Patents

Literature

53results about How to "Deep stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

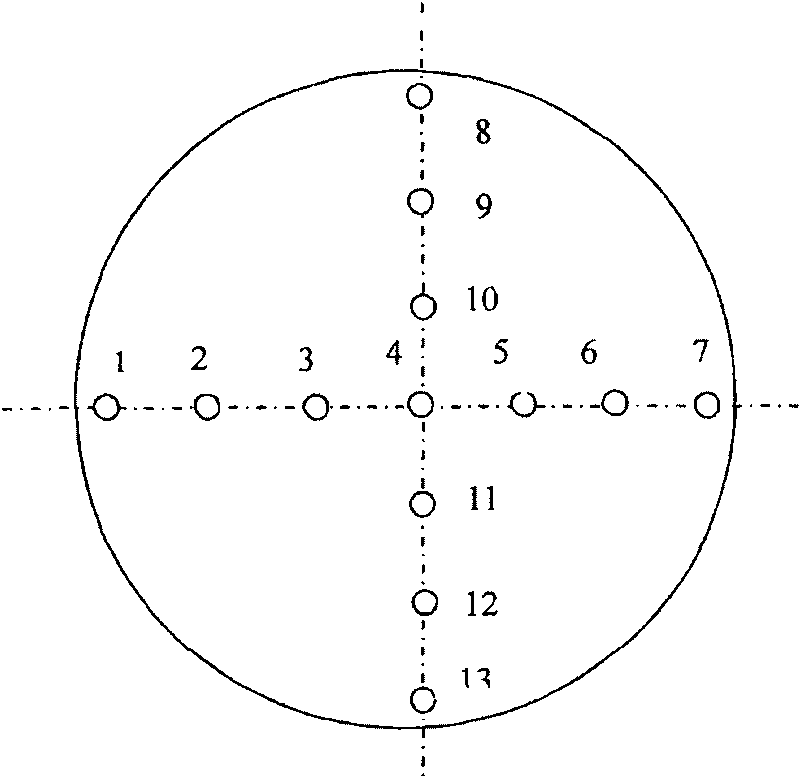

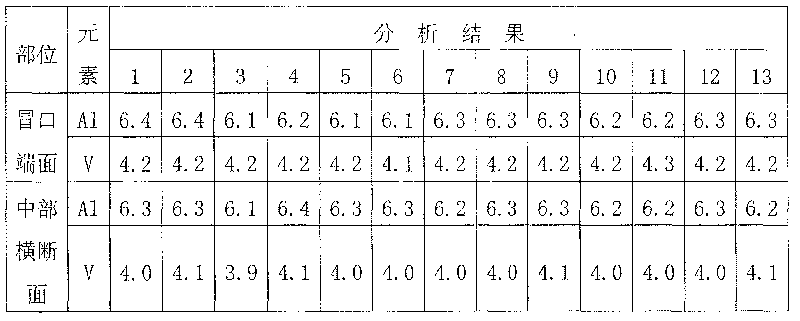

Method for producing large-sized zirconium ingot with the specification Phi of more than 600mm

The invention relates to a method for producing large-sized zirconium ingot with the specification Phi of more than 600mm, and the technical characteristics lie in that a consumable electrode with relatively uniform components is prepared by adopting dosing, mixing and vacuum plasma arc electrode assembly and welding technology, and vacuum consumable electric arc melting is carried out for at least twice by adopting technology of 'speed reducing melting' and 'component uniformity controlling' and the like under the conditions that the melting speed control parameter is 10-40kg / min and the arc stability control is carried out with the magnetic induction of 10-50 Gauss and the stable arc current alternate control time of 1-60 seconds. Compared with the prior art, the invention has the advantages that the large-sized zirconium ingot produced by the invention has uniform and stable chemical components and excellent ingot surface quality, is better than small ingot melted by vacuum consumable electric arc, and has the advantages of high yield, high production efficiency and being easy for producing large zirconium material and the like; and the invention is applicable to producing ingots for large zirconium material.

Owner:BAOJI TITANIUM IND CO LTD

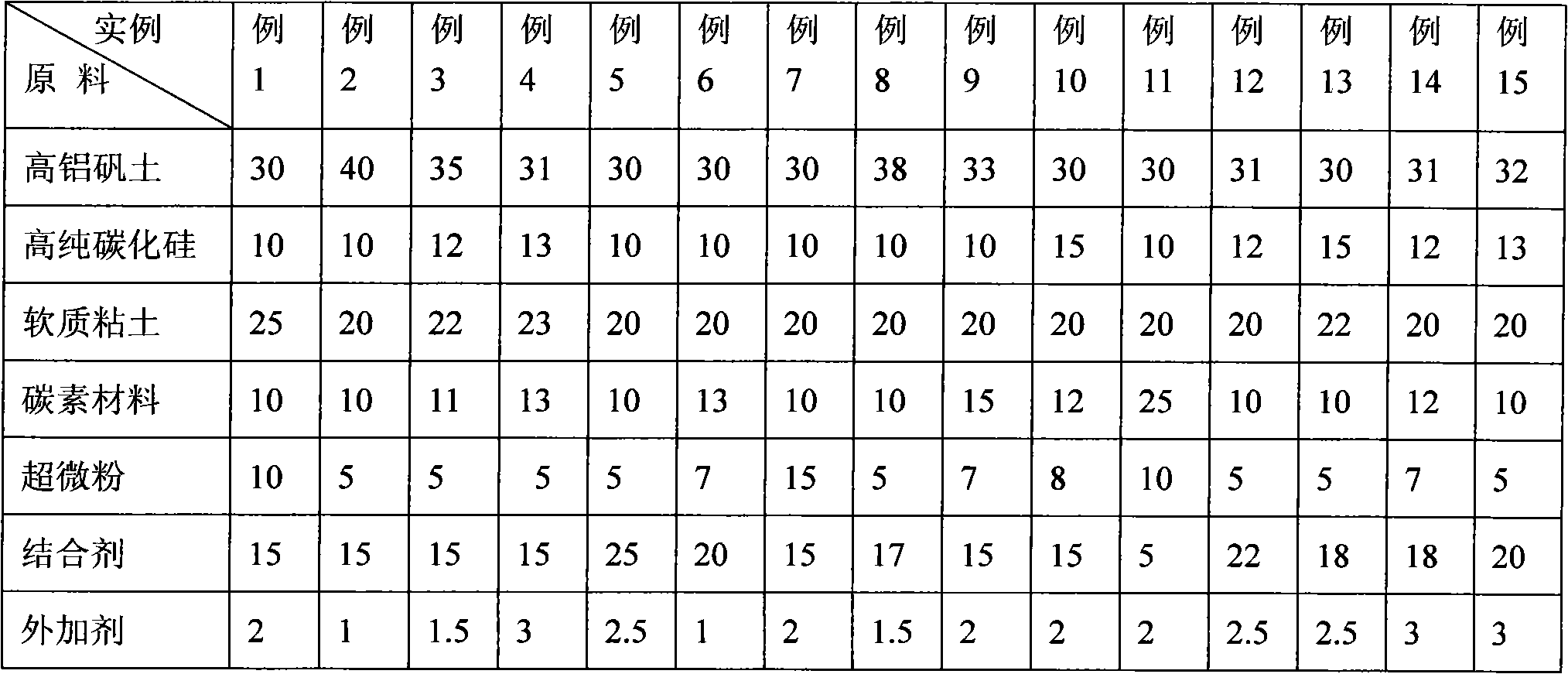

Anhydrous stemming for blast furnace

The invention relates to an anhydrous stemming for a blast furnace. The anhydrous stemming is prepared from the following raw materials in percentages by weight: 30-40 percent of high-alumina bauxite, 10-15 percent of high-purity silicon carbide, 20-25 percent of soft clay, 10-25 percent of carbonaceous material, 5-15 percent of submicron powder, 15-25 percent of binding agent, and additionally silicon metal powder addictives accounting for 1-3 percent of the total weight of the raw materials. The anhydrous stemming has the advantages of favorable high-temperature fire performance, linearity change ratio of lower than 0.3 percent under the condition of 1400 DEG C*2h, breaking strength of more than or equal to 10MPa, high intensity, slag-iron resistant scouring, easy sintering, excellent work performance, less pollution and low production cost, and is beneficial to environment protection as well as popularization and application.

Owner:HENAN HUAXI FURNACE REFRACTORY

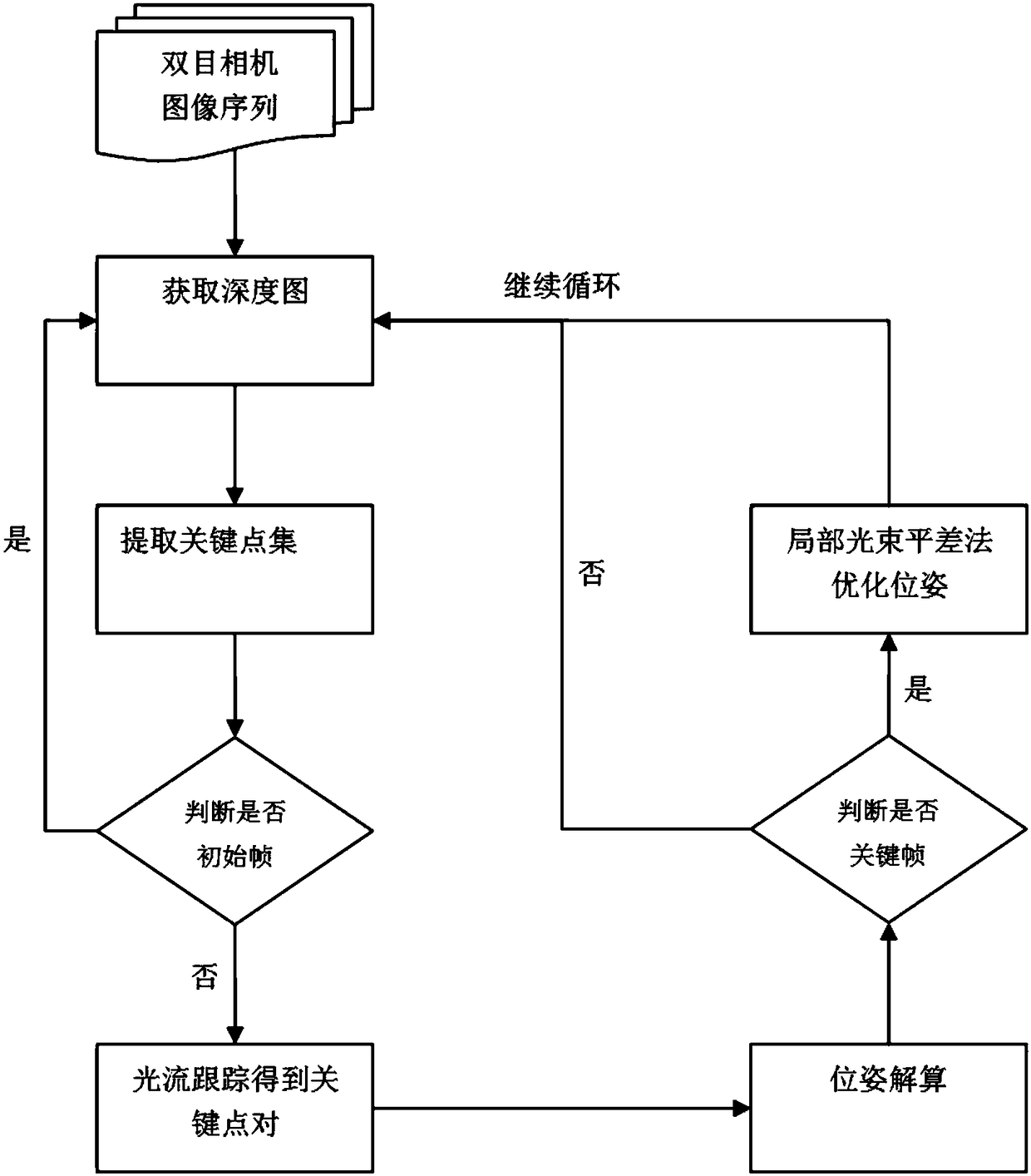

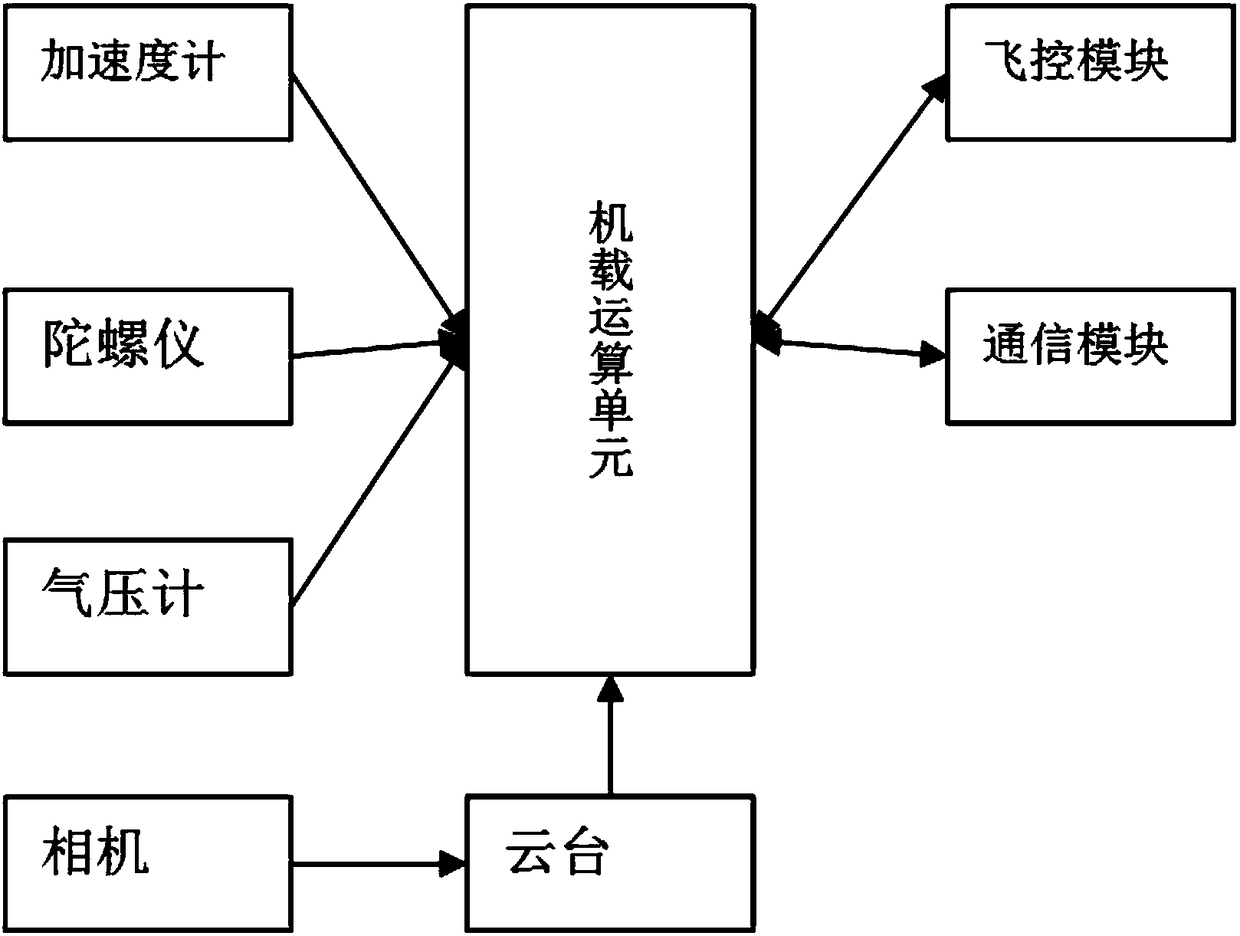

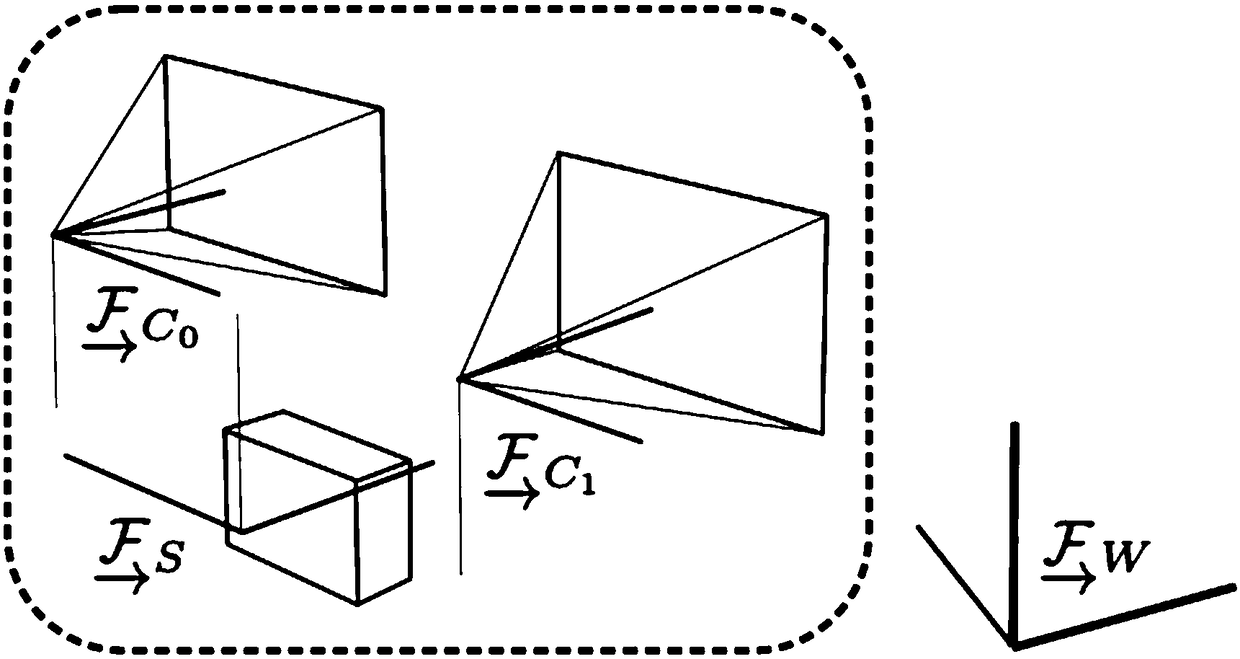

Binocular vision-based unmanned aerial vehicle positioning and navigating method

ActiveCN108520559AImprove the problem that the target depth cannot be accurately estimatedHigh precisionImage data processingControl systemUncrewed vehicle

The invention discloses a binocular vision-based unmanned aerial vehicle positioning and navigating method. The method comprises the steps that an image left-right view and a camera parameter can be obtained based on a binocular camera of an unmanned airborne control system, and obtain a corrected left-right view, and further obtain the depth information of the corresponding pixel; the key pointsof the left view are extracted to be filtered and screened; a matched key point set is found through optical flow tracking in the current frame, and a matched key point pair is obtained; a final poseresult is obtained according to the matched key point pair calculation cost function; finally, the input continuous image frames are screened to obtain a key image frame, and a combined cost functionis calculated for the key point set and the pose of the key image frame, and the cost function can be optimized and solved to obtain a updated pose. According to the method, the reliable depth data can be quickly obtained through the binocular camera; meanwhile, the matching relation is quickly calculated by utilizing the optical flow method; the real-time performance is high, the algorithm robustness is high, and the unmanned aerial vehicle positioning and navigation work can be completed under the indoor and outdoor large and medium scenes.

