Patents

Literature

35 results about "UltraBattery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

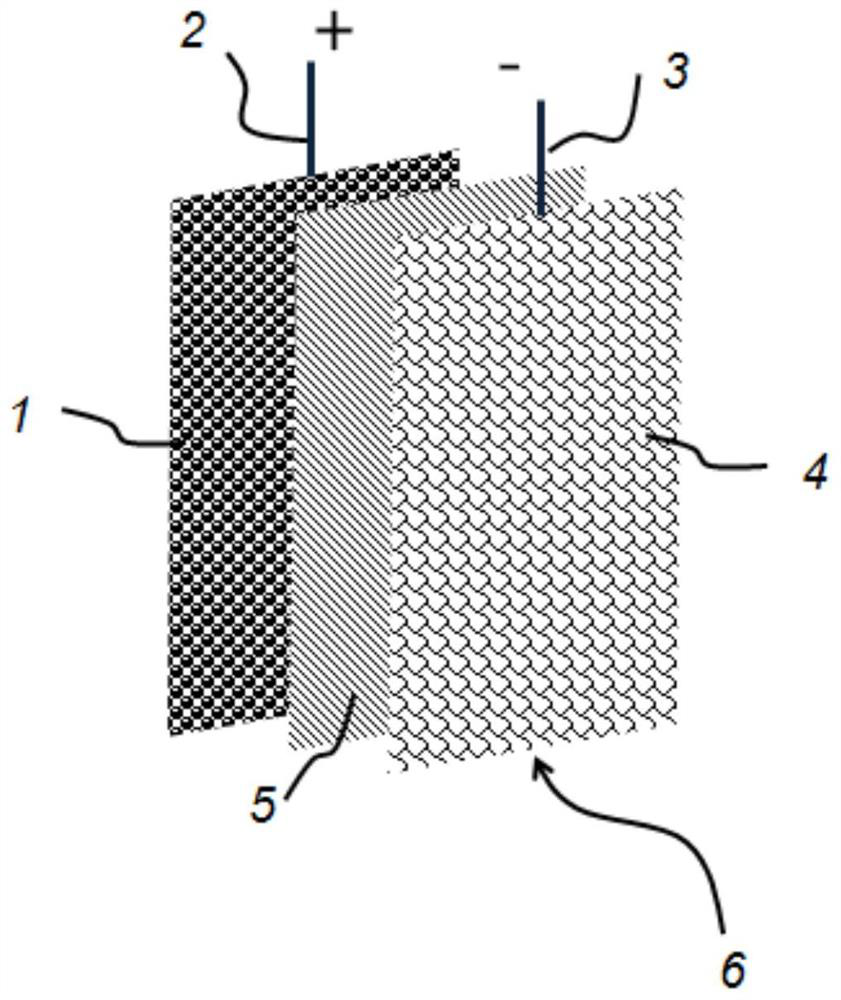

UltraBattery is a hybrid energy storage device invented by Australia's Commonwealth Scientific and Industrial Research Organisation (CSIRO). UltraBattery combines ultracapacitor technology with lead-acid battery technology in a single cell with a common electrolyte.

