Patents

Literature

74results about How to "Stable Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

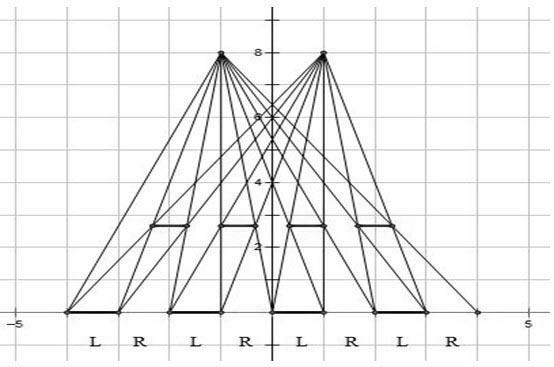

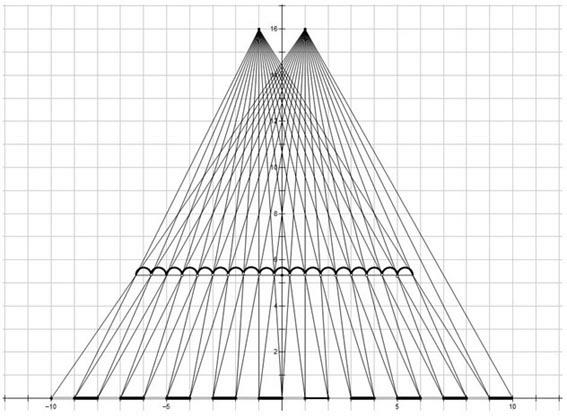

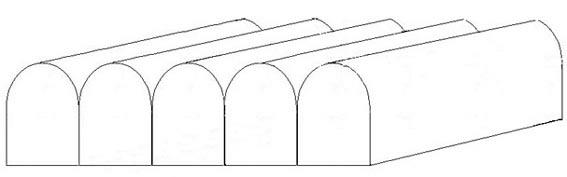

