A Small Size Ring Heating Rod with High Heating Power

A heating rod, small size technology, used in the shape of heating elements, ohmic resistance heating parts, nuclear power generation and other directions, can solve the problem of no inert gas, increase the binding force of inner and outer tubes, affect the mechanical properties of materials, etc., and achieve high heat flux density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

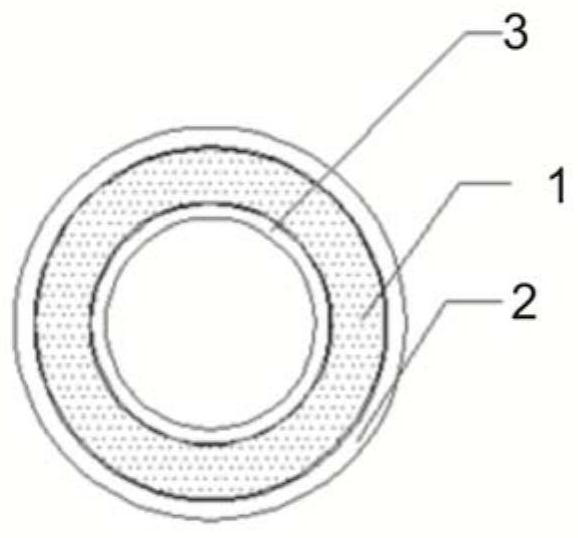

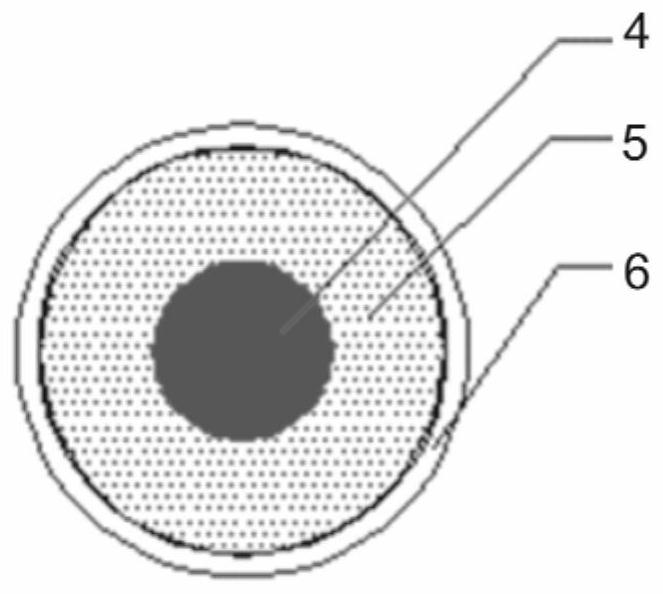

[0033] Such as Figure 7 As shown, the present invention discloses a small-sized annular heating rod with high heating power, including a heating rod inner casing 9, a heating rod outer casing 11 and a ceramic insulating ring 13; the heating rod outer casing 11 is sleeved on the heating rod Outside the inner shell 9; the ceramic insulating ring 13 is arranged between the inner and outer shells of the heating rod to support the inner shell 9 of the heating rod and the outer shell 11 of the heating rod; the ceramic insulating ring 13 is also provided with circumferentially distributed Multiple heating holes (such as Figure 8 shown); the heating hole is provided with a capillary heating wire 12.

[0034] The thickness of the ceramic insulating ring 13 is 1-100 mm; the inert gas cavity is a hole with a thickness of 0.1-50 mm.

[0035] The small-size a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com