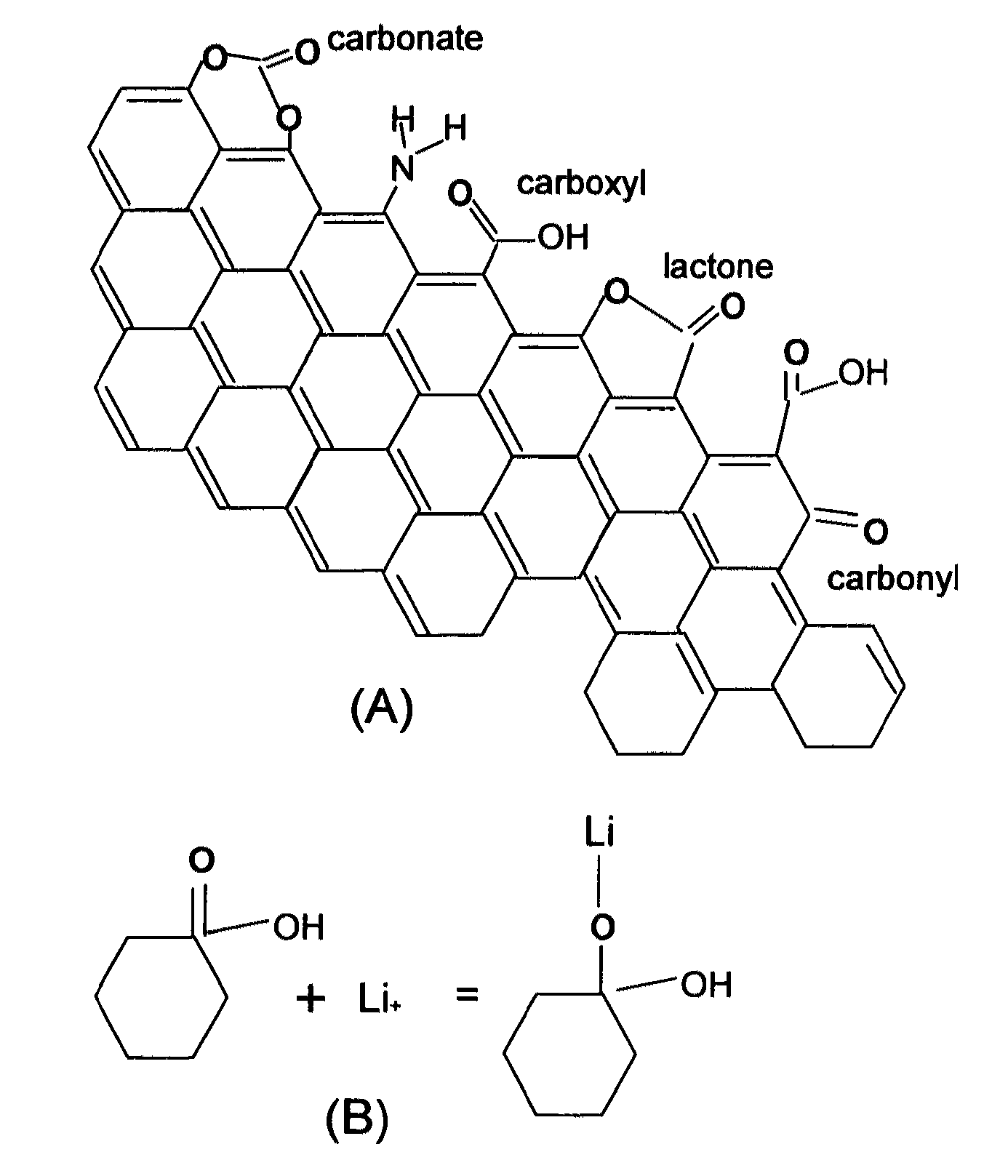

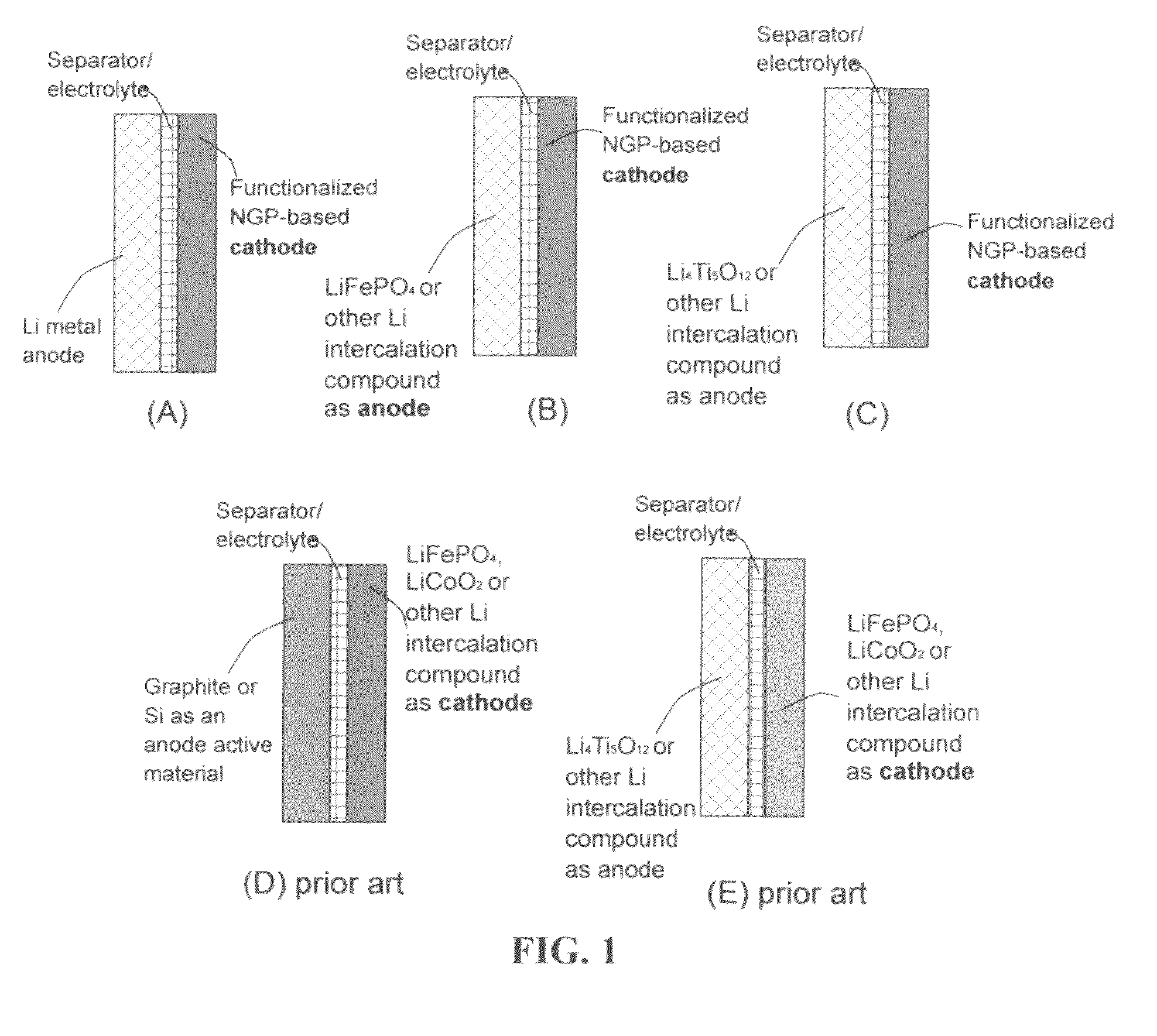

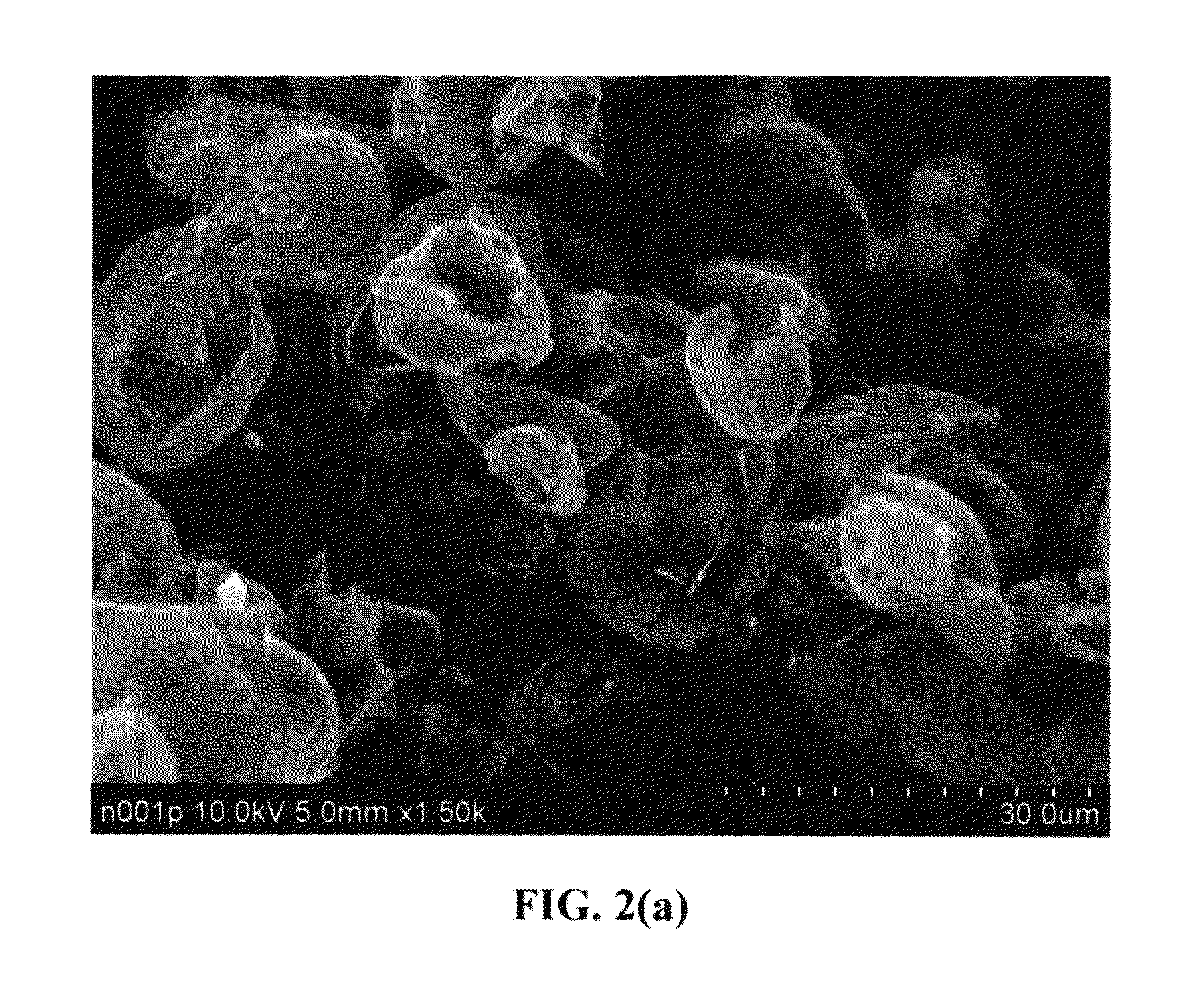

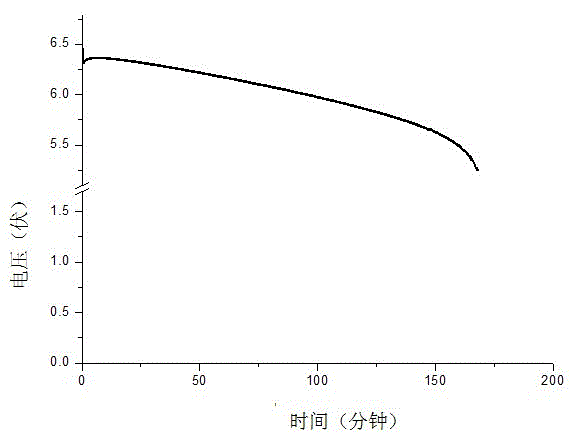

Lithium super-battery with a functionalized nano graphene cathode

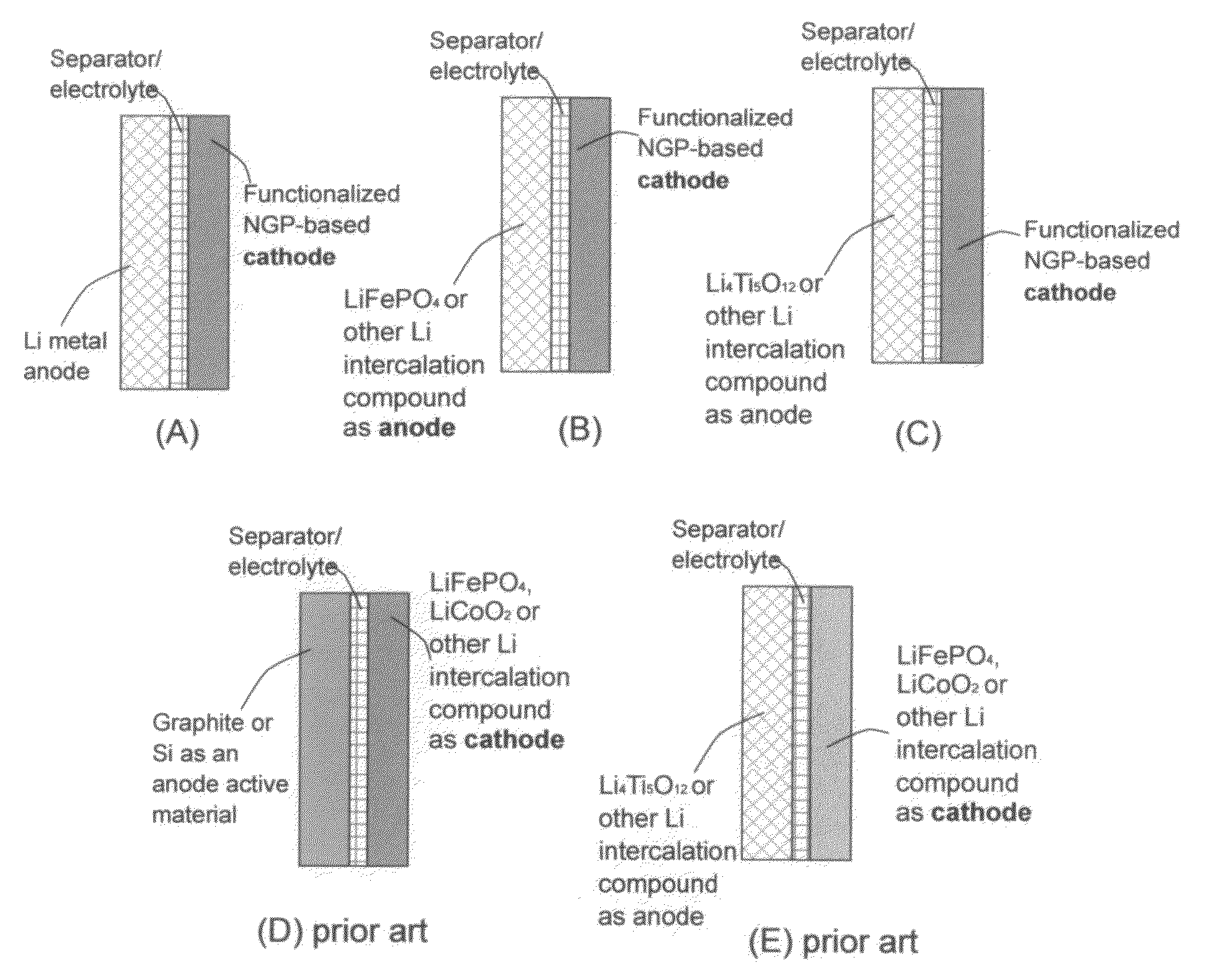

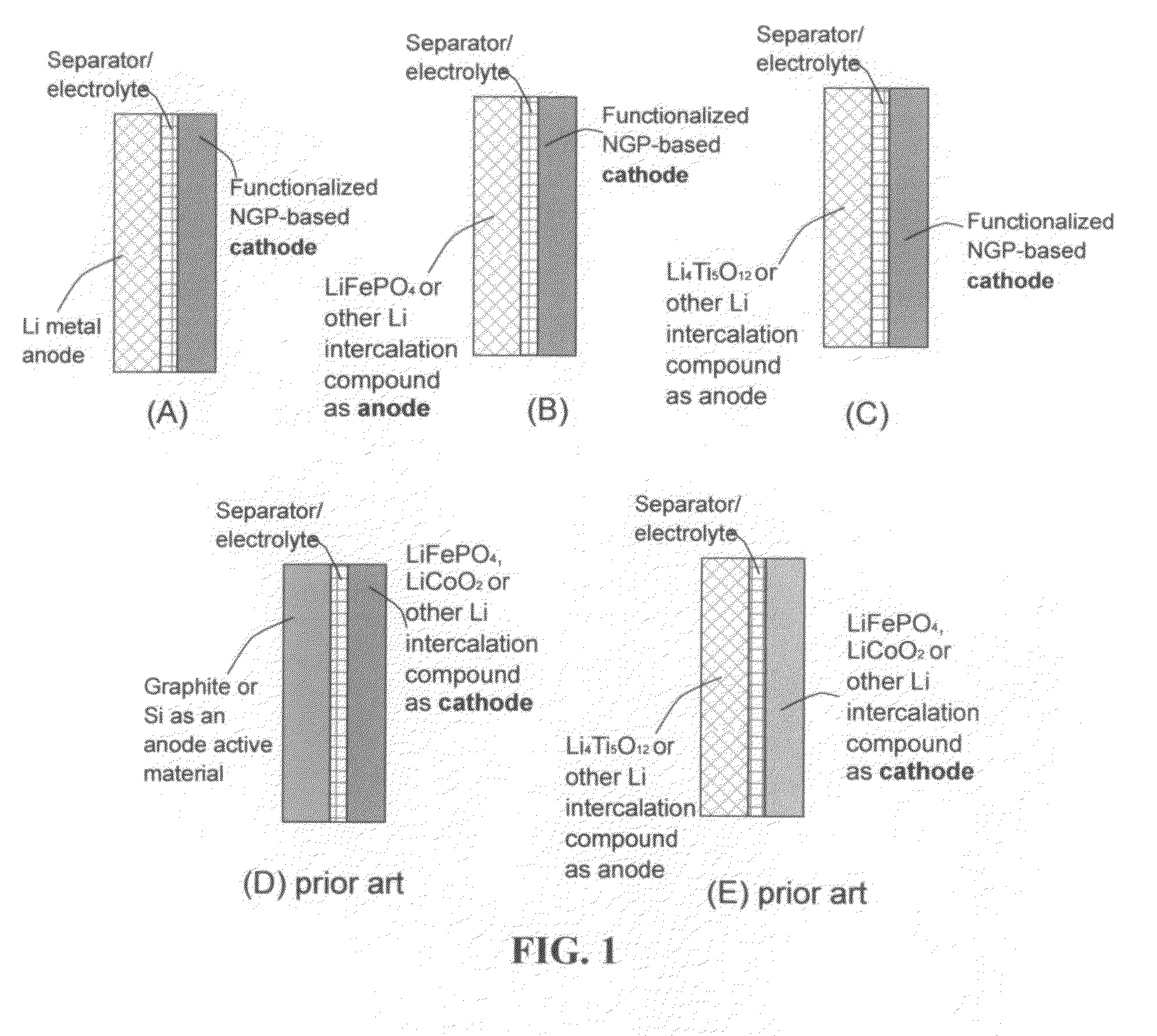

An electrochemical energy storage device, lithium super-battery, comprising a positive electrode, a negative electrode, a porous separator disposed between the two electrodes, and a lithium-containing electrolyte in physical contact with the two electrodes, wherein the positive electrode comprises a plurality of chemically functionalized nano graphene platelets (f-NGP) or exfoliated graphite having a functional group that reversibly reacts with a lithium atom or ion. In a preferred embodiment, a lithium super-battery having a f-NGP positive electrode and Li4Ti5O12 negative electrode exhibits a gravimetric energy ˜5 times higher than conventional supercapacitors and a power density ˜10 times higher than conventional lithium-ion batteries. This device has the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

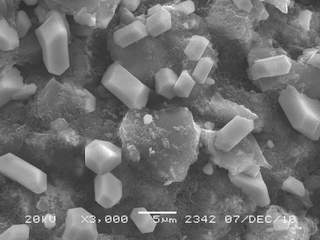

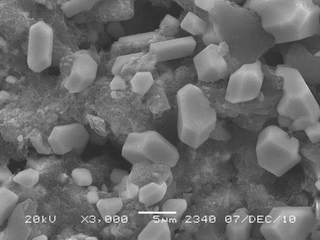

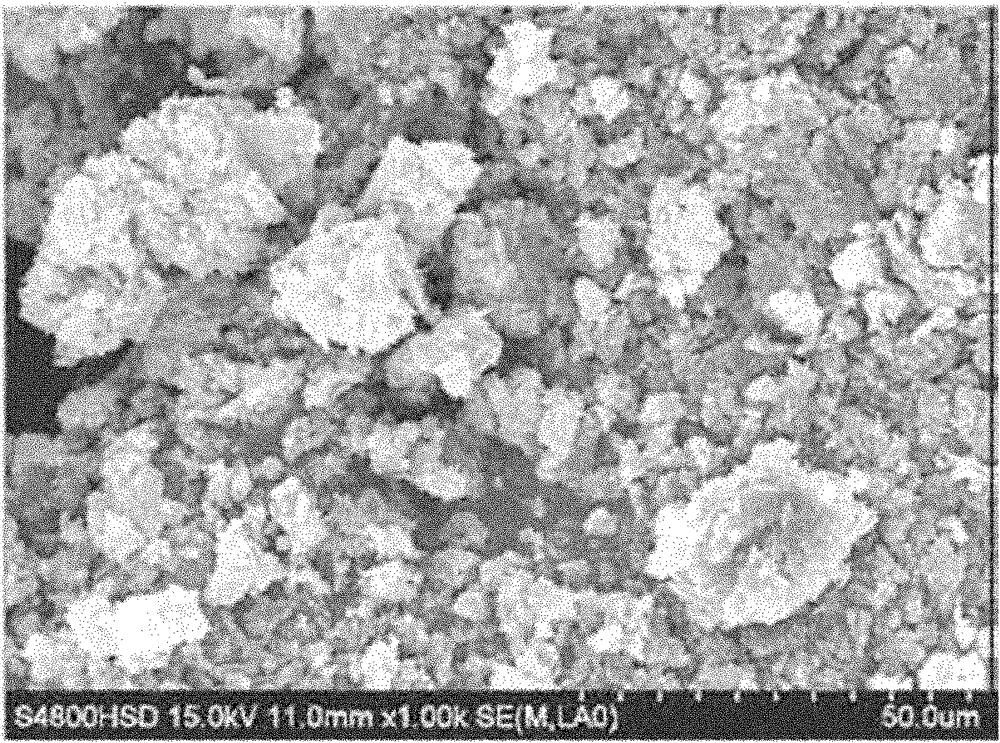

Lead-carbon composite material

ActiveCN102074702AProportionally largeEnhanced interface bindingCell electrodesCapacitanceCarbon composites

The invention relates to a lead-carbon composite material, which is prepared by depositing lead inside active carbon particles and among active carbon particles through an electrolytic deposition method. The lead is 5 to 65 mass percent of the lead-carbon composite material, and grows in a polyhedral particle shape from holes of the active carbon so as to achieve good interfacial bond of the lead and the carbon. The lead-carbon composite material has larger specific gravity, and is more easily mixed with anode active materials of a lead-acid storage battery, such as lead powder and the like uniformly. The lead-carbon composite material has the specific capacitance of 72 to 115F / g in sulfuric acid electrolyte with the density of 1.28g / m<3>, so the lead-carbon composite material can directly serve as an anode material of an ultrabattery, or serve as the anode active material of the ultrabattery to be applied to ultrabattery manufacture.

