange membrane material based on sulfonated calixarene grafted polybenzimidazole; the strength problem of the proton membrane is solved by utilizing the rigidity of polybenzimidazole, the electric conduction problem of the proton membrane is solved by utilizing the sulfonation structure of the calixarene, a channel can be provided for proton transfer by utilizing an electron-rich structure model in calixarene, and the problem of large-scale proton migration is well solved.

Owner:SHENZHEN GAS CORP +1

Polymorphic multifunctional medical conductive preparation

PendingCN114709001AConductive connection is stableStable electrical signal outputNon-metal conductorsSurgical adhesivesCellulosePolyethylene glycol

The invention belongs to the field of conductive preparations, and discloses a polymorphic multifunctional medical conductive preparation, which comprises a stirring device and the following components: distilled water, sodium chloride, povidone iodine, 1, 2-propylene glycol, polyethylene glycol and sodium carboxymethyl cellulose. The problem of conduction between electrodes of various medical devices and the skin can be effectively solved, stable electric signal output is formed, accurate diagnosis data and treatment effects are obtained, residues on the inner wall of the stirring kettle can be cleaned through the arranged spraying mechanism, and the spraying mechanism is convenient to use. And then the scraping plate is started according to the actual situation to scrape the inner wall of the stirring kettle, so that personnel can conveniently clean the interior of the stirring kettle.

Owner:哈尔滨奥博医疗器械有限公司

A method of applying gallium-based thermal interface materials to aluminum substrates to enhance interfacial heat transfer

ActiveCN110014718BImprove heat transfer performanceSolve conductive problemsAnodisationLaminationThin membraneLiquid metal

The invention discloses a method for applying a gallium-based thermal interface material to an aluminum substrate to enhance interfacial heat transfer. 10‑25 minutes; (2) Preparation of aluminum oxide film: Alkali washing, polishing, deoxidation, and chromic acid anodic oxidation of pretreated aluminum sheet to prepare aluminum oxide film; (3) Preparation of three-layer structure sample: Gallium-based The liquid metal is coated on the aluminum oxide film surface of the aluminum sheet, stacked together in the order of aluminum substrate, aluminum oxide film, gallium-based liquid metal, aluminum oxide film, and aluminum substrate, and prepared under a pressure of 4-11MPa. The invention realizes the application of gallium-based liquid metal thermal interface materials on the surface of aluminum substrates for the first time to enhance heat transfer between interfaces, fills the gap in this field, and solves the electrical conduction problem existing when liquid metal thermal interface materials are applied to metal-solid interfaces .

Owner:DALIAN MARITIME UNIVERSITY

Production process of low-dimensional nano lead-carbon super battery

PendingCN114188617AReduce consumptionSolving Sulfation ProblemsCell electrodesFinal product manufactureElectrical batteryUltraBattery

The invention provides a production process of a low-dimensional nano lead-carbon super battery, and relates to the technical field of lead-acid storage batteries, the production process comprises the steps of grid production, positive electrode lead paste preparation, negative electrode lead paste preparation, plate coating and curing, assembly, formation production and post-treatment; the low-dimensional multi-stage nano carbon is added to improve the technical problems of performance deterioration of the corrosion layer of the lead-carbon super battery grid in the circulation process, ion migration region limitation and control, negative electrode sulfation and the like, the failure of the battery can be reduced, the cycle life of the lead-acid battery for power can be prolonged, and resource consumption can be reduced.

Owner:河池市科学技术情报和创新服务所 +1

Insulation and heat-conducting coating for new energy automobile and preparation method thereof

InactiveCN109306221ARaw materials are easy to getReduce manufacturing costFireproof paintsAntifouling/underwater paintsChemical reactionNew energy

The invention provides insulation and heat-conducting coating for a new energy automobile. The insulation and heat-conducting coating is characterized by being prepared from the following raw materialcomponents in parts by weight: 55 to 65 parts of a thiol fluorosilicone film-forming copolymer, 15 to 25 parts of a surface modified beryllium oxide coated graphene oxide, 1 to 3 parts of a curing agent, 1 to 3 parts of a de-foaming agent, 1 to 3 parts of a dispersant, 1 to 3 parts of a diluting agent, 10 to 15 parts of a co-solvent and 1 to 2 parts of a catalyst, wherein the thiol fluorosiliconefilm-forming copolymer is prepared from quaternary ammonium salt 15, 4-(diethylamino)benzophenone, tetrafluoropropyl acrylate, triphenylvinylsilane and 3-methyl-2-buten-1-thiol through chemical reaction. The invention further discloses a preparation method of the insulation and heat-conducting coating for the new energy automobile. The insulation and heat-conducting coating for the new energy automobile, prepared by the method, has excellent comprehensive performance and also has the advantages of excellent insulation performance and heat conductivity, great adhesion force with a matrix and excellent weather resistance.

Owner:ZHEJIANG DIHENG IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com