A 3D graphene carbon electrode, preparation method and full battery

A technology of graphene treatment and carbonization, which is applied in the manufacture of electrolyte storage batteries, non-aqueous electrolyte storage batteries, lithium storage batteries, etc. The specific capacity performance index of chemical energy storage devices does not fully exploit the problems of graphene's large specific surface and high conductivity, and achieves the effects of stable and controllable product performance, low manufacturing cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

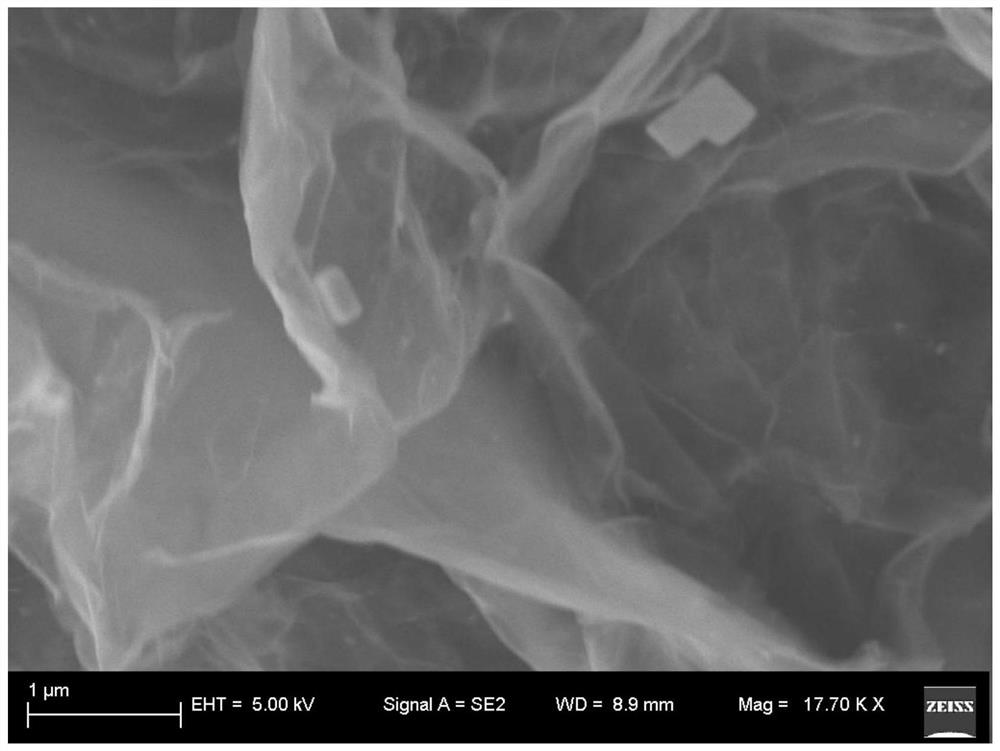

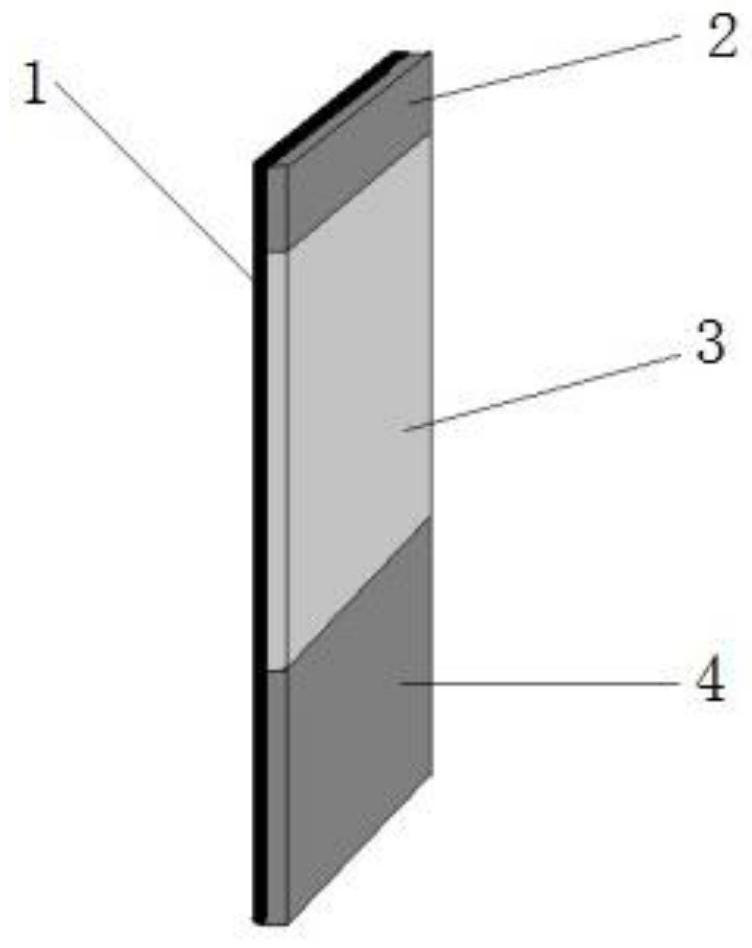

[0040] A preparation method of a 3D graphene carbon electrode comprises: (1) taking a piece of flexible expanded graphite paper strip with a thickness of 1cm*3cm and a thickness of 0.05mm, washing and drying, and mixing 96.85% acetylene black and 1.55% sodium carboxymethylcellulose % and styrene-butadiene rubber 1.60%, fully stirred, and adjusted into a paste-like carbon-containing conductive paste; the paste-like carbon-containing conductive paste was evenly spread on one side of the graphite paper strip, and the thickness of the laying was 0.08mm. like figure 2 As shown in the figure, a carbon-containing conductive adhesive layer 1 is formed, and then the coated expanded graphite-carbon-containing conductive adhesive sheet is vacuum-dried at room temperature for 5 hours to obtain a composite electrode material sheet of expanded graphite-carbon-containing conductive adhesive;

[0041] (2) Laminate the electrode material sheet of expanded graphite-carbon-containing conductive...

Embodiment 2

[0045] In this embodiment, in a method for preparing a 3D graphene carbon electrode, steps (1) and (2) are the same as those in Embodiment 1, and are not repeated here. The difference is in step (3).