Owner:ZHUZHOU SMELTER GRP +1

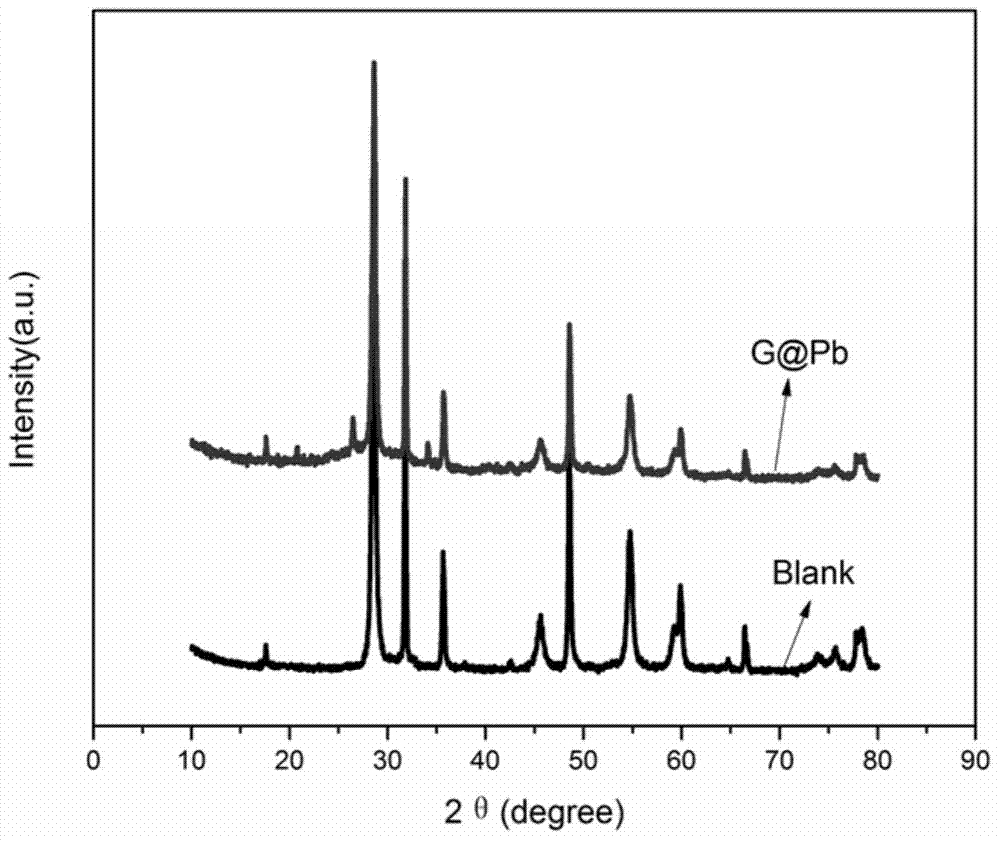

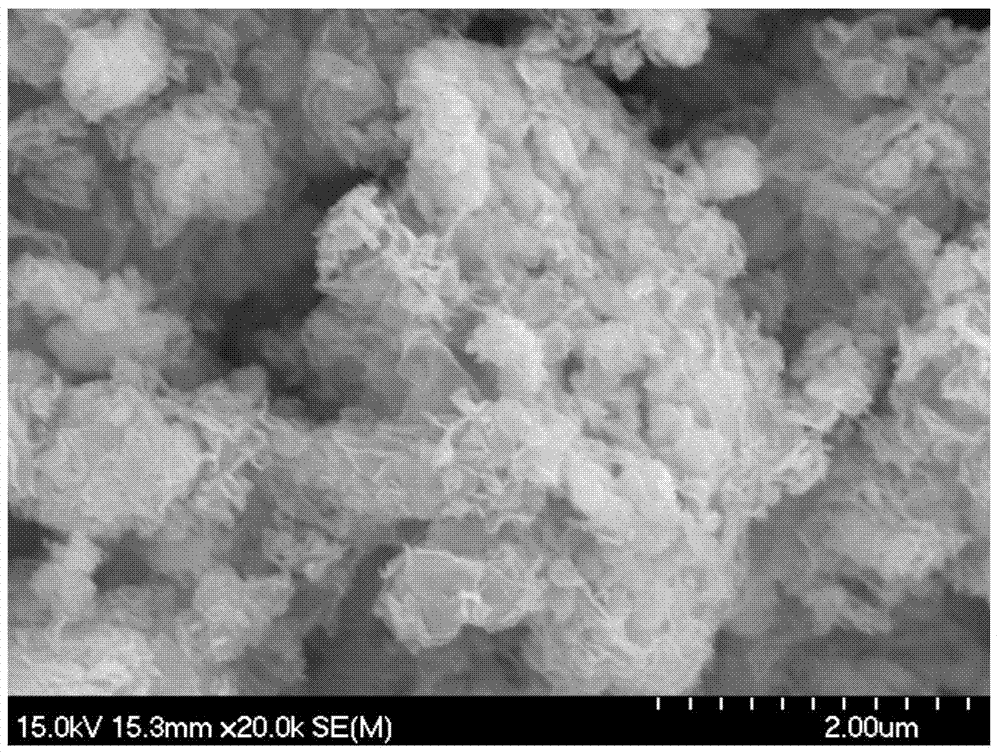

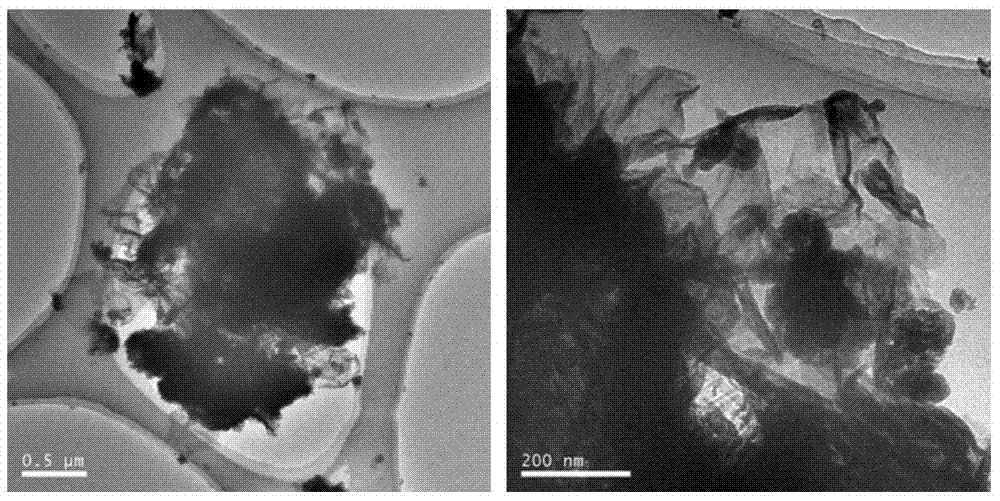

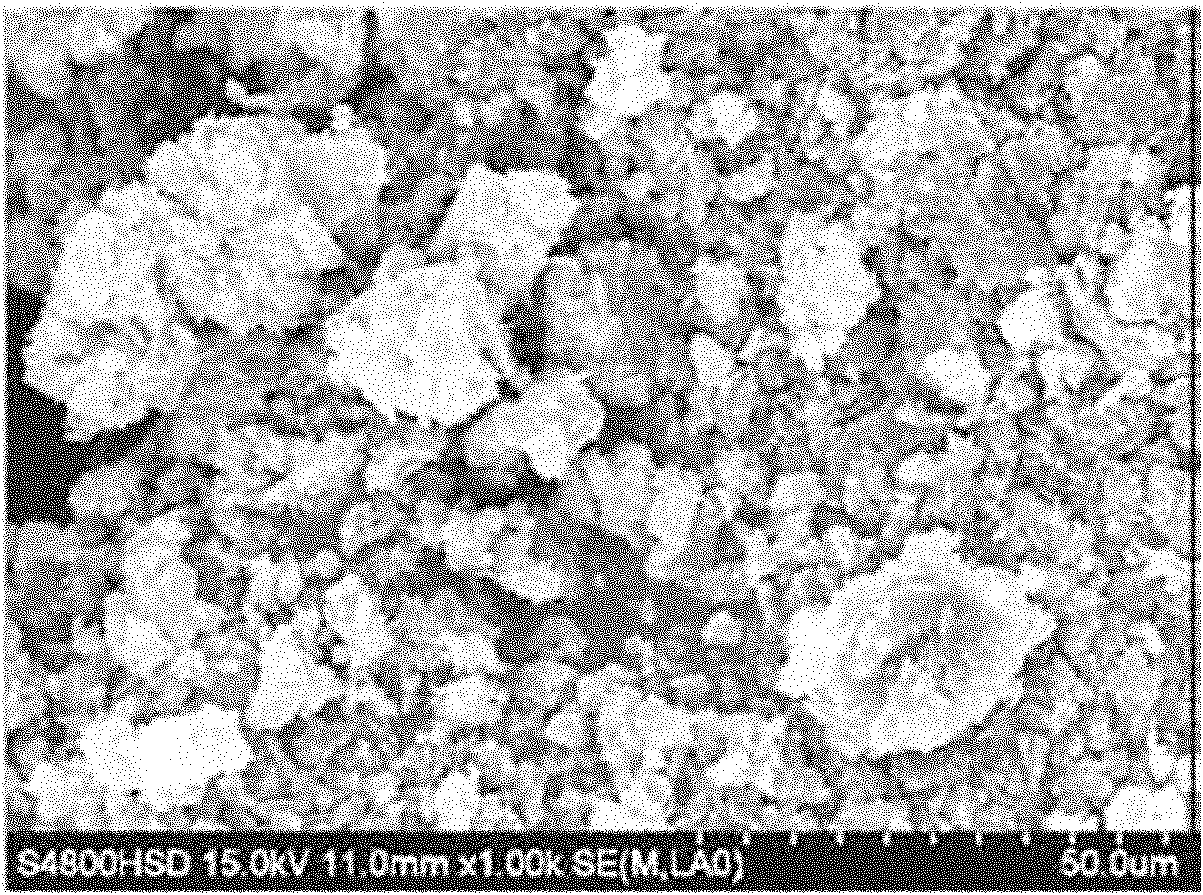

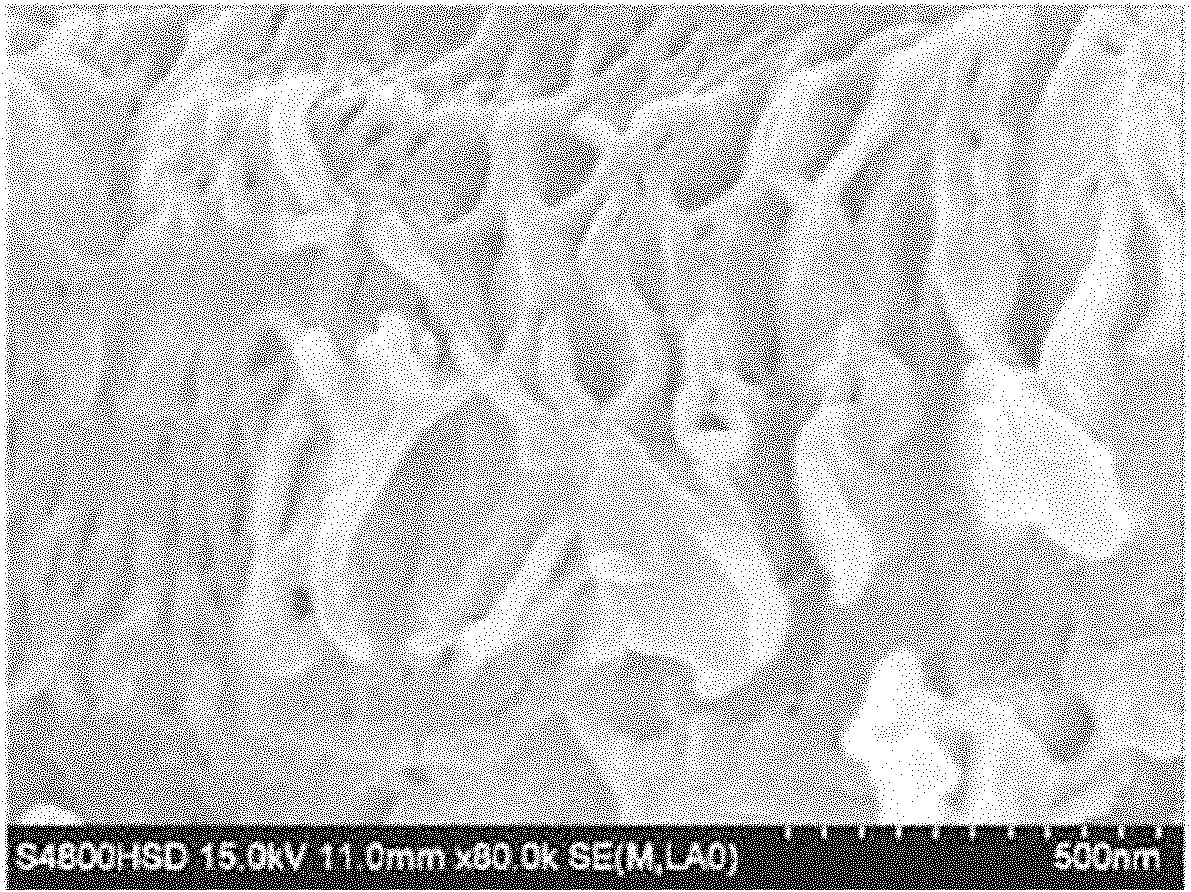

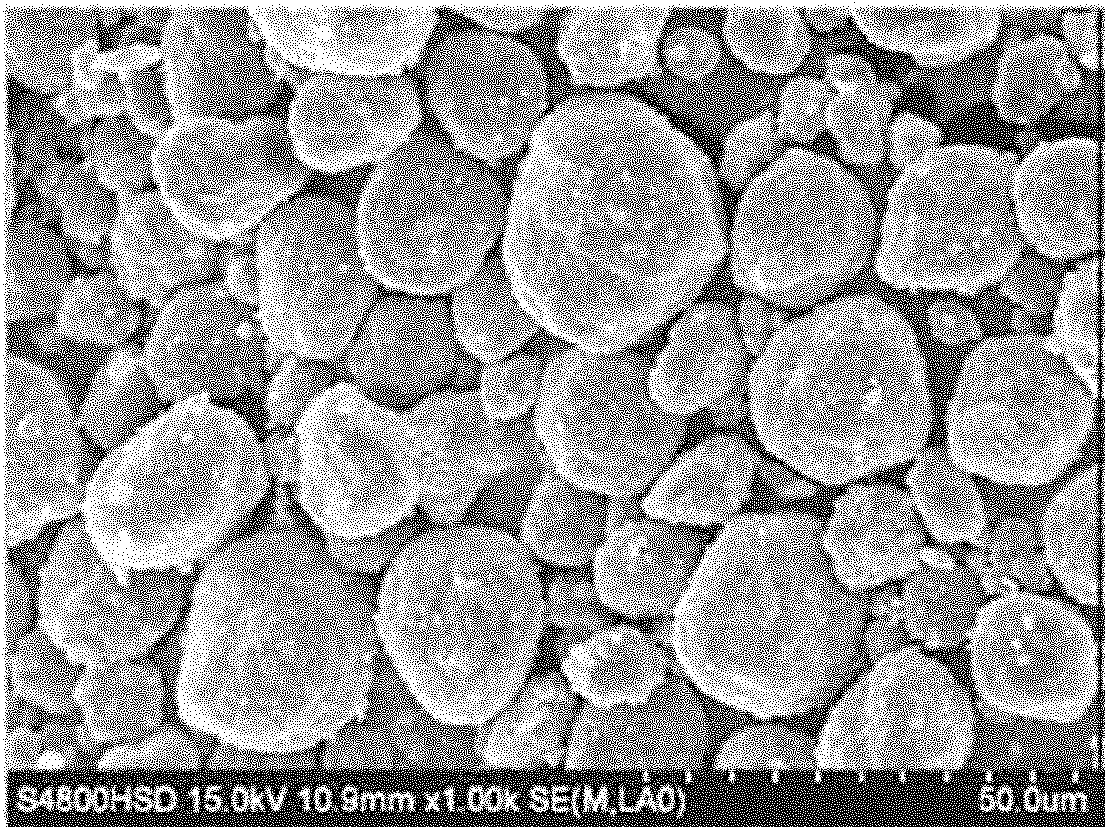

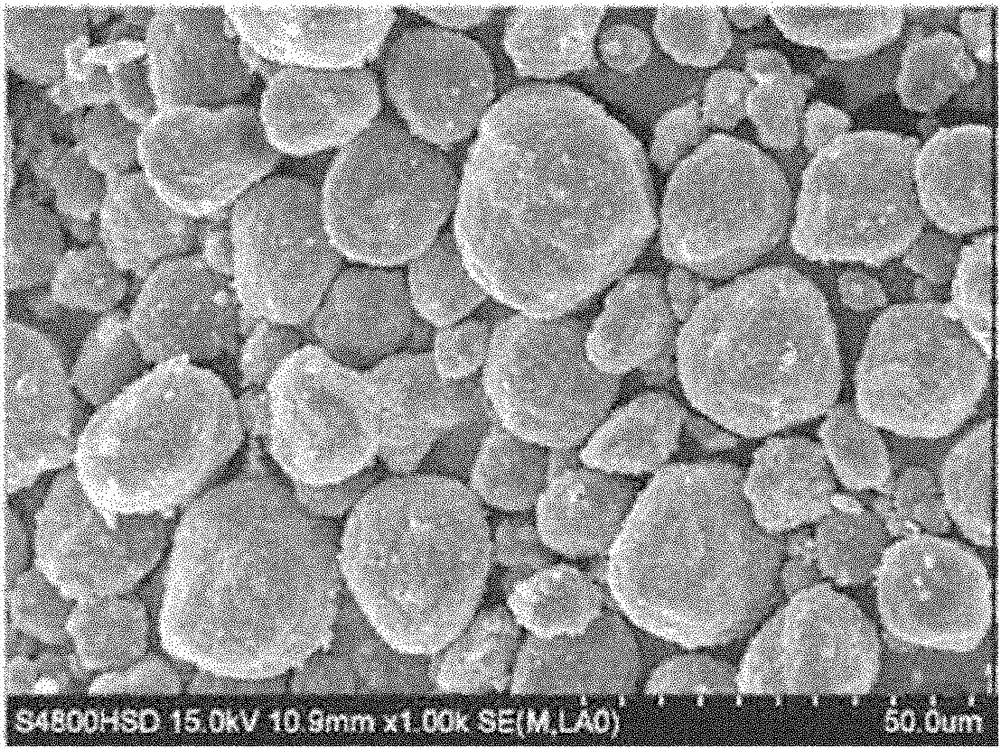

Graphene coated lead powder composite material and application thereof

InactiveCN103579616AGood dispersionImprove uniformityFinal product manufactureLead-acid accumulator electrodesCouplingCvd graphene

The invention discloses a graphene coated lead powder composite material and an application thereof. A preparation method of graphene coated lead powder composite material comprises the following steps of: (1) modifying lead powder by using an aminosilane coupling agent so that the lead powder has positive charges on the surface, and then obtaining the modified lead powder with positive charges; (2) carrying out self-assembly of the modified lead powder obtained in the step (1) with oxidized graphene in deionized water A through electrostatic adsorption to obtain the oxidized graphene coated lead powder composite material; and (3) reducing the oxidized graphene coated lead powder composite material obtained in the step (2) into the graphene coated lead powder composite material. The graphene coated lead powder composite material can be used as the cathode material of a lead-carbon super battery. A polar plate made from the graphene coated lead powder composite material is good in mechanical strength; a battery made from the composite material as the cathode material is excellent in charge / discharge performance, power density, specific capacity and cycle life.

Owner:ZHEJIANG UNIV OF TECH

Lead carbon mixed negative lead paste and preparation method thereof

ActiveCN102881867AEvenly dispersedGood dispersionLead-acid accumulator electrodesFiberActivated carbon

The invention discloses a lead carbon mixed negative lead paste and a preparation method thereof. The lead paste is prepared by the following raw materials of, according to weight part proportions, 100 of lead powder, 0.01-2 of gas phase grown carbon fibers, 0.01-2 of high specific surface carbon black, 0.01-5 of activated carbon, 0.01-2 of a hydrogen evolution inhibitor, 0.3-2 of barium sulfate, 0-1.2 of sodium lignosulfonate, 0.5-2 of a humic acid, 0.05-0.1 of short fibers, 5-20 of water and 4-15 of sulfuric acid (the concentration is 1.2-1.40 g / mL). Due to the addition of the gas phase grown carbon fibers, the lead carbon mixed negative lead paste can maintain stable apertures and good active interface; and the high conductive characteristic and high capacitance characteristic of the carbon materials can be fully played. The preparation method of the lead carbon mixed negative lead paste employs a mode of firstly immersing the carbon materials, and then mixing the lead powder and the carbon powder, thereby realizing the better uniform distribution of the carbon. The charging acceptance capability and HRPSoC cycle life of the battery can be significantly improved by using the lead carbon mixed negative lead paste to make a lead carbon super battery.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