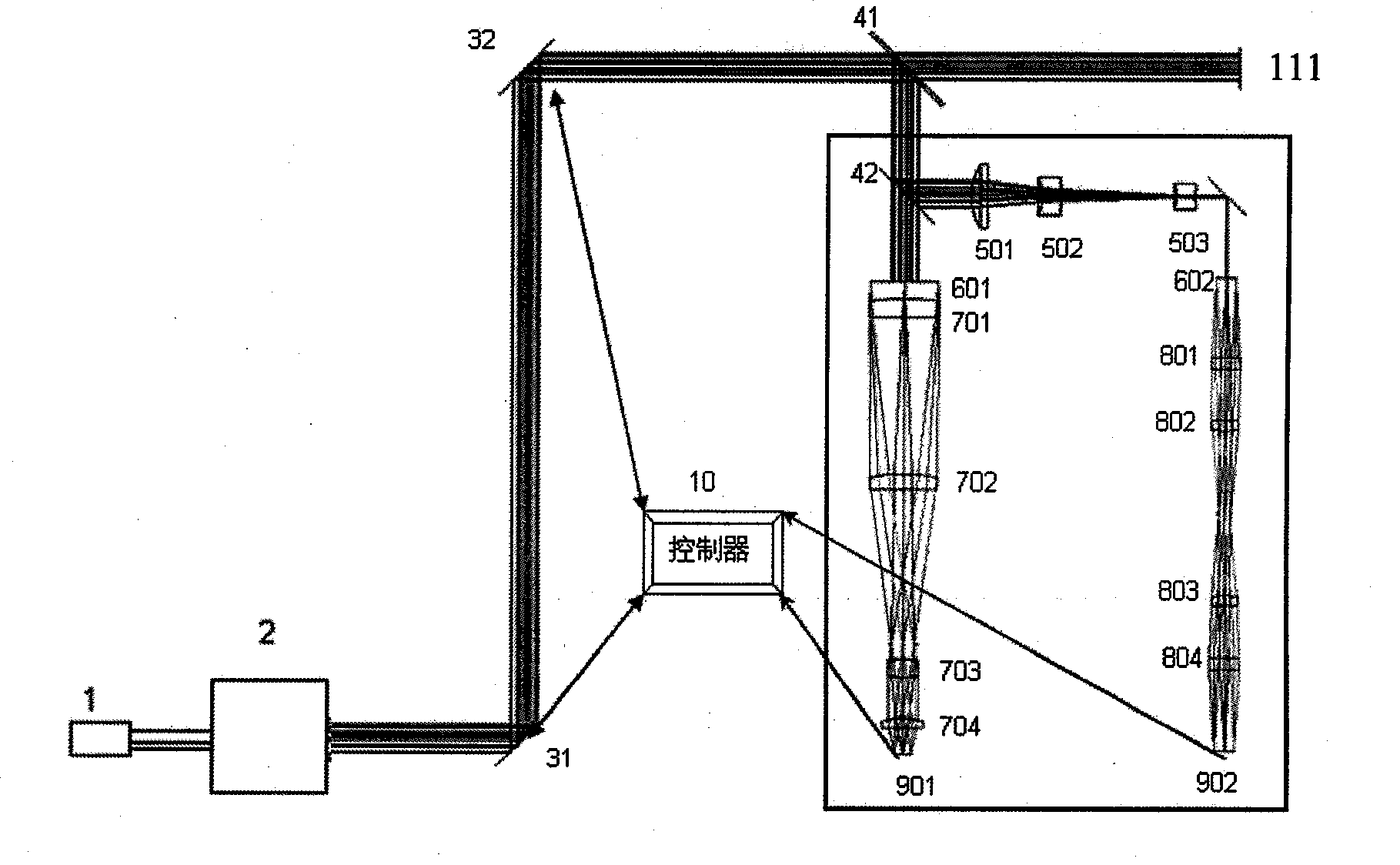

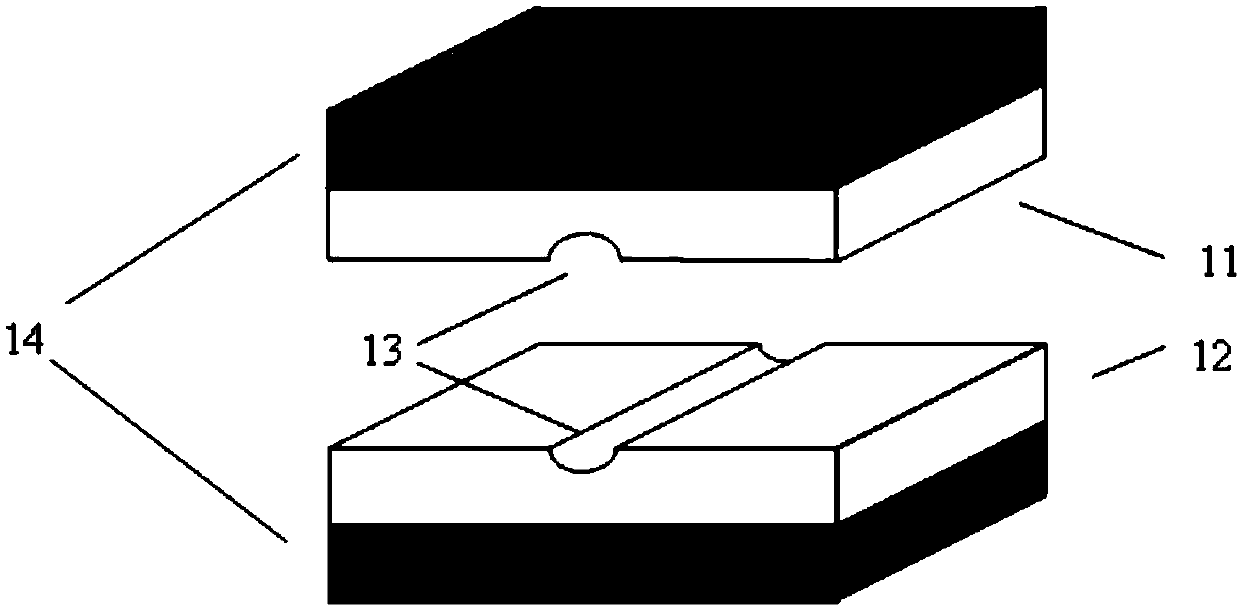

Stereoscopic display

InactiveCN102207632AEnsure system brightnessGuaranteed resolution and overall color uniformityNon-linear opticsOptical elementsLens effectImage resolution

