Carbon cathode plate for super cell

A super battery and negative plate technology, applied in the direction of circuits, capacitors, electrical components, etc., to achieve the effects of wide sources, low cost, and improved charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 80g of activated carbon, 10g of acetylene black, 5g of polyvinylidene fluoride, and 5g of powdered lead nitrate with an average particle size of 5 μm, mix them evenly, add an appropriate amount of N-methylpyrrolidone (NMP), and stir the above materials to make a paste , Press the paste on a plodder to form a carbon strip of appropriate thickness, and then cut it into a carbon sheet that meets the size of the grid. Then use a manual hydraulic press to press the carbon sheet into the grid, and dry it in an oven at 60°C to obtain a finished carbon negative plate.

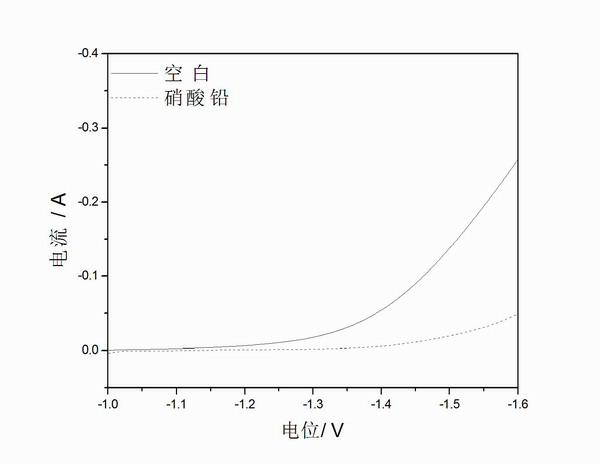

[0022] like figure 1 As shown, using the linear potential scanning method (LSV) to study the blank carbon negative plate and the carbon negative plate added with the hydrogen evolution inhibitor lead nitrate, it was found that the addition of lead nitrate made the hydrogen evolution overpotential of the carbon negative plate move to the negative potential direction, which can effectively It can effectively...

Embodiment 2

[0024] Take 80g of activated carbon, 10g of acetylene black, 5g of polyvinylidene fluoride, and 5g of powdered zinc nitrate with an average particle size of 5 μm, mix them evenly, add an appropriate amount of N-methylpyrrolidone (NMP), and stir the above materials to make a paste , Press the paste on a plodder to form a carbon strip of appropriate thickness, and then cut it into a carbon sheet that meets the size of the grid. Then use a manual hydraulic press to press the carbon sheet into the grid, and dry it in an oven at 60°C to obtain a finished carbon negative plate.

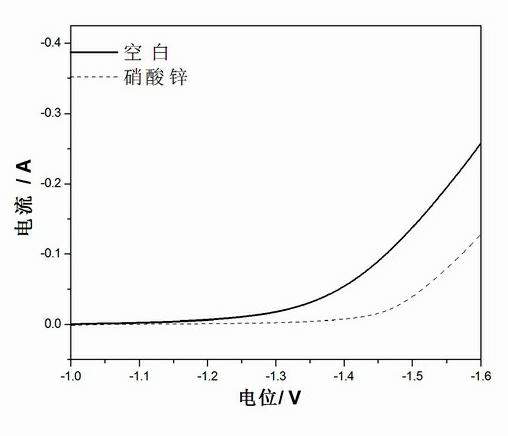

[0025] like figure 2 As shown, using the linear potential scanning method (LSV) to study the blank carbon negative plate and the carbon negative plate added with the hydrogen evolution inhibitor zinc nitrate, it was found that the addition of zinc nitrate made the hydrogen evolution overpotential of the carbon negative plate move to the negative potential direction, which can effectively It can effectivel...

Embodiment 3

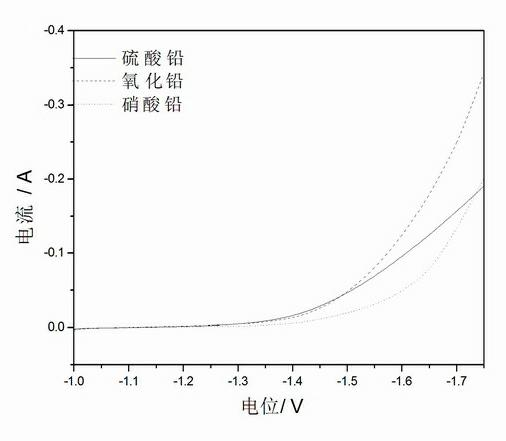

[0027] Take 75g of activated carbon, 11g of acetylene black, 4.5g of polyvinylidene fluoride, 5g of powdered lead nitrate with an average particle size of 2μm, and 4.5g of powdered zinc nitrate with an average particle size of 2μm, mix them evenly, and add an appropriate amount of N-methylpyrrolidone (NMP), the above materials are stirred to make a paste, and the paste is pressed into a carbon belt with an appropriate thickness on a plodder, and then cut into a carbon sheet that meets the size of the grid. Then use a manual hydraulic press to press the carbon sheet into the grid, and dry it in an oven at 60°C to obtain a finished carbon negative plate.

[0028] Experiments have found that the mixture of lead nitrate and zinc nitrate can effectively suppress the hydrogen evolution problem of the carbon electrode of the capacitor at the end of charging, thereby improving the charging efficiency of the super battery and effectively improving the cycle life of the lead-acid battery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com