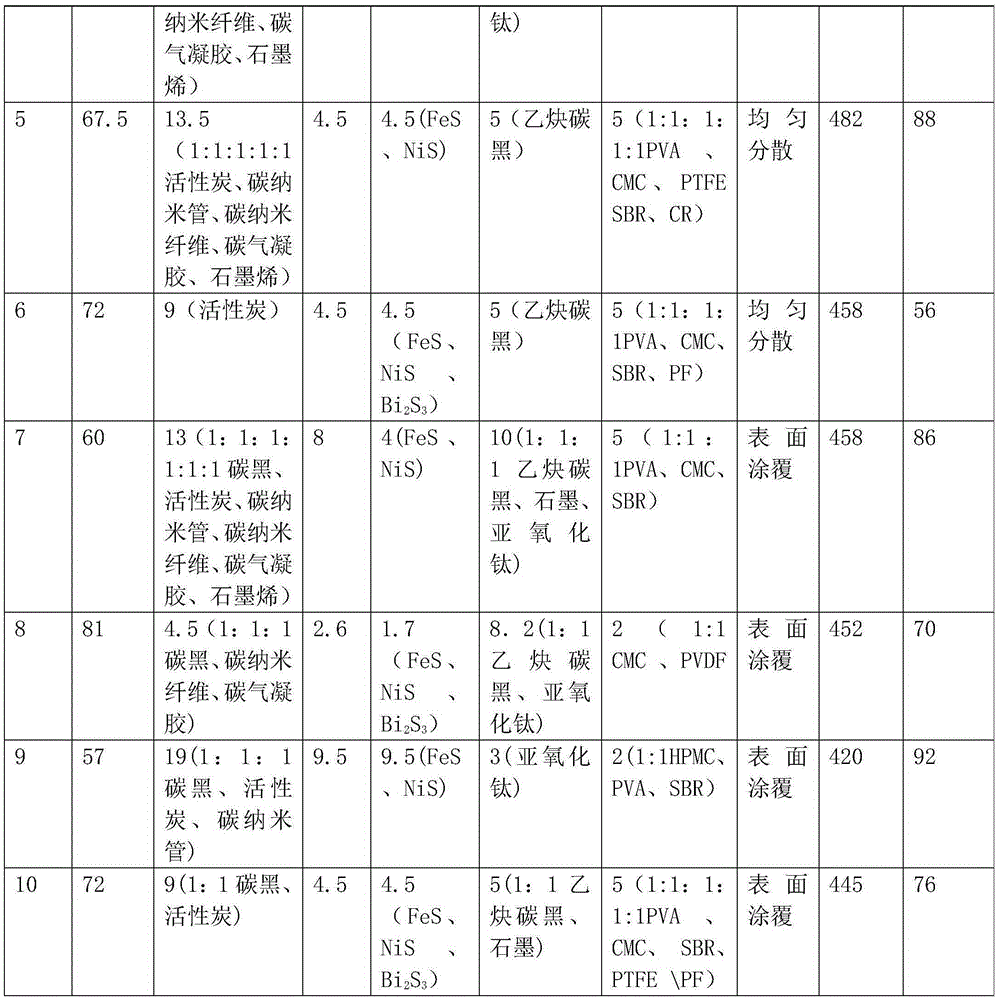

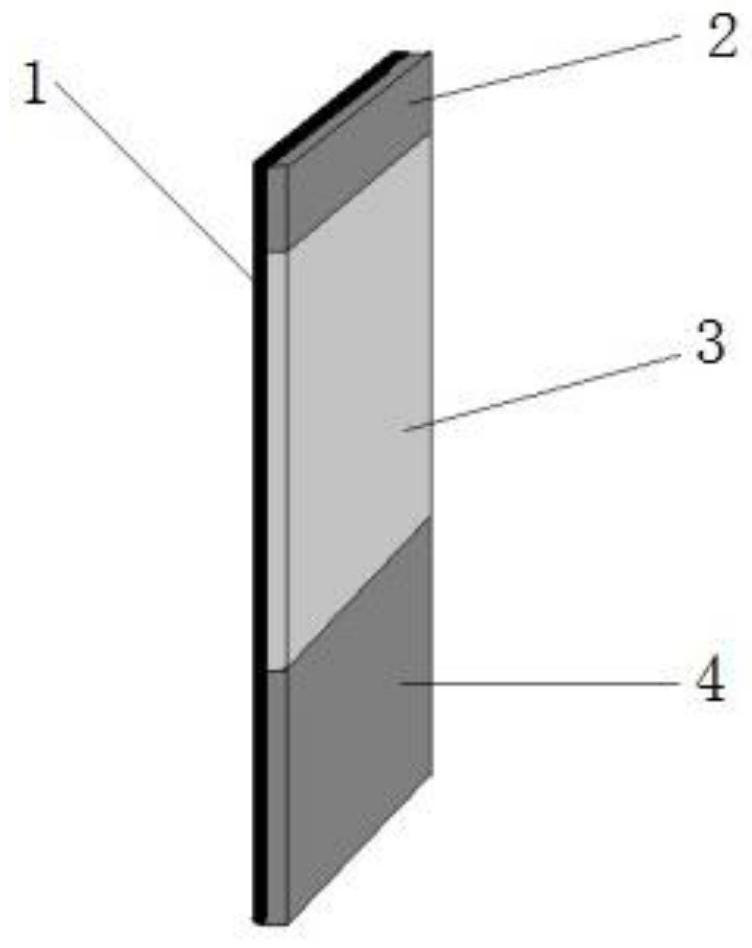

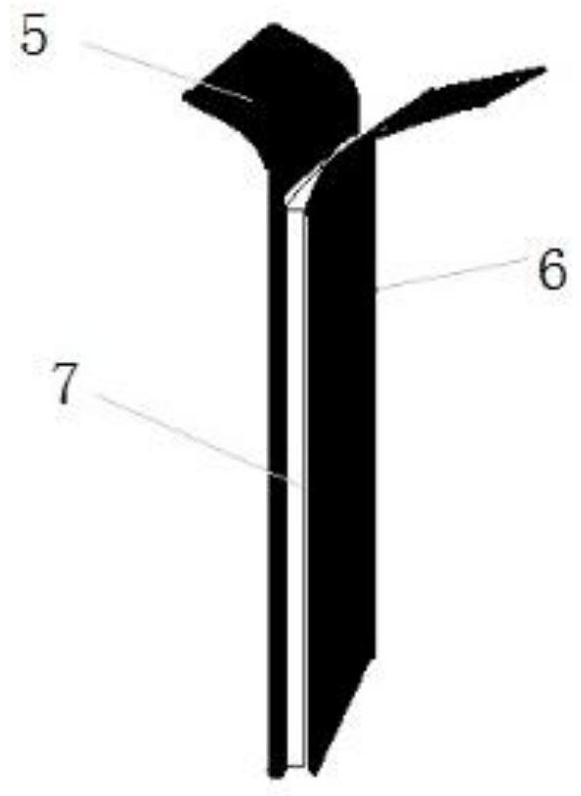

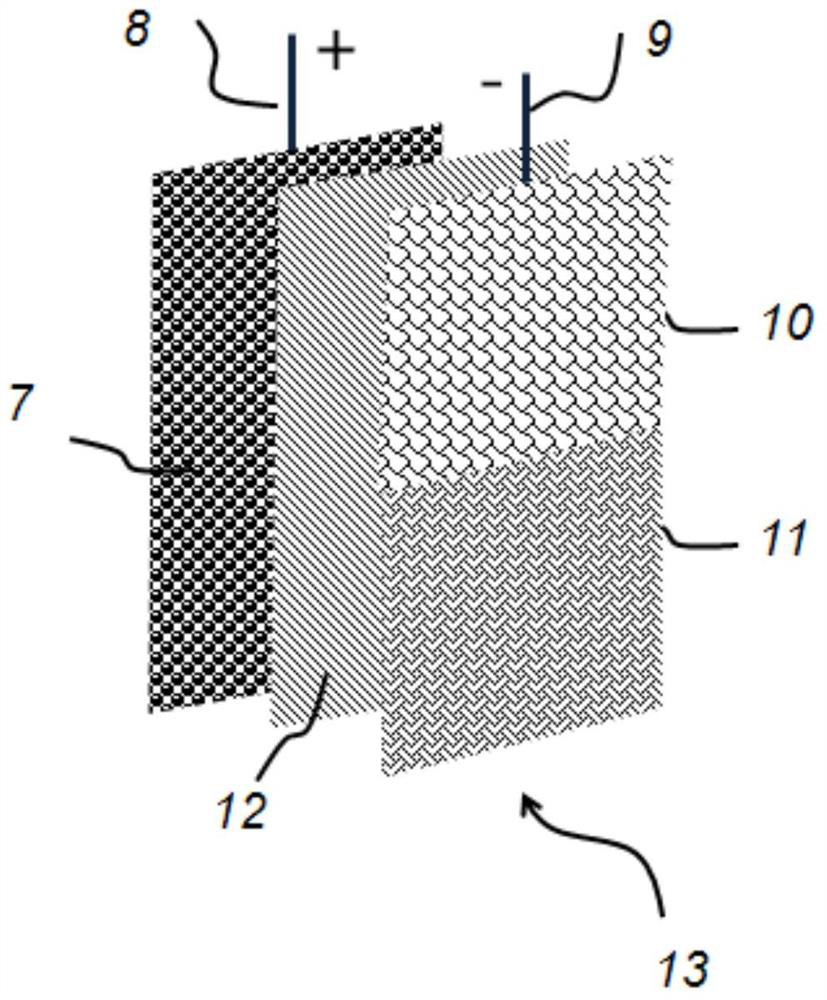

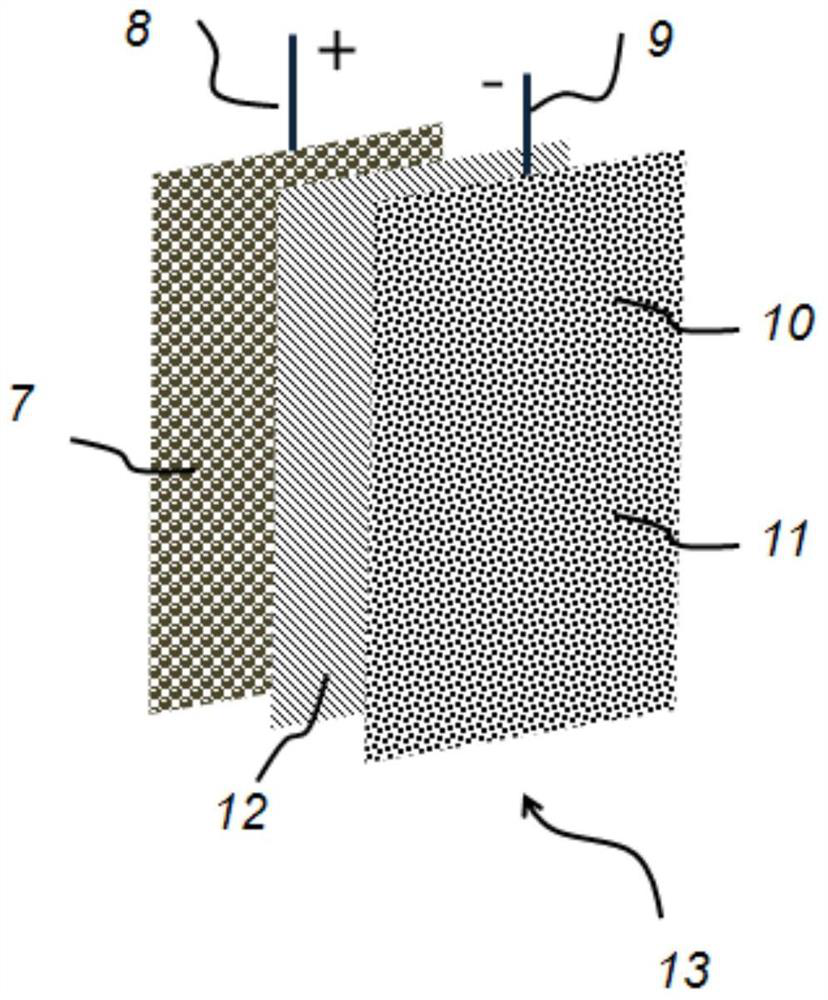

Negative plate of lead acid super battery, production method and lead acid super battery assembled by negative plate

ActiveCN102064319AWith super capacitor performanceExtend your lifeLead-acid accumulatorsLead-acid accumulator electrodesCapacitanceElectrical battery

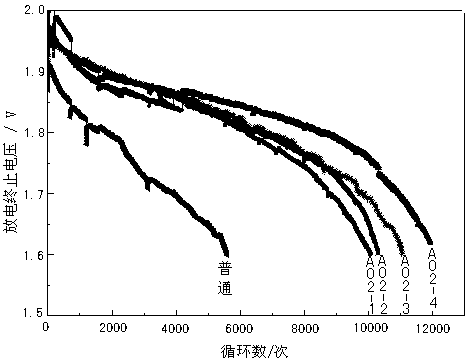

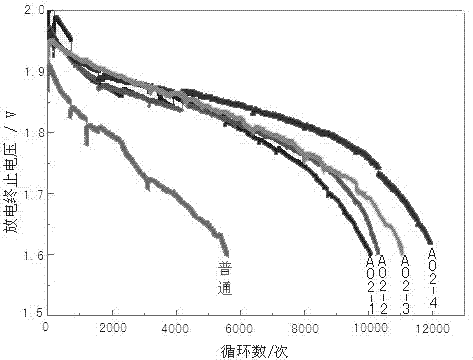

The invention discloses a negative plate of a lead acid super battery, a production method and a lead acid super battery assembled by the negative plate, solving the problem of short service life of the charge state of a magnifying power part of the traditional lead acid super battery. The negative plate comprises a negative plate grid and negative lead plaster, wherein capacitance carbon plaster is coated on the surface of the negative lead plaster, and expansion intermediate phase carbon microballoons are added to the negative lead plaster; and the capacitance carbon plaster comprises activated carbon loading lead oxide, stearic acid, acetylene black, and the like. In the invention, the negative plate is formed by the method that the materials of the negative lead plaster are coated onto the negative plate and after cured and formatted, the capacitance carbon plaster is coated onto the outer surface and cured; and a super capacitive negative plate is obtained by doping high-capacitance and high-conductivity expansion intermediate phase carbon microballoons into the negative lead plaster to match with active substances in the capacitance carbon plaster. The service life of the assembled lead acid super battery is prolonged by 3-5 times compared with that of the traditional lead acid super battery, and the power is improved by 5 times, thus the lead acid super battery can be applied to medium and low hybrid electric vehicles and low-configuration pure electric vehicles.

Owner:HARBIN INST OF TECH

Lithium super-battery with a functionalized nano graphene cathode

An electrochemical energy storage device, lithium super-battery, comprising a positive electrode, a negative electrode, a porous separator disposed between the two electrodes, and a lithium-containing electrolyte in physical contact with the two electrodes, wherein the positive electrode comprises a plurality of chemically functionalized nano graphene platelets (f-NGP) or exfoliated graphite having a functional group that reversibly reacts with a lithium atom or ion. In a preferred embodiment, a lithium super-battery having a f-NGP positive electrode and Li4Ti5O12 negative electrode exhibits a gravimetric energy ˜5 times higher than conventional supercapacitors and a power density ˜10 times higher than conventional lithium-ion batteries. This device has the best properties of both the lithium ion battery and the supercapacitor.

Owner:GLOBAL GRAPHENE GRP INC +1

Preparation method of super storage battery lead-carbon negative plate

ActiveCN102856528AEliminate Spike DischargeIncrease output powerElectrode manufacturing processesLead-acid accumulator electrodesElectrical polarityProcess engineering

Owner:TIANNENG GRP JIANGSU TECH

Super lead-acid storage battery containing carbon-coated lead composite material and preparation method of super lead-acid storage battery

InactiveCN102983327AImprove charge reception capabilityIncrease capacityCell electrodesFinal product manufacturePower batteryElectrolytic agent

The invention discloses a super lead-acid storage battery containing carbon-coated lead composite material and a preparation method of the super lead-acid storage battery. In terms of weight, a cathode contains 0.5-20 % of carbon-coated lead composite material and an anode uses 10-68.85 % of Pb3O4 as an active material; and through the adoption of the traditional paste mixing, plate coating, curing and drying procedures, a valve-controlled sealed super battery with 1.0-1.4 g / cm<2> sulfuric acid as electrolyte or a colloid super storage battery containing 4-8 % of nanometer gas phase SiO2 and containing sulfuric acid with concentration of 1.0-1.4 g / cm<2> is prepared. The super lead-acid storage battery disclosed by the invention has the advantages of higher initial energy, better charging accepting capacity, better low temperature performance, more excellent large current discharging characteristic and longer cycle life and completely satisfies use requirements of power batteries. The super lead-acid storage battery disclosed by the invention is helpfully applied to electric automobile batteries or used for upgrading and remodeling the traditional storage batteries.

Owner:ZHUZHOU SMELTER GRP +1

Hydrothermal preparation method of carbon coated lead powder composite materials for lead carbon super batteries

InactiveCN102610801AHigh mechanical strengthImprove mass to powerCell electrodesSecondary cells servicing/maintenanceElectrical batteryOrganosolv

The invention discloses a hydrothermal preparation method of carbon coated lead powder composite materials for lead carbon super batteries. Deionized water is added into carbohydrates to be prepared into solution or sol, lead powder is added for ultrasonic dispersion, the mixture is subjected to hydrothermal reaction so that the carbohydrates are carbonized to be coated on the surface of aluminum powder particles, original solvents and deionized water are used for alternately washing the coated materials, and the vacuum drying is carried out to obtain the carbon coated lead powder composite materials. The lead carbon super batteries made of the carbon coated lead powder composite materials have the advantage that the charging and discharging cyclic service life and the weight-to-power ratio are respectively and obviously prolonged and improved through being compared with those of the existing lead acid storage batteries.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Carbon cathode plate for super cell

InactiveCN102306555AImprove charging efficiencyImprove cycle lifeElectrolytic capacitorsElectrical batteryUltraBattery

The invention discloses a carbon cathode plate for a super cell. The carbon cathode plate comprises the ingredients of active carbon, acetylene black and polyvinylidene fluoride, and is characterized by also comprising a hydrogen evolution inhibitor. According to the invention, a hydrogen evolution problem which is generated by a capacitor carbon electrode in a charging final stage and caused by large operation potential difference between a lead cathode plate and a capacitor carbon electrode in the super cell is solved, thus charging efficiency of the super cell is improved, large granule lead sulfate formed in discharging is promoted to be converted into spongy lead, and a cycle life of a plumbic acid cell is effectively raised. The hydrogen evolution inhibitor has a wide composition source and low cost, and has no special requirement for production equipment. The hydrogen evolution inhibitor has a simple and practicable preparation method, and is suitable for large scale productionapplication.

Owner:SOUTH CHINA NORMAL UNIVERSITY

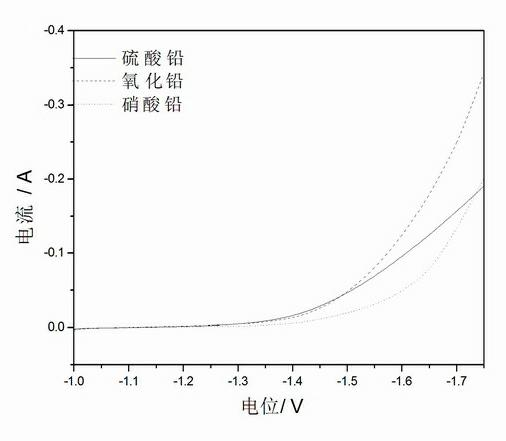

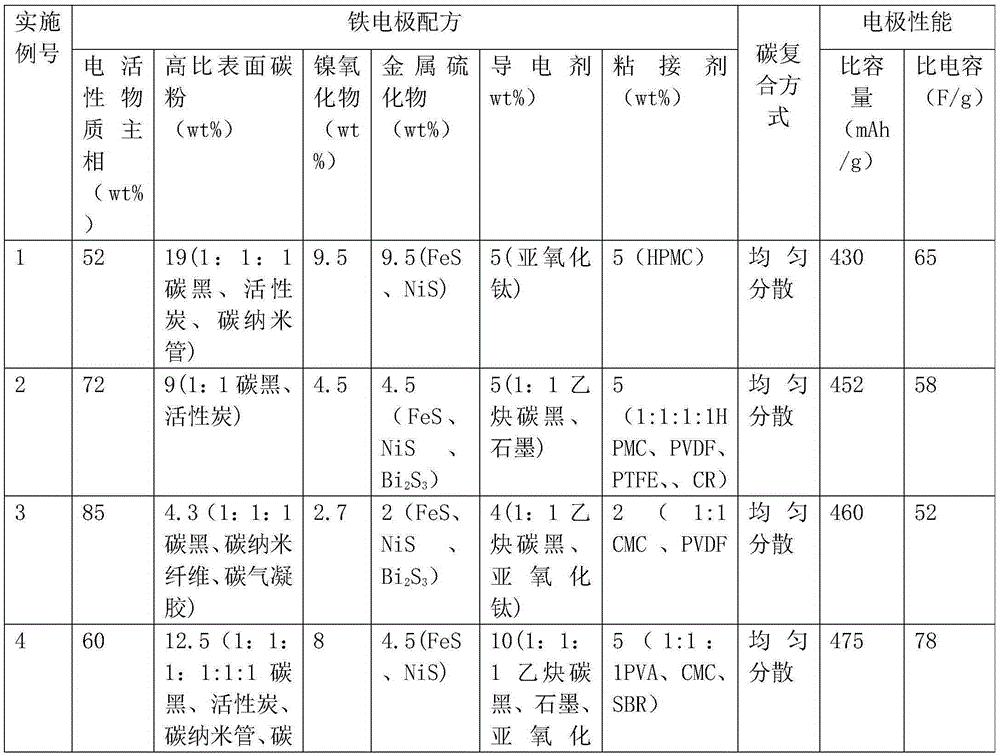

Alkaline capacitor battery iron electrode and preparation method thereof

InactiveCN105428626AHigh strengthIncrease profitNegative electrodesAlkaline accumulator electrodesCapacitanceSlurry

The invention provides an alkaline super capacitor battery iron electrode, comprising a porous metal collector electrode substrate and an electrode material, wherein 85-95wt percent of the electrode material is an electrochemical active composite material, 5-15wt percent of the electrode material is formed by a conductive agent and a binder, and the electrochemical active composite material comprises an electrochemical active material and an additive. The invention also provides a preparation method of the alkaline super capacitor battery iron electrode; first electrode material slurry is subjected to filling and coating through an electrode plate slurry pulling automatic production line, and is prepared into the iron electrode by drying, prepressing, rolling, stamping and slicing, separating slices, and spot welding of electrode lugs. The iron electrode made by the preparation method disclosed by the invention is high in strength, good in electrical property, simple in manufacturing process, good in consistency and low in cost; a formula and the preparation method of the iron electrode are suitable for making iron cathodes of alkaline secondary batteries, such as a nickel-iron battery, an iron / air battery and a silver-iron battery, which are environment-friendly, with high capacity and high power, thus manufacturing corresponding super-batteries or super capacitor batteries.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Preparation process for cathode of lead-charcoal superbattery

InactiveCN102867942AEffective dispersionSmall self-dischargeLead-acid accumulator electrodesActivated carbonElectrical battery

The invention provides a preparation process for a cathode of a lead-charcoal superbattery. Carbon materials are evenly distributed in a plumbic acid cathode so that organic combination of super electrical characteristics and battery performance is achieved. By means of the preparation process for the cathode of the lead-charcoal superbattery, charcoal material powder is independently and evenly dispersed in water through high-speed stirring and then mixed with lead powder and other cathode additives to be evenly dispersed. The charcoal material comprises activated carbon. Capacity preserving rate of the battery manufactured through the previous manufacture process cannot reach the standard requirement (the capacity preserving rate of the battery is no lower than 96% in the standard requirement), the battery manufactured by firstly pre-dispersing carbon in water and then performing paste mixing is obviously reduced in self discharge, and the capacity preserving rate of the battery exceeds the standard requirement. Further, the current is large, and cycle life is obviously improved.

Owner:ZHEJIANG NARADA POWER SOURCE CO LTD +2

Electrolyte of super battery

InactiveCN102738519ANo pollution in the processEfficient powerLead-acid accumulatorsElectrolytic agentSODIUM METAPHOSPHATE

The invention discloses an electrolyte of a super battery. The electrolyte comprises 35-50% of sulfuric acid, 1-10% of a silicate, 0.1-2% of sodium hexametaphosphate, 0.2-1% of nanometer carbon, 0.3-1.5% of cetyltrimethylammonium bromide, 0.1-1.5% of a sulfate, 0.02-0.4% of a polymeric stabilizing agent and 45-52% of water. The electrolyte of the invention allows the charging accept capability of the battery to be improved and the cycle life of the battery to be obviously improved. The electrolyte has the advantages of no generation of corrosive gases in the production process, realization of no pollution in the preparation process and the use process and no pollution of wastes, and fundamental solving of main disadvantages of electrolytes of traditional lead acid batteries.

