Lead-carbon composite material

A composite material, lead-carbon technology, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of difficult uniform dispersion, large specific surface area of carbon materials, and reduced service life, and achieve tight interface bonding, enhanced interface bonding, and inhibition Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

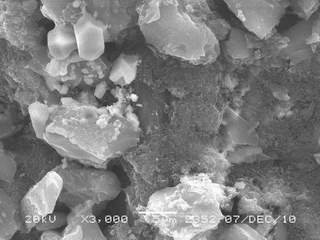

[0030] Weigh 6g to have a specific surface area of 50 m 2 / g and 24g specific surface area is 3000 m 2 Grind activated carbon, 3g carbon black, and 3g PVDF in a mortar and mix evenly, add 13g toluene to dissolve and make a paste, apply it evenly on the lead plate, and put it in a vacuum drying oven at a temperature of 50°C Dry under conditions for 2 hours. Take out the activated carbon plate and place it in a lead acetate solution with a concentration of 0.05mol / L and soak for 10 minutes. The lead plate is used as the positive electrode, the activated carbon plate is used as the negative electrode, and the lead acetate solution is used as the electroplating solution for electrodeposition. The electroplating current density is controlled at 10 mA / cm 2 , the electrodeposition time is 10s, and the obtained lead-carbon composite material is dried in a vacuum oven at 55°C for 4 hours, and the dried product is scraped off the lead plate to obtain the lead-carbon composite materia...

Embodiment 2

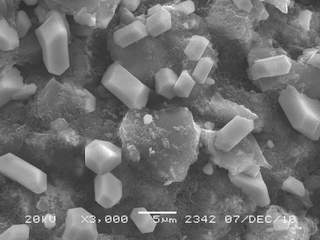

[0032] Weigh 64g specific surface area is 200 m 2 / g and 16g specific surface area is 1000 m 2 Grind activated carbon, 10g carbon black, and 10g PTFE in a mortar and mix evenly, add 30g nitrogen methyl pyrrolidone to dissolve and make a paste, apply it evenly on a titanium plate, and put it in a vacuum oven. Dry at 60°C for 8 hours. Take out the activated carbon plate and place it in a lead nitrate solution with a concentration of 2mol / L and soak for 30 minutes. The lead plate is used as the positive electrode, the activated carbon plate is used as the negative electrode, and the lead nitrate solution is used as the electroplating solution for electrodeposition. The electroplating current density is controlled at 500 mA / cm 2 , the electrodeposition time is 500s, and the obtained lead-carbon composite material is dried in a vacuum oven at 80°C for 8 hours, and the dried product is scraped off the titanium plate to obtain the lead-carbon composite material, and the obtained lea...

Embodiment 3

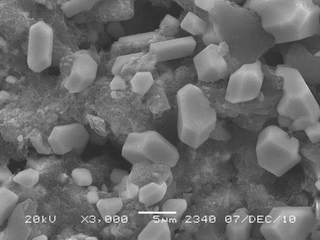

[0034] Weigh 20g specific surface area is 600 m2 / g and 20g specific surface area is 1900 m 2 Grind activated carbon, 8g carbon black, and 9g neoprene rubber in a mortar and mix evenly, add 20g N,N dimethylformamide to dissolve and adjust to a paste, apply it evenly on the lead plate, put Put it into a vacuum drying oven, and dry it for 6 hours at a temperature of 55°C. Take out the activated carbon plate and place it in a concentration of 1.2mol / L lead fluoroborate solution for 20 minutes. The lead plate is used as the positive electrode, the activated carbon plate is used as the negative electrode, and the lead fluoroborate solution is used as the electroplating solution for electrodeposition. The electroplating current density is controlled at 50 mA / L. cm 2 , the electrodeposition time is 60s, and the obtained lead-carbon composite material is dried in a vacuum oven at 70°C for 6 hours, and the dried product is scraped off the lead plate to obtain the lead-carbon composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com