[0046] Among them, (3) as figure 2 As shown, peel off the tape on the electrode material sheet graphite battery reaction surface 4 and the tab region 2 of the expanded graphite-carbon-containing conductive adhesive composite, and stick the tape on the graphite on the battery reaction surface 4 for 3 times, and the battery reaction surface The graphite surface of 4 is used as the positive electrode, the 10M sulfuric acid solution is the electrolyte solution, the counter electrode is the carbon electrode, and the direct current voltage is 2.7V; the current is 0.1mA / cm 2 -1000mA / cm 2 ; Time 30min, the surface graphite falls off, and the excess graphite is rinsed with pure water. That is, the micromechanical exfoliation and the electrochemical expansion treatment are respectivel...

Embodiment 3

[0049] In this embodiment, the steps (1), (2) and (3) of a method for preparing a 3D graphene carbon electrode are the same as those in Embodiment 1, and are not repeated here.

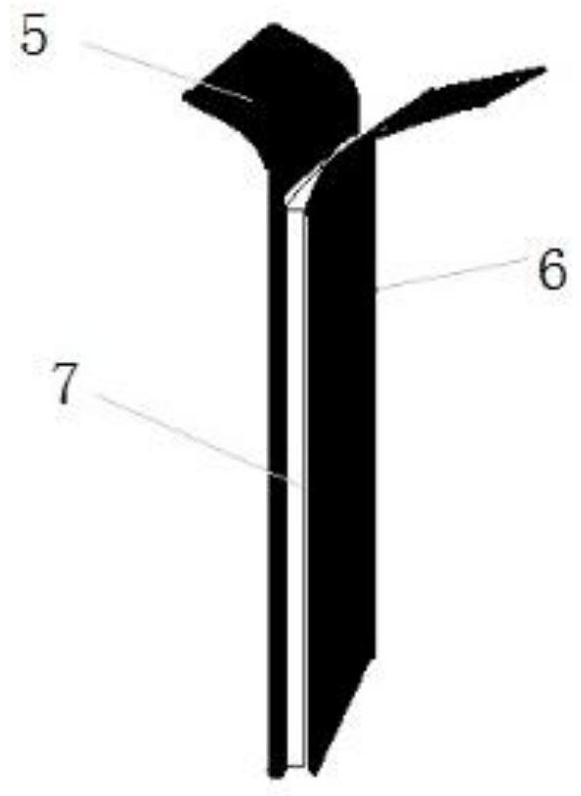

[0050] This embodiment also includes a method for preparing a full battery composed of 3D graphene carbon electrodes, such as Figure 4 As shown, the above-mentioned 3D graphene electrode formed is used as the battery positive electrode 5, the sulfuric acid solution of 5M is the electrolyte solution 9, the other grapheneized carbon electrode of the counter electrode is the negative electrode 6, and the reference electrode is the mercurous sulfate electrode 8. A carbon-carbon three-electrode full battery is formed in the beaker, which is charged with direct current relative to the mercurous sulfate electrode 8, such as Figure 7 As shown, constant current 1mA charging up to 1.437V, constant voltage 1.437V charging 30min, current 0.1mA / cm 2 -1000mA / cm 2 , the constant current discharge current is 0.1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com