Alkaline capacitor battery iron electrode and preparation method thereof

A supercapacitor battery and iron electrode technology, which is applied in the direction of alkaline battery electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low charging efficiency, low utilization rate of active materials, and poor high-rate discharge characteristics, etc., to achieve enhanced Good utilization rate, good consistency and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation steps of the first electrode material slurry are as follows:

[0040] Step 1: Put the adhesive in the above weight percentage in the mixing barrel of the mixer, add the pure water and stir evenly;

[0041] Step 2: Add the high specific surface carbon powder in the above weight percentage in stages, then add the conductive agent in the above weight percentage, stir for 0.5-1h, and then add the NiO or Ni(OH) in the above weight percentage 2 and metal sulfide, and then stirred for 0.5-1h;

[0042] Step 3: adding the electrochemically active substance in the above weight percentage in stages, and stirring for 2-4 hours after the addition, to obtain the first electrode material slurry.

[0043] As a preferred mode, the preparation method specifically includes the following steps:

[0044] Step 1: After the nickel foam is pre-pressed to about 80% of the initial thickness, a layer of high-temperature-resistant tape is symmetrically pasted on the front and bac...

Embodiment

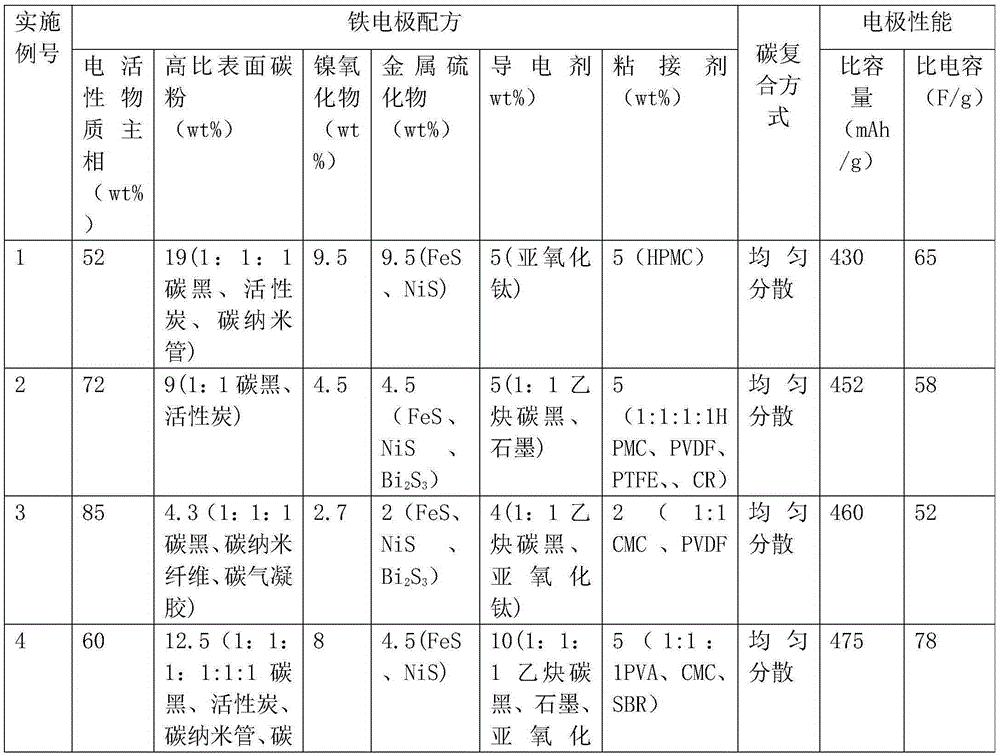

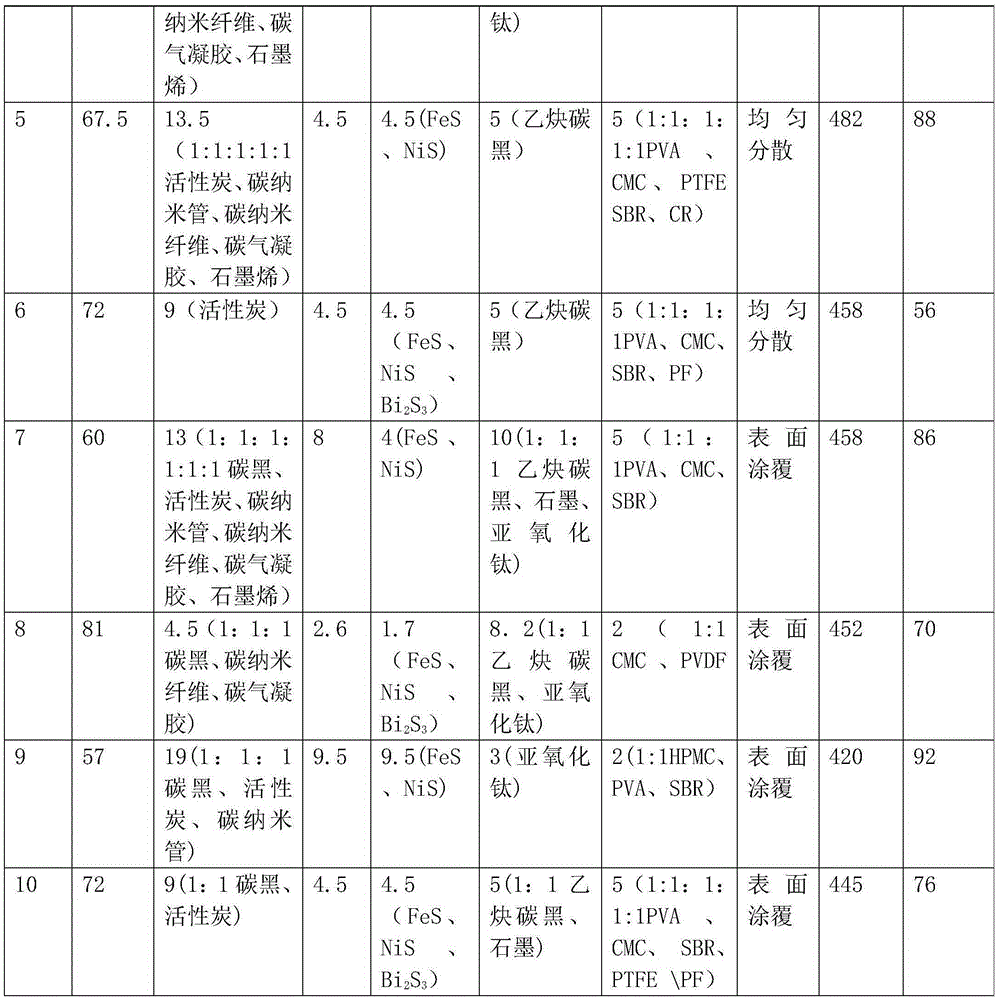

[0064] Concrete formula and test performance (accounting for electrode material wt %) of each embodiment of table 1

[0065]

[0066]

[0067] From the above data, it can be concluded that the present invention can improve the battery specific capacity of the iron negative electrode by adding a certain amount of high specific surface carbon material to the iron electrode material, and at the same time make the iron electrode have a higher capacitive specific capacitance, In this way, it is possible to realize the "internal parallel" combination of capacitor and battery electrodes, so that nickel-iron, iron-air, silver-iron and other batteries made of iron negative electrodes have high energy density of batteries and high power density of supercapacitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com