Owner:西安因诺航空科技有限公司

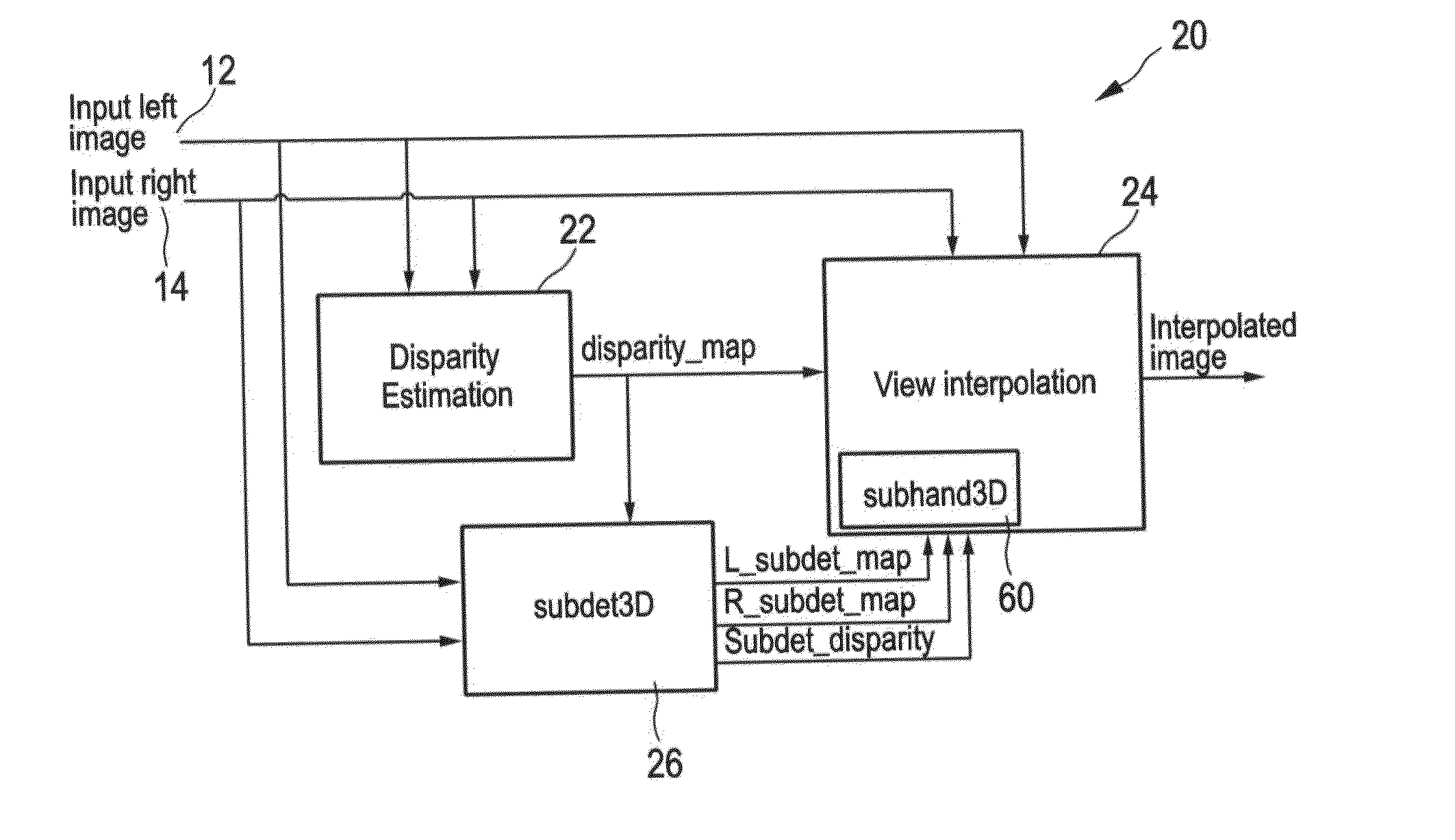

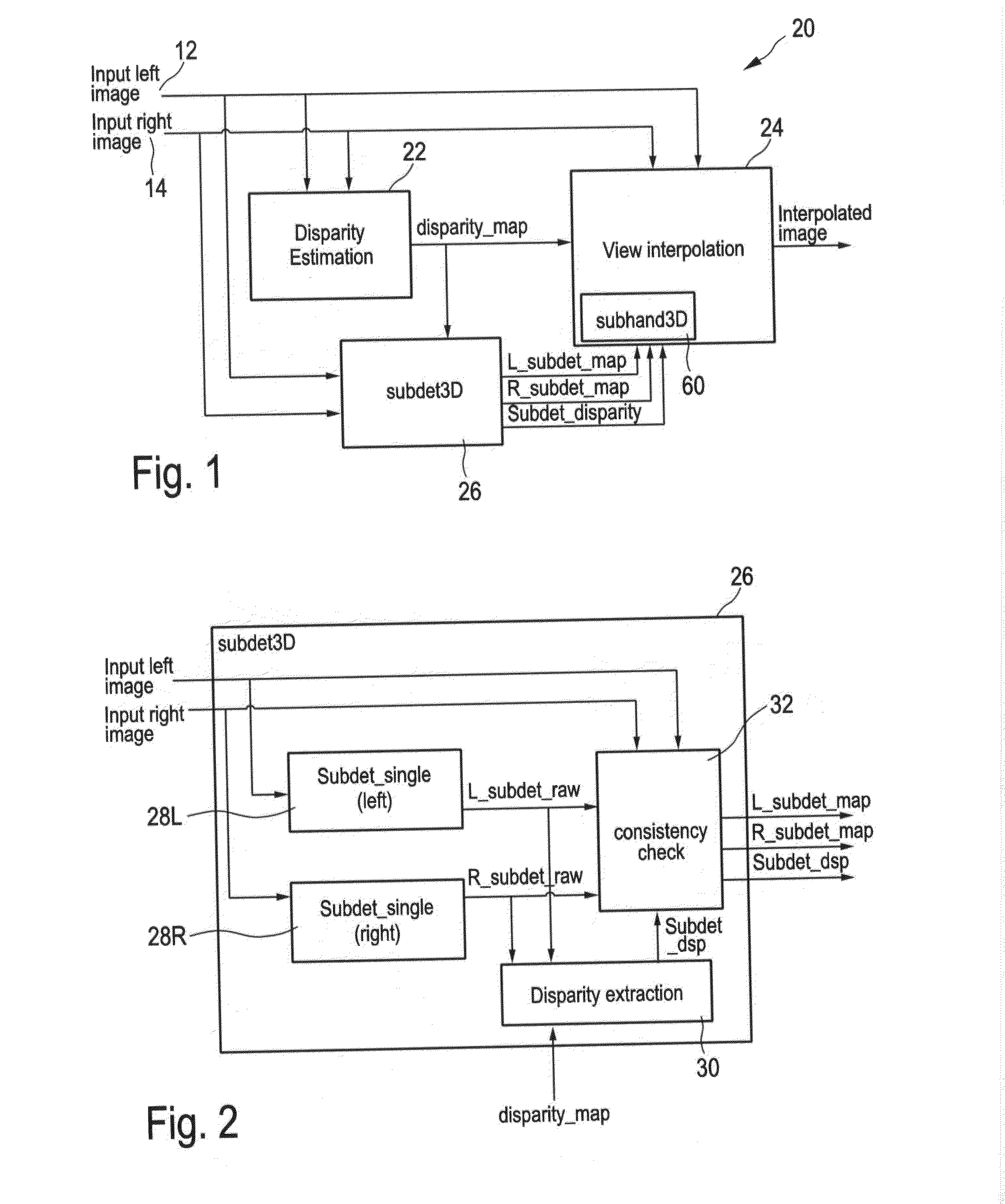

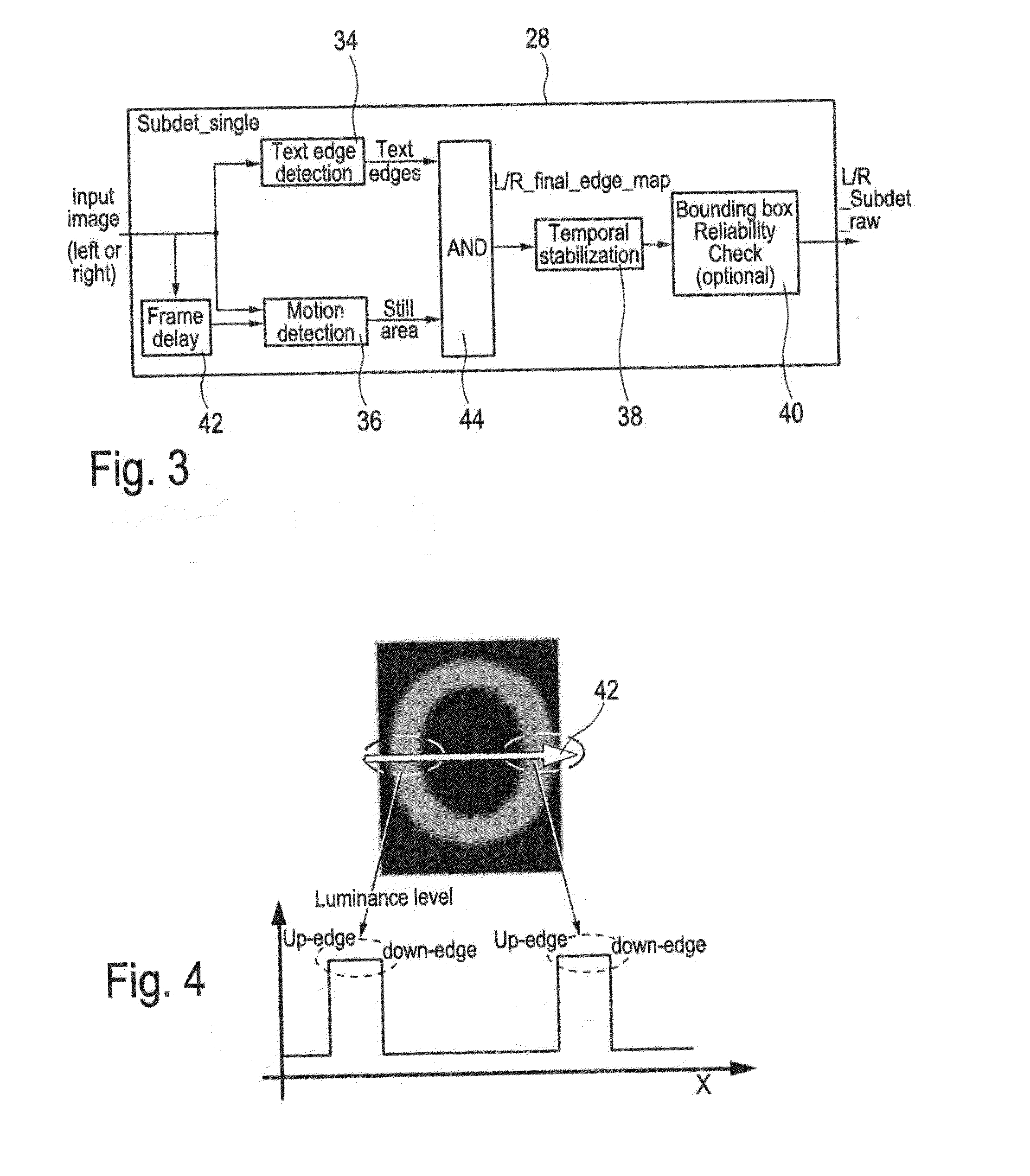

Subtitle detection for stereoscopic video contents

A right image and a left image is provided. Then a disparity estimation map relating to both images is provided and a left subtitle detection map for the left image and a right subtitle detection map for the right image are generated. Each map indicates subtitle areas within an image. For said subtitle areas and based on said disparity estimation map a subtitle disparity value for X and Y directions common for all subtitle areas is determined. Said left and right subtitle maps and said subtitle X and Y disparity values are used in an image interpolation process.

Owner:SONY CORP

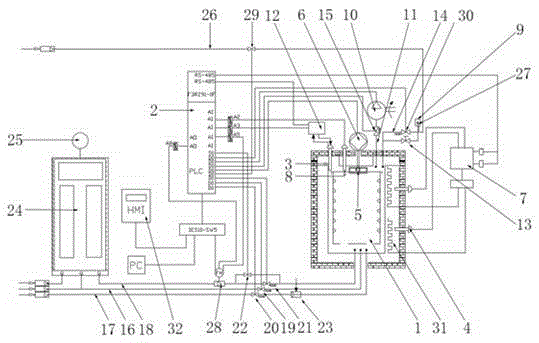

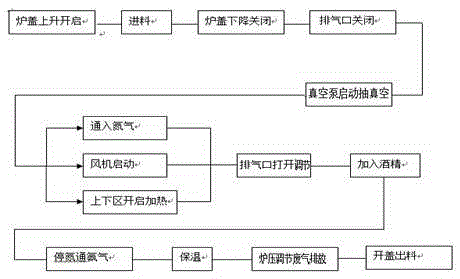

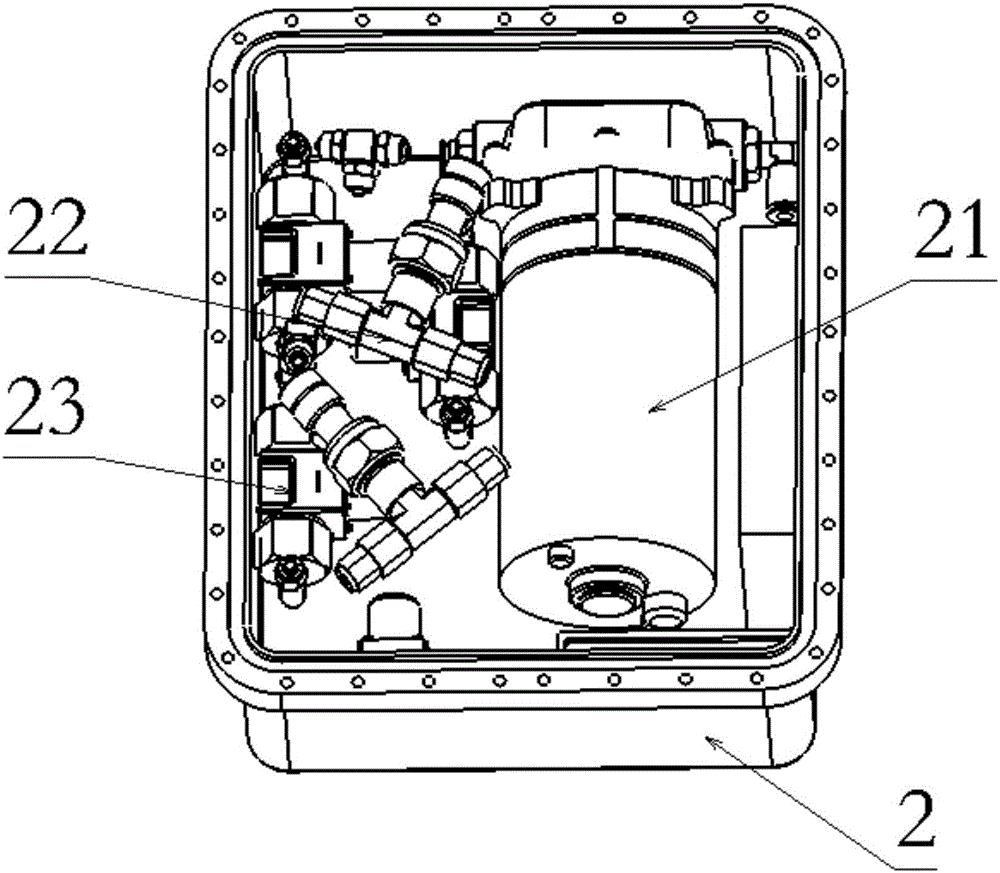

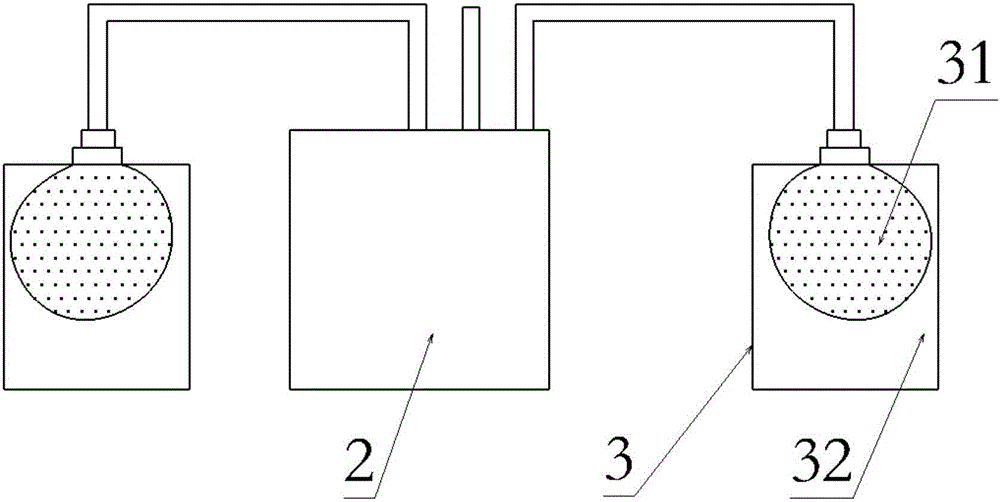

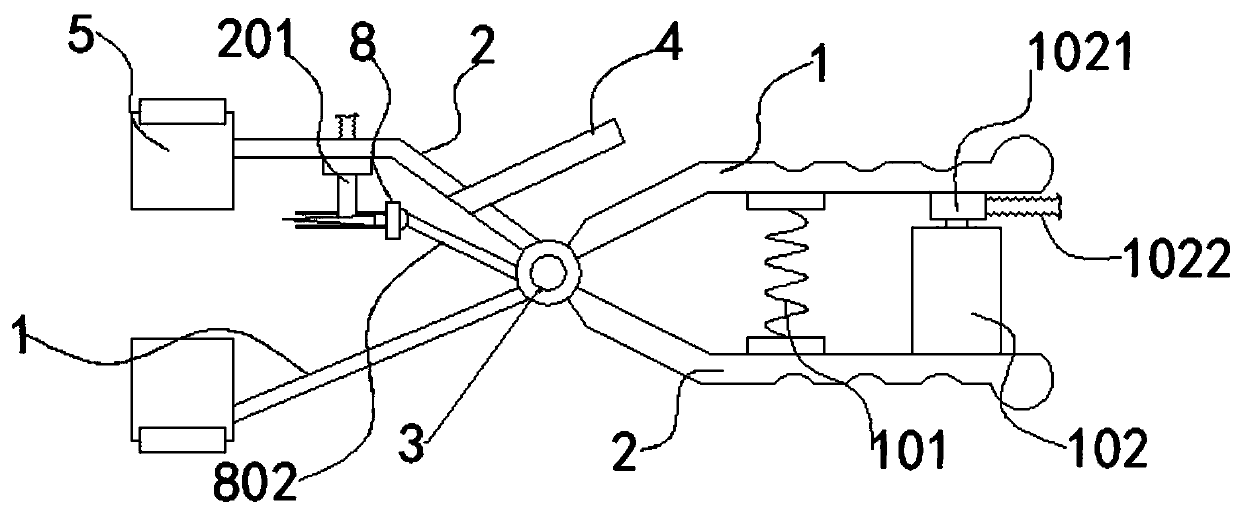

Gas carbonitriding automatic control method and device

ActiveCN105369190ADeep stabilityStable UniformitySolid state diffusion coatingAutomatic controlClosed loop feedback

The invention discloses a gas carbonitriding automatic control method and device. The device comprises nine devices, namely, a nitriding furnace 1, a PLC, a pressure sensor, a hydrogen probe, a thermocouple, a blade, a fan, a heating and temperature control device and an air exhausting device. After being subjected to degreasing, cleaning and surface treatment, a part is subjected to closed loop feedback control of a vacuum pump, nitrogen, ammonia, ethyl alcohol, temperature and pressure in the furnace, so that the nitrocarburizing of various common nitriding steel such as high-speed steel and stainless steel is achieved. The device is energy-saving and efficient in use, easy to maintain and free of pollution, the product is high in quality performance, the PLC control system is adopted to quickly confirm and control the depth of the white etching layer and the reticular layer of the part to be stable according to the number of corresponding parts and the technological parameters of the material, the uniformity of stainless steel mass production is stable, the ammonia consumption is less, the energy consumption is low, the nitridation time is short, and the efficiency is high.

Owner:XINAN TOOLS GUIZHOU PROV

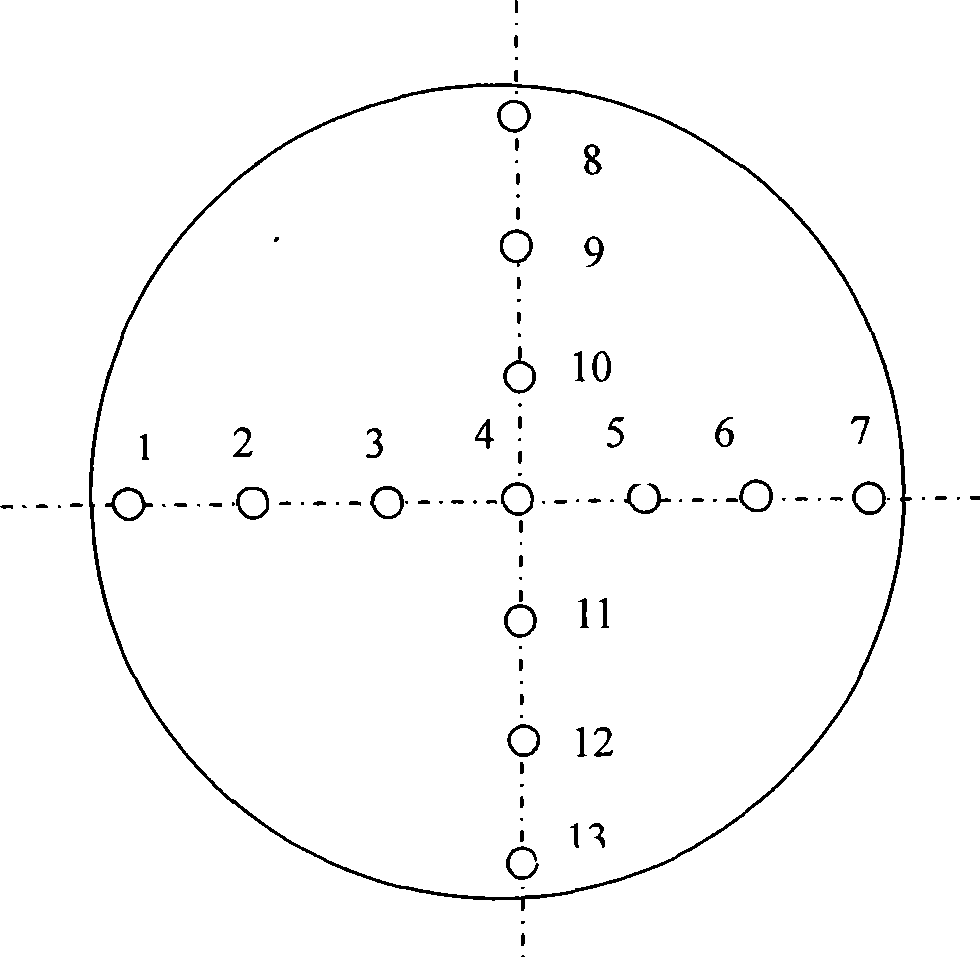

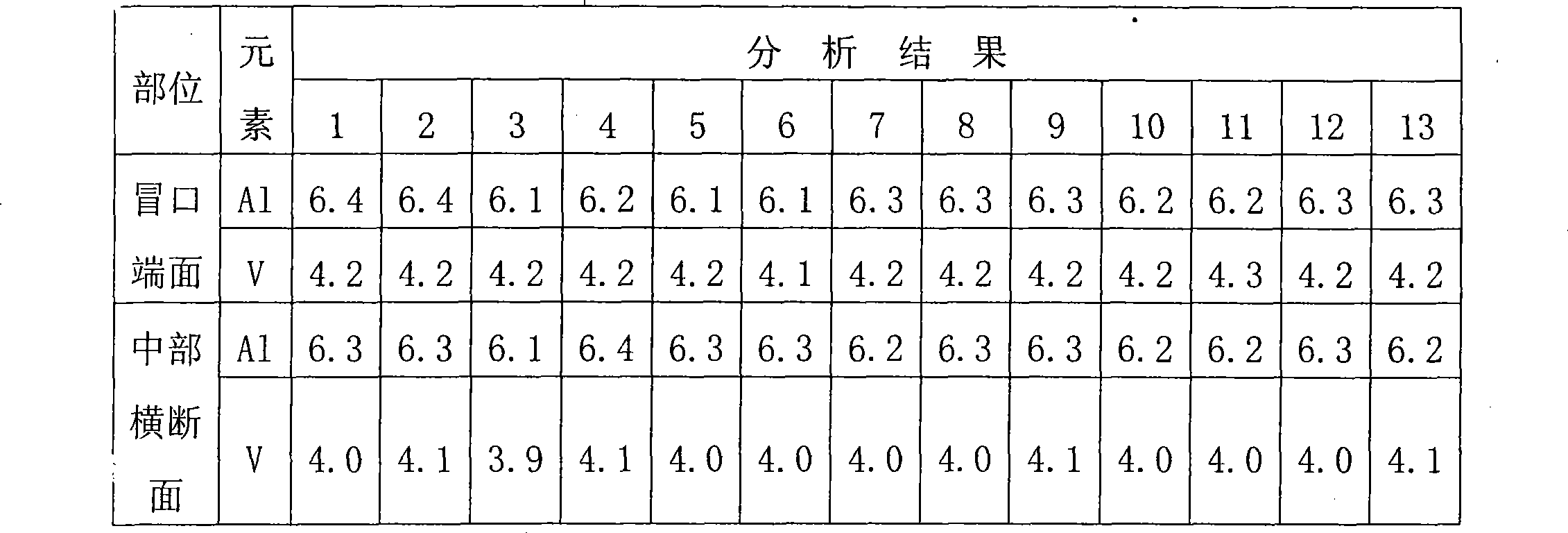

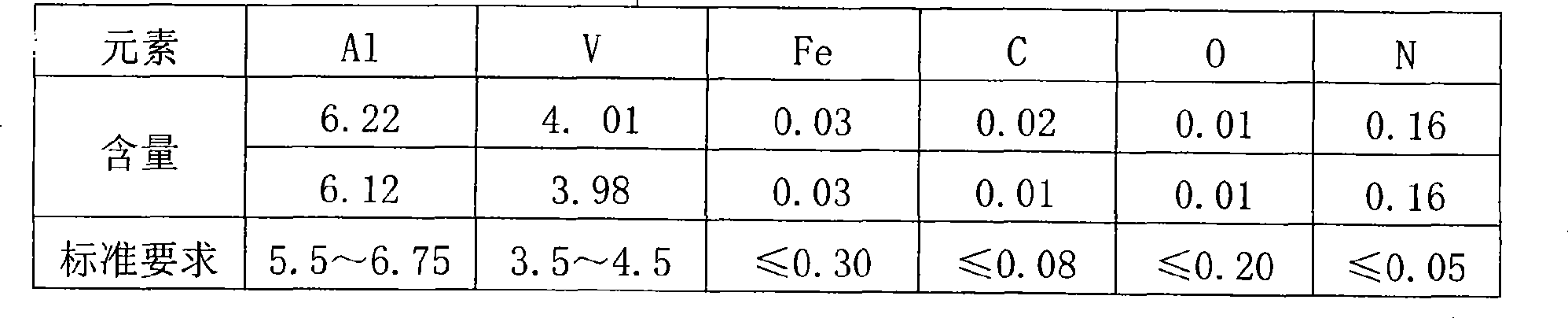

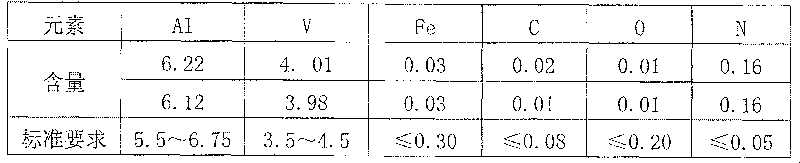

Preparation of Ti-6Al-4V titanium alloy large-sized casting ingot

ActiveCN101476050AStable sequential solidification processSequential solidification process controllableMelting tankTi 6al 4v

The invention relates to a large-scale ingot casting method for preparing Ti-6Al-4V titanium alloy, the invention adopts multiple-time vacuum self-consuming smelting method on the basis of routine technique, adopts a 'constant speed' finished product smelting method and adopts smelting speed control parameters to control the technological parameters in the finished product smelting process.The invention is characterized in that the smelting speed control parameter is 20-32Kg / min; the real smelting weight is on-line measured each second or according to a set time and an instant smelting speed is the ratio of the real smelting weight and the measurement time interval; if the smelting speed is higher than a desired value, the smelting current is then reduced; if the smelting speed is lower than the desired value, the smelting current is then increased. By using the control method, temperature field can be controlled effectively, distribution coefficient can be optimized, stabilization of the from and depth of the melting bath can be assured, which make the ingot casting sequence and solidification process stable and controllable, and homogeneity of components of large-scale ingot casting can also be assured.

