Production process of low-dimensional nano lead-carbon super battery

A super battery, low-dimensional nanotechnology, applied in lead-acid batteries, lead-acid battery construction, battery electrodes, etc., to achieve the effect of improving reversibility, increasing active sites, and improving deep cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

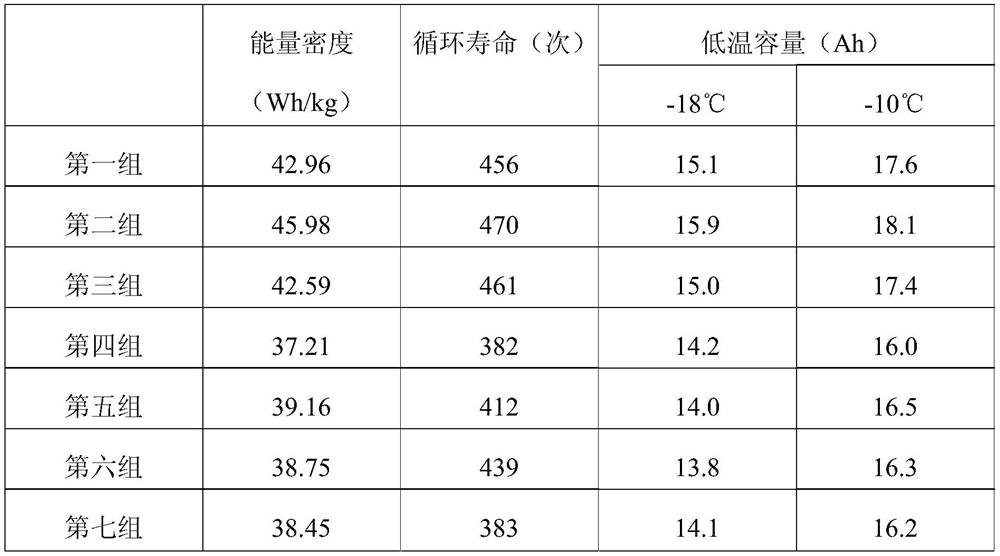

Examples

Embodiment 1

[0027] Preparation of low-dimensional multi-level nano-carbon:

[0028] This embodiment provides a method for preparing low-dimensional multi-level nano-carbon, comprising the following steps:

[0029] (1) Preparation of graphene oxide: Mix concentrated sulfuric acid and concentrated phosphoric acid according to the mass ratio of 2:1 and add them to a beaker equipped with natural graphite powder, then add potassium permanganate to the beaker, and stir magnetically for 0.8h , then heated to 48°C and then stirred at constant temperature for 10 hours, then cooled to room temperature; slowly added cold water to the beaker, and then added 30% hydrogen peroxide drop by drop, so that the solution changed from gray black to bright yellow, and the mixture in the beaker Separation by suction filtration, then cleaning by suction filtration with deionized water and cleaning the obtained product with 2.0M hydrochloric acid to remove metal impurities therein; then filtering and cleaning wit...

Embodiment 2

[0035] Preparation of low-dimensional multi-level nano-carbon:

[0036] This embodiment provides a method for preparing low-dimensional multi-level nano-carbon, comprising the following steps:

[0037] (1) Preparation of graphene oxide: mix concentrated sulfuric acid and concentrated phosphoric acid in a ratio of 3:1 according to the mass ratio and add them into a beaker equipped with natural graphite powder, then add potassium permanganate into the beaker, stir magnetically for 1h, Reheat to 50°C and stir at constant temperature for 12 hours, then cool to room temperature; slowly add cold water to the beaker, and then add 30% hydrogen peroxide drop by drop, so that the solution turns from gray black to bright yellow, then pump the mixture in the beaker Filter and separate, then use deionized water to filter and clean, and the product obtained is washed with 2.0M hydrochloric acid to remove metal impurities; then filter and clean with deionized water again until the solution i...

Embodiment 3

[0043] Preparation of low-dimensional multi-level nano-carbon:

[0044] This embodiment provides a method for preparing low-dimensional multi-level nano-carbon, comprising the following steps:

[0045] (1) Preparation of graphene oxide: Mix concentrated sulfuric acid and concentrated phosphoric acid in a ratio of 4:1 by mass and add them to a beaker containing natural graphite powder, then add potassium permanganate to the beaker, and stir magnetically for 1.2 h , then heated to 52°C and stirred at constant temperature for 11 hours, then cooled to room temperature; slowly added cold water to the beaker, and then added 30% hydrogen peroxide drop by drop, so that the solution changed from gray black to bright yellow, and the mixture in the beaker Separation by suction filtration, then cleaning by suction filtration with deionized water and cleaning the obtained product with 2.0M hydrochloric acid to remove metal impurities therein; then filtering and cleaning with deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com