Owner:TIANNENG GRP JIANGSU TECH

Super battery carbon supplementing method

The invention discloses a super battery carbon supplementing method. The method comprises the following steps: 1, preparing a paste from 100 parts by weight of lead powder, 4-10 parts by weight of sulfuric acid, 0.1-8 parts by weight of a binder, 0.1-2 parts by weight of barium sulfate, 0.01-2 parts by weight of a hydrogen evolution inhibitor, 1-4 parts by weight of active carbon, 0.1-2 parts by weight of heterogeneous graphite, 0.05-0.5 parts by weight of acetylene black, 1-4 parts by weight of humic acid, 12-21 parts by weight of water, and 0.1-0.2 parts by weight of short fibers, and smearing; 2, curing smeared negative plates under conditions that the temperature is 80DEG C and the relative humidity is 96% for not less than 60h; 3, forming the cured negative plates for not less than 20h; and 4, adding carbon materials which are same with the carbon materials in step 1 and have a weight being 0.4-20% of the total volume of an acid solution in a boric acid pool, washing the negative plates formed in step 3 with water, immersing the negative plates in the boric acid pool for 10-20min, fishing out, sending to a drying device, and drying.

Owner:TIANNENG GRP JIANGSU TECH

Microwave preparation method for carbon-coated lead powder composite for lead-carbon super batteries

ActiveCN102637858BHigh mechanical strengthImprove mass to powerCell electrodesMicrowave methodOrganic solvent

The invention discloses a microwave preparation method for a carbon-coated lead powder composite for lead-carbon super batteries. The method includes: weighing carbonhydrate and lead powder, making the carbonhydrate into solution or sol, adding the lead powder, stirring to obtain uniform paste mixture, and carbonizing the paste mixture by the microwave method while using shielding gas during carbonization to enable lead powder composite to be coated by carbon; and using organic solvent and deionized water to alternatively wash the coated composite, and vacuum drying to obtain the carbon-coated lead powder composite. Large-current charge-discharge cycle life and mass ratio power of lead-carbon super batteries made of the carbon-coated lead powder composite are evidently improved as compared with those of existing lead-acid batteries.

Owner:TIANNENG BATTERY GROUP +1

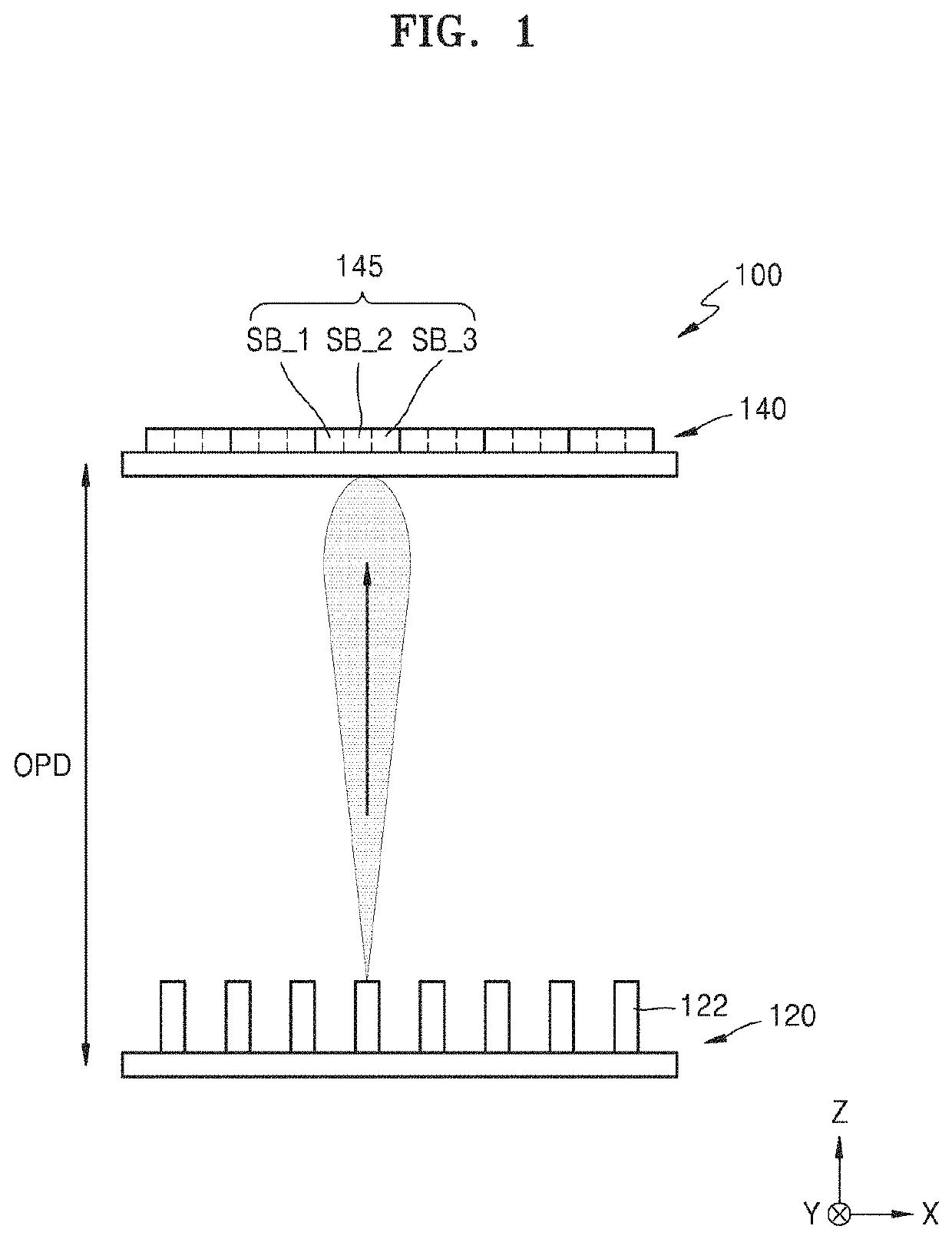

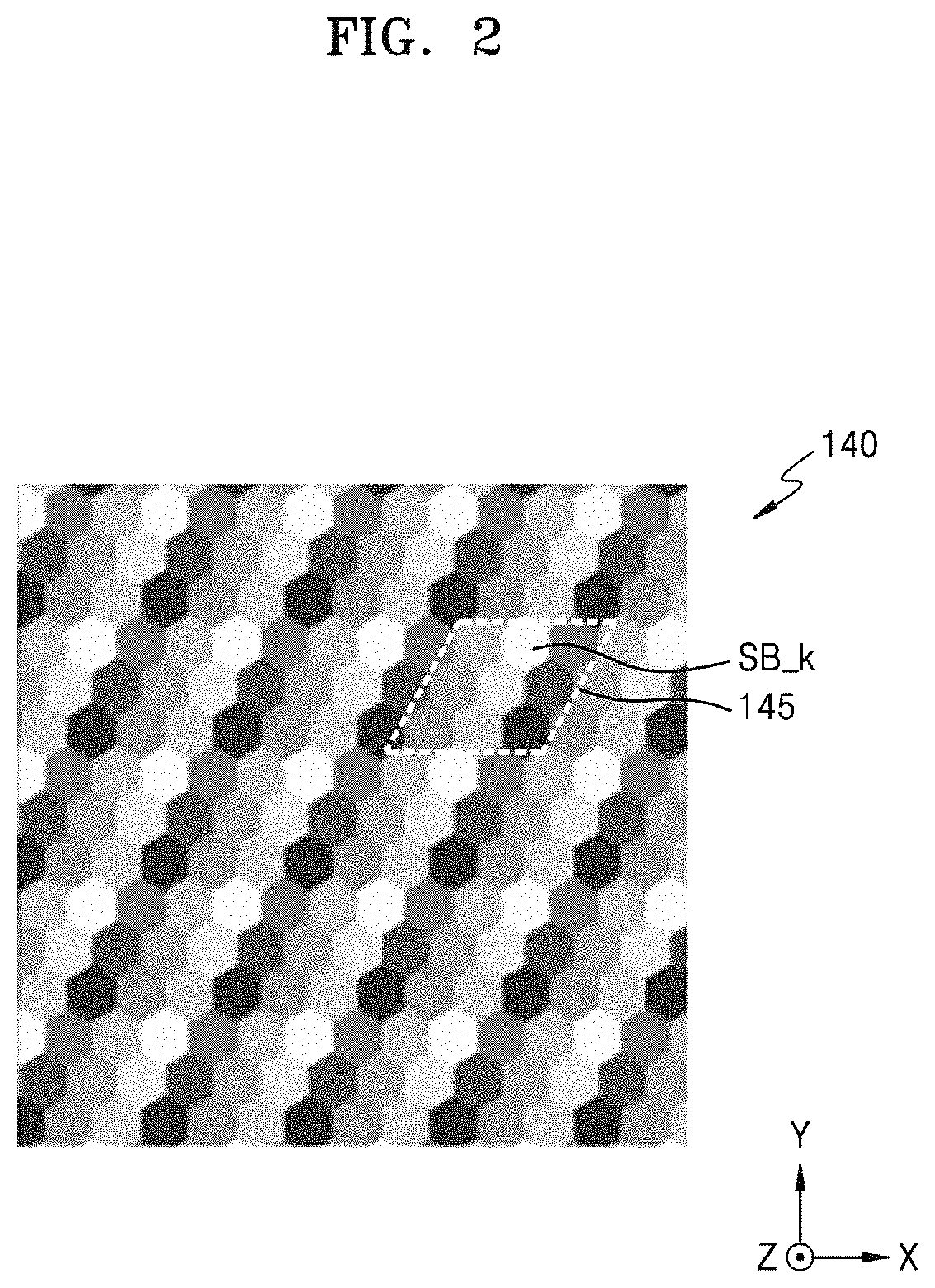

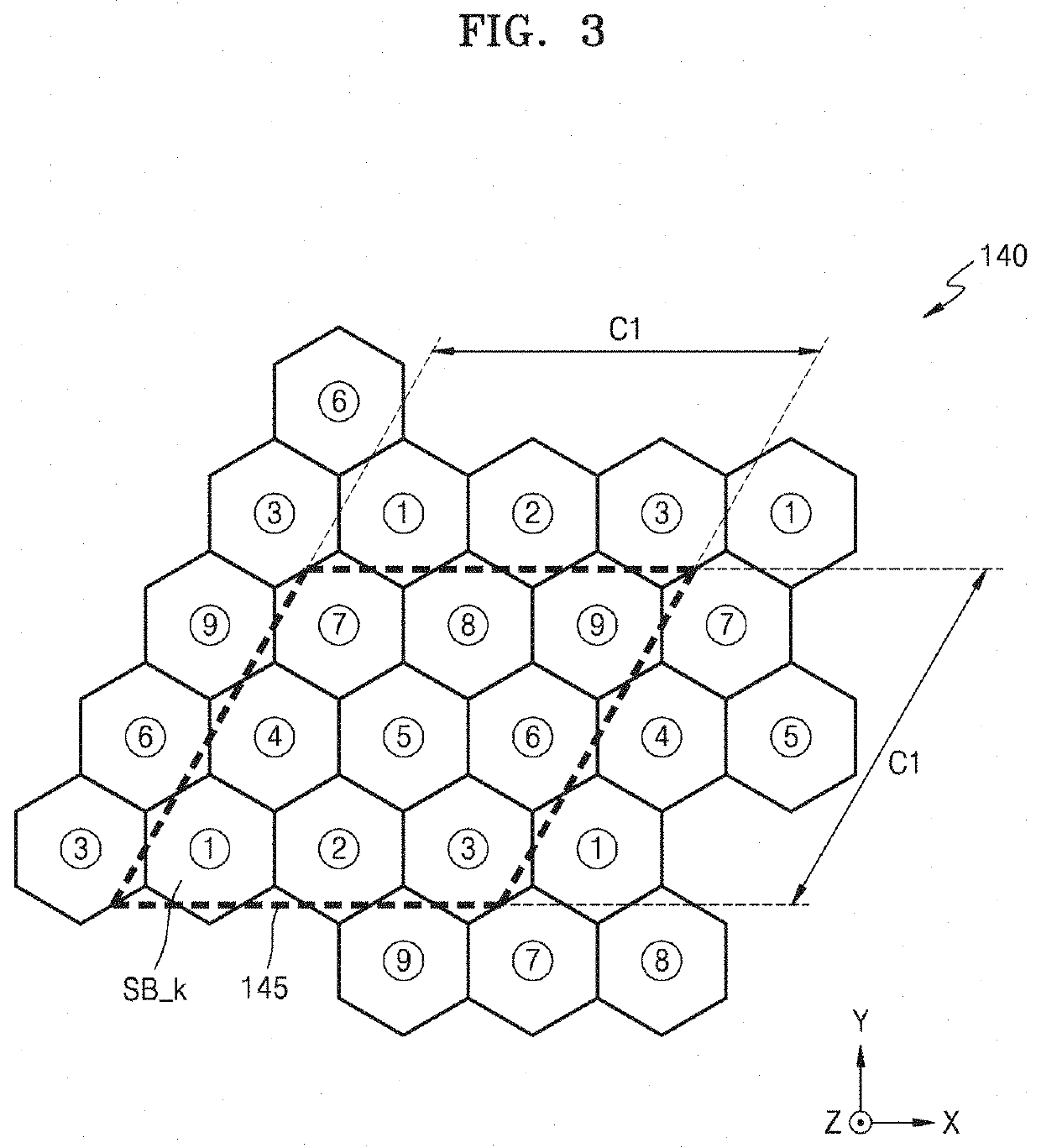

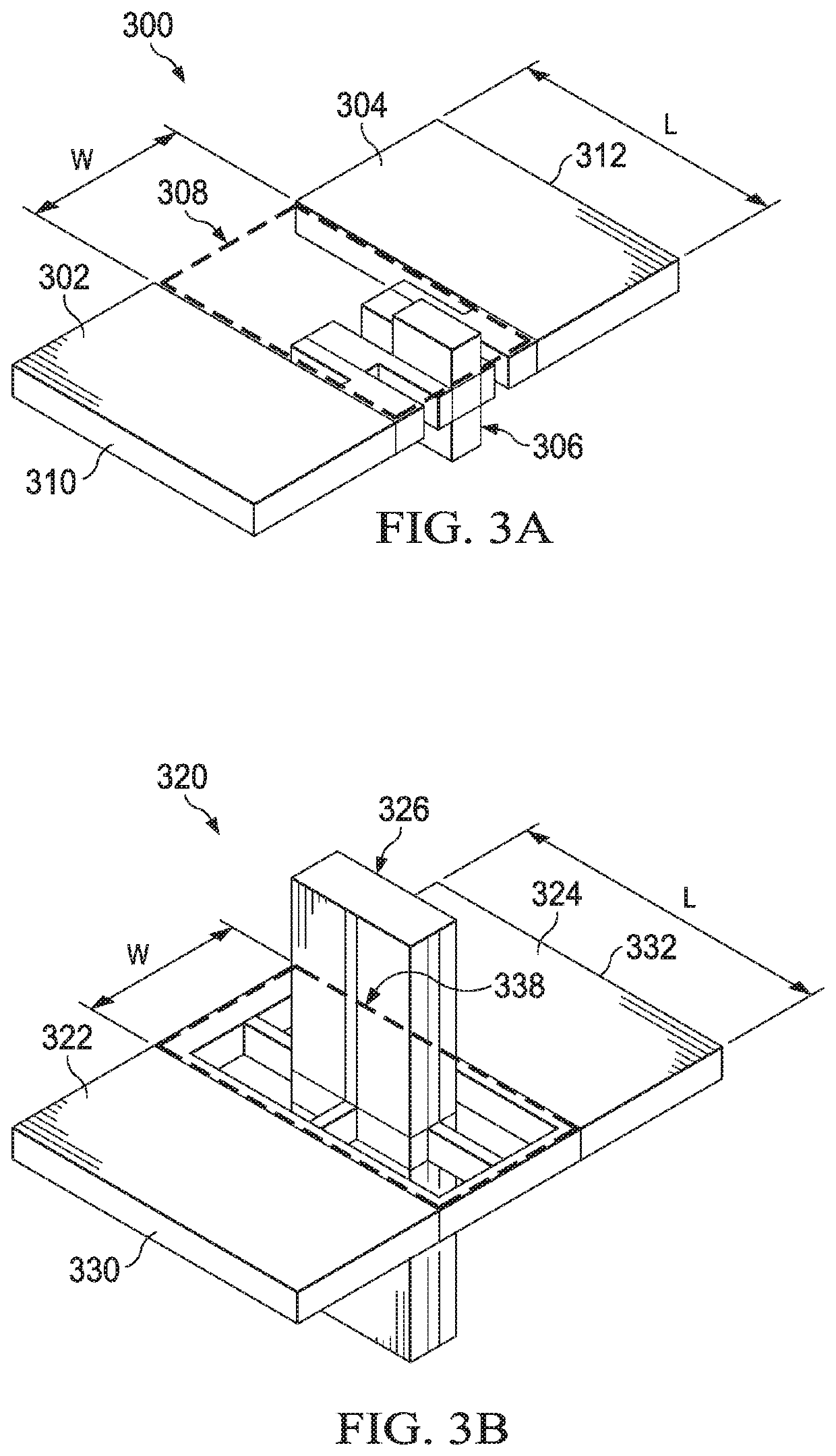

Structured light projector and electronic device including the same

Provided is a structured light projector including a light source configured to emit light, and a nanostructure array configured to form a dot pattern based on the light emitted by the light source, the nanostructure array including a plurality of super cells each respectively including a plurality of nanostructures, wherein each of the plurality of super cells includes a first sub cell that includes a plurality of first nanostructures having a first shape distribution and a second sub cell that includes a plurality of second nanostructures having a second shape distribution.