Owner:BAOJI TITANIUM IND CO LTD

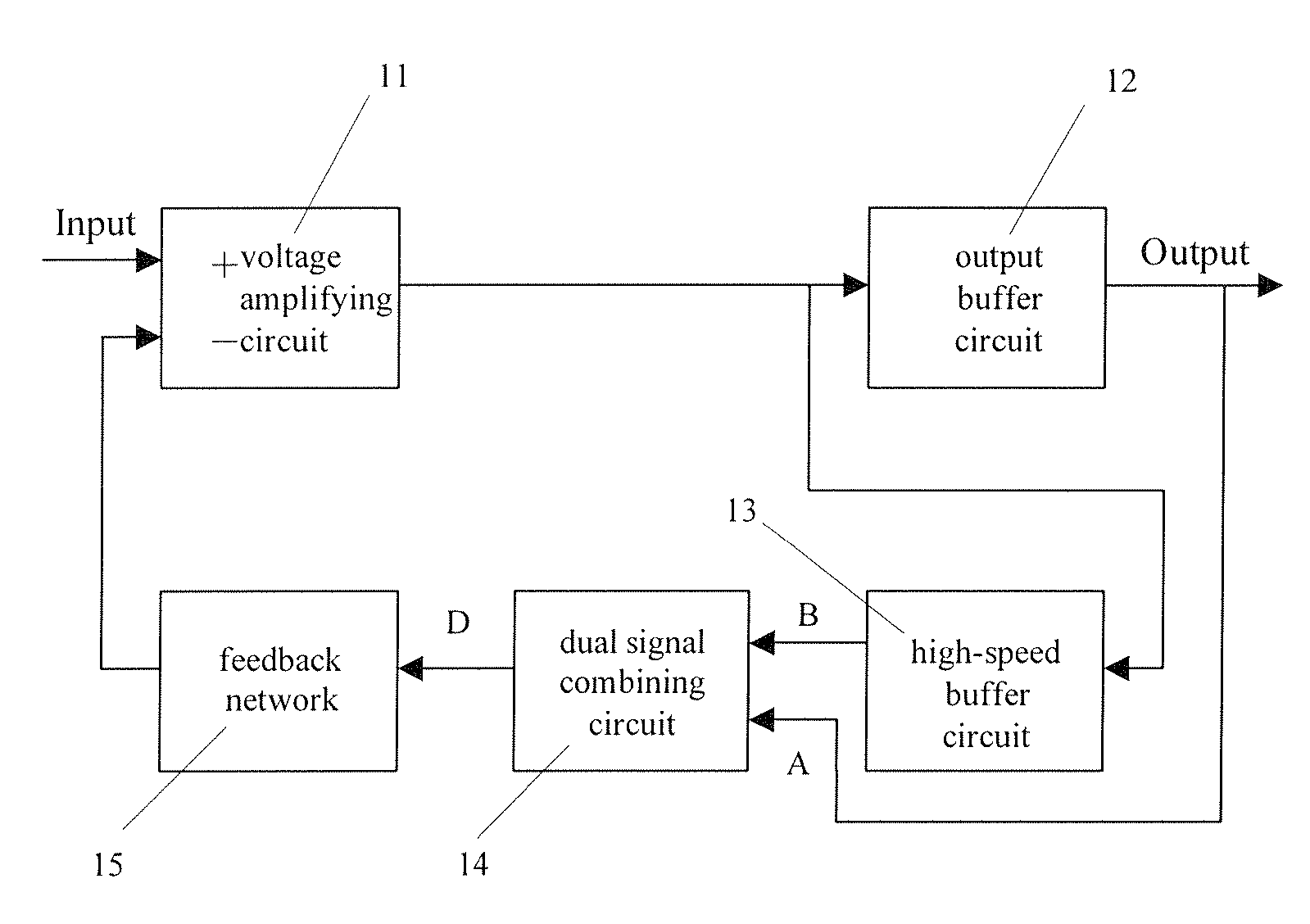

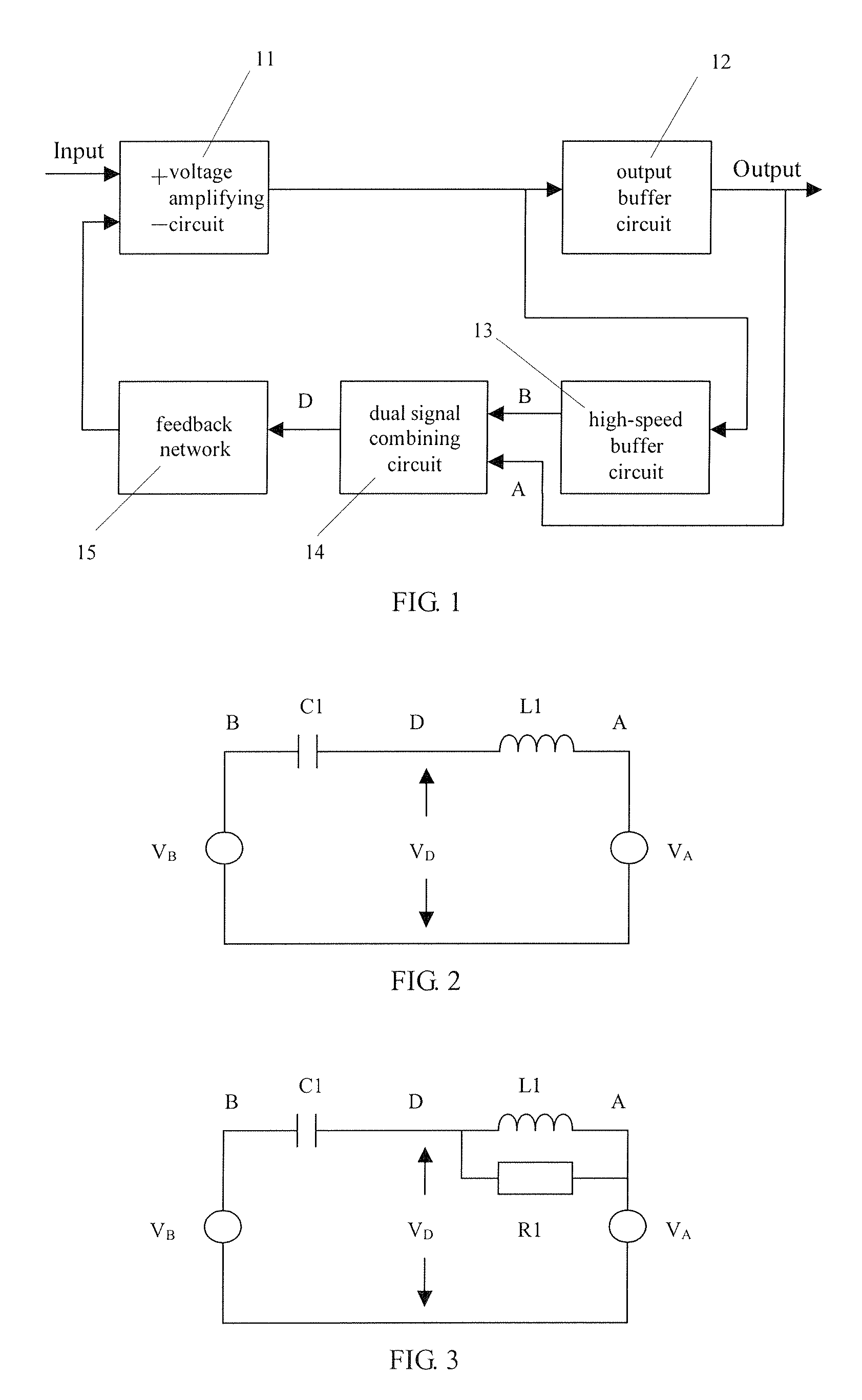

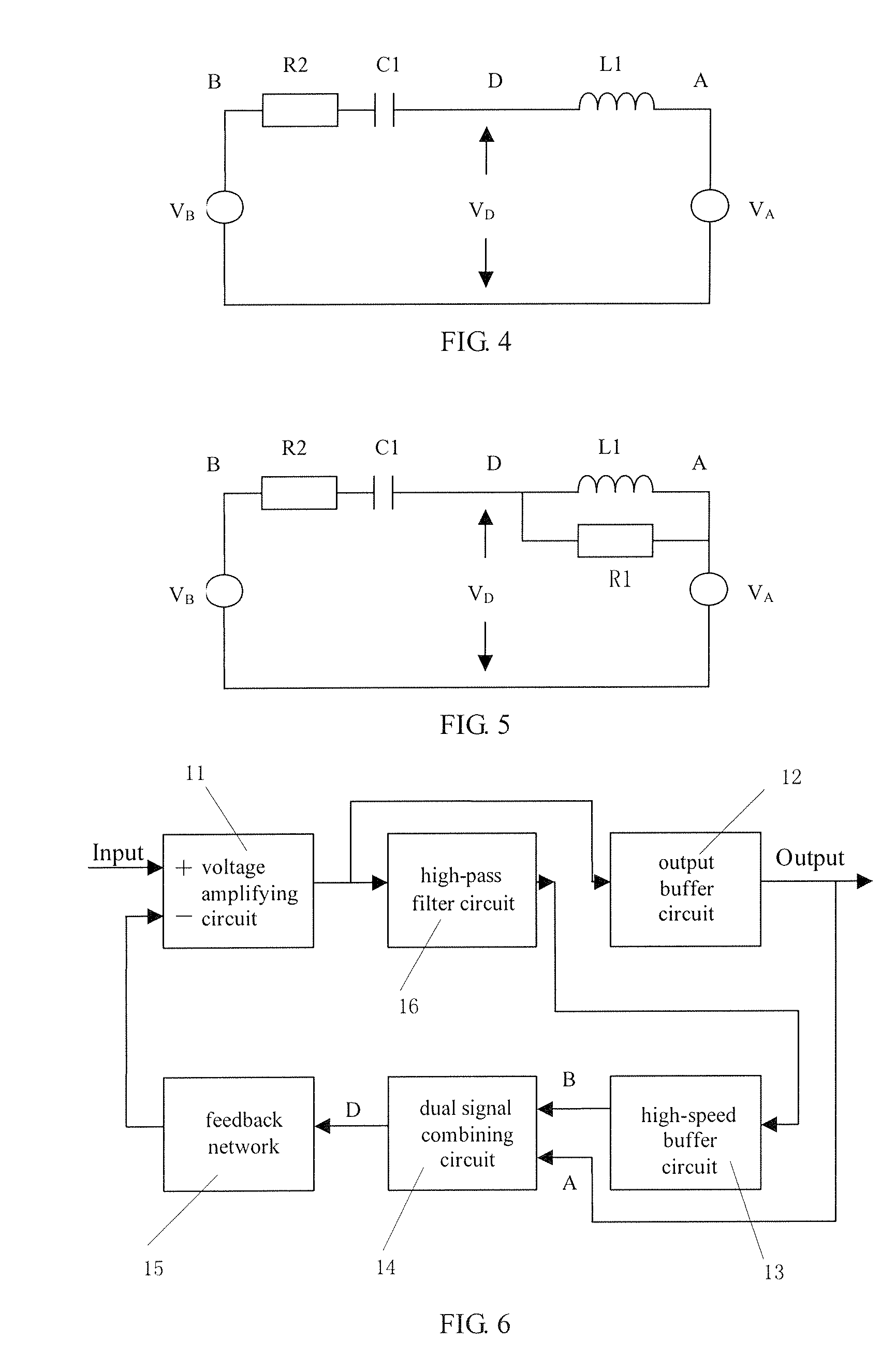

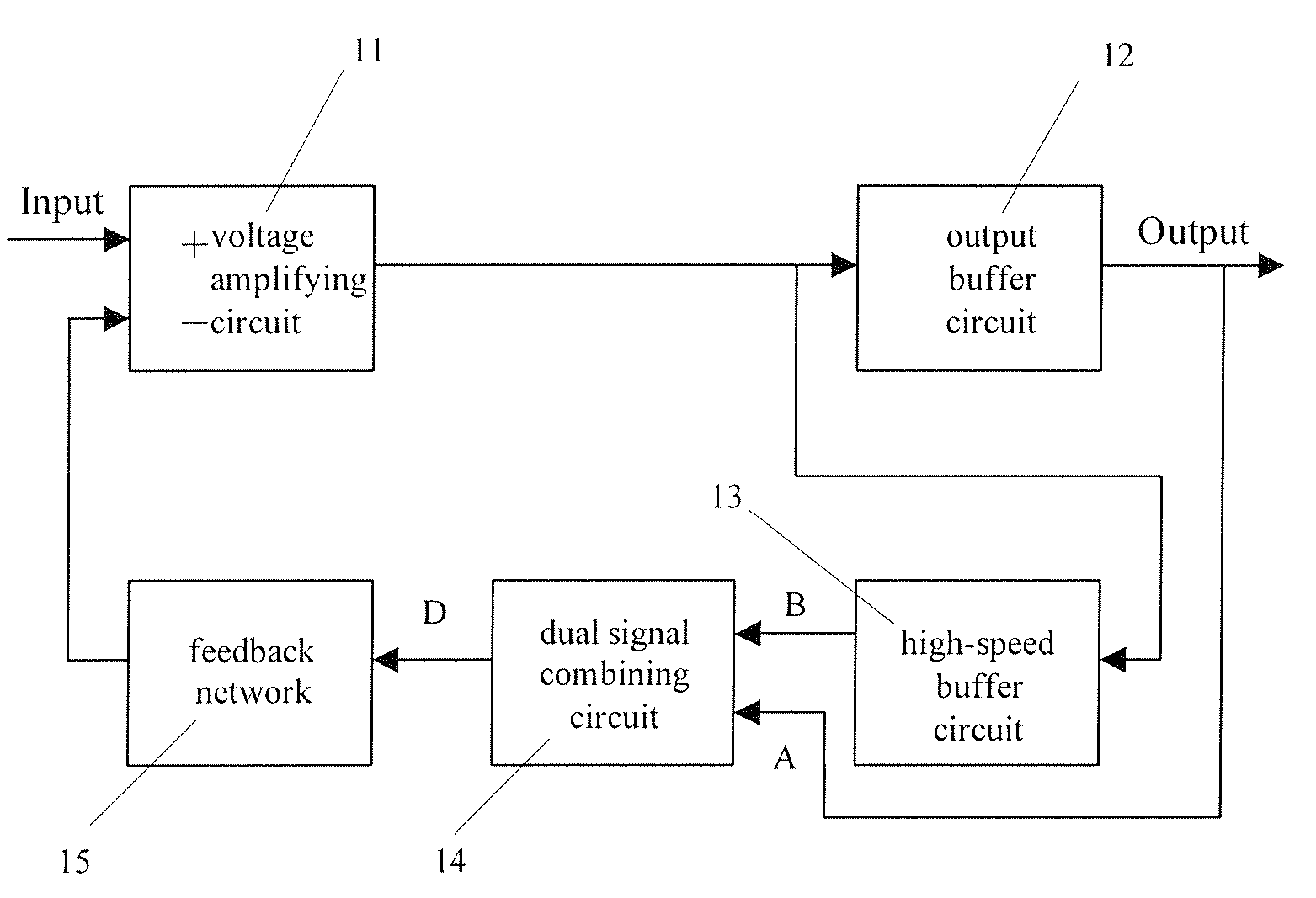

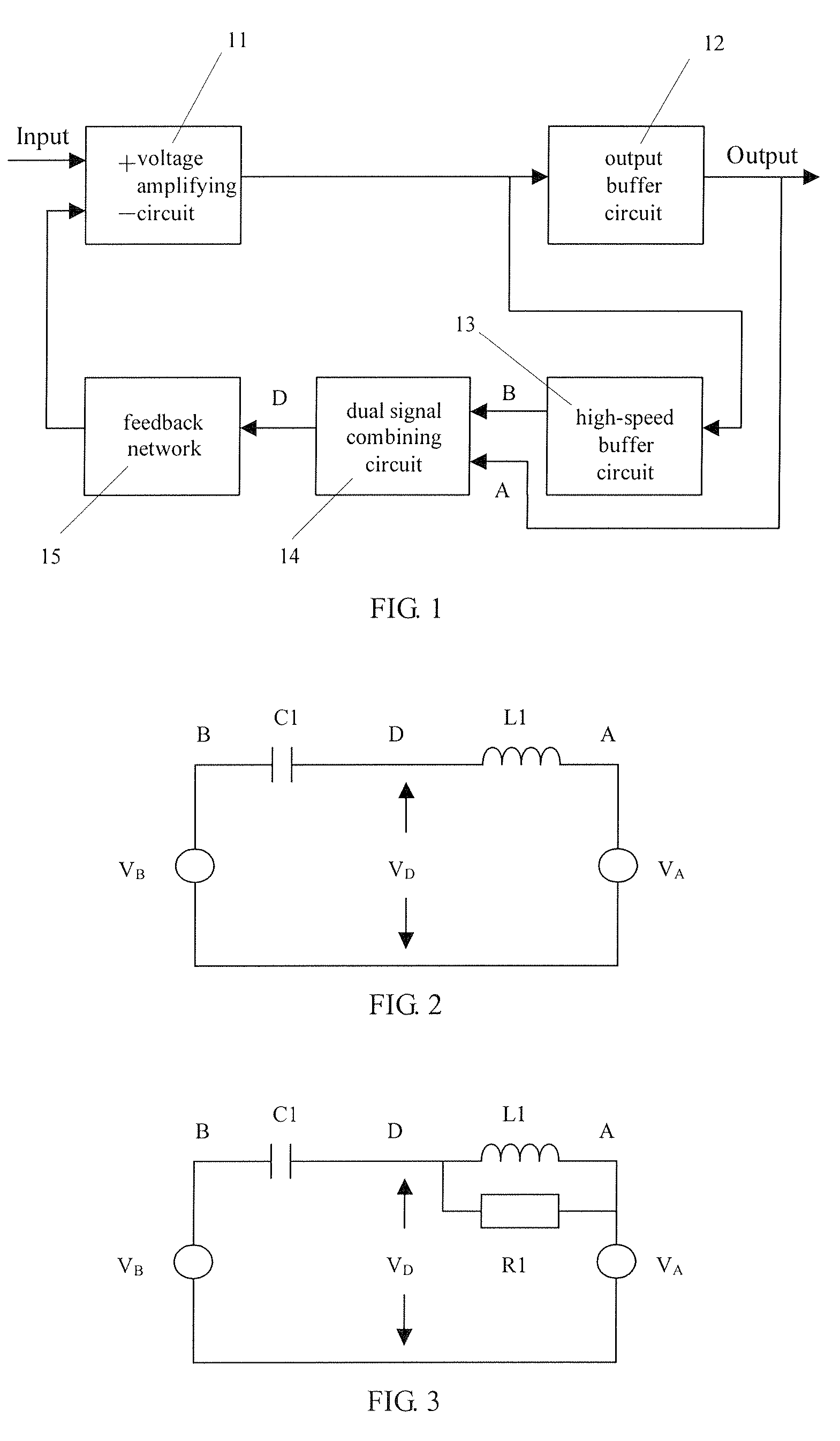

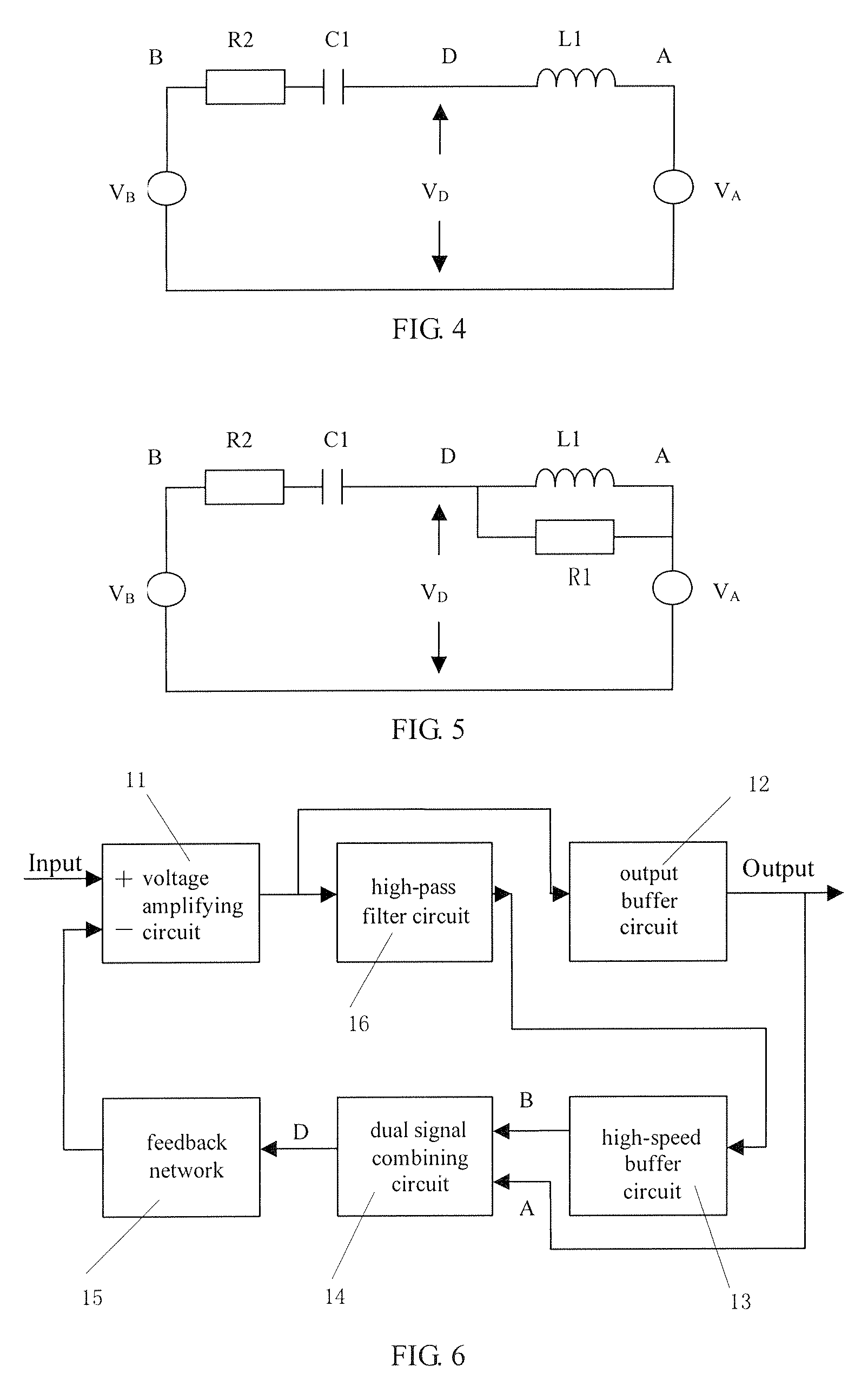

Method For Double Sampling Loop Negative Feedback And Double Sampling Negative Feedback Amplifier

InactiveUS20070296502A1Increasing feedback depthAdd depthAmplifier modifications to reduce non-linear distortionNegative-feedback-circuit arrangementsNegative feedbackPhase shifted

A method for double sampling loop negative feedback comprising: obtaining a low-frequency feedback signal from the output of the amplifier; obtaining a high-frequency feedback signal from part of the amplifier of which high-frequency phase shift is low, wherein two-ways sampling signals have the same amplifying phase; combining the two-ways sampling signals together using a series capacitor-inductor double signal combining circuit to form one signal, the signal having low phase shift at both high and low-frequency and being used for negative loop feedback. The invention also provides a double negative feedback amplifier using the method.

