Graphene coated lead powder composite material and application thereof

A technology of graphene-coated and ene-coated lead powder, which is applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., can solve the problems of complicated process in the early stage, difficulty in industrialization, and large environmental pollution, and achieve improvement Conductive properties, prolonging life, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 40g of commercial lead powder, 200ml of ethanol and 4ml of deionized water under high-speed stirring for 10min, then add 0.1g of aminosilane coupling agent KH550, heat and stir at 60°C for 10h, suction filter and wash to remove uncontaminated lead powder The coupled KH550 is dried and ground to obtain a modified positively charged lead powder.

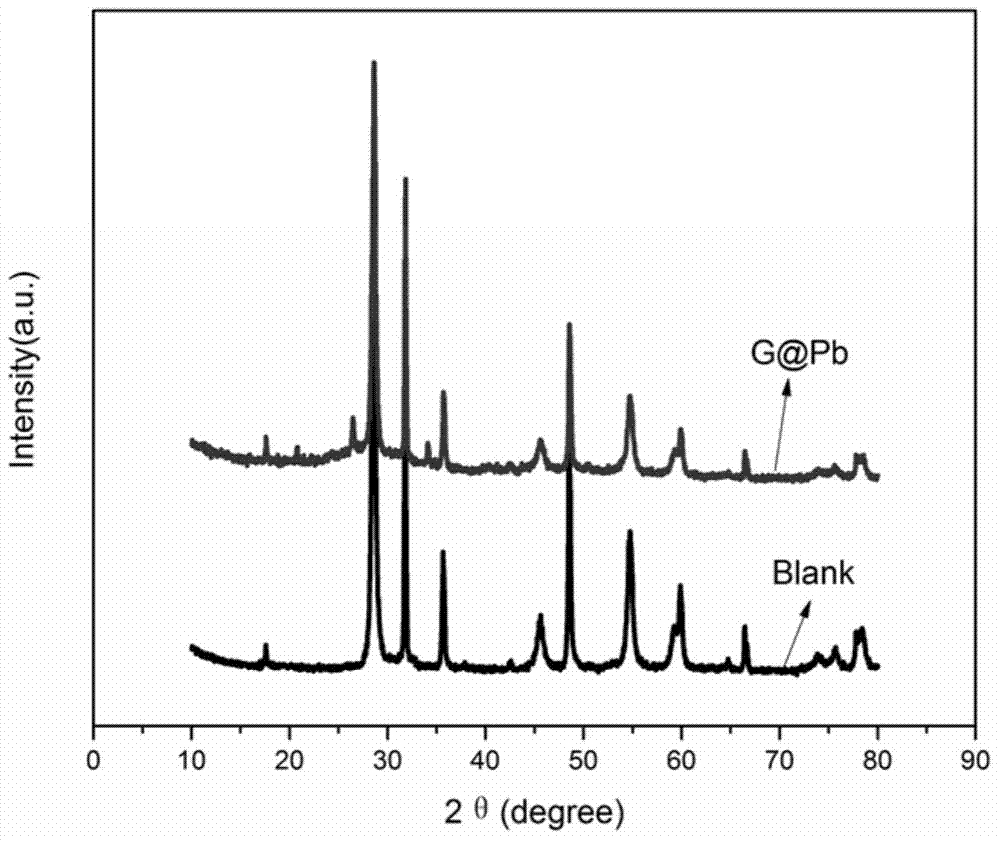

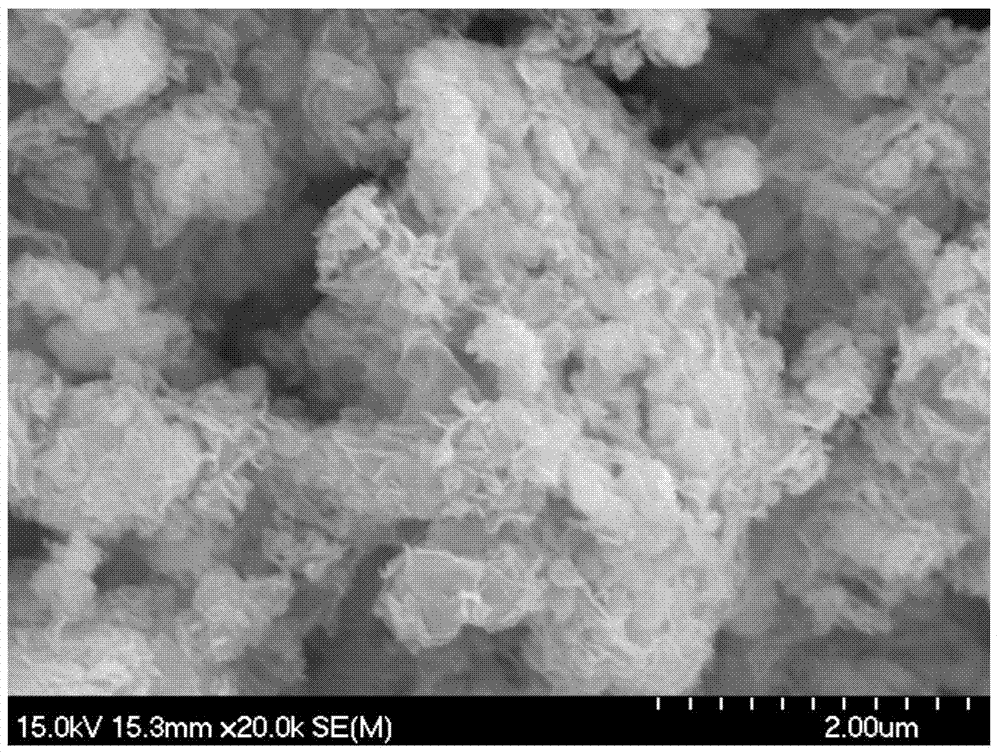

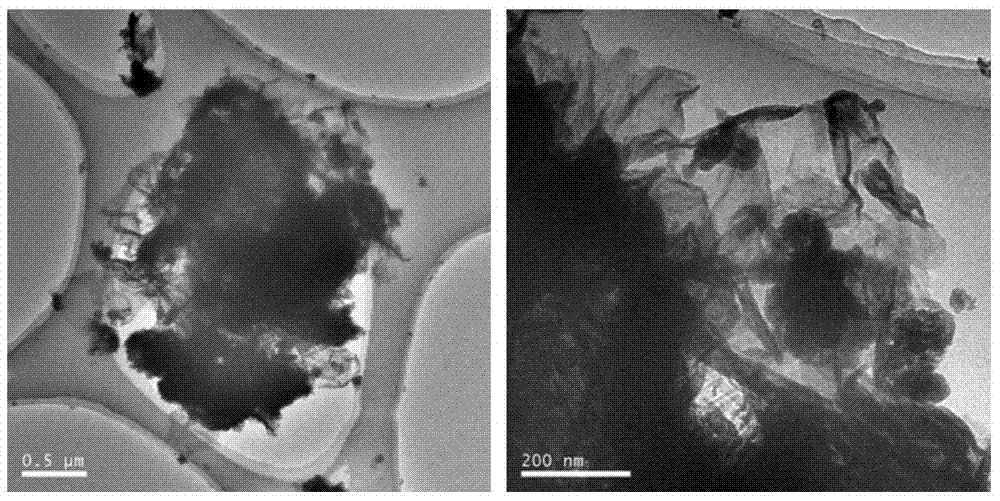

[0039] Take 300ml of graphene oxide aqueous solution with a concentration of 1mg / ml, and ultrasonically disperse it uniformly for 1h. Add the above-mentioned modified lead powder into 100ml of deionized water, stir for 10min, then slowly add 300ml of graphene oxide aqueous solution, shake and stir, after standing for 30min, it can be seen that the solution is obviously stratified, and the color of the upper layer becomes lighter. Slowly clarify, the color of the sediment in the lower layer gradually turns brown, suction filtration, washing, drying, and grinding to obtain a composite material of graphene oxide-coated lead pow...

Embodiment 2

[0042] Mix 40g of commercial lead powder, 200ml of ethanol and 4ml of deionized water under high-speed stirring for 10min, then add 0.1g of aminosilane coupling agent KH550, heat and stir at 60°C for 10h, suction filter and wash to remove uncontaminated lead powder The coupled KH550 is dried and ground to obtain a modified positively charged lead powder.