Owner:SAMSUNG ELECTRONICS CO LTD

Lead carbon super battery moisturizing maintenance method

ActiveCN103413982AReduce adverse effectsImprove cycle lifeSecondary cells charging/dischargingProcess engineeringEnvironmental engineering

The invention discloses a lead carbon super battery moisturizing maintenance method. The method comprises the following steps: adding deionized water in each unit cell battery for three times according to 40-60%, 20-40% and 10-30% of the water addition of the unit cell battery, non-standing or standing for 0-3h after adding water for each time, charging according to a moisturizing test process, extracting surplus acid at the final phase of the charging, wherein the moisturizing test process comprises charging for 16-20h with constant current which is 0.1 time of 2 hourly rated capacity and constant voltage which is battery unit cell voltage limited at 2.5 V, and then charging for 4-6h with constant current which is 0.025 time of 2 hourly rated capacity. The bad influence caused to the battery performance by conventional irregular moisturizing is solved, and after being maintained by the method disclosed by the invention, the circulating life of the lead carbon super battery is greatly improved.

Owner:TIANNENG GRP JIANGSU TECH

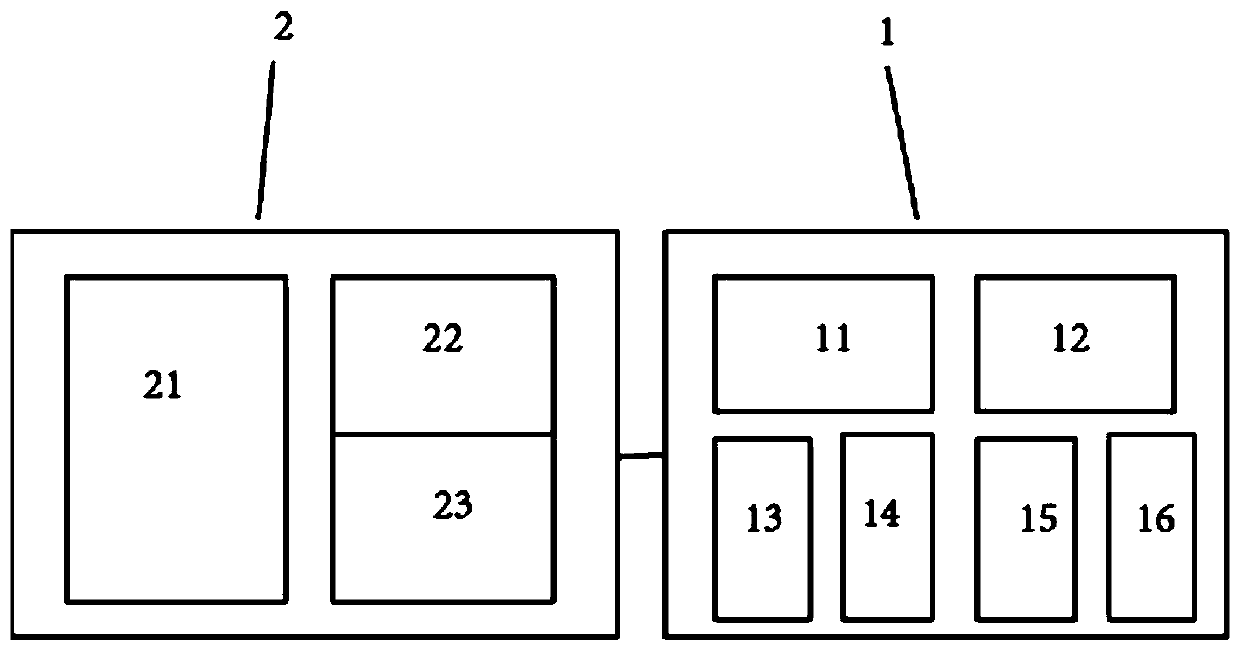

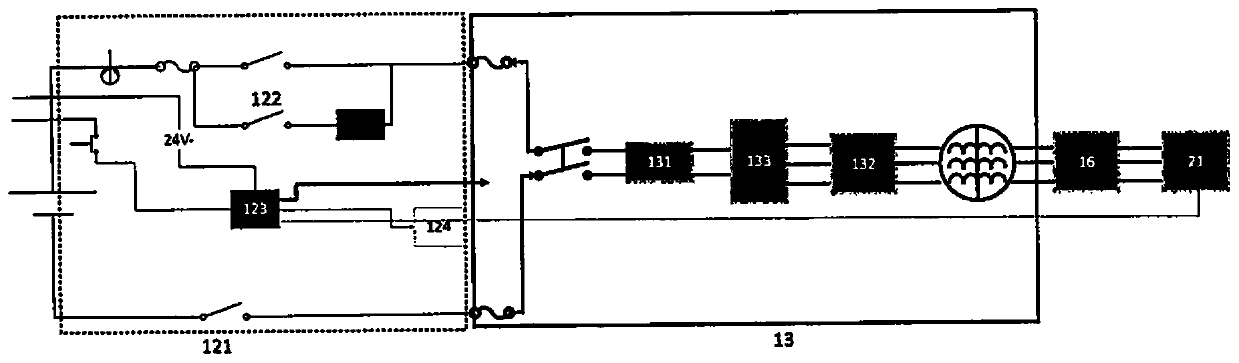

Flash welding machine with high-power superbattery for energy storage and power supply

PendingCN111347143AProtect healthNo noise pollutionWelding electric suppliesElectrical batteryUltraBattery

Provided a flash welding machine with a high-power superbattery for energy storage and power supply. The flash welding machine comprises a battery energy storage power supply system (1) and a flash welding machine set (2), wherein an energy storage battery pack (11), a convergence cabinet (12), an energy storage converter (13) and an isolation transformer (14) are arranged in the battery energy storage power supply system (1); and a mobile alternating current welding machine (22), a mobile direct current welding machine (23) and a welding machine auxiliary equipment load (21) are arranged in the flash welding machine set (2). A flash welding machine system is assembled in a container form, can be fixed on a rail transit tool and is conveniently transported to a construction site, the energy storage superbattery is adopted for power supply, dense smoke, noise and harmful gas pollution brought when a traditional flash welding machine configured with a diesel generating set works are completely eliminated, greenness and environment protection are achieved, the construction environment is improved, and steel rail welding construction of subways and tunnels is extremely facilitated.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

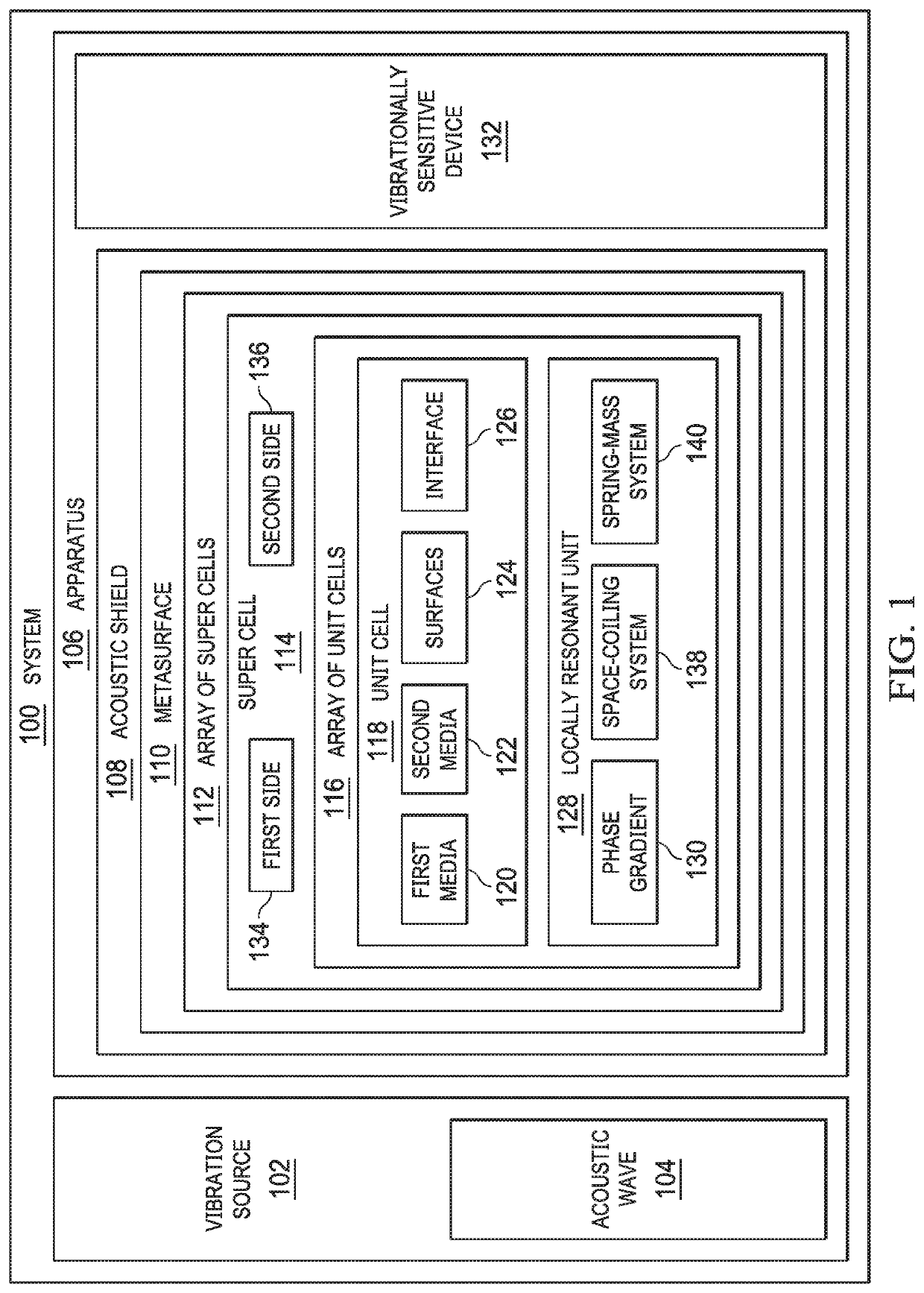

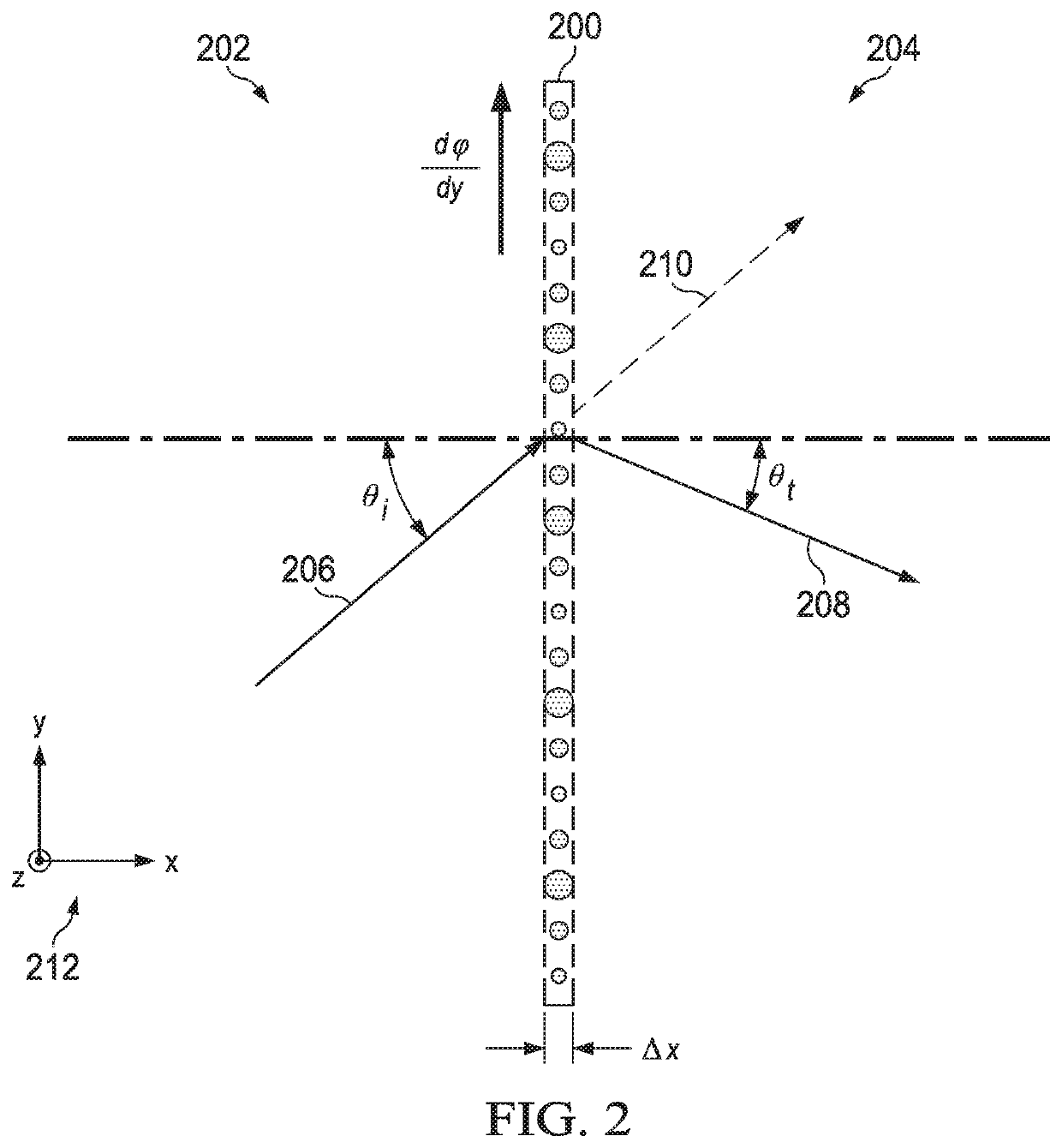

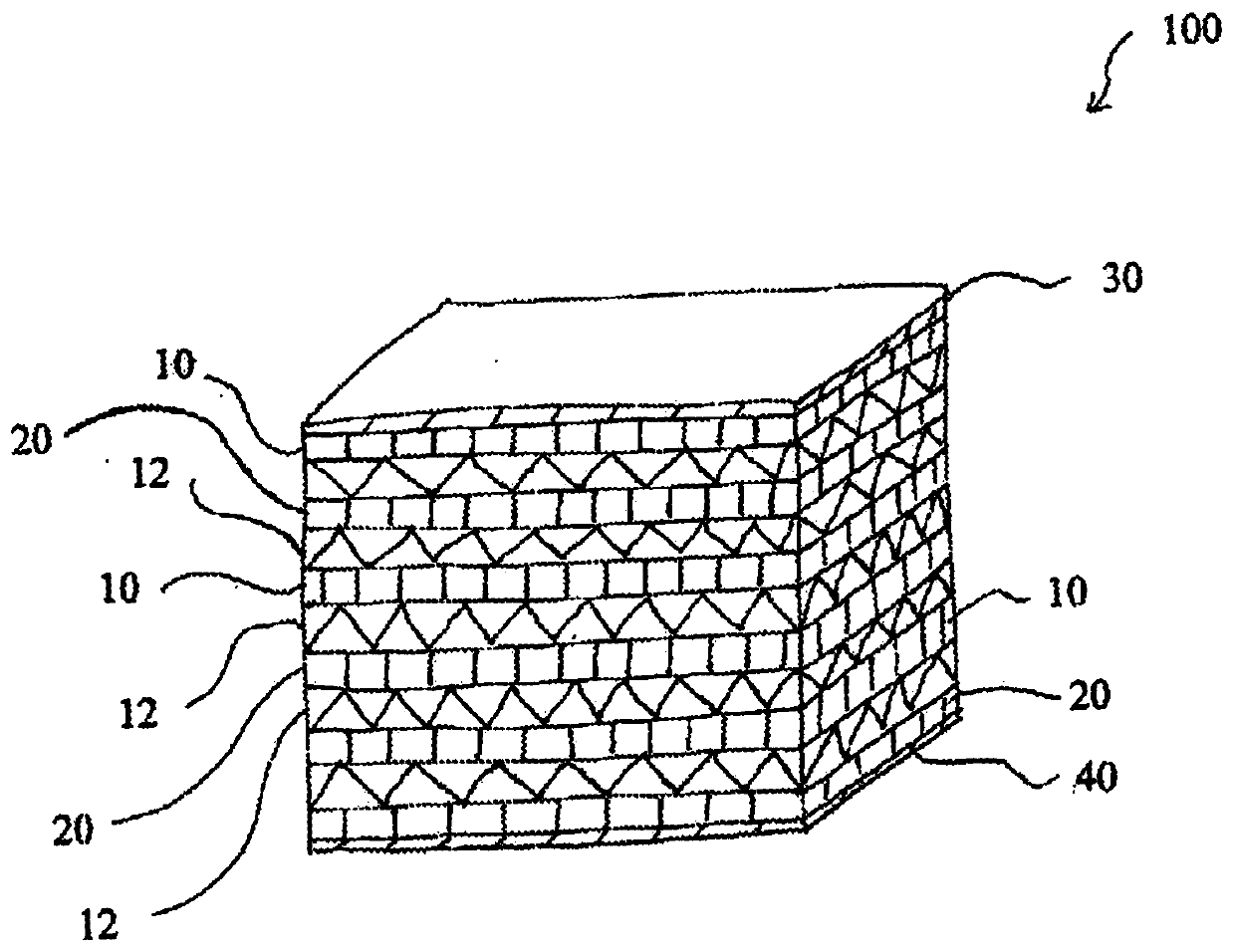

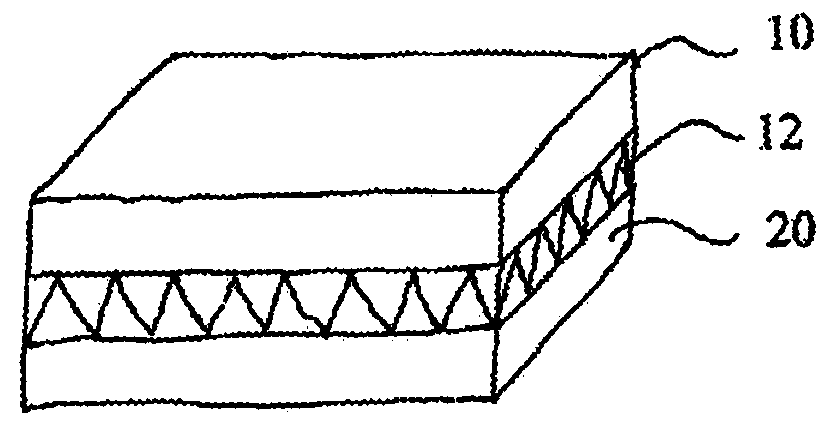

Total-internal reflection elastic metasurfaces: design and application

An acoustic shield for protecting a vibrational sensitive device includes a first unit cell and a second unit cell. The first unit cell includes a first locally resonant unit. The first locally resonant unit controls a first phase gradient and the first unit cell includes a first surface. The second unit cell includes a second surface proximate to the first surface. The second unit cell includes a second locally resonant unit embedded along the second interface. The second locally resonant unit controls a second phase gradient. The first phase gradient is different from the second phase gradient. The first unit cell and the second unit cell comprise a super cell. The acoustic shield is configured such that a vibrational wave from a first side of the super cell to a second side of the super cell is substantially attenuated.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

Hydrothermal preparation method of carbon coated lead powder composite materials for lead carbon super batteries

InactiveCN102610801BHigh mechanical strengthImprove mass to powerCell electrodesSecondary cells servicing/maintenanceElectrical batteryOrganosolv

The invention discloses a hydrothermal preparation method of carbon coated lead powder composite materials for lead carbon super batteries. Deionized water is added into carbohydrates to be prepared into solution or sol, lead powder is added for ultrasonic dispersion, the mixture is subjected to hydrothermal reaction so that the carbohydrates are carbonized to be coated on the surface of aluminum powder particles, original solvents and deionized water are used for alternately washing the coated materials, and the vacuum drying is carried out to obtain the carbon coated lead powder composite materials. The lead carbon super batteries made of the carbon coated lead powder composite materials have the advantage that the charging and discharging cyclic service life and the weight-to-power ratio are respectively and obviously prolonged and improved through being compared with those of the existing lead acid storage batteries.