Owner:ZHOU ZONGSHAN

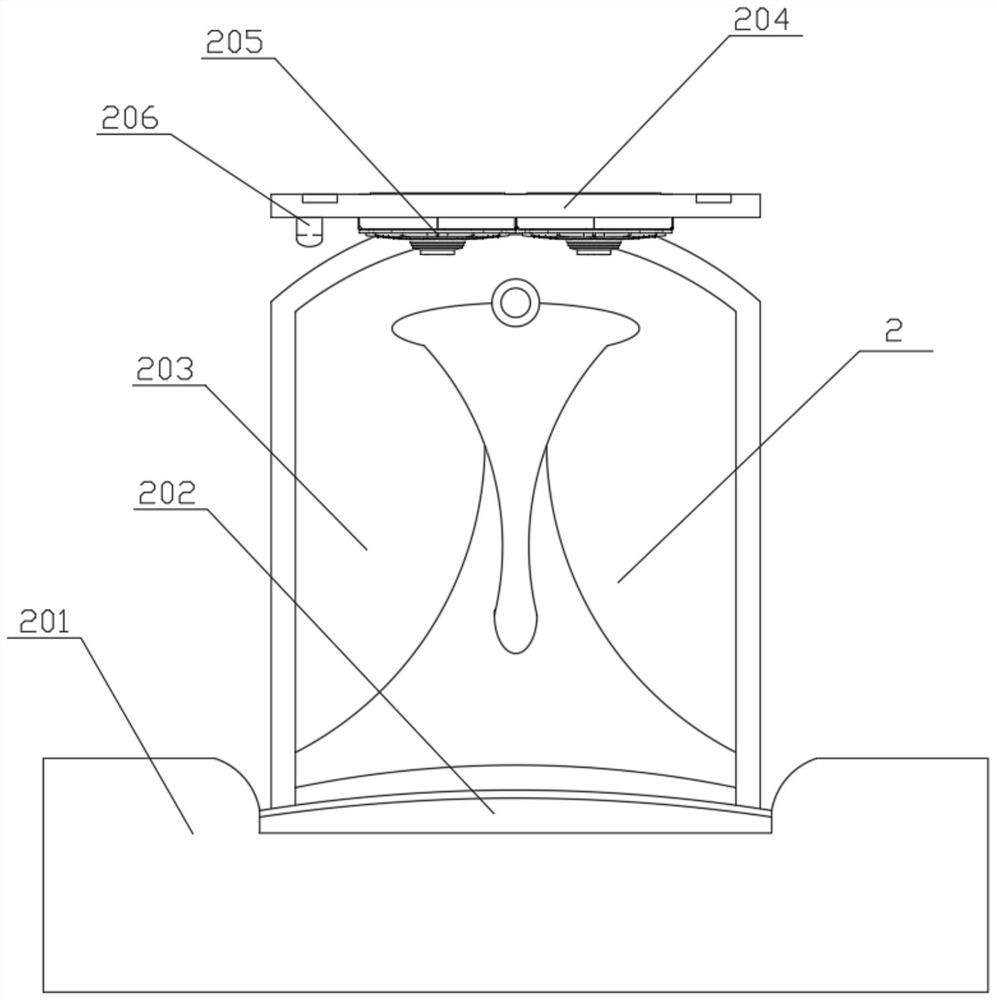

Control method based on underwater floating and sinking device

InactiveCN106347611AUps and downs fastDeep stabilityUnderwater vesselsUnderwater equipmentUnderwaterControl theory

The invention provides a control method based on an underwater floating and sinking device. The method comprises the steps of depth value initializing: defining the depth value range and defining the absolute depth 0 value; depth value setting: setting the preset depth value; speed value setting: setting the preset floating speed, the preset sinking speed and the preset suspending speed; depth detection: detecting the current position depth value of the underwater floating and sinking device; depth comparison: comparing the current position depth with the preset depth value; speed detection: detecting the current floating or sinking or suspending speed of the underwater floating and sinking device; speed comparison: comparing the current speed with the preset floating speed, the preset sinking speed and the preset suspending speed. The control method has the advantages that the fast floating, the fast diving and the suspending at the set speed of a bionic robot in water are realized; the response speed of the control method is high; the flexibility is good; the depth is kept stable.

Owner:HANGZHOU CHANG DONG INTELLIGENT TECH CO LTD

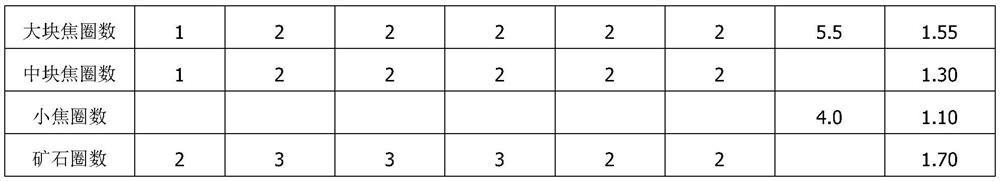

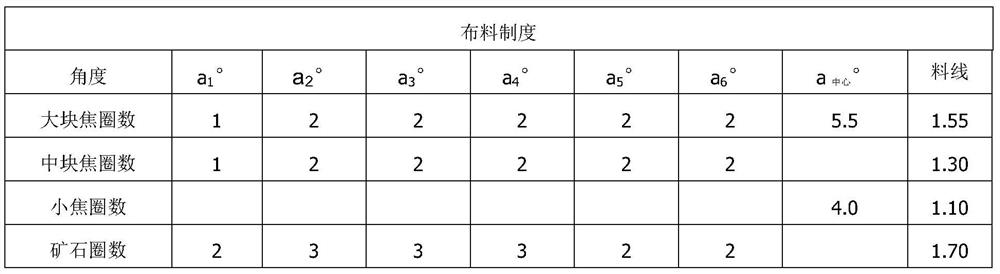

Smelting method for medium coke used in large bell-less blast furnace in high proportion

The invention relates to the technical field of ferrous metallurgy, in particular to a smelting method for medium coke used in a large bell-less blast furnace in a high proportion. According to the smelting method, medium coke is prevented from being distributed into the center of the blast furnace by a small coke distribution method, a damping-down material improving structure is proposed after a large amount of medium coke is used, and central airflow development and rapid recovery are guided by adopting a load sharing and central tank coke adding method; a proper edge load increasing and large batch weight smelting method is provided to inhibit edge airflow development; and a stokehole tapping structure is enhanced, the clay ramming amount is standardized, the iron notch depth is stabilized, and the effective tapping time is guaranteed. These measures are adopted when the medium coke used in the high proportion is produced, so that the medium coke can be successfully prevented from being distributed into the center of the blast furnace to influence the quality of furnace core coke under the condition of not reducing coke load, rapid recovery after damping down of the blast furnace is guaranteed, edge coal airflow can be stabilized and the central airflow can be developed in daily operation, a hearth is facilitated to be active, and long-term stable smooth operation of the blast furnace is ensured.

Owner:ANGANG STEEL CO LTD

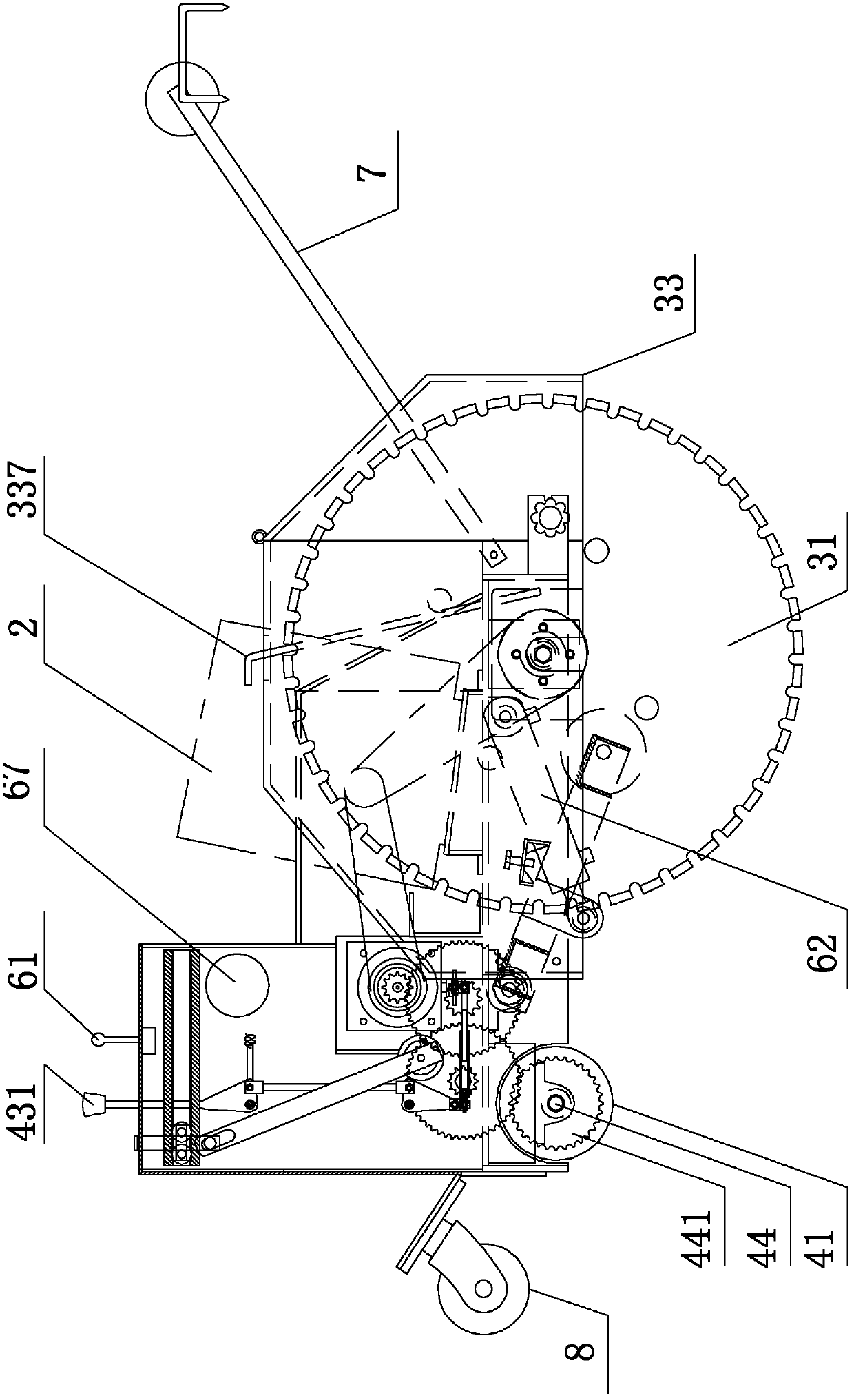

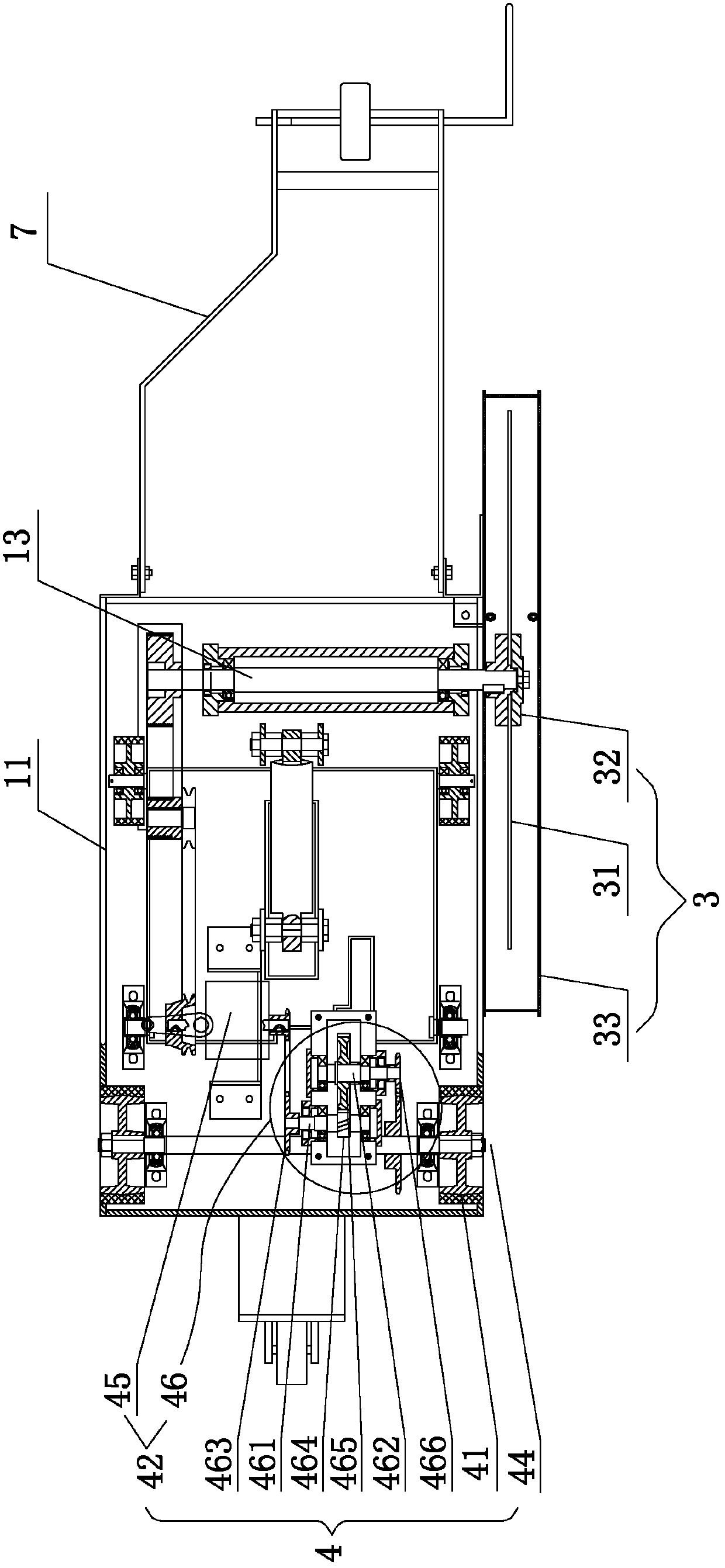

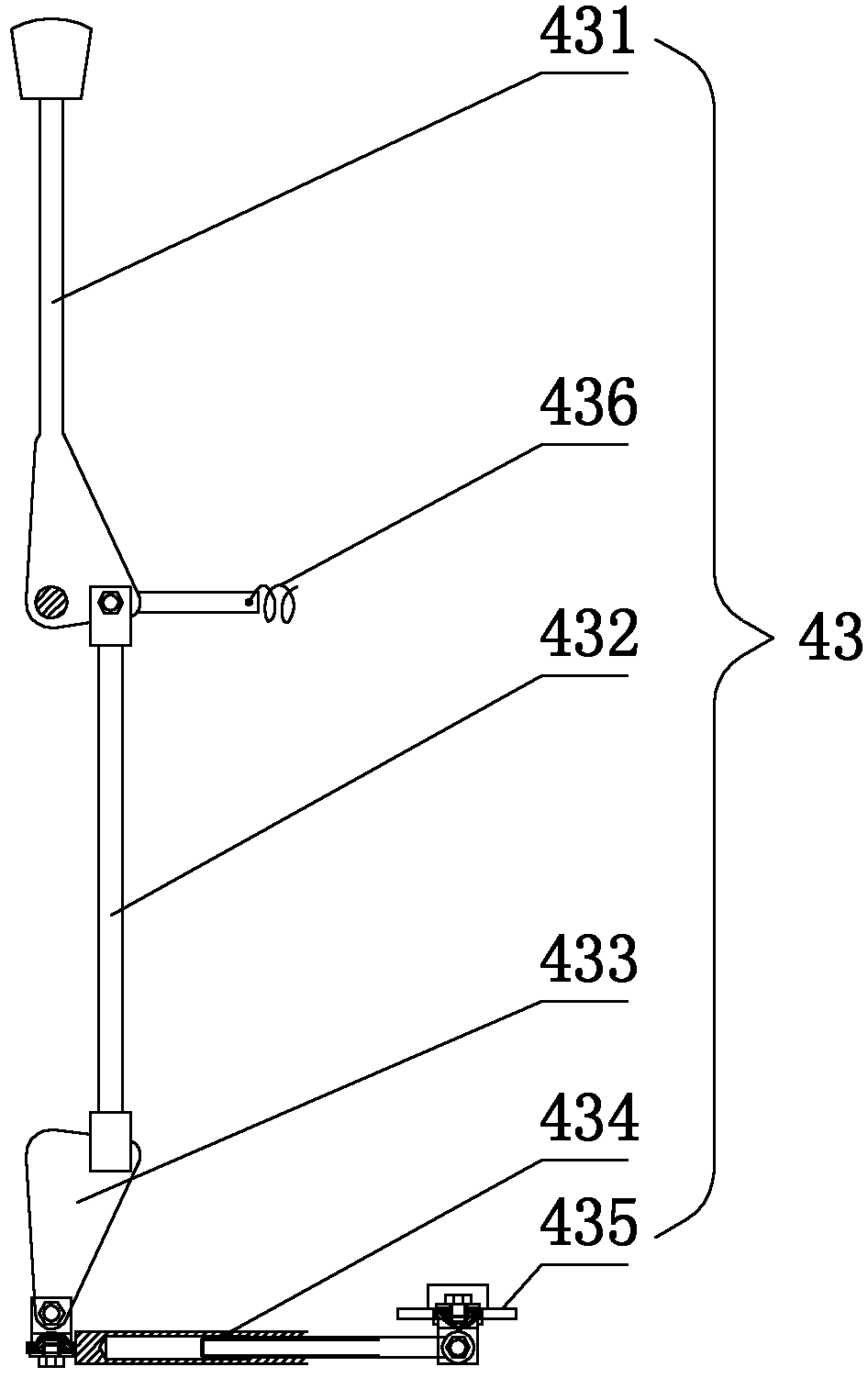

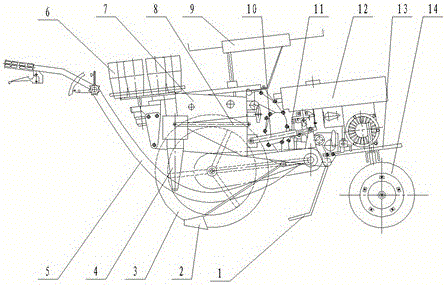

Hydraulic control self-propelled road surface cutter

ActiveCN103290774AAchieve self-improvementCompact structureServomotorsRoads maintainenceVehicle frameDrive wheel

The invention relates to a hydraulic control self-propelled road surface cutter which comprises a frame, an engine, a cutting device, a walking device and a support device, wherein the cutting device, the walking device and the support device are fixedly mounted on the frame; the cutting device is provided with a blade; the walking device is provided with a drive wheel, a transmission mechanism and a walking control mechanism; the support device is provided with a small chassis, a front walking wheel, a scale pointer flange and a hydraulic oil cylinder; the hydraulic control self-propelled road surface cutter is also provided with a hydraulic control device; and the hydraulic control device is provided with a support hydraulic pump, a support overflow valve, a support system, a walking hydraulic pump, a walking overflow valve and a walking system. The hydraulic control self-propelled road surface cutter provided by the invention adopts an infinitely variable speed hydraulic driver to realize self propelling, has the advantages of simple and compact structure and good working stability, is convenient to use, realizes convenient control on the cutting depth and operation speed, can visually display the cutting depth, is suitable for cutting various road surfaces and can improve the working environment.

Owner:CHANGZHOU JIEHE MACHINERY

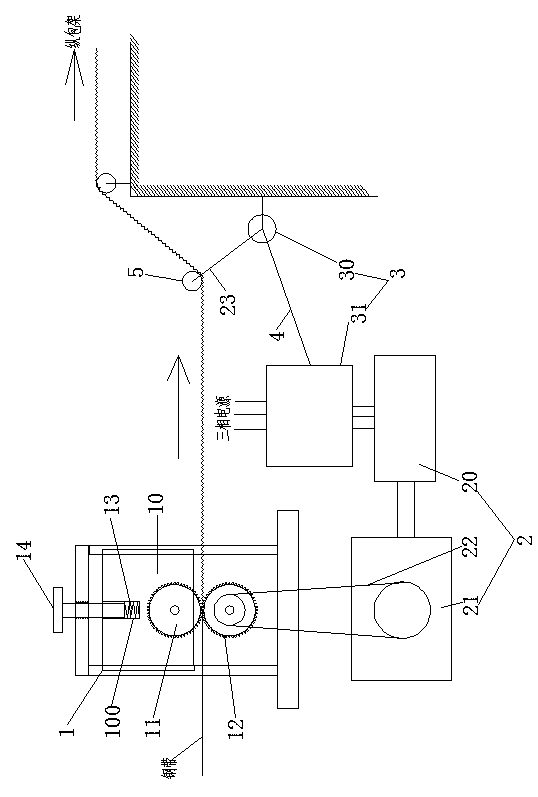

Corrugating device for steel strip and aluminum strip

The invention discloses a corrugating device for a steel strip and an aluminum strip. The corrugating device comprises a corrugating rack, a driving mechanism and an electric control system, wherein a sliding block, an upper roller and a lower roller are arranged in the corrugating rack; the sliding block is arranged at the upper half part of the corrugating rack; the lower roller is arranged at the lower half part of the corrugating rack; the upper roller is fixedly arranged on the sliding block; a screw hole is formed in the middle of the upper part of the sliding block; a spring is arranged in the screw hole; an adjusting screw is also arranged in the screw hole; the driving mechanism comprises a three-phase alternating current motor, a speed reducer, a chain type driving belt and a swing arm; the electric control system comprises an angle sensor and a frequency converter; the speed reducer is connected with the lower roller through the chain type driving belt; the three-phase alternating current motor is connected with the speed reducer; an electrical output end of the frequency converter is connected with a power supply end of the three-phase alternating current motor; the angle sensor is connected with a control end of the frequency converter through a lead and is connected with a guide wheel through the swing arm. According to the corrugating device disclosed by the invention, the synchronization of the corrugating speed and a production line can be ensured, the corrugating depth can be regulated and stable corrugating speed is maintained.