[0043] Take 400ml of graphene oxide aqueous solution with a concentration of 1mg / ml, and ultrasonically disperse it uniformly for 1h. Add the above-mentioned modified lead powder into 100ml of deionized water, stir for 10min, then slowly add 350ml of graphene oxide aqueous solution, shake and stir, after standing for 30min, it can be seen that the solution is obviously stratified, and the color of the upper layer becomes lighter. Slowly clarify, the color of the sediment in the lower layer gradually turns brown, suction filtration, washing, drying, and grinding to obtain a composite material of graphene oxide-coated lead pow...

Embodiment 3

[0046] First, mix 40g of commercial lead powder, 200ml of ethanol and 4ml of deionized water under high-speed stirring for 10min, then add 0.2g of aminosilane coupling agent KH570, heat and stir at 60°C for 10h, suction filter, and wash to remove the lead powder that is not mixed with the lead powder. The coupled KH570 is dried and ground to obtain a modified positively charged lead powder.

[0047] Take 500ml of graphene oxide aqueous solution with a concentration of 1mg / ml, and ultrasonically disperse it uniformly for 1h. Add the above-mentioned modified lead powder into 100ml of deionized water, stir for 10min, then slowly add 300ml of graphene oxide aqueous solution, shake and stir, after standing for 30min, it can be seen that the solution is obviously stratified, and the color of the upper layer becomes lighter. Slowly clarify, the color of the sediment in the lower layer gradually turns brown, suction filtration, washing, drying, and grinding to obtain a composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com