Owner:SOUTH CHINA NORMAL UNIVERSITY

A negative plate lead paste for high-performance start-stop lead-carbon super battery and preparation method thereof

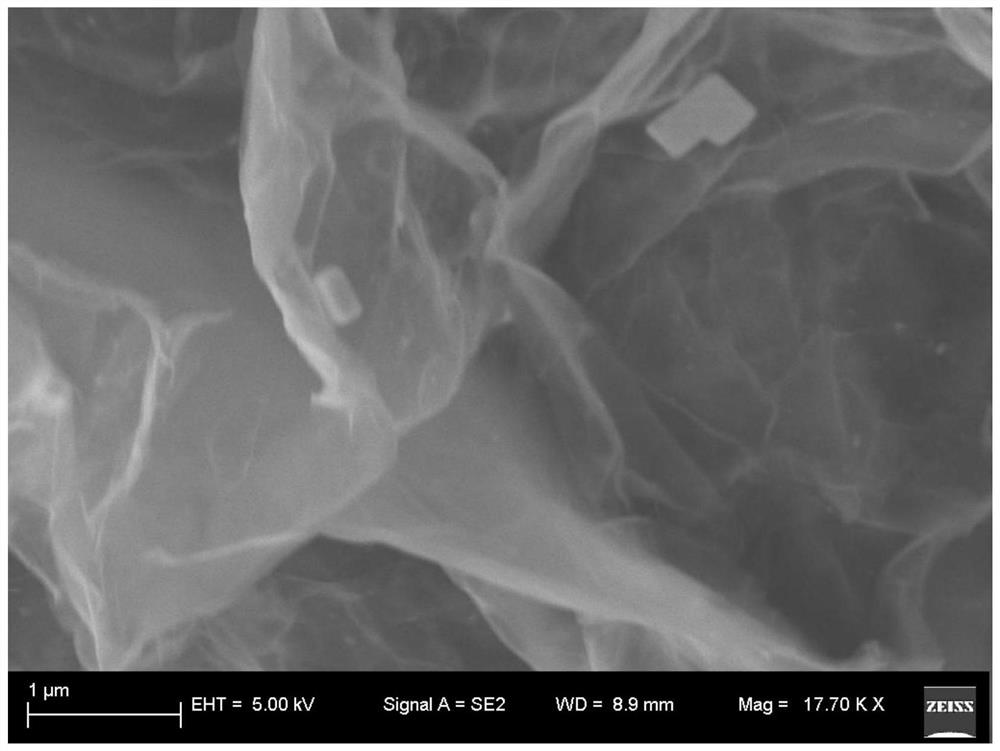

ActiveCN109103426BImprove conductivityHigh activityElectrode manufacturing processesLead-acid accumulatorsCarbon compositesFiber

The invention belongs to the technical field of lead-acid batteries, in particular to a negative plate lead paste used for starting and stopping lead-carbon super batteries with high performance and apreparation method thereof. The carbon material used in the negative plate lead paste prepared by the invention is graphene, the homogeneous dispersion of graphene, lead powder and hydrogen evolutioninhibitor in lead paste is achieved by using aniline oligomer derivative as graphene dispersant and ball milling process. The graphene agglomeration is avoided, and a good lead-carbon composite structure is established, and the hydrogen evolution reaction of lead-carbon negative electrode is inhibited. The negative plate lead paste prepared by the invention adds xanthan gum or sodium alginate tocompletely or partially replace the traditional polyester fiber as a binder, so that the emulsifying stability, adhesion and adhesion of the negative electrode lead paste are effectively improved, andthe problems of serious water loss and easy shedding of active materials in the cycle process of lead-carbon batteries are solved, and the charging acceptance and cycle life of the lead-carbon batteries are remarkably improved.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

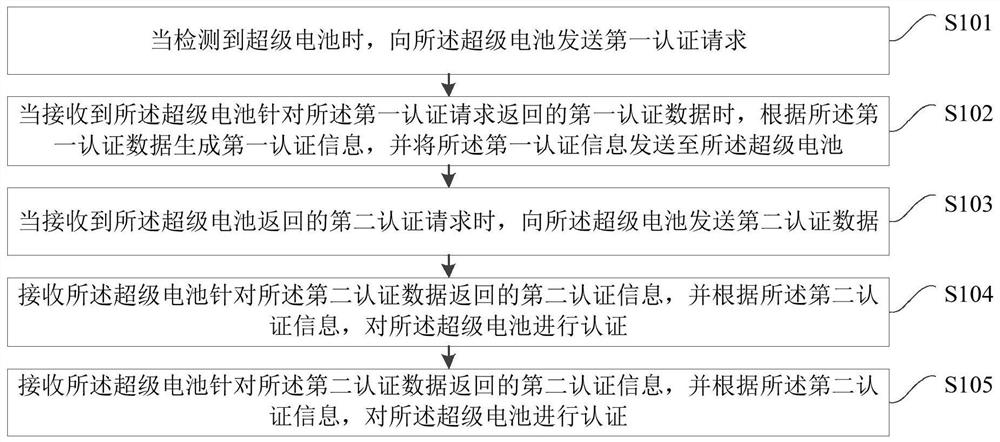

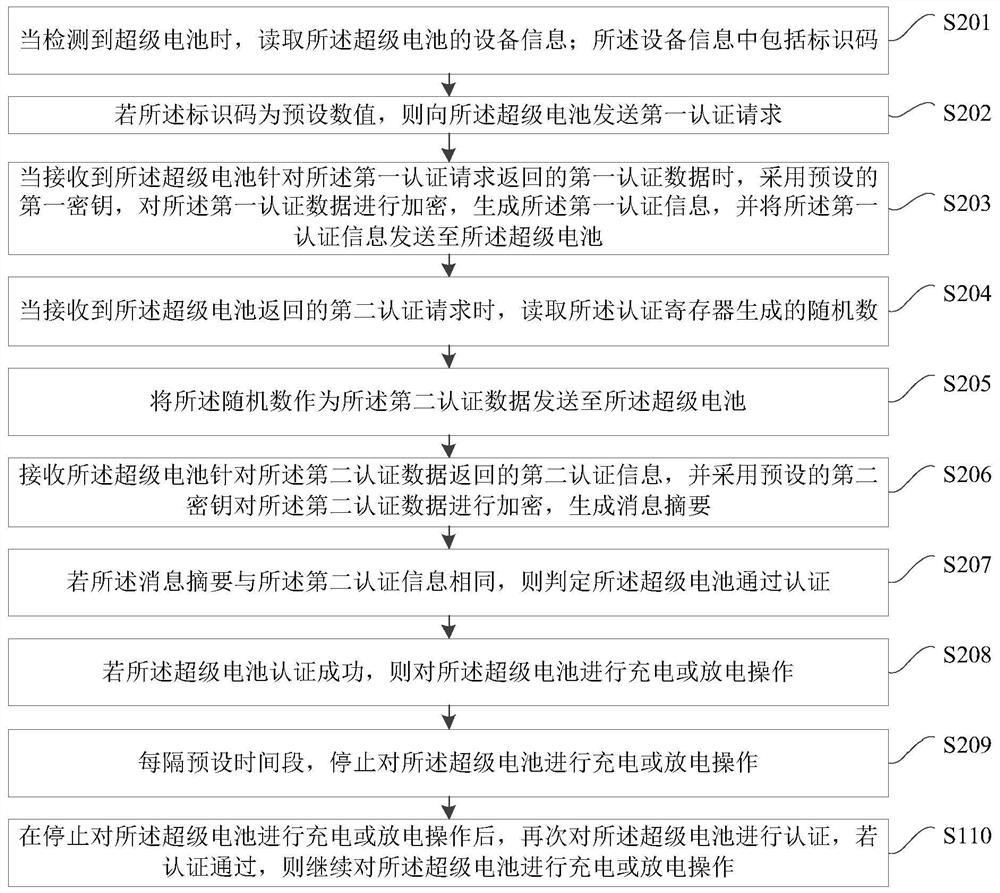

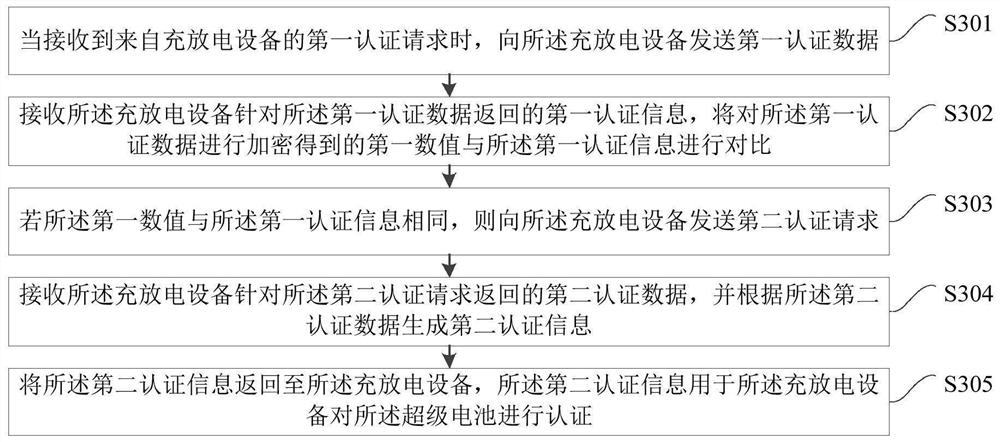

A battery authentication method, device, terminal device and medium

ActiveCN112073199BGuaranteed accuracyIrregularCircuit authenticationUser identity/authority verificationTerminal equipmentUltraBattery

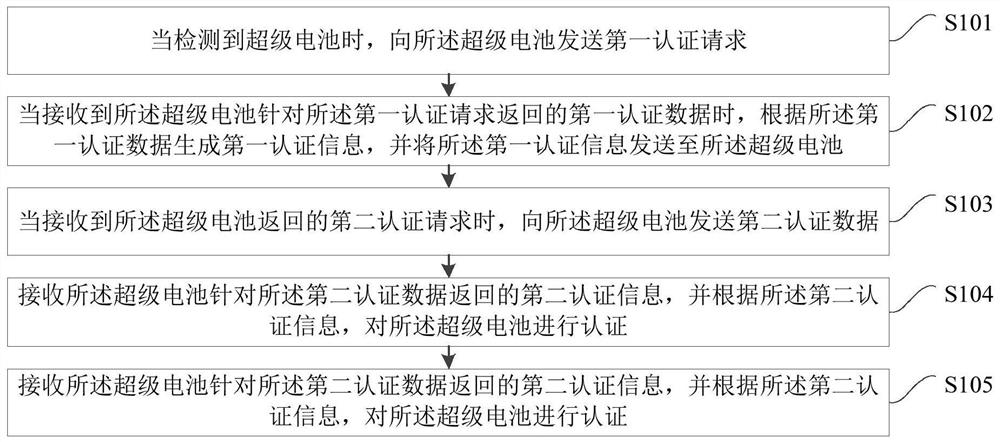

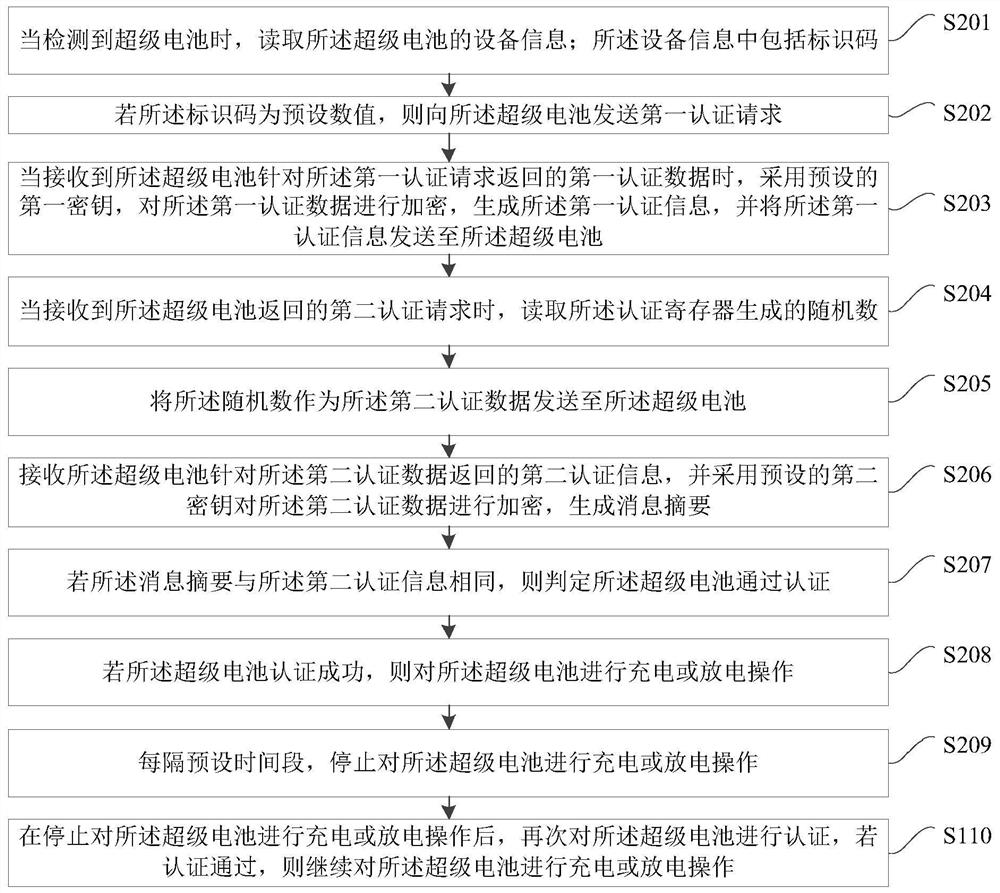

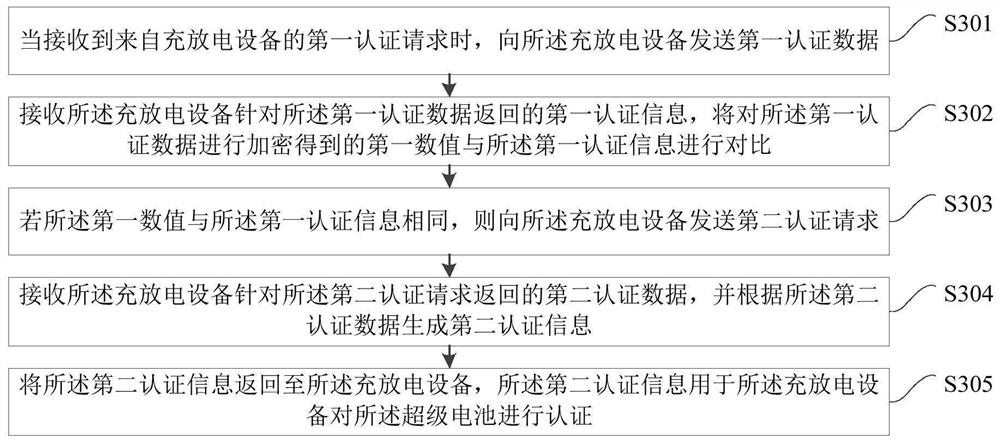

This application is applicable to the field of battery technology, and provides a battery authentication method, device, terminal equipment and medium. The method includes: when a super battery is detected, sending a first authentication request to the super battery; When the super battery responds to the first authentication data returned by the first authentication request, generate first authentication information according to the first authentication data, and send the first authentication information to the super battery; when receiving the first authentication information When the second authentication request returned by the super battery, send the second authentication data to the super battery; receive the second authentication information returned by the super battery for the second authentication data, and according to the second authentication information, Authenticate the super battery; if the super battery is successfully authenticated, perform a charge or discharge operation on the super battery. Through the above method, the security of authentication between the battery and the charging and discharging device can be improved.

Owner:SHENZHEN IMMOTOR TECH CO LTD

Lead carbon super battery moisturizing maintenance method

ActiveCN103413982BReduce adverse effectsImprove cycle lifeSecondary cells charging/dischargingProcess engineeringEnvironmental engineering

The invention discloses a water supply and maintenance method for a lead-carbon super battery. In the method, each cell is added three times according to 40%-60%, 20%-40%, and 10%-30% of the water added to the cell. Ionized water, do not stand still after adding water each time or the standing time is 0-3h, charge according to the water replenishment test process, and remove excess acid before charging. V, 0.1 times the rated capacity of the 2-hour rate, constant current and constant voltage charging for 16-20 hours, and then 4-6 hours of constant-current charging with a current of 0.025 times the rated capacity of the 2-hour rate. The invention solves the bad influence on the performance of the battery caused by non-standard water replenishment in the past, and after maintenance through this method, the cycle life of the lead-carbon super battery can be greatly improved.