Owner:吴江通信电缆厂

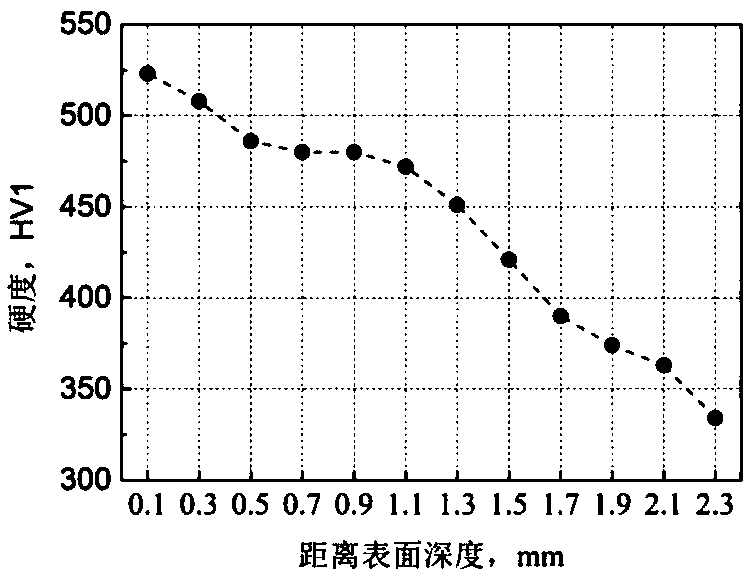

Martensitic stainless steel rod for automobile turbocharger rivet

The invention discloses a martensitic stainless steel rod for an automobile turbocharger rivet and belongs to the technical field of stainless steel rods. The martensitic stainless steel rod comprisesthe following chemical elements in percentage by mass: 0.12-0.22% of C, less than or equal to 1.00% of Si, less than or equal to 1.50% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S, 15.00-17.00% of Cr, 1.50-2.50% of Ni, 0.01-0.30% of N, 0.0001-0.0010% of B and the balance of Fe and inevitable impurities. The martensitic stainless steel rod has the advantages that deltaferrite caused in surface sensitive quenching of an automobile turbocharger rivet can be avoided, the problems of large rivet surface sensitive quenching hardness and hardening layer depth fluctuation and low pass percentages in the prior art can be solved, and the rivet sensitive quenching property pass percentage can be up to 98% or greater.

Owner:BEIJING BEIYE FUNCTIONAL MATERIALS CORP

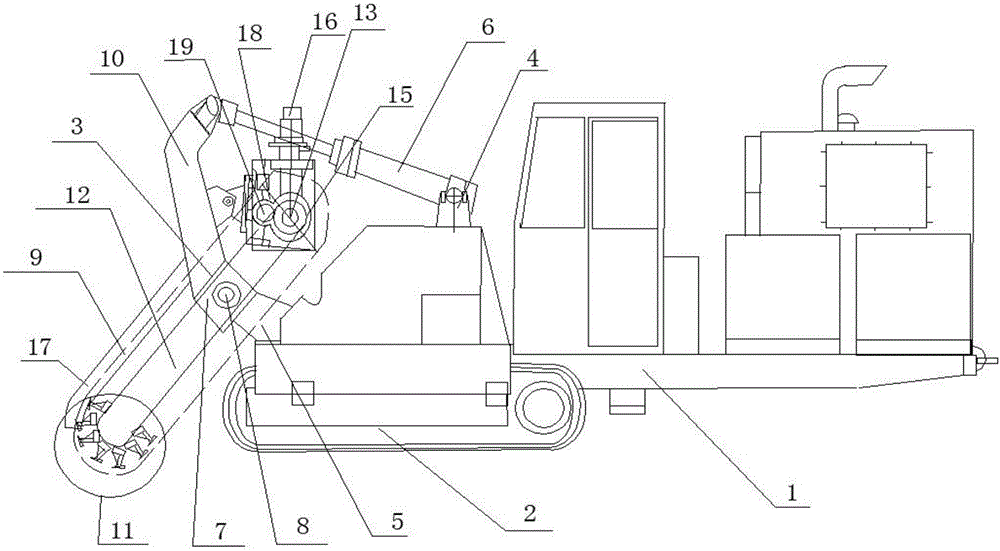

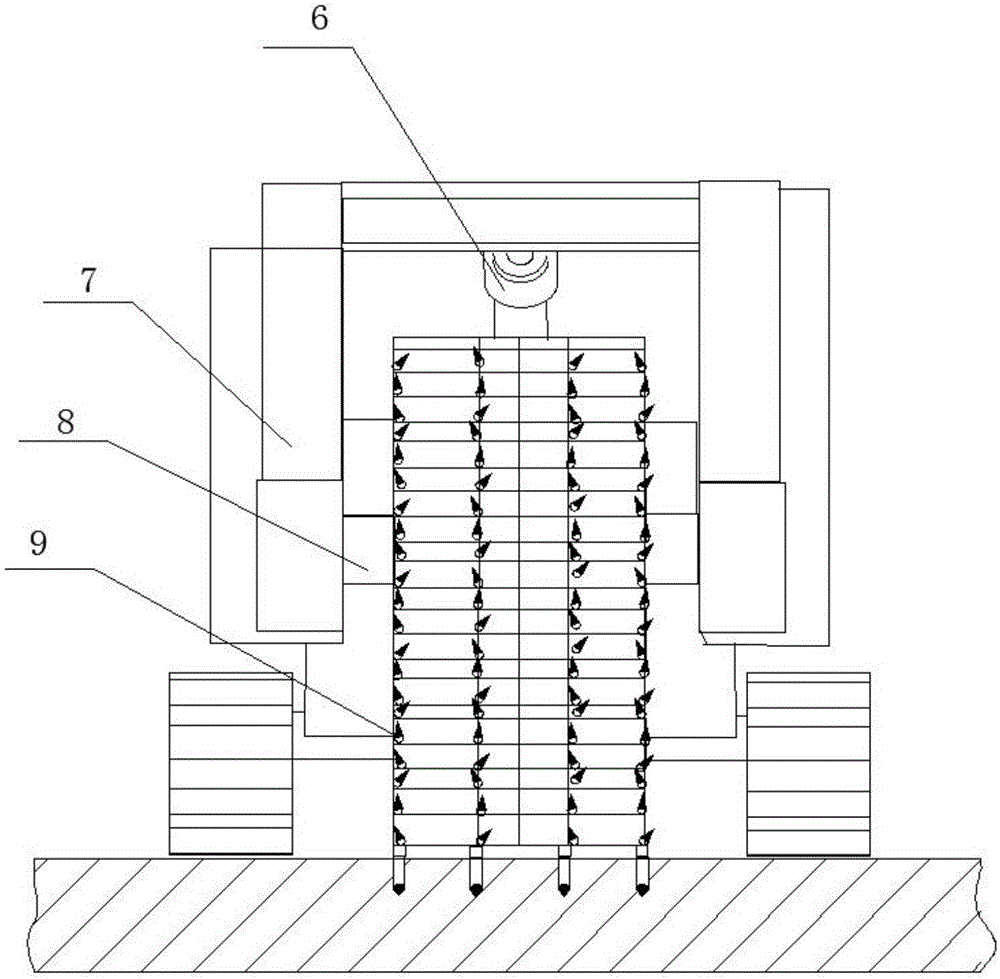

Slotting equipment for additionally arranging dowel bars at joints of cement concrete pavement plates

ActiveCN106592401AAdjustable sizeAvoid complex processPaving detailsRoads maintainenceRoad surfacePiston rod

The invention discloses slotting equipment for additionally arranging dowel bars at joints of cement concrete pavement plates. The slotting equipment controls an arc-shaped supporting arm to match with a supporting bar to act through stretching out and drawing back of a hydraulic oil cylinder piston rod so that a slotting and cutting device can be driven to rotate, and adjusting of the slotting depth is achieved. The slotting equipment is clear in principle, simple in structure, convenient to operate and capable of saving time and effort, precisely controlling the position, size, distance and depth of slotting and slotting a plurality of slots at the same time; and compared with manual slotting, the slotting equipment has the characteristics of being high in efficiency, capable of reducing manufacturing cost, convenient to operate and the like.

Owner:中南安全环境技术研究院股份有限公司

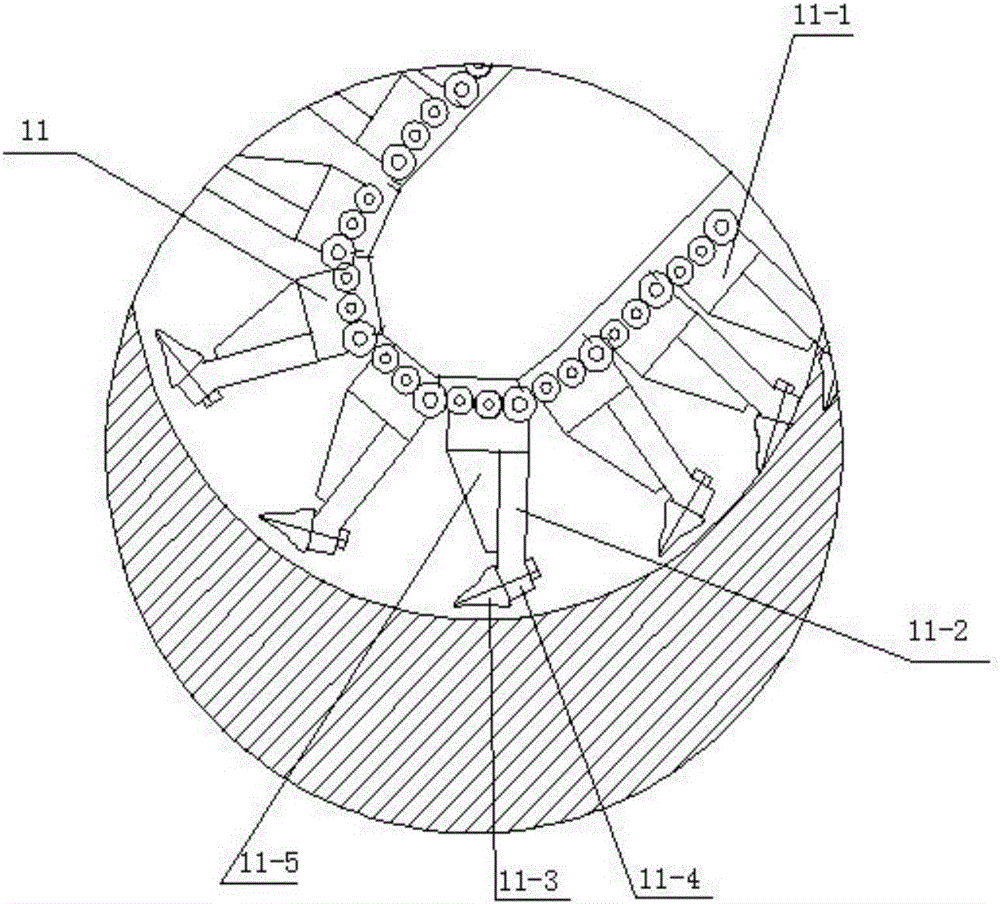

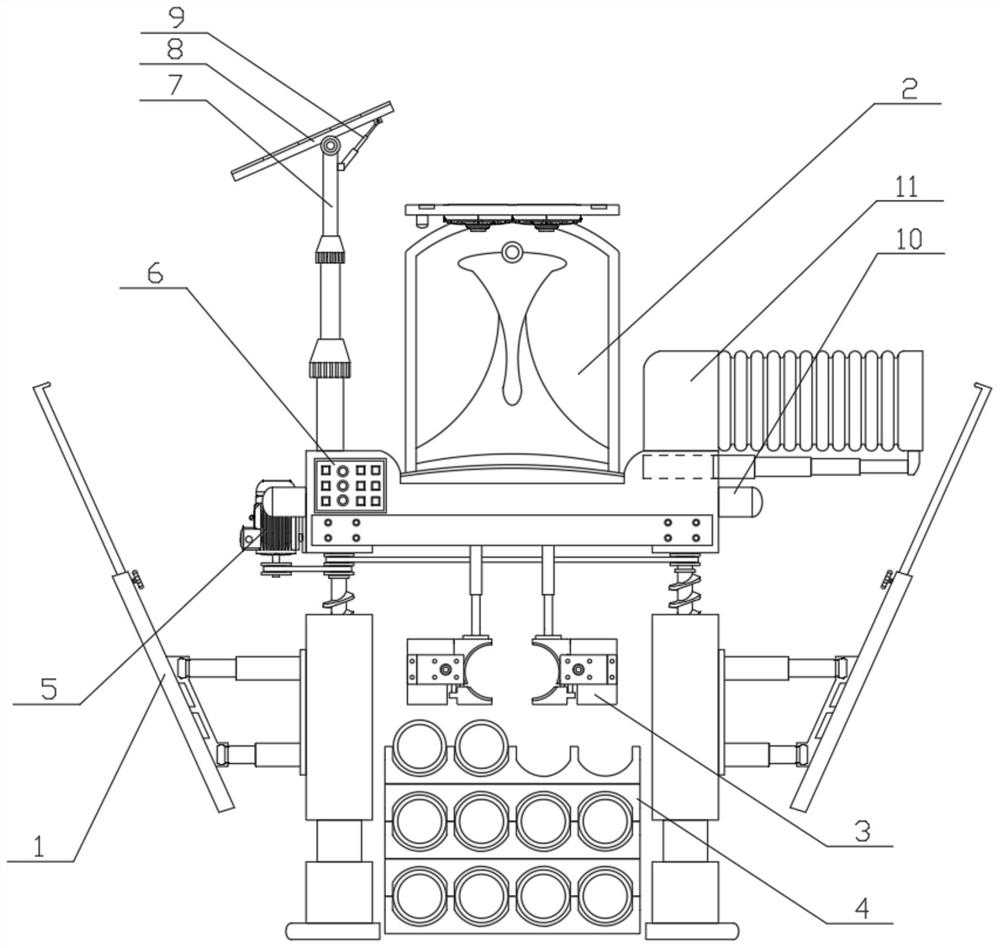

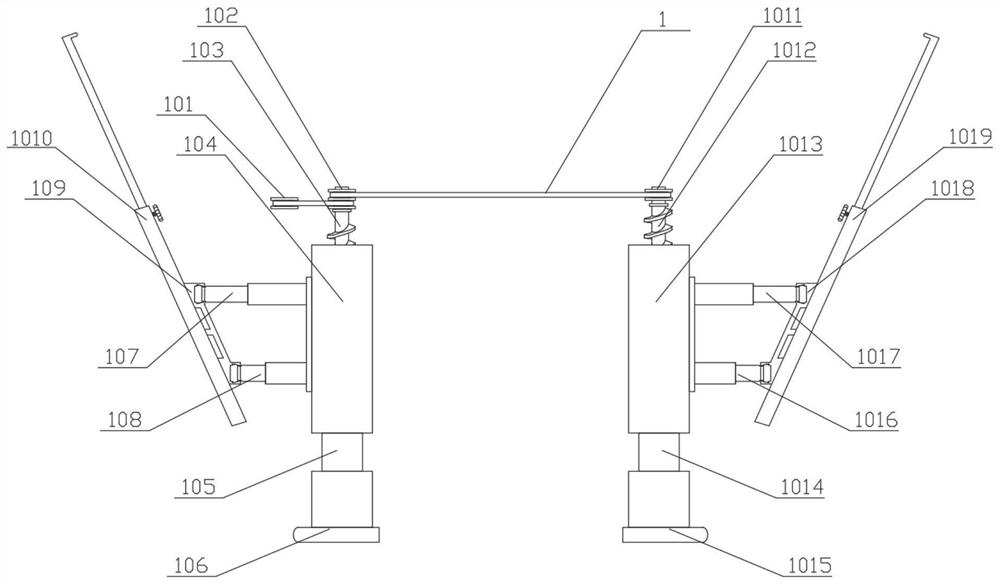

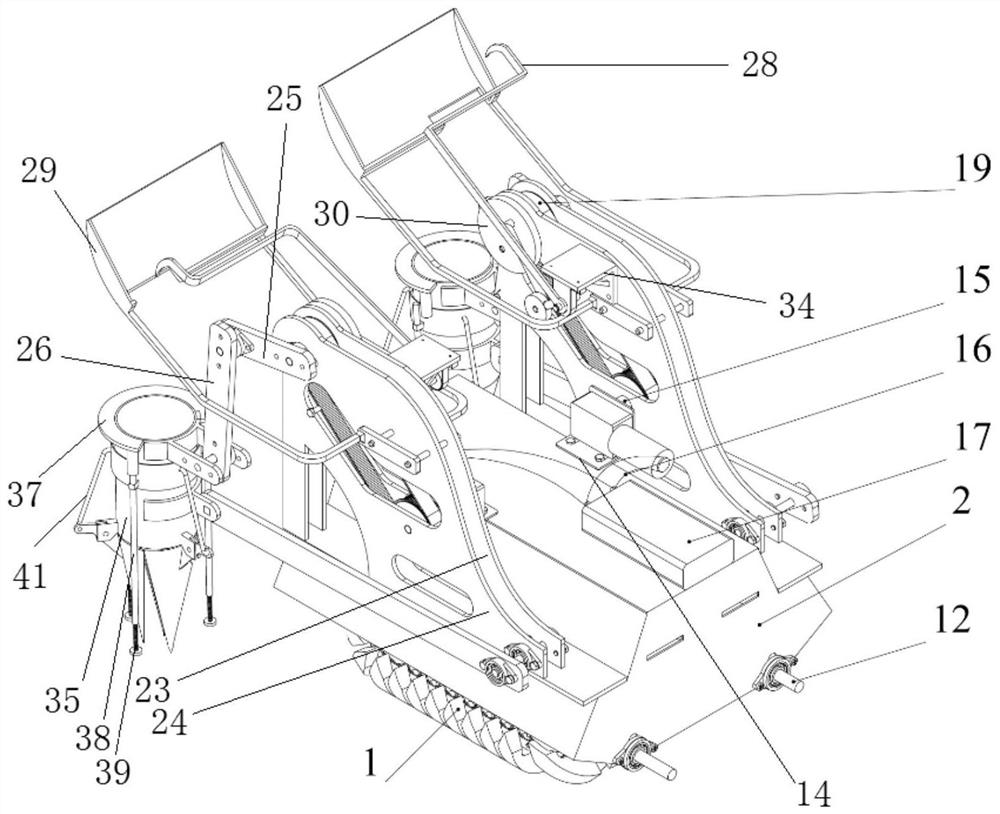

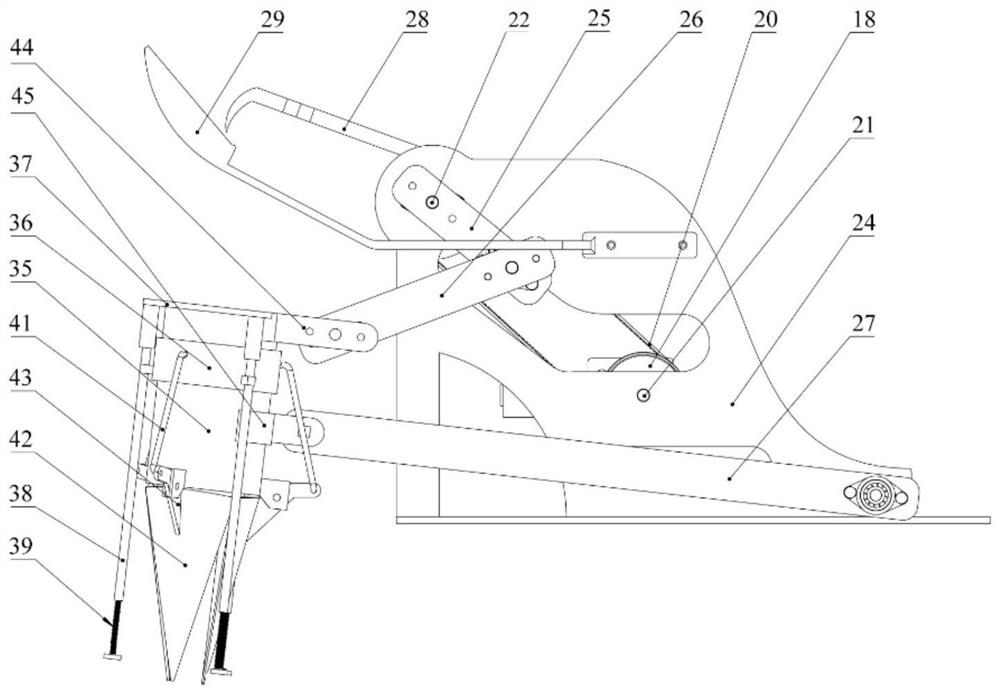

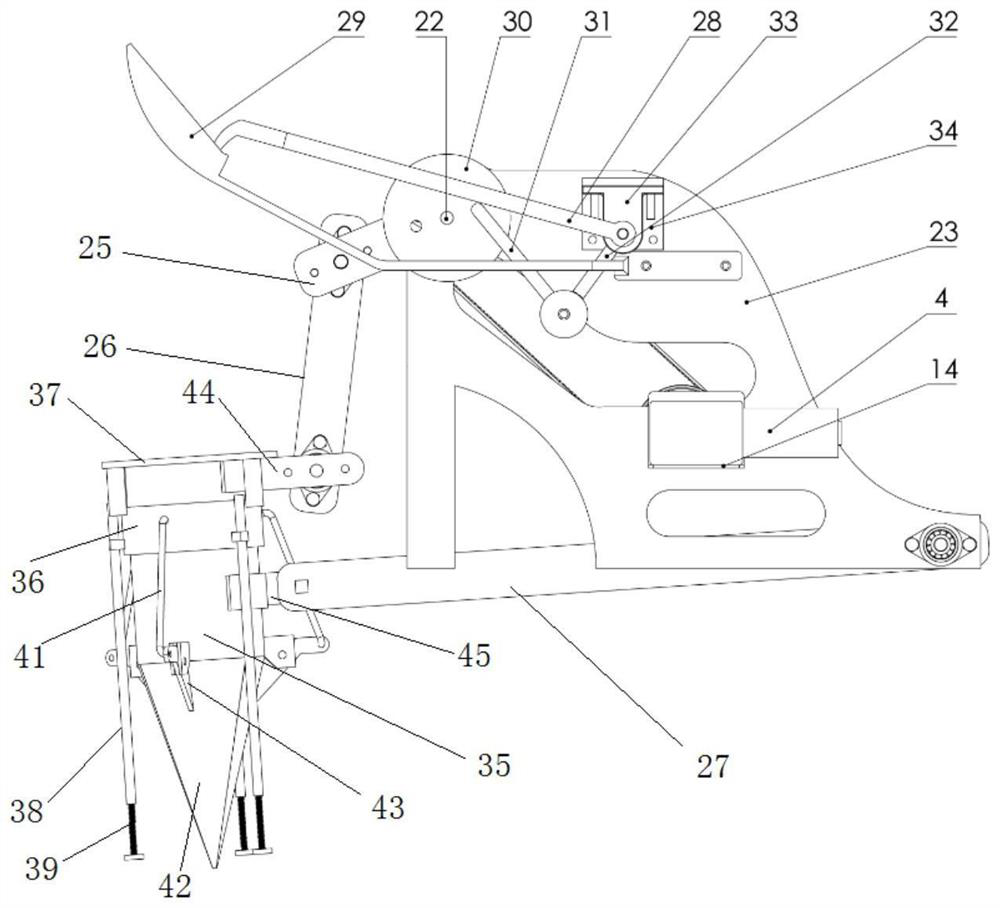

Ridge height self-adaption seedling digging planting machine

PendingCN106538124AImprove uprightnessDeep stabilityTransplantingFurrow making/coveringControl switchSeedling

The invention discloses a ridge height self-adaption seedling digging planting machine. The ridge height self-adaption seedling digging planting machine comprises a ridge height sensor, a digging plough, a rear wheel, a planting part, an operation handrail, a seedling releasing device, a seedling planting gearbox, a connecting rod mechanism, a seedling storage rack, a hydraulic system, a walking gearbox, an engine, a rack and a front wheel, wherein the ridge height sensor is arranged below the rack; the seedling planting gearbox, the walking gearbox and the engine are arranged on the rack; the front wheel is arranged at the front end of the rack; an output shaft of the engine is connected to an input shaft of the walking gearbox; the walking gearbox is provided with three output shafts; the seedling storage rack is arranged at the top of the machine; the seedling planting gearbox is provided with three output shafts; the operation handrail is fixed on the rack; and various control switches are arranged on the operation handrail. The ridge height self-adaption seedling digging planting machine has the advantages of simultaneous completion digging and planting, high degree of automation, stable seedling planting depth and good row spacing consistency.

