Conductive automatic clamping device for electrode of electric slag furnace

An automatic clamping and electroslag furnace technology, which is applied in the field of special metallurgical equipment, can solve the problems of long cooling time and low production efficiency of large electroslag ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

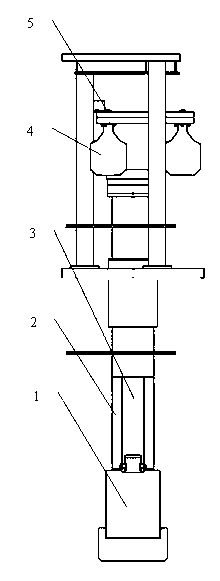

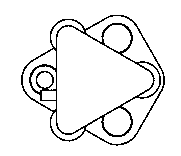

[0011] With reference to the drawings, the structure includes auxiliary electrode 1, conductive material rod 2, fixed shaft 3, film cylinder 4, fixed plate 5, marbles 6; wherein conductive material rod 2 is connected to auxiliary electrode 1 through marbles 6, and the fixed shaft 3 and the fixed plate 5 are fixed on the furnace head support, the conductive material rod 2 is outside the fixed shaft 3, and the conductive material rod 2 is connected with three film cylinders 4 to form an up and down moving sleeve.

[0012] The fixed shaft 3 and the fixed plate 5 form a fixed shaft part, and the fixed shaft 3 and the fixed plate 5 are fixed on the furnace head support.

[0013] The up-and-down moving sleeve is formed by connecting a conductive material rod 2 and three film cylinders 4. Under the power of the film cylinder 4, the conductive material rod 2 moves vertically outside the fixed shaft 3.

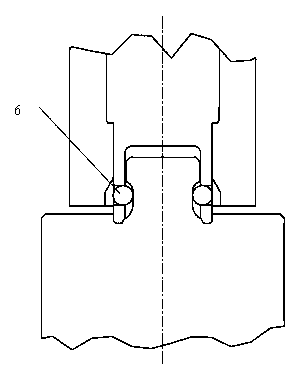

[0014] Several marbles 6 take on the role of connecting the conductive material rod 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com