Owner:TIANNENG GRP JIANGSU TECH

Battery authentication method and device, terminal equipment and medium

ActiveCN112073199AGuaranteed accuracyIrregularCircuit authenticationUser identity/authority verificationTerminal equipmentUltraBattery

The invention is applicable to the technical field of batteries, and provides a battery authentication method and device, terminal equipment and a medium. The method comprises the following steps: when a super battery is detected, sending a first authentication request to the super battery; when first authentication data returned by the super battery for the first authentication request is received, generating first authentication information according to the first authentication data, and sending the first authentication information to the super battery; when a second authentication request returned by the super battery is received, sending second authentication data to the super battery; receiving second authentication information returned by the super battery for the second authentication data, and authenticating the super battery according to the second authentication information; and if the super battery is authenticated successfully, charging or discharging the super battery. Through the method, the safety of authentication between the battery and the charging and discharging equipment can be improved.

Owner:SHENZHEN IMMOTOR TECH CO LTD

Negative plate of lead acid super battery, production method and lead acid super battery assembled by negative plate

ActiveCN102064319BWith super capacitor performanceExtend your lifeLead-acid accumulatorsLead-acid accumulator electrodesCapacitanceActivated carbon

The invention discloses a negative plate of a lead acid super battery, a production method and a lead acid super battery assembled by the negative plate, solving the problem of short service life of the charge state of a magnifying power part of the traditional lead acid super battery. The negative plate comprises a negative plate grid and negative lead plaster, wherein capacitance carbon plasteris coated on the surface of the negative lead plaster, and expansion intermediate phase carbon microballoons are added to the negative lead plaster; and the capacitance carbon plaster comprises activated carbon loading lead oxide, stearic acid, acetylene black, and the like. In the invention, the negative plate is formed by the method that the materials of the negative lead plaster are coated onto the negative plate and after cured and formatted, the capacitance carbon plaster is coated onto the outer surface and cured; and a super capacitive negative plate is obtained by doping high-capacitance and high-conductivity expansion intermediate phase carbon microballoons into the negative lead plaster to match with active substances in the capacitance carbon plaster. The service life of the assembled lead acid super battery is prolonged by 3-5 times compared with that of the traditional lead acid super battery, and the power is improved by 5 times, thus the lead acid super battery can be applied to medium and low hybrid electric vehicles and low-configuration pure electric vehicles.

Owner:HARBIN INST OF TECH

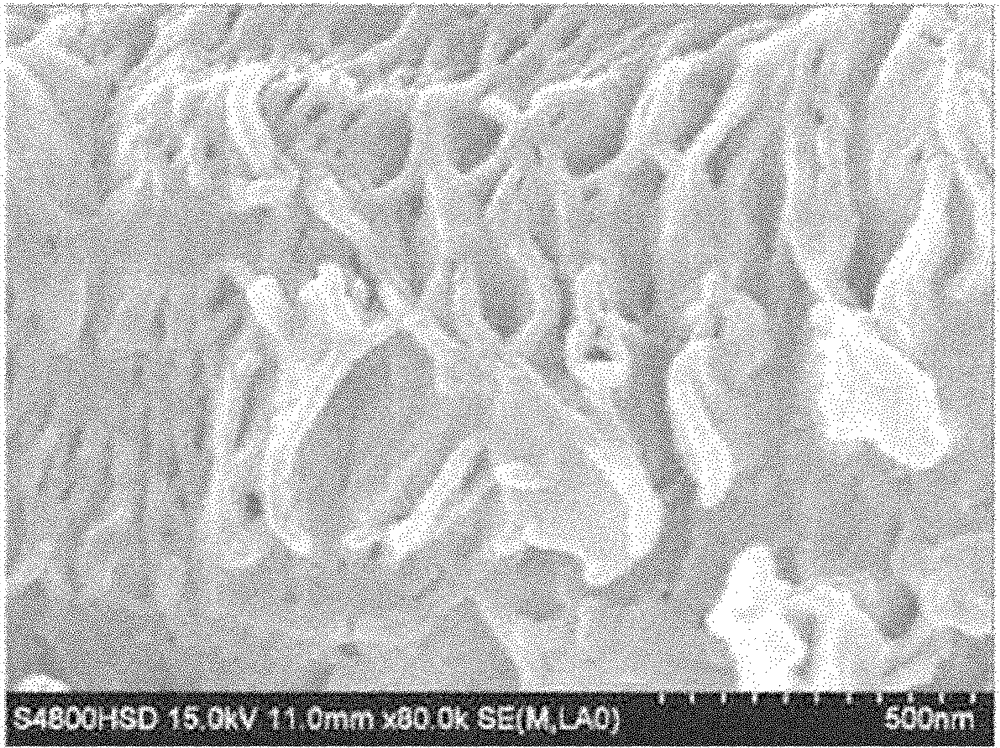

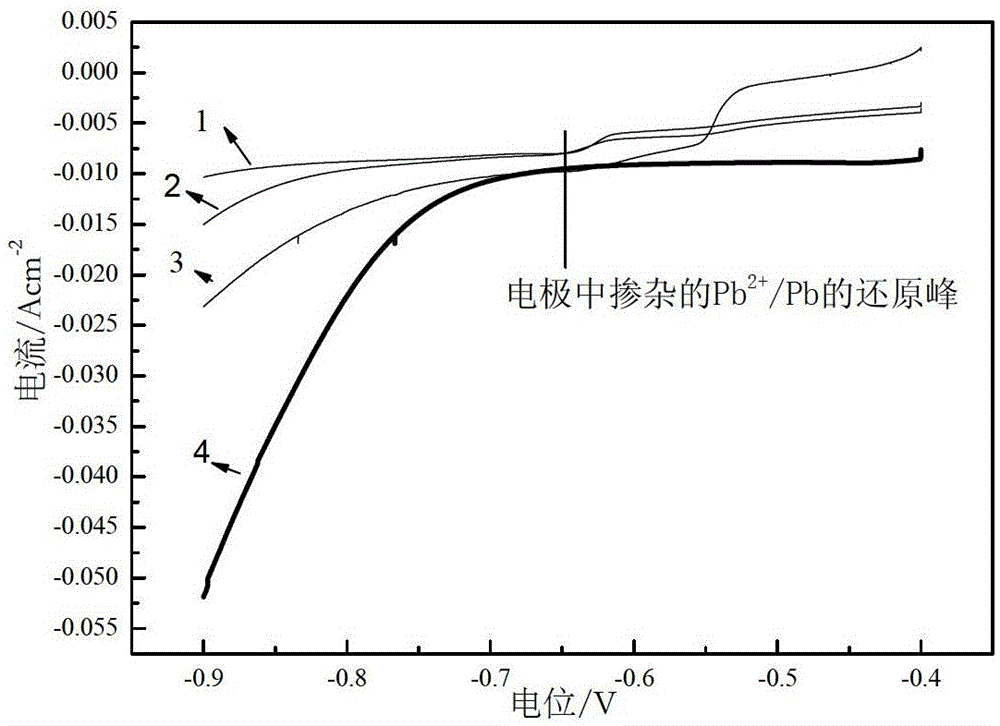

A method for chemically doping Pb on the surface of negative electrode carbon material for super battery

Owner:CENT SOUTH UNIV

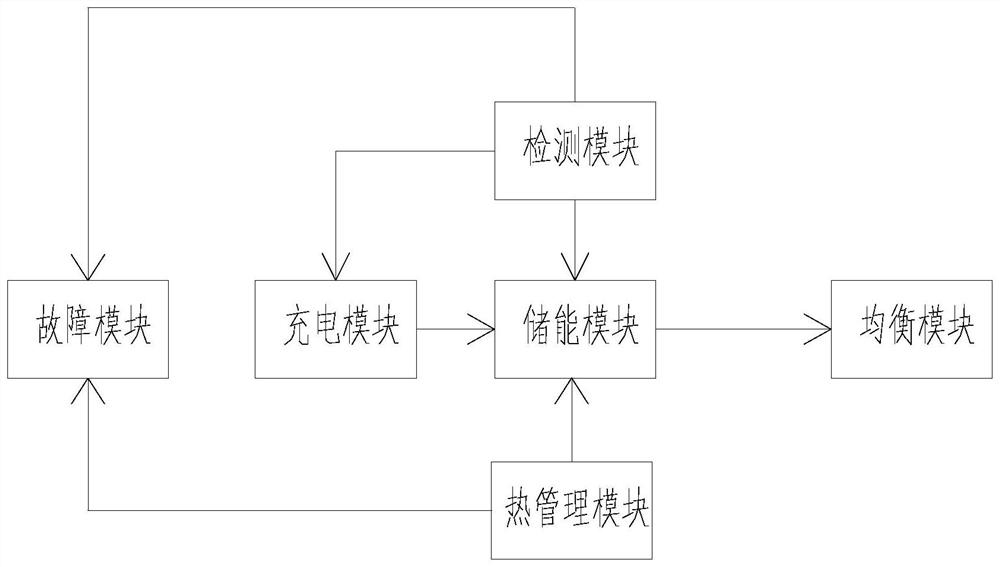

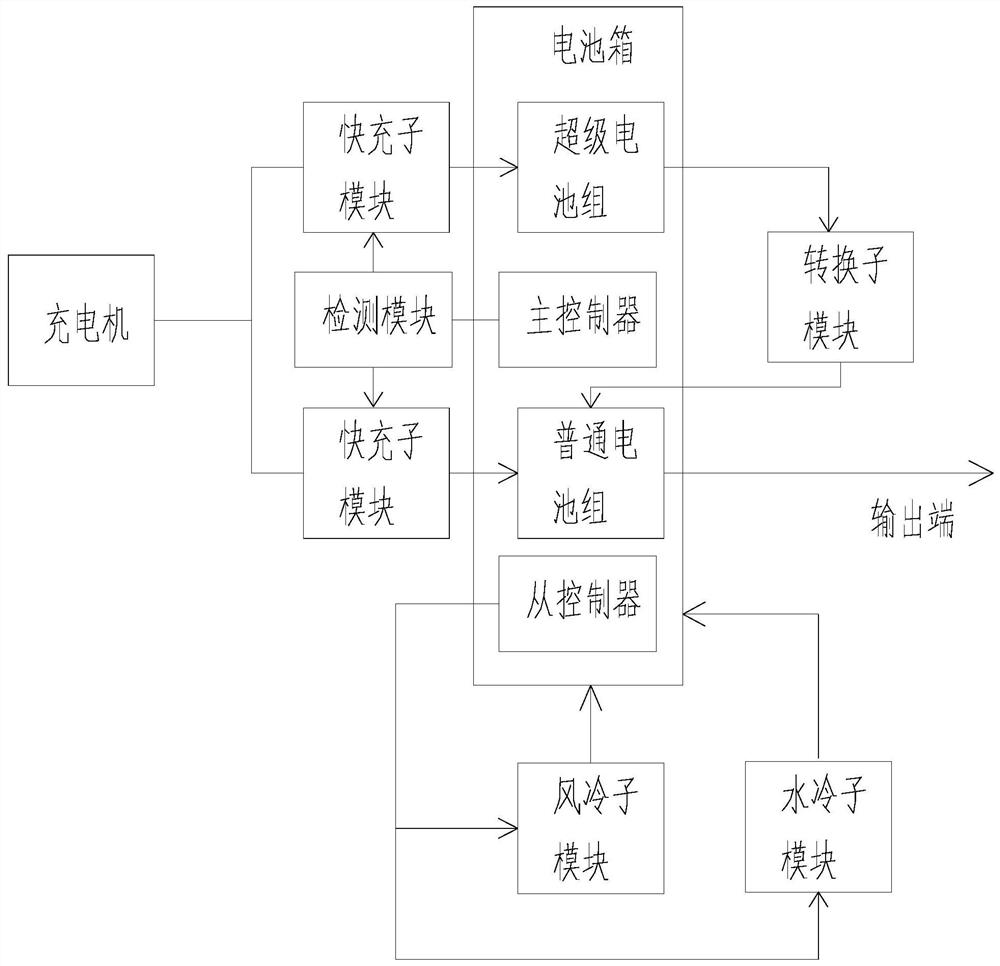

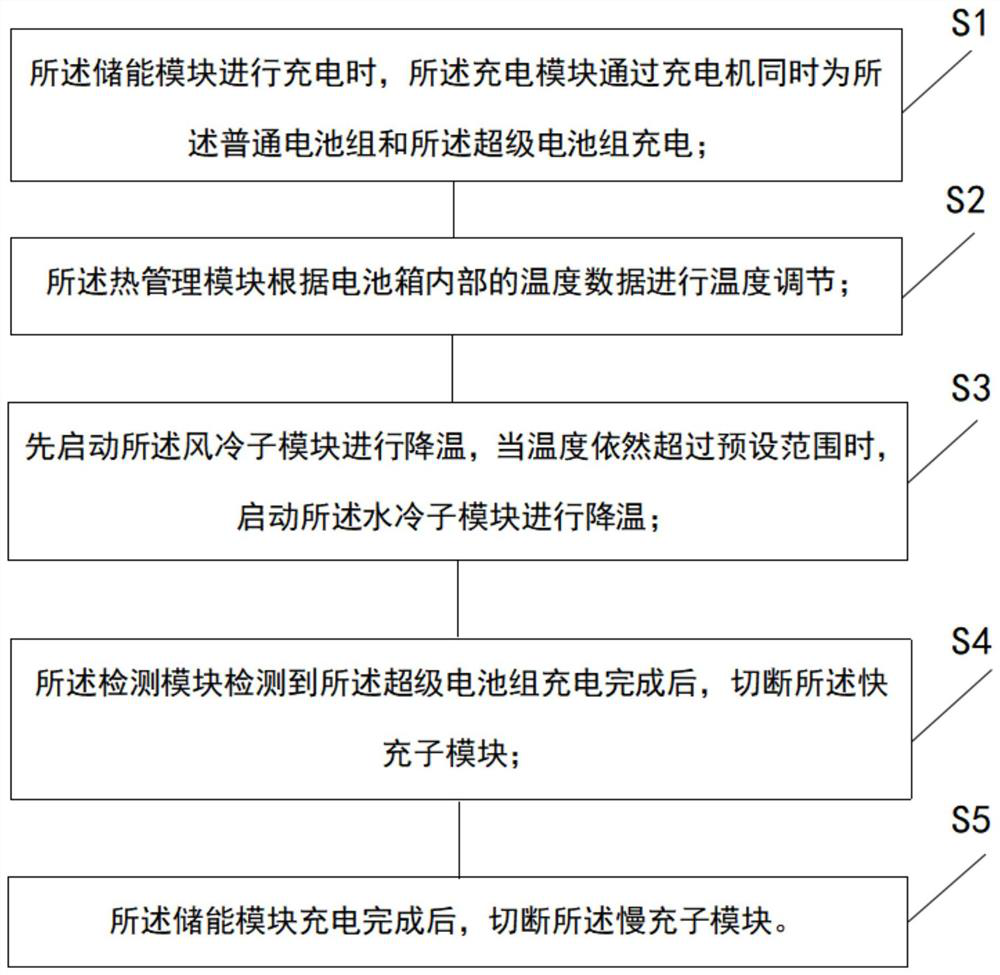

BMS equalization battery management control system, method and circuit

PendingCN113765186AExtended service lifeExtended use timeCharge equalisation circuitElectric powerElectrical batteryUltraBattery

The invention relates to the technical field of battery management, in particular to a BMS equalization battery management control system, method and circuit. The BMS equalization battery management control system comprises an energy storage module, a charging module, a detection module and a thermal management module; the energy storage module is formed by connecting a super battery pack and a common battery pack in parallel, the charging module is electrically connected with a charger and the energy storage module, and hybrid charging is performed through the super battery pack and the common battery pack. The detection module is electrically connected with the master controller and is used for detecting the residual electric quantity of the super battery pack and the common battery pack, the heat management module is electrically connected with the slave controller and is used for adjusting the temperature according to the temperature data, and the temperature in the battery box is adjusted through the heat management module, so the service life of the battery is prolonged.

Owner:中圆科技(苏州)有限公司

A 3D graphene carbon electrode, preparation method and full battery

ActiveCN110289390BHigh specific capacityWide variety of sourcesFinal product manufactureCell electrodesElectrical batteryElectric capacity

The invention relates to the application of graphene carbon materials to the technical field of batteries or capacitive chemical energy storage, in particular to a 3D graphene carbon electrode, a preparation method and a full battery. Using graphite paper as raw material, carbon-containing conductive adhesive is coated on one side of the graphite paper, dried and cured to form an electrode material compounded with carbon-containing conductive adhesive and graphite paper; part of the other side of the graphite paper is grapheneized to form 3D graphene carbon electrodes. The invention prepares a high specific capacity carbon positive electrode and a full battery with the characteristics of a super battery; the raw material sources are wide, the cost is low, the preparation method is simple and environmentally friendly; the product performance is stable and controllable, and is suitable for industrial production.

Owner:YANCHENG TEACHERS UNIV

Super electrical battery

InactiveCN109804448AIncrease capacityReduce manufacturing costProtecting/adjusting hybrid/EDL capacitorHybrid capacitor electrodesBinding energyElectrical conductor

An electric energy storage device is provided, which includes first and second conductor layers, and positive and negative electrodes. Each of the first and second conductor layers has both surfaces coated with ionic or dipole material. A bilayer is comprised of the first conductor layer and the second conductor layer and ionic material layer sandwiched between them. A multilayer structure is comprised of millions of bilayers which are stacked together one by one. The positive electrode is attached to the first conductor layer and the negative electrode is attached to the last conductor layer.The first conductor layer is stacked on top of the second conductor layer with a nanometer-scale interval and with the ionic material layer inbetween, forming a bilayer structure and a quantum heterostructure. The first and second conductor layers form a bilayer configured to store electrical energy in the bilayer in a form of binding energy.

Owner:李宇镛

Tungsten-based material super battery and super capacitor

A high-performance tungsten-based super battery system, covering the corresponding material-structure-process integrated design and construction method. In this technology, tungsten-based materials are used as negative electrodes, and high specific surface carbon or lead oxide positive materials are assembled into four types of super batteries, including 1) tungsten-carbon super battery, 2) tungsten-tungsten super battery, 3) tungsten-oxidized Lead super battery, 4) super battery system with mixed tungsten (containing lead oxide, lead and carbon materials), that is, the above two types of super batteries are used in combination.

Owner:合肥集新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com