Owner:SICHUAN RES & DESIGN INST OF AGRI MACHINERY

Method for double sampling loop negative feedback and double sampling negative feedback amplifier

InactiveUS7403068B2Add depthImprove stabilityAmplifier modifications to reduce non-linear distortionNegative-feedback-circuit arrangementsNegative feedbackPhase shifted

A method for double sampling loop negative feedback comprising: obtaining a low-frequency feedback signal from the output of the amplifier; obtaining a high-frequency feedback signal from part of the amplifier of which high-frequency phase shift is low, wherein two-ways sampling signals have the same amplifying phase; combining the two-ways sampling signals together using a series capacitor-inductor double signal combining circuit to form one signal, the signal having low phase shift at both high and low-frequency and being used for negative loop feedback. The invention also provides a double negative feedback amplifier using the method.

Owner:ZHOU ZONGSHAN

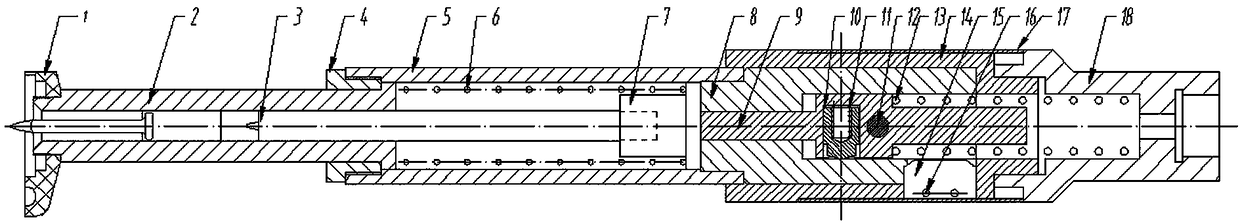

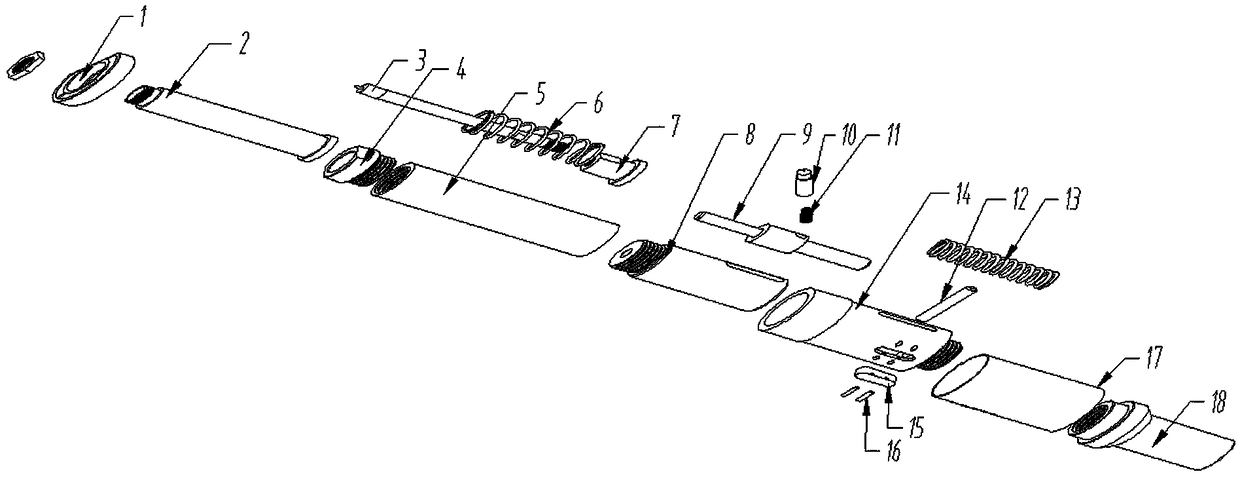

push nailer

The invention discloses a pressing type powder actuated tool, which comprises a firing mechanism and a launching mechanism. The firing mechanism comprises a firing seat and a firing column arranged in the firing seat; the launching mechanism comprises a gun barrel, a gun barrel fixing sleeve, a gun barrel pressure spring and a firing pin; the gun barrel is slidably arranged at one end of the gun barrel fixing sleeve in a sleeving way; the other end of the gun barrel fixing sleeve is fixedly arranged on the firing seat in a sleeving way; the firing pin comprises a firing head, a rod body and a seat body; the firing head and the seat body are connected into a whole through the rod body; the firing head is located in the gun barrel; the seat body is located at the firing end of the firing column; the gun barrel pressure spring is arranged on the rod body in a sleeving way and is located between the gun barrel and the seat body. The pressing type powder actuated tool provided by the invention utilizes the integral type firing pin to replace a firing pin with a split type structure in the prior art, and a firing pin sleeve pipe is removed, so that the problem that drug residues easily enter a gap between the firing pin and the firing pin sleeve is solved, the service life of the powder actuated tool is greatly prolonged, the manufacturing cost of the whole powder actuated tool is reduced, and the whole structure of the powder actuated tool is simplified.

Owner:SICHUAN DEYANG CITY LIXIE

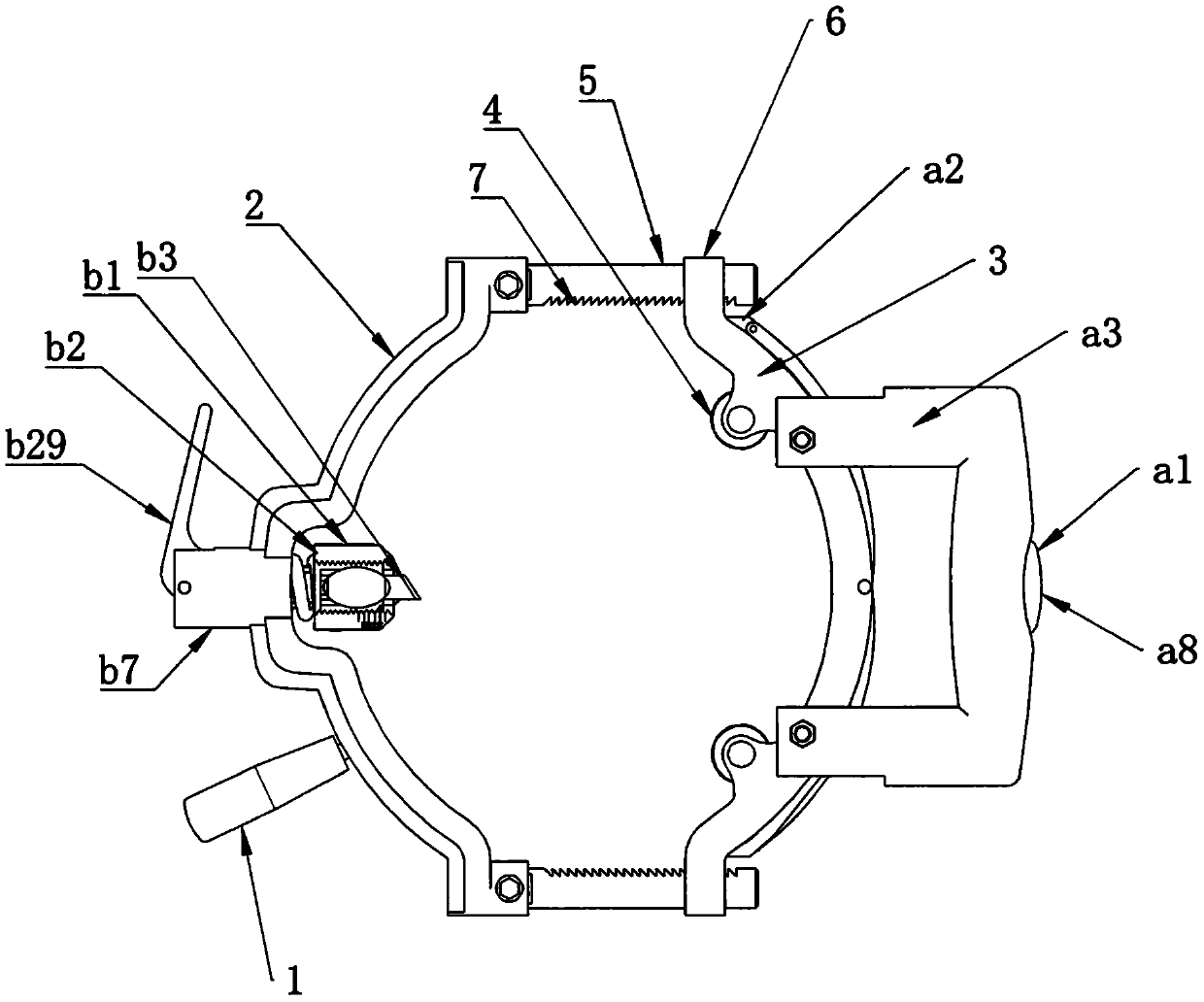

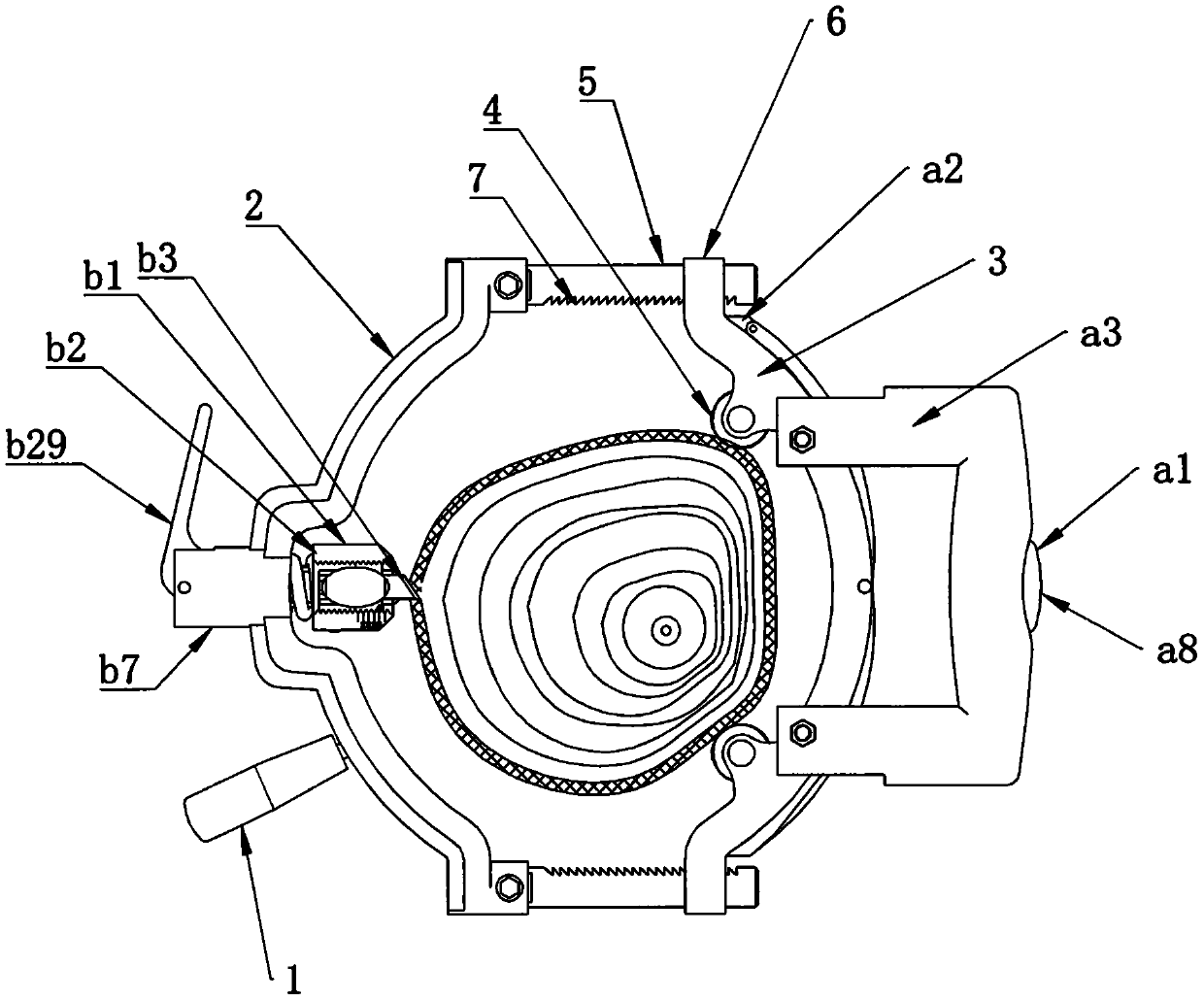

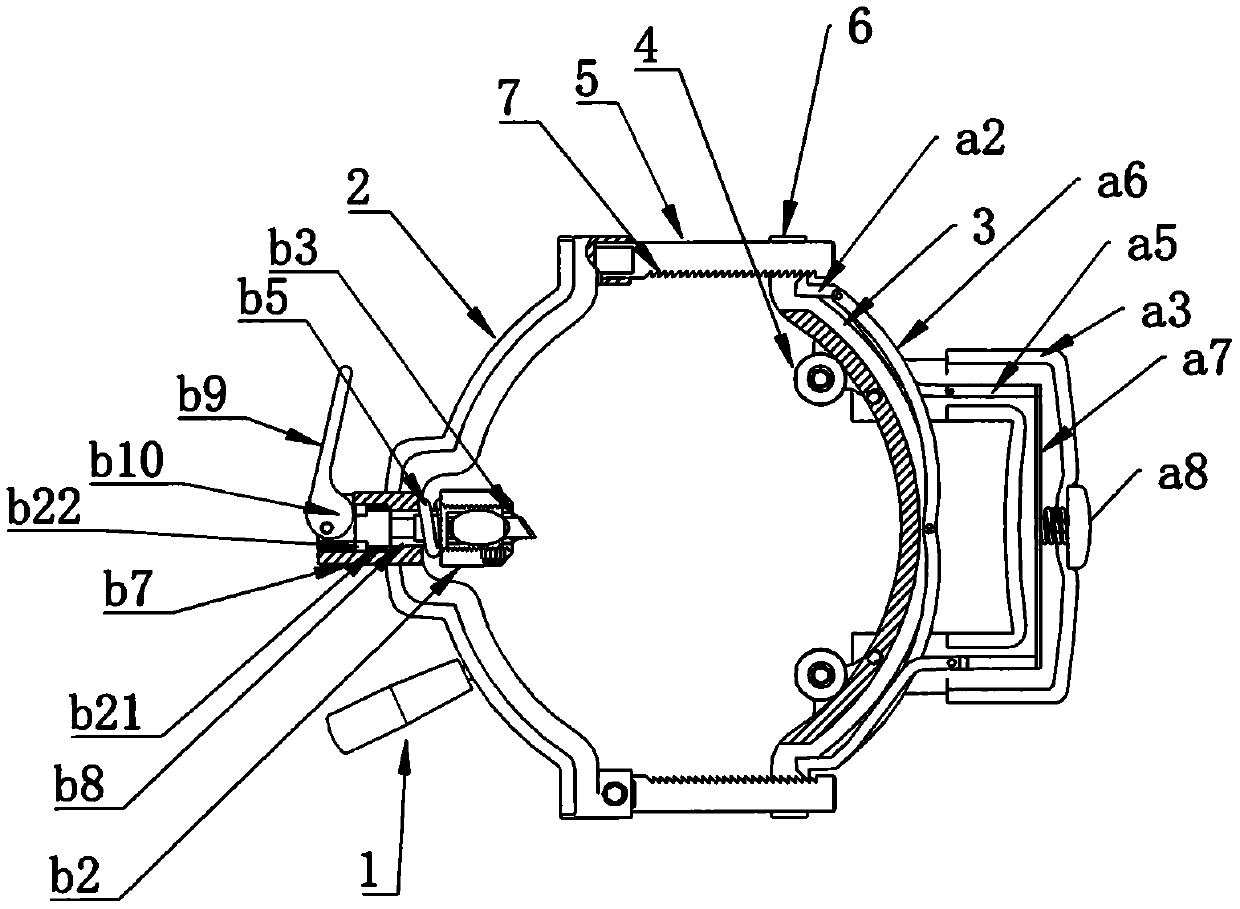

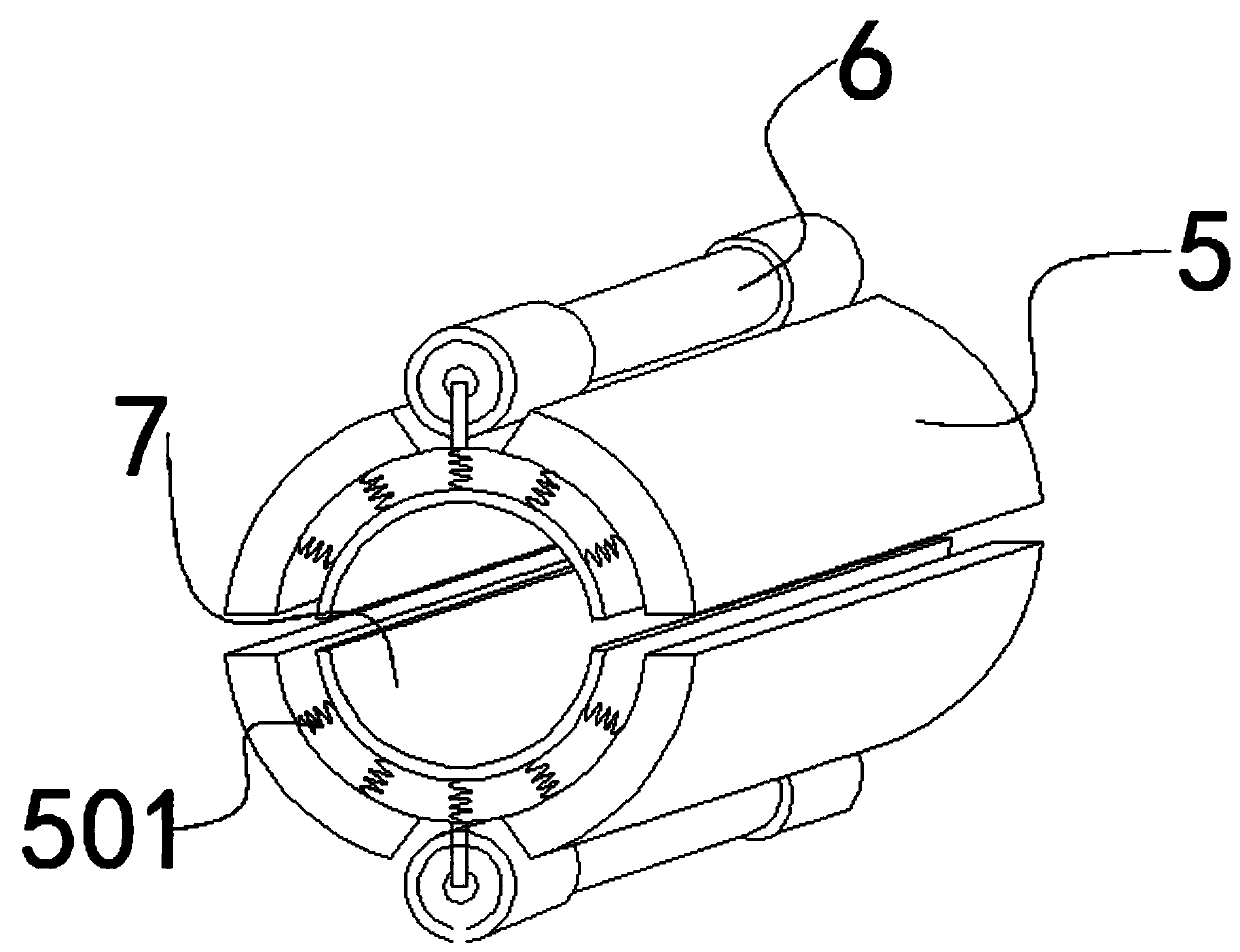

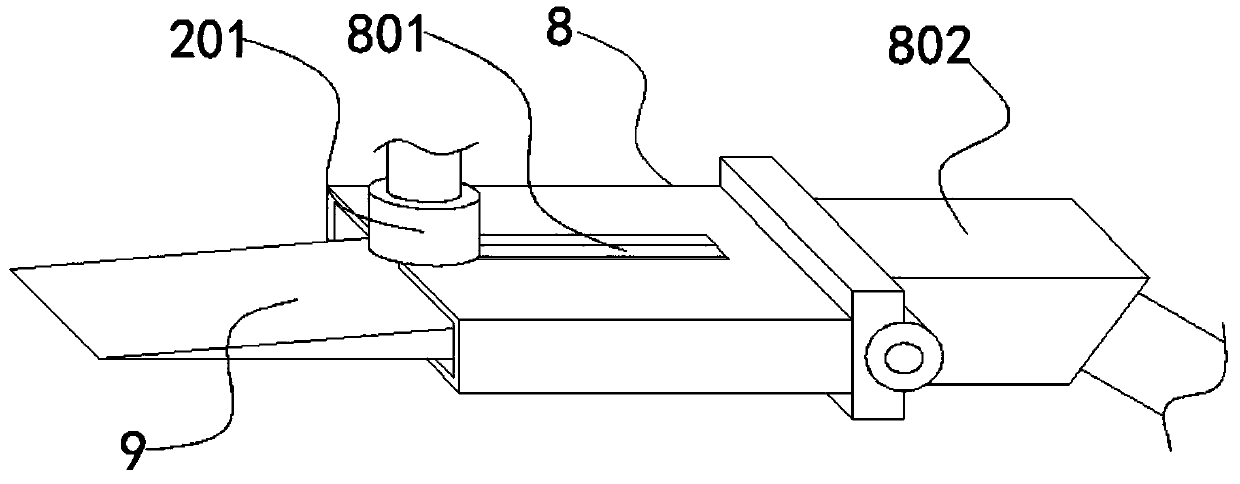

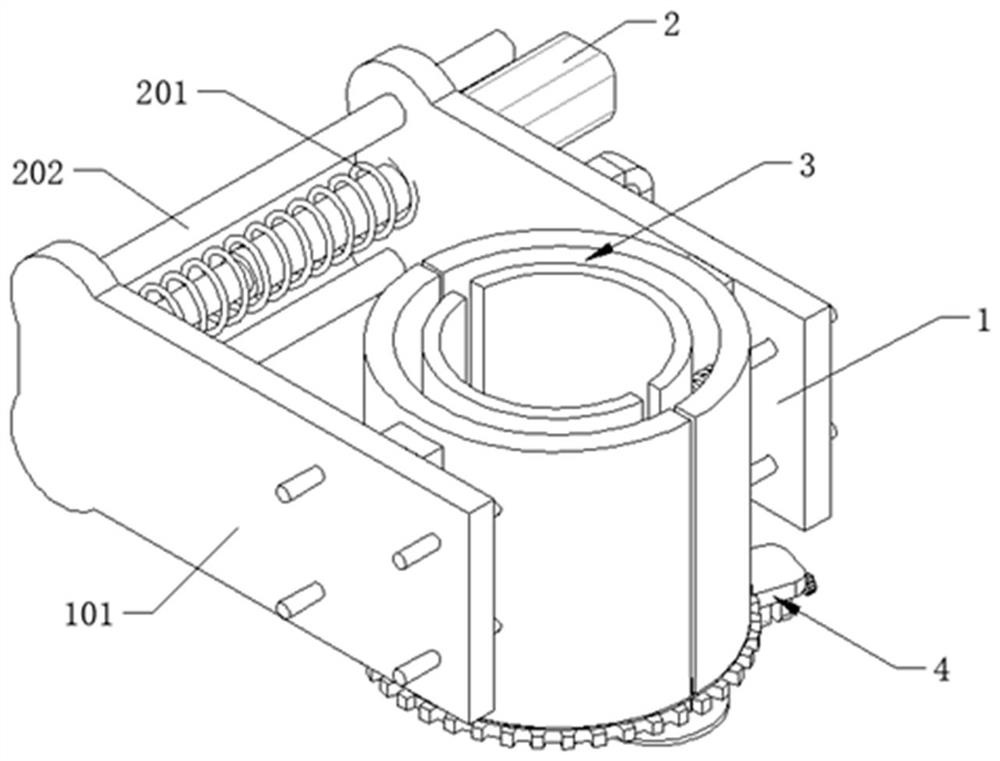

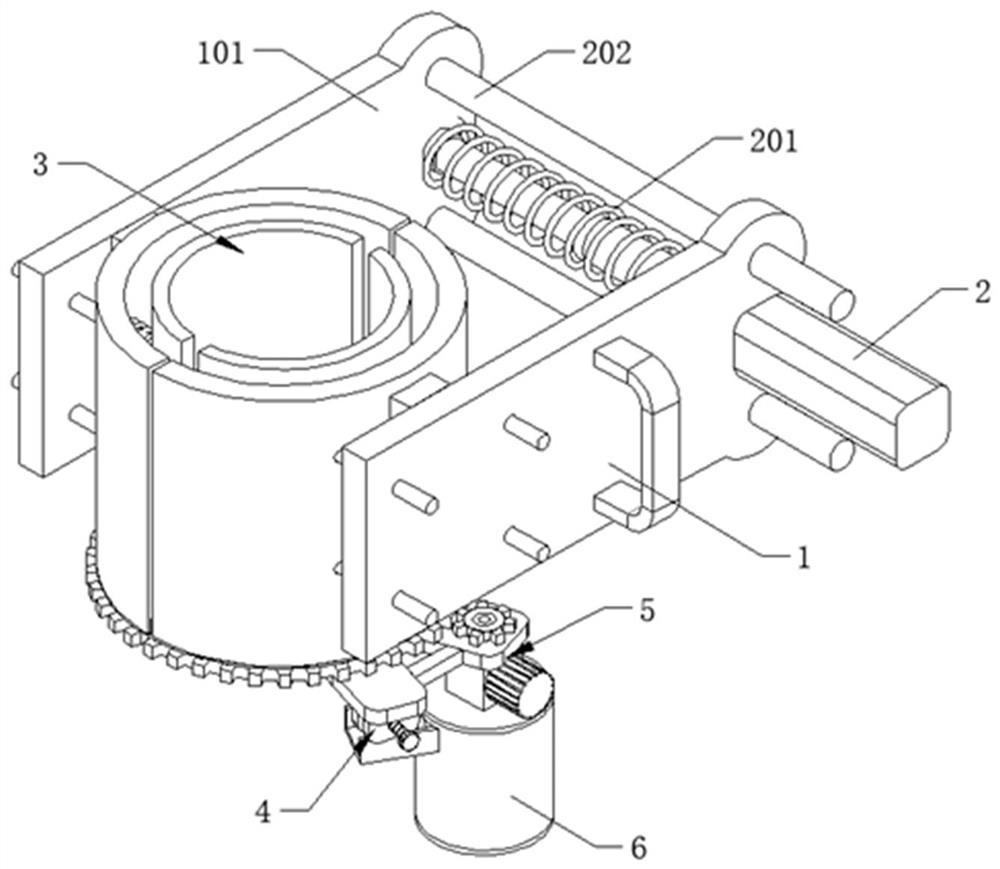

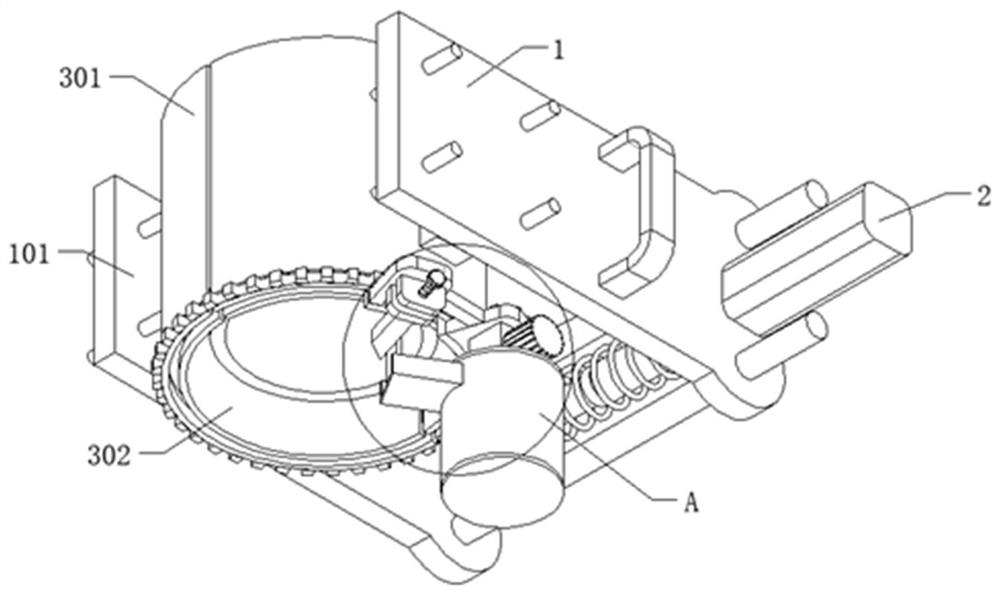

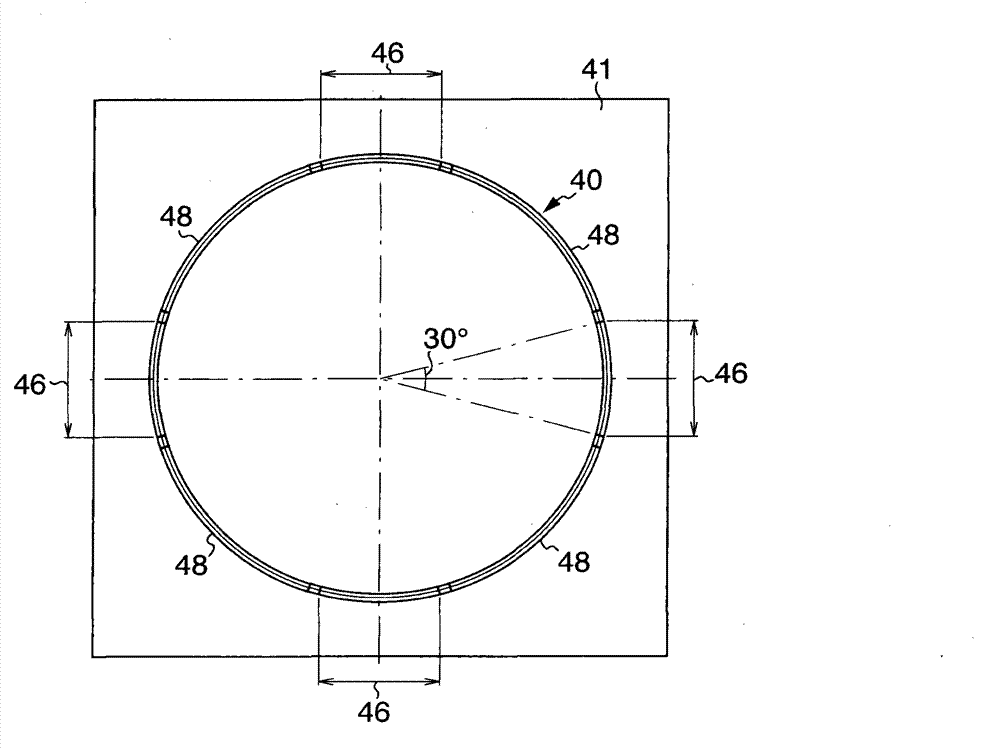

Annular girdling device

PendingCN111165199APlay a guiding roleStable depth of cutCuttersCutting implementsTool bitTree trunk

The invention discloses an annular girdling device. The annular girdling device comprises a main support and an auxiliary support which enclose a containing cavity for containing a trunk, wherein a locking assembly is arranged between the main support and the auxiliary support and used for adjusting the annular diameter of the supports; a tool bit assembly is arranged on the inner side face, corresponding to the trunk, of the main support; a roller is arranged on the inner side face, corresponding to the trunk, of the auxiliary support; the tool bit assembly comprises a tool apron, two blades,a positioning wheel and a first spring piece; the tool apron is arranged on the main support in a sliding manner and keeps deformation pressure in the trunk direction through the first spring piece;the positioning wheel is arranged at the end, facing the trunk, of the tool apron; the two blades are arranged above and below the positioning wheel in parallel; and each blade comprises a cutting part which is back on to the tool apron and extends out in the positioning wheel direction. The annular girdling device is convenient to operate, and the cutting depth and width can be stably controlled.

Owner:JINHUA VOCATIONAL TECH COLLEGE

An integrated equipment for erecting and installing pp pipes

ActiveCN110445083BDeep stabilityStable speedCable installations in underground tubesStructural engineeringTransfer mechanism

The invention discloses a PP pipeline erection and installation integrated device, which comprises a support transfer mechanism and an operation controller, wherein a sunshade work chair is arranged at the top of the support transfer mechanism. In order to solve the problem that workers at the bottom are likely to be injured by crashing during pipeline installation and erection, the pipelines aredifficult to socket weld, insufficient in socket welding depth, not ideal in socket welding effect, likely to separate and fracture, and cannot be socket welded after accumulated, and manual socket welding has a risk of slipping so that workers fall down to cause unnecessary casualties, the support transfer mechanism, the sunshade work chair and an automatic socket welding device are designed to socket weld pipelines at different heights, so as to facilitate equipment transfer, provide an operation platform, stabilize the socket welding efficiency, achieve autonomous pipeline pillow placement,achieve mechanized socket welding, meet the socket welding strength requirements, reduce the time and scope of work activities at the bottom in a work area, socket weld high pipelines, and reduce therisk of climbing.

Owner:杭州鸿顺管业有限公司

Grafting knife suitable for rootstock ends

The invention provides a grafting knife suitable for rootstock ends. The grafting knife suitable for rootstock ends comprises a positioning rod and a water seepage port, wherein a first cross arm anda second cross arm are rotatably connected to the outside of a bearing shaft jointly, a reset spring is fixedly connected to a portion between the first cross arm and the second cross arm on one side,and a water storage cavity is fixedly connected to the upper portion of the second cross arm on one side. The other side of the first cross arm is in contact with the lower edge of a push-type pump,the interior of a cutting knife and the interior of a pressure-bearing rod are hollow, and a guide pipe penetrates through the pressure-bearing rod and extends to the interior of the cutting knife. When the first cross arm and the second cross arm are stressed, the push-type pump can be pressurized, growth liquid in the water storage cavity can be pumped out by the push-type pump, and is guided into the cutting knife through the guide tube, the growth liquid is drained from the water seepage port, and along with cutting of the cutting knife, the growth liquid is just smeared inside the notch of a rootstock.

Owner:张卫

Girdling device based on agricultural planting maintenance and using method of girdling device

ActiveCN111990092AWon't hurtDeep stabilityCuttersCutting implementsFruit treeAgricultural engineering

The invention discloses a girdling device based on agricultural planting maintenance and a using method of the girdling device, and belongs to the technical field of agricultural planting auxiliary devices. The girdling device based on the agricultural planting maintenance comprises a first fixing plate, a second fixing plate, a fixing assembly and a girdling assembly, wherein an air cylinder is connected between the first fixing plate and the second fixing plate; the fixing assembly is connected to the inner walls of the first fixing plate and the second fixing plate; a second supporting plate is slidably connected to the bottom wall of the fixing assembly; and the second supporting plate is connected with the girdling assembly through a connecting plate, a transmission assembly is connected to the bottom wall of the second supporting plate, a gear ring is arranged on the outer wall of the fixing assembly and connected with the output end of the transmission assembly, a material collecting barrel is further arranged at the bottom of the transmission box, and a crushing assembly is arranged in the material collecting barrel. The girdling device can effectively improve the stabilityperformance in the girdling process of fruit trees, improves the girdling effect of the fruit trees, can automatically rotate for girdling, reduces the labor intensity, and improves the girdling efficiency.

Owner:萧县禾盛种业有限公司

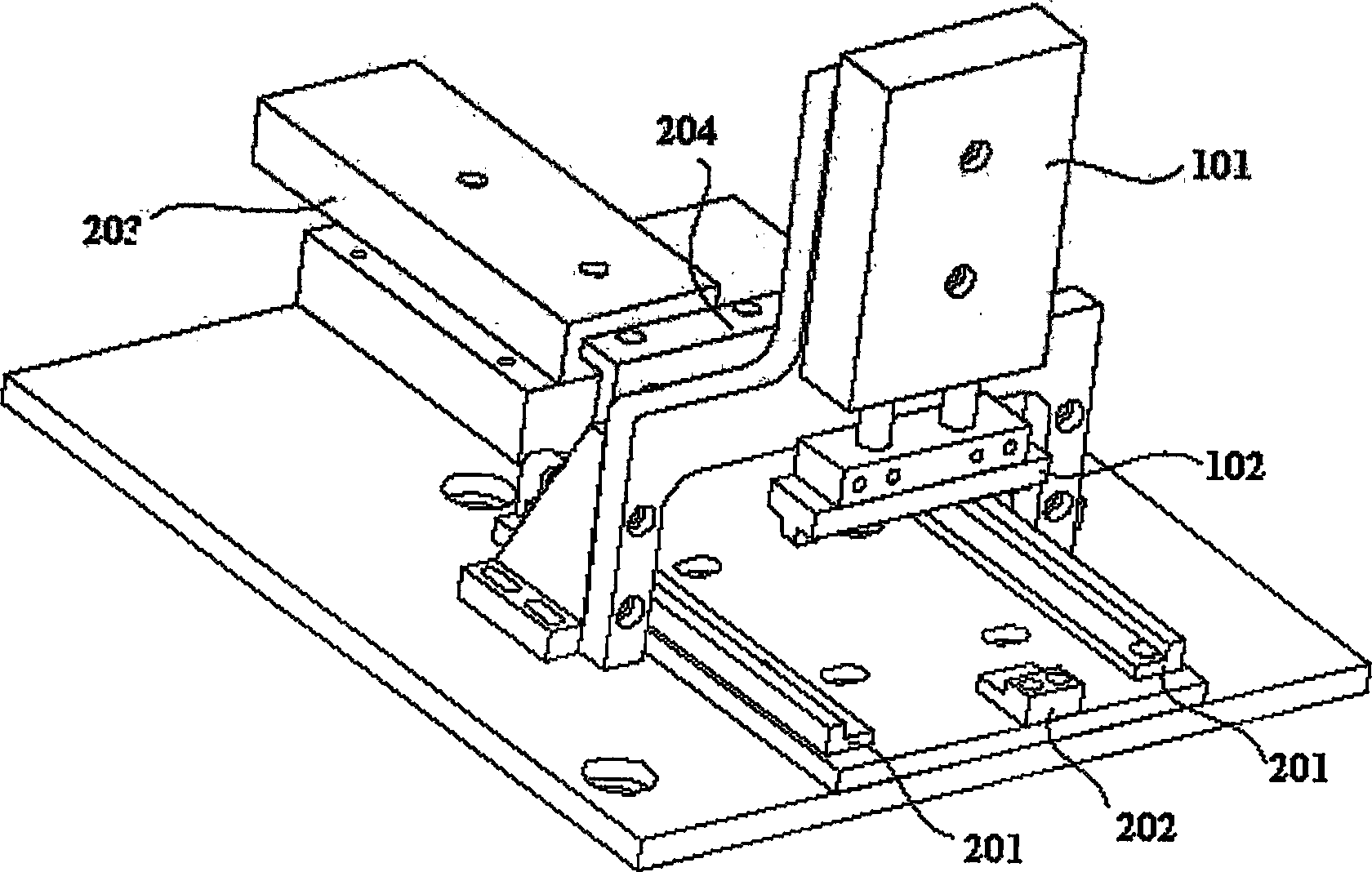

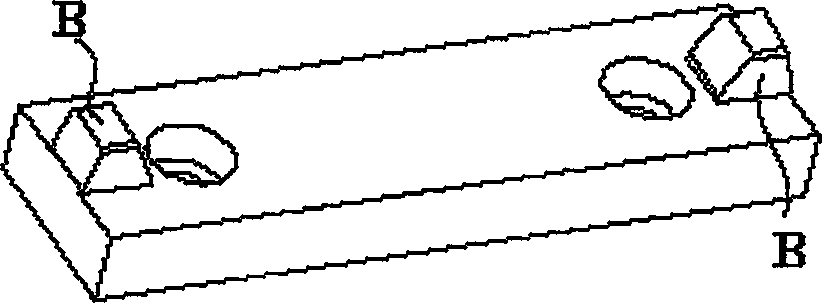

Equipment for automatic riveting butt jointed seal ring of separability type hard disk drive

InactiveCN1873824AReduce workloadImprove work efficiencyReducing physical parameters of carriersHard disc driveButt joint

The invention discloses a seal ring automatic riveting device for separable hard disk driver (HDD) butt, comprising fixing device and riveting device, where the fixing device can fix the driver casing seat to make the to-be-riveted slot opening upward and the riveting device comprises drive mechanism and active head, the active head has horny salience adapted to the slot and can move up and down under the drive of the drive mechanism. And its advantages: it adopts simple fixing and riveting devices to mechanically riveting butt seal ring in the separable HDD, largely reducing workload of operators, and raising working efficiency; and assuring stability and reliability of product quality.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

Maintenance method for iron notch of European smelting furnace

The invention discloses a maintenance method for an iron notch of a European smelting furnace. The method comprises the following operation steps that 1) a water-free stemming iron plugging port withgood quick-drying and quick-hardening performance is selected, and 1-2% of silicon nitride and 2-3% of aluminum micropowder are added into stemming, the slag iron scouring resistance of the stemming is improved, sintering of stemming in a duct is accelerated in a mode of pre-opening of the iron notch and baking and temperature raising of an iron notch channel, the slag iron scouring resistance ofthe stemming is further improved, and the iron tapping amount of a single furnace is controlled below 450 tons / furnace by controlling the iron tapping interval time; 2) an oxygen supply parameter above the iron notch is controlled, and oxygen supply at an air port above the iron notch is stopped; 3) tapping time is controlled to tap clean slag iron as much as possible; and 4) sectional mud beatingis carried out, wherein the first section is only used as a channel for sealing the iron notch, after 10 seconds of stopping, after half coke and coke in a cavity at the front end of the iron notch settle down, a second section of stemming starts to be beaten to form an initial stemming bag, then after 10 seconds of stopping, a third section is beaten, and all the stemming is beaten in sequence in four sections, wherein the beating amount of each section is 40 L, and it is ensured that the beaten-in stemming forms a stable stemming bag in a furnace cylinder.

Owner:XINJIANG BAYI IRON & STEEL

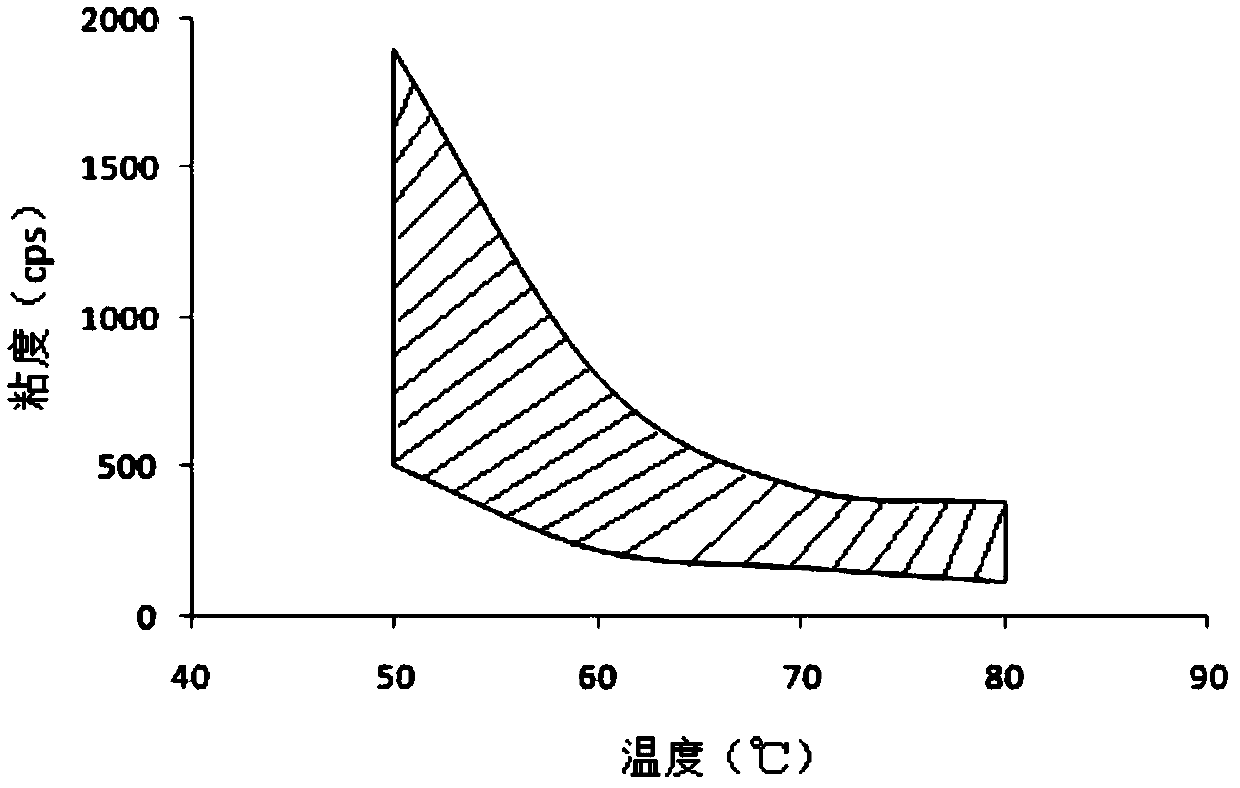

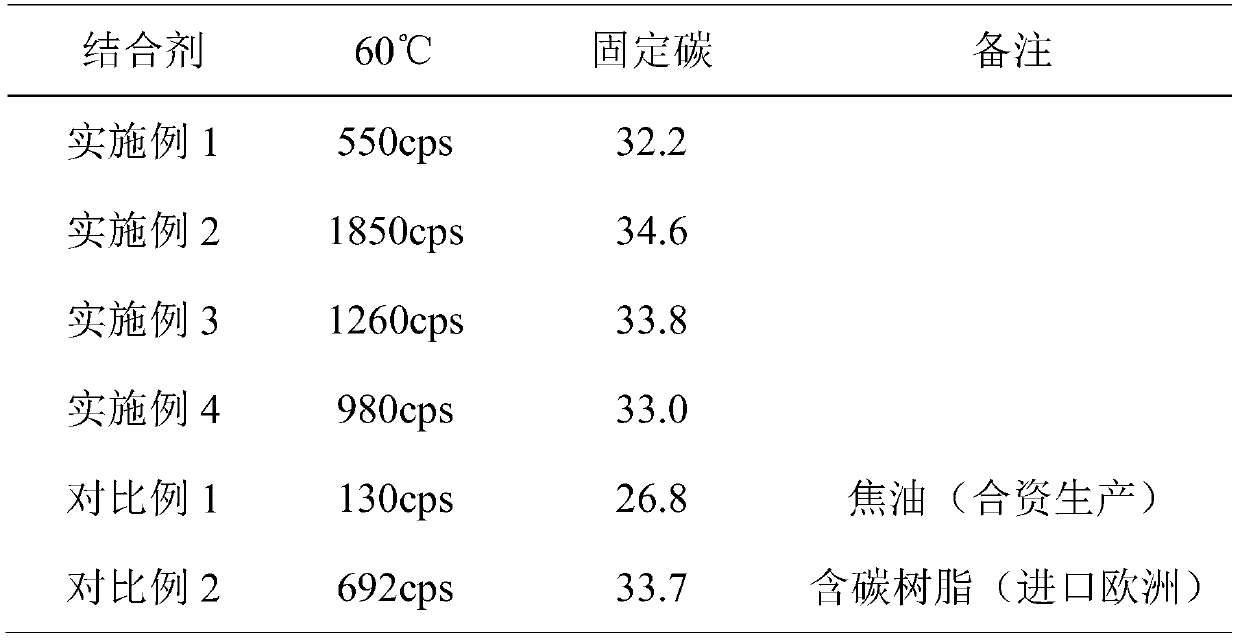

Binder for blast furnace clay and blast furnace clay

The invention discloses a binding agent for a blast furnace stemming and the blast furnace stemming. The binding agent is prepared from, by mass, 40-70 parts of coal tar distillation kettle substrate, 30-60 parts of novolac resin and 2-5 parts of surfactant, wherein a preparation method of the coal tar distillation kettle substrate is comprises the steps that coal tar is added to a high-temperature ceramic reaction kettle, heating and stirring are performed at the temperature of 230 DEG C for 1.5-2.5 hours, and the coal tar distillation kettle substrate is obtained after reaction and degassing. A blast furnace stemming material needs additional 12-17.5 parts of binding agent. The blast furnace stemming made from the binding agent and the blast furnace stemming material is environmentally friendly, smokeless and outstanding in durability effect, really protect refractory bricks at the lower portion of a tap hole, and accordingly the service life of a blast furnace is prolonged. The blast furnace stemming made from the binding agent and the blast furnace stemming material is high in sintering speed, is resistant to erosion and scouring, is environmentally friendly and smokeless, can completely replace imported products and has the important significance on supporting of energy saving and environmental protection of the iron-making industry in our country, prolonging of the service life of blast furnaces and technical progress.

Owner:XUZHOU SUPAI HIGH TEMPERATURE NEW MATERIAL CO LTD

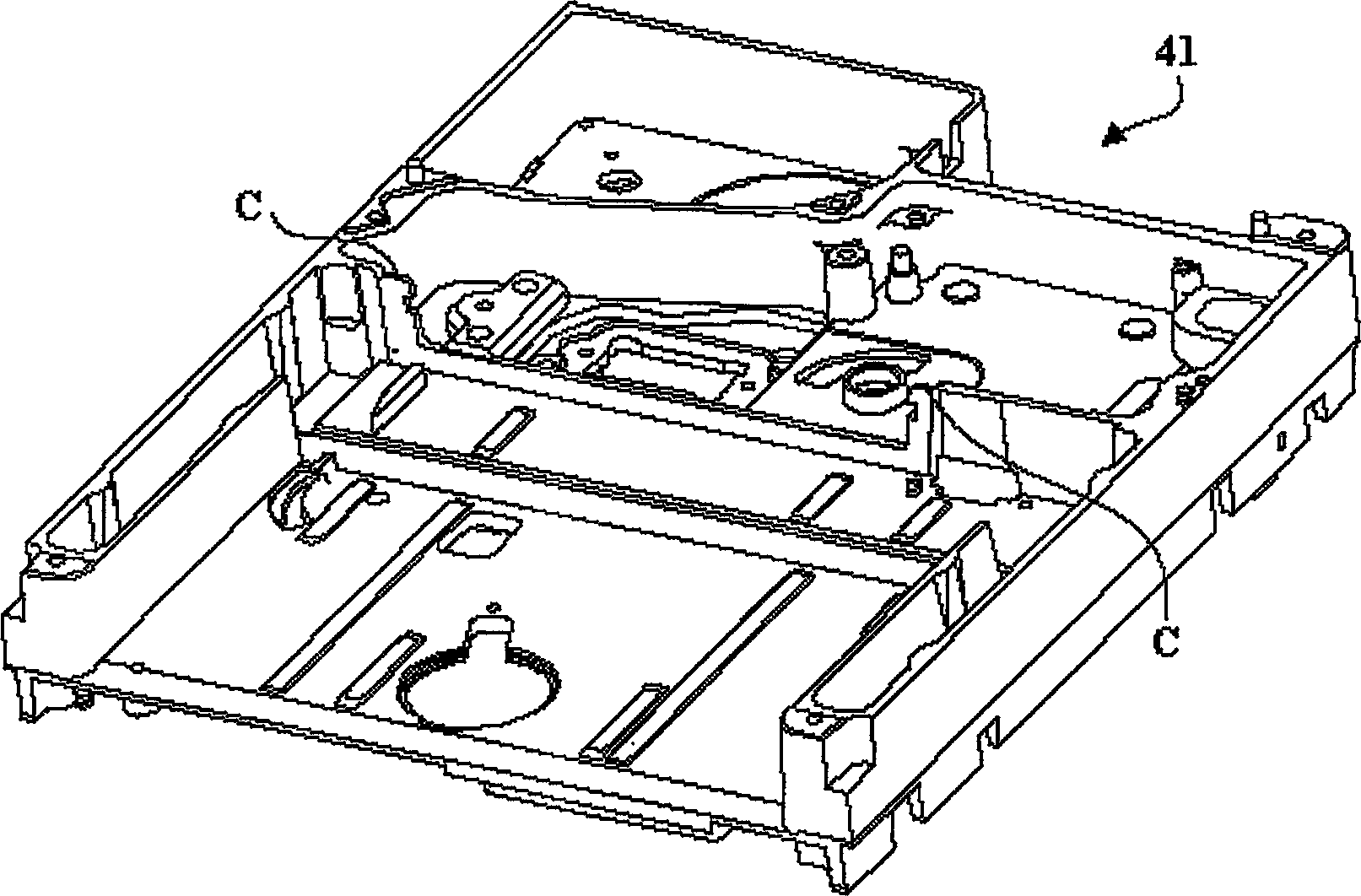

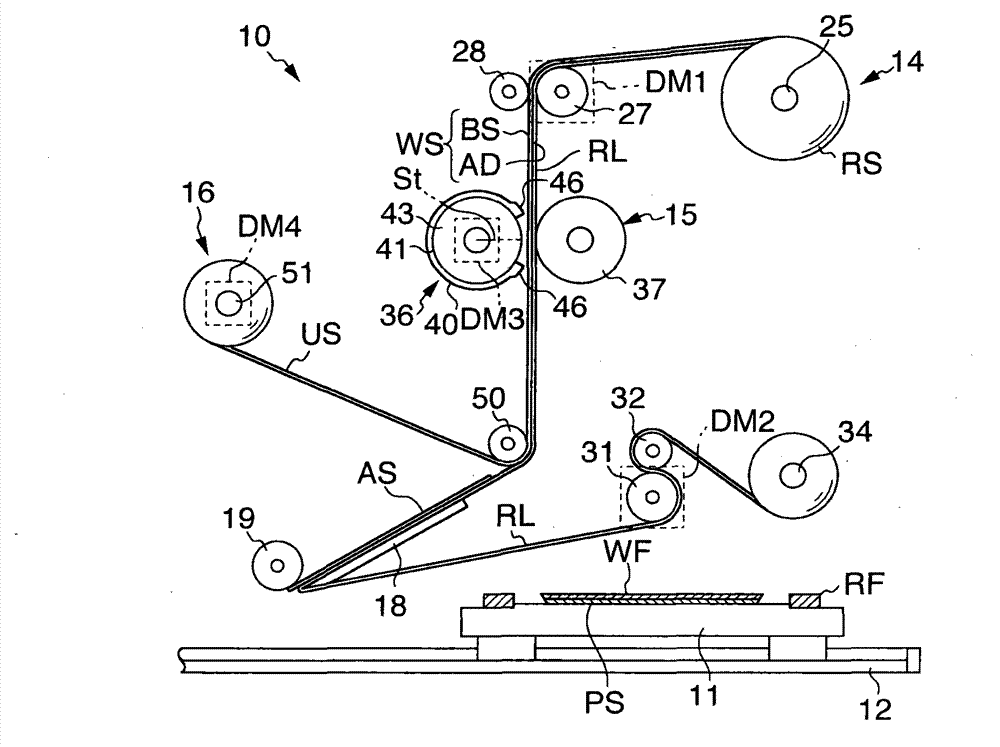

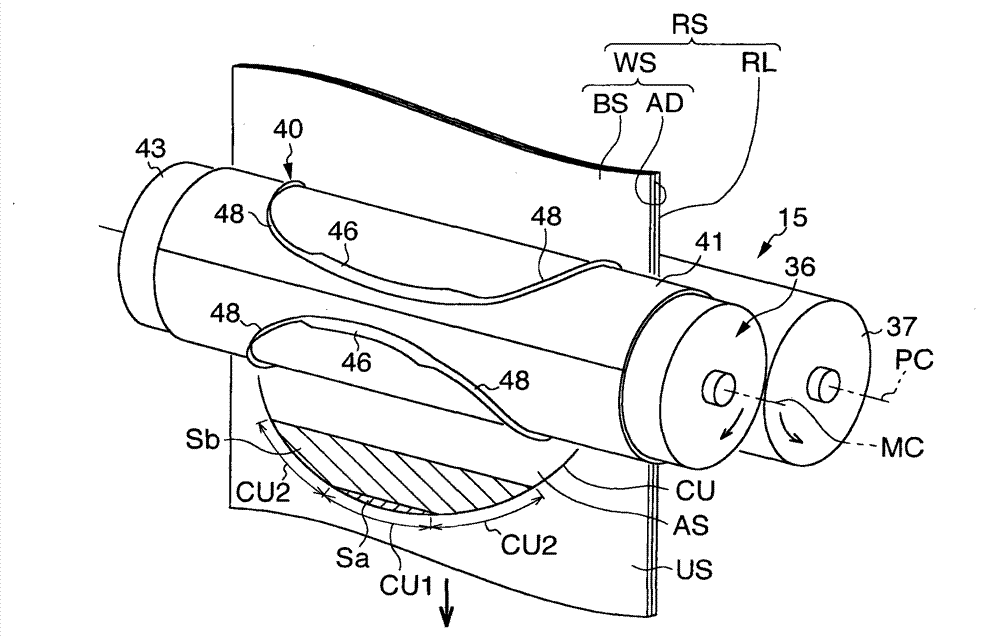

Apparatus and method for bonding sheet, and apparatus and method for manufacturing sheet

ActiveCN103035558AWell formedChange positionSemiconductor/solid-state device manufacturingBand shapeMechanical engineering

The invention provides an apparatus and a method for bonding a sheet, and an apparatus and a method for manufacturing the sheet, which can well achieve the formation, the stripping and the bonding of a bonding sheet even when a stripping sheet is thinned. The sheet bonding device (10) comprises a discharging unit (14) discharging raw material rolls (RS) formed by temporarily bonding a band sheet (WS) on a band-shaped stripping sheet (RL); a cutting unit (15) forming a cut port (CU) on the band sheet (WS) and further forming a bonding sheet (AS) on the inner side of the cut port (CU); and a stripping plate (18) making the bonding sheet (AS) stripped from an initial stripping area (discharging direction front Sa) to a lower stripping area (inner side area SB). The cutting unit (15) is arranged in a way to form a cut port deeper than the initial cut port (CU1) corresponding to the initial stripping area (Sa) and a lower cut port (CU2) corresponding to the lower stripping area (Sb).

Owner:LINTEC CORP

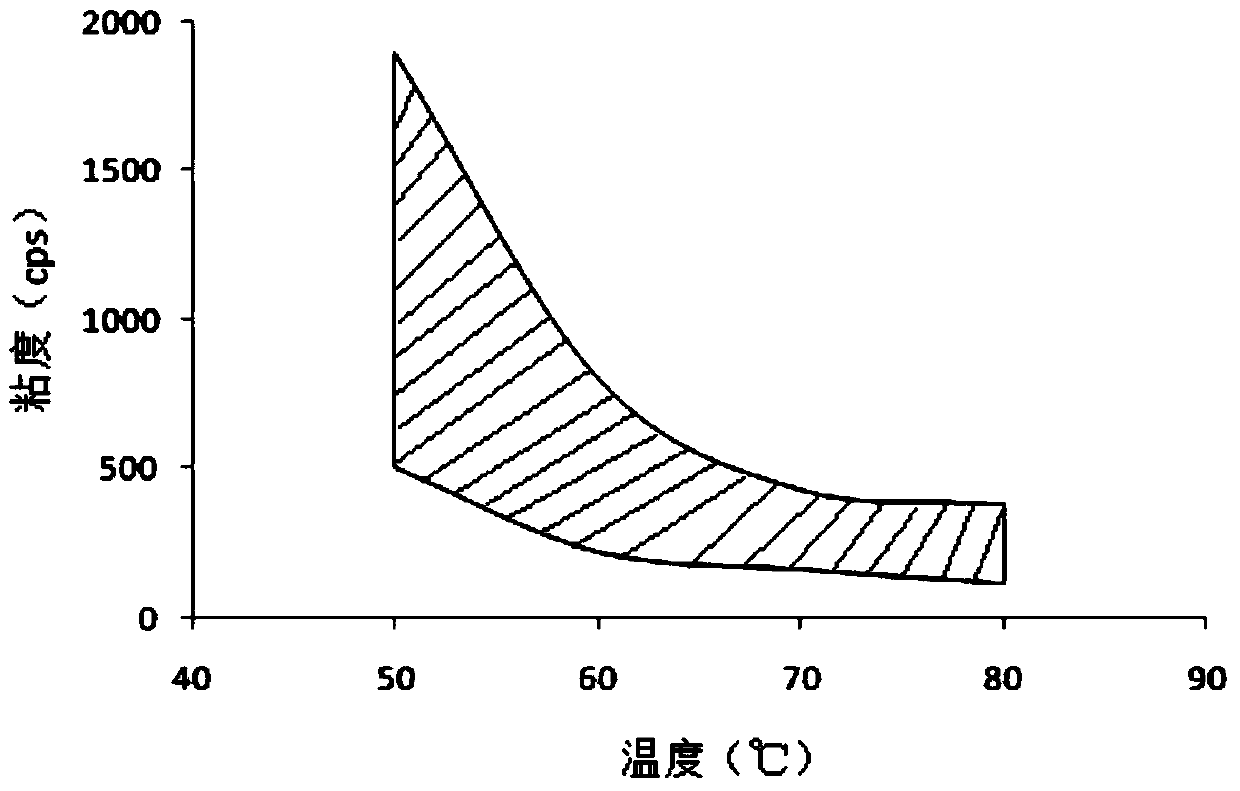

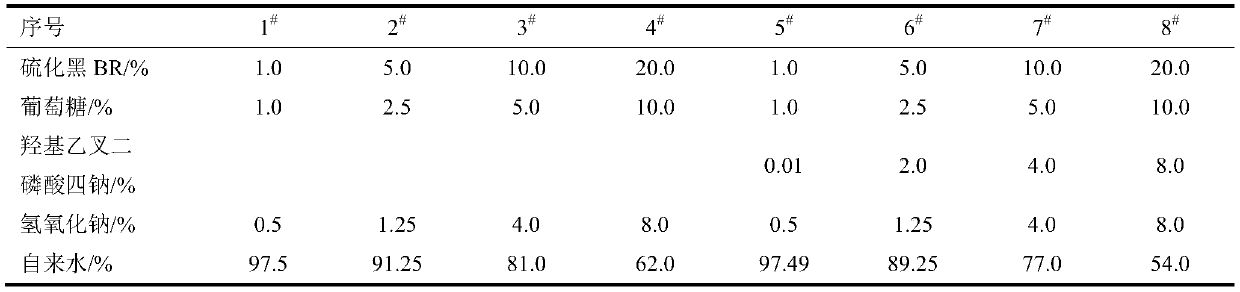

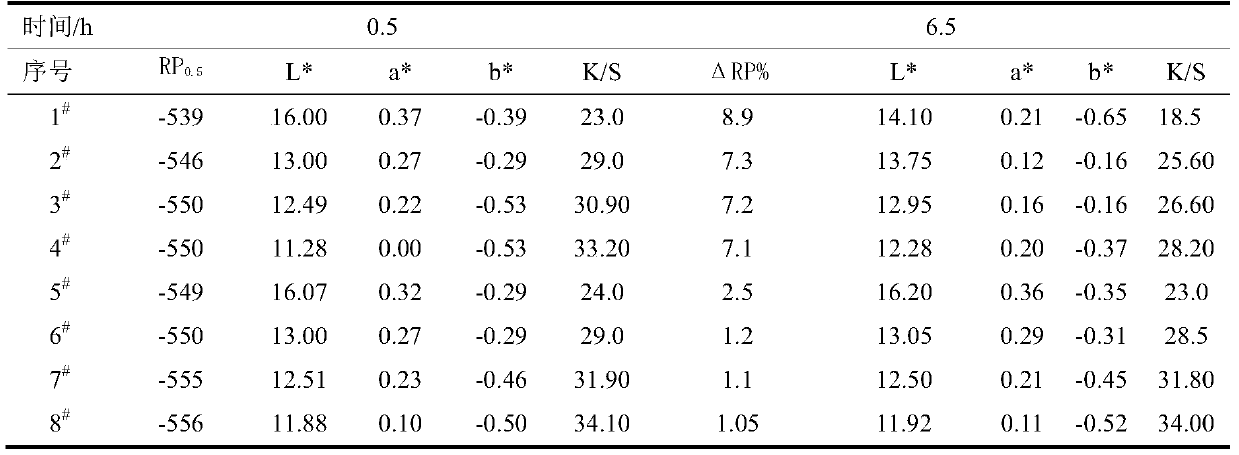

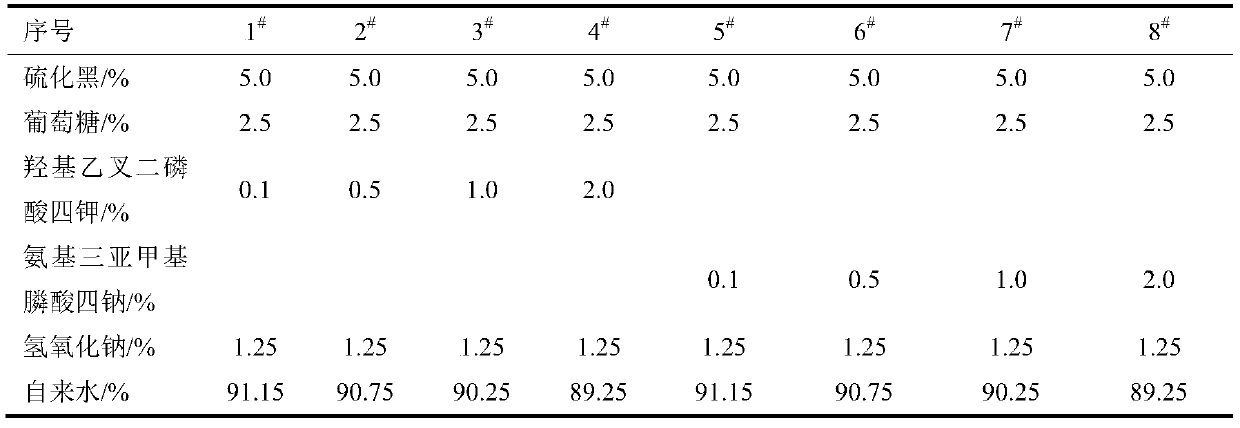

A group of compounds for stabilizing the reduction potential and dyeing performance of sulfur dyeing systems and methods of use thereof

The invention relates to a group of compounds for stabilizing the reduction potential and the dyeing performance of a sulfur dye dyeing system, and a use method thereof. 0.1-20.0 wt% of an organophosphate compound is added to a sulfur dye / glucose / sodium hydroxide system, and then the obtained system is used for sulfur dye dyeing. A sulfur dye forms a soluble leuco compound under the reduction effect of a glucose / sodium hydroxide system, cellulose fibers are dyed with the soluble leuco compound, and the organophosphate compound is added to effectively stabilize the reduction potential in the reduction system and realize the stability of the dyeing performance. Compared with organophosphate-free reduction systems, the reduction system reduces the reduction potential reduction rate after 6 hprolongation at 90 DEG C to 1-2% from 6-8%, improves the color depth by 20% or more, basically keeps the color tone and the dye depth of a fabric basically stable. An effective way is provided for solving environmental pollution in the dyeing process of the sulfur dye and realizing the continuous and stable industrial application of glucose in the dyeing process.

Owner:石家庄美施达生物化工有限公司

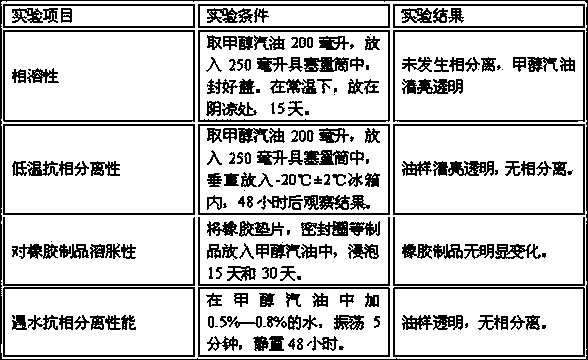

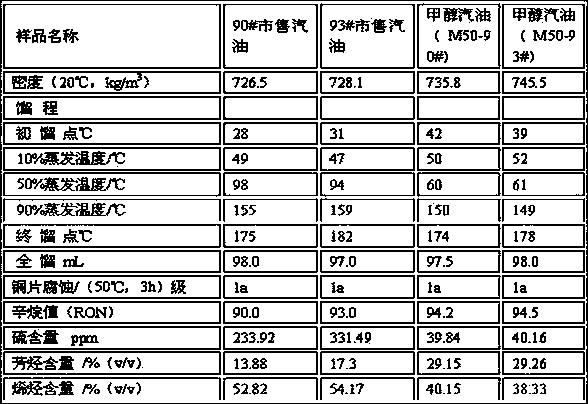

Additive for producing high-performance methanol gasoline

The invention discloses a technical formula of an additive for producing high-performance methanol gasoline. The technical formula of the additive for producing the high-performance methanol gasolinemainly comprises the following components by weight percentage: 20-30 percent of isobutanol, 0.1-2.5 percent of 2,4-di-tert-butyl-4 cresol, 25-40 percent of isoamylol, 8-16 percent of dioctyl phthalate, 3-10 percent of dioctanol, 0.05-0.1 percent of methylcyclopentadienyl manganese tricarbonyl, 1-3 percent of dicyclohexylammonium nitrite, 0.5-1.5 percent of glyceryl triacetate and 0.5-3 percent of mixture of aldehyde condensation compounds. The methanol gasoline prepared by the additive has the advantages that methanol and gasoline can be stably and mutually soluble, rubber and metal parts of an automobile are protected; cold start of the automobile is easily realized, the combustion of the gasoline is sufficient and the power of the automobile is enhanced.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Preparation of Ti-6Al-4V titanium alloy large-sized casting ingot

ActiveCN101476050BStable sequential solidification processSequential solidification process controllableMelting tankPower flow

The invention relates to a large-scale ingot casting method for preparing Ti-6Al-4V titanium alloy, the invention adopts multiple-time vacuum self-consuming smelting method on the basis of routine technique, adopts a 'constant speed' finished product smelting method and adopts smelting speed control parameters to control the technological parameters in the finished product smelting process.The invention is characterized in that the smelting speed control parameter is 20-32Kg / min; the real smelting weight is on-line measured each second or according to a set time and an instant smelting speed is the ratio of the real smelting weight and the measurement time interval; if the smelting speed is higher than a desired value, the smelting current is then reduced; if the smelting speed is lower than the desired value, the smelting current is then increased. By using the control method, temperature field can be controlled effectively, distribution coefficient can be optimized, stabilization ofthe from and depth of the melting bath can be assured, which make the ingot casting sequence and solidification process stable and controllable, and homogeneity of components of large-scale ingot casting can also be assured.

Owner:BAOJI TITANIUM IND CO LTD

Device and method for transplanting seedlings in dry land

ActiveCN110122006BEvenly spacedAvoid Manual TransplantingTransplantingFurrow making/coveringReciprocating motionAgricultural engineering

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com