The invention relates to a stereoscopic display. On the basis of an electric control varifocal lens technology, the distribution and fluctuation degree of the refractive index of a holographic polymer dispersed liquid crystal box is changed by responding to voltage applied between a linear transparent electrode and a transparent conductive film so as to achieve a lens effect on visible light in the control voltage direction. A period can be switched between a two-dimensional (2D) working mode and a three-dimensional (3D) working mode and dynamic tracking regulation can be carried out according to the position of a user. The stereoscopic display is compatible with the conventional liquid crystal panel manufacturing technology, and has simple process and low cost. An electric control naked eye three-dimensional imaging effect is achieved and the brightness of a system is not lost. A display placement state can be rapidly switched in the transverse direction, the longitudinal direction and multiple directions, and the stability of resolution and integrated color uniformity is ensured. A three-dimensional naked eye stereoscopic display system can dynamically regulate various parameters of an equivalent cylindrical lens according to the position of a viewer so as to ensure the optimal viewing effect.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

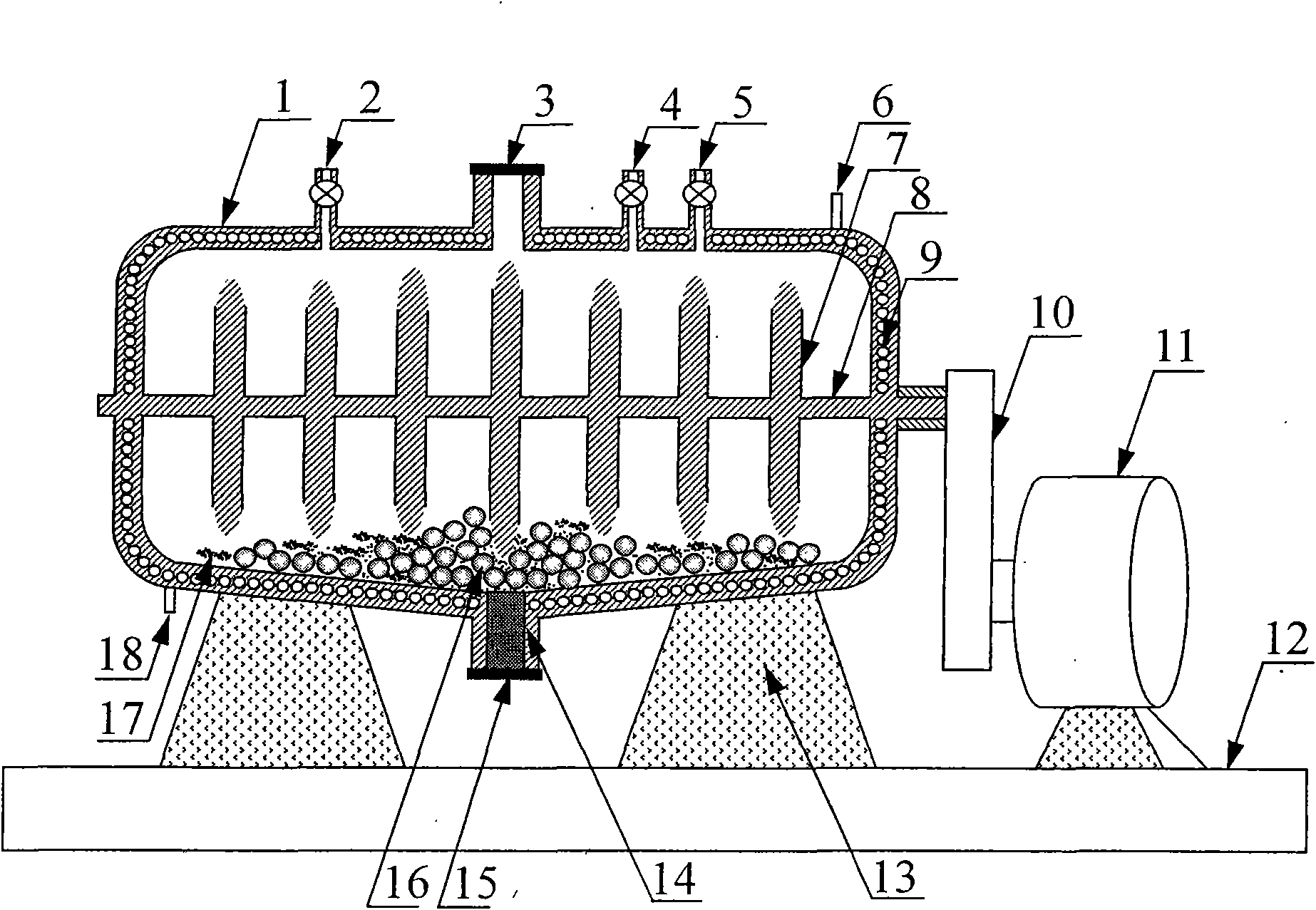

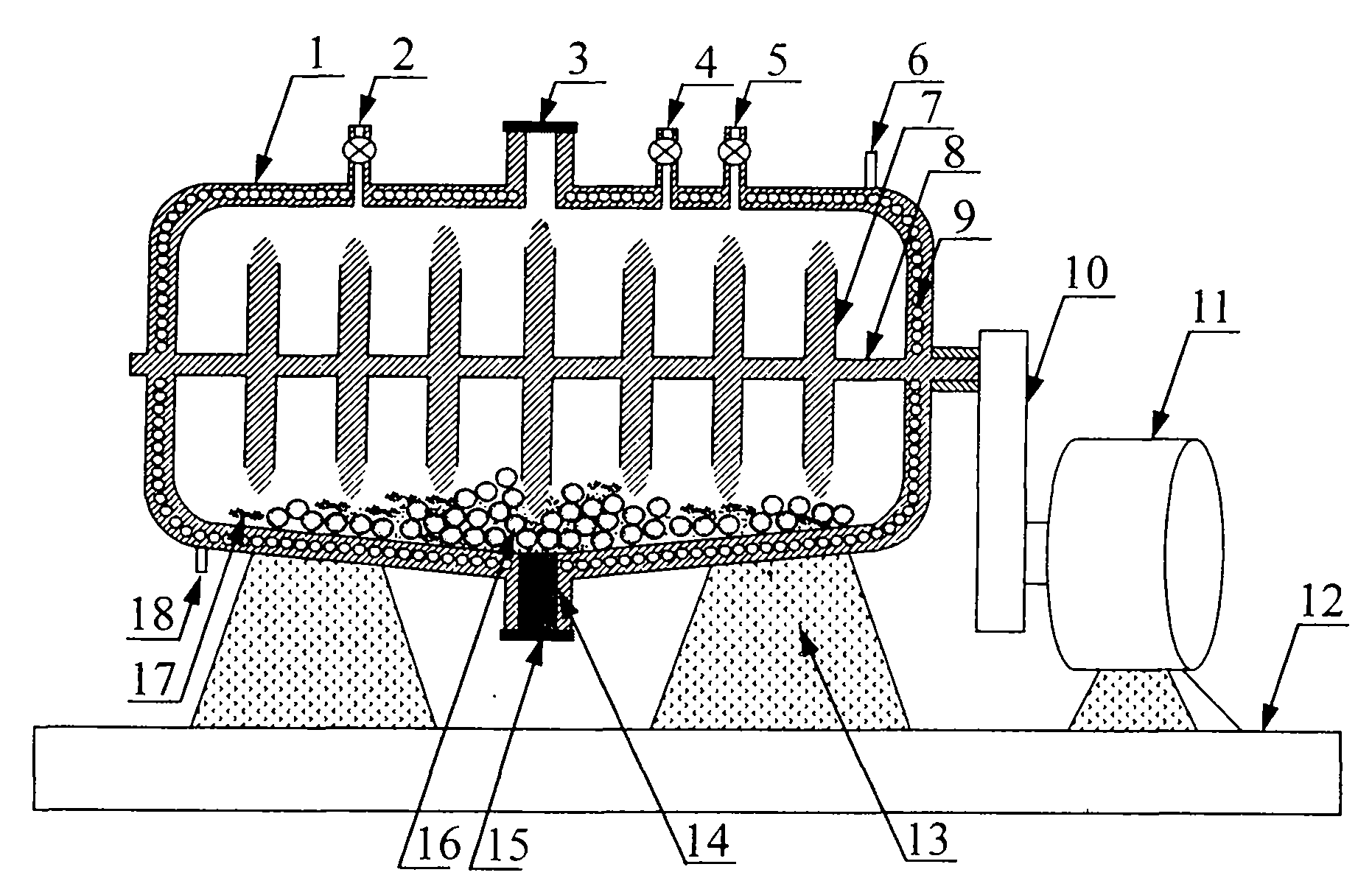

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

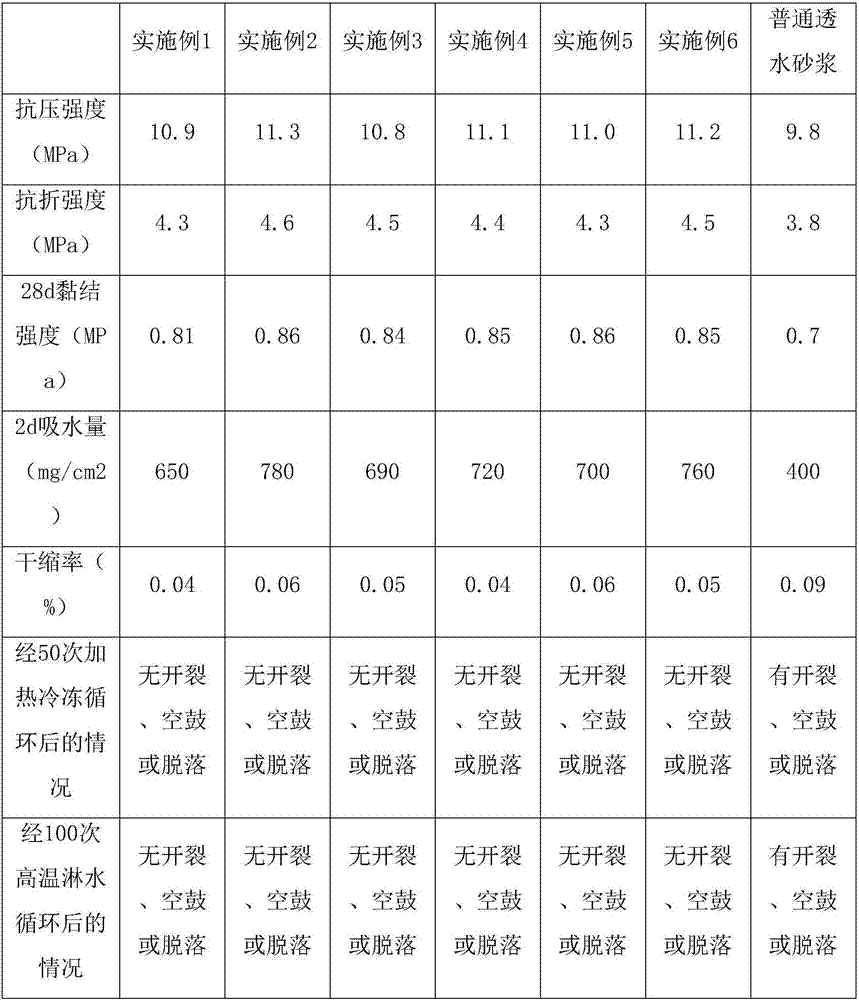

High-modulus permeable environment-friendly mortar used for sponge city and produced by utilizing construction waste and preparation method thereof

The invention provides high-modulus permeable environment-friendly mortar used for a sponge city and produced by utilizing construction waste and a preparation method thereof. The method comprises the steps of manually crushing abandoned construction waste bricks and abandoned concrete, screening the materials into a 15-20 mm range and a 20-30 mm range, performing washing and airing, soaking the materials in a sodium silicoaluminate solution, taking the materials out for activation, and obtaining renewable active construction waste aggregate; taking sandstone, granite and limestone as raw materials, performing soil removal and mechanical crushing, performing screening to a 1-2 mm range, a 2-5 mm range and a 5-10 mm range, and performing washing and airing to form manufactured sand aggregate; placing the renewable active construction waste aggregate, the manufactured sand aggregate and cement in a blender to perform uniform mixing, adding water-borne epoxy resin high-viscosity grafting cementing material, continuing to perform stirring, adding carbon fiber web, rubber powder, quaternary ammonium salt modified bentonite, dispersible latex powder, cellulose ether, lignocellulose and water reducing agent admixture, nano titanium dioxide ultraviolet absorbent and water, performing uniform mixing, and obtaining the high-modulus permeable environment-friendly mortar used for a sponge city and produced by utilizing construction waste.

Owner:绍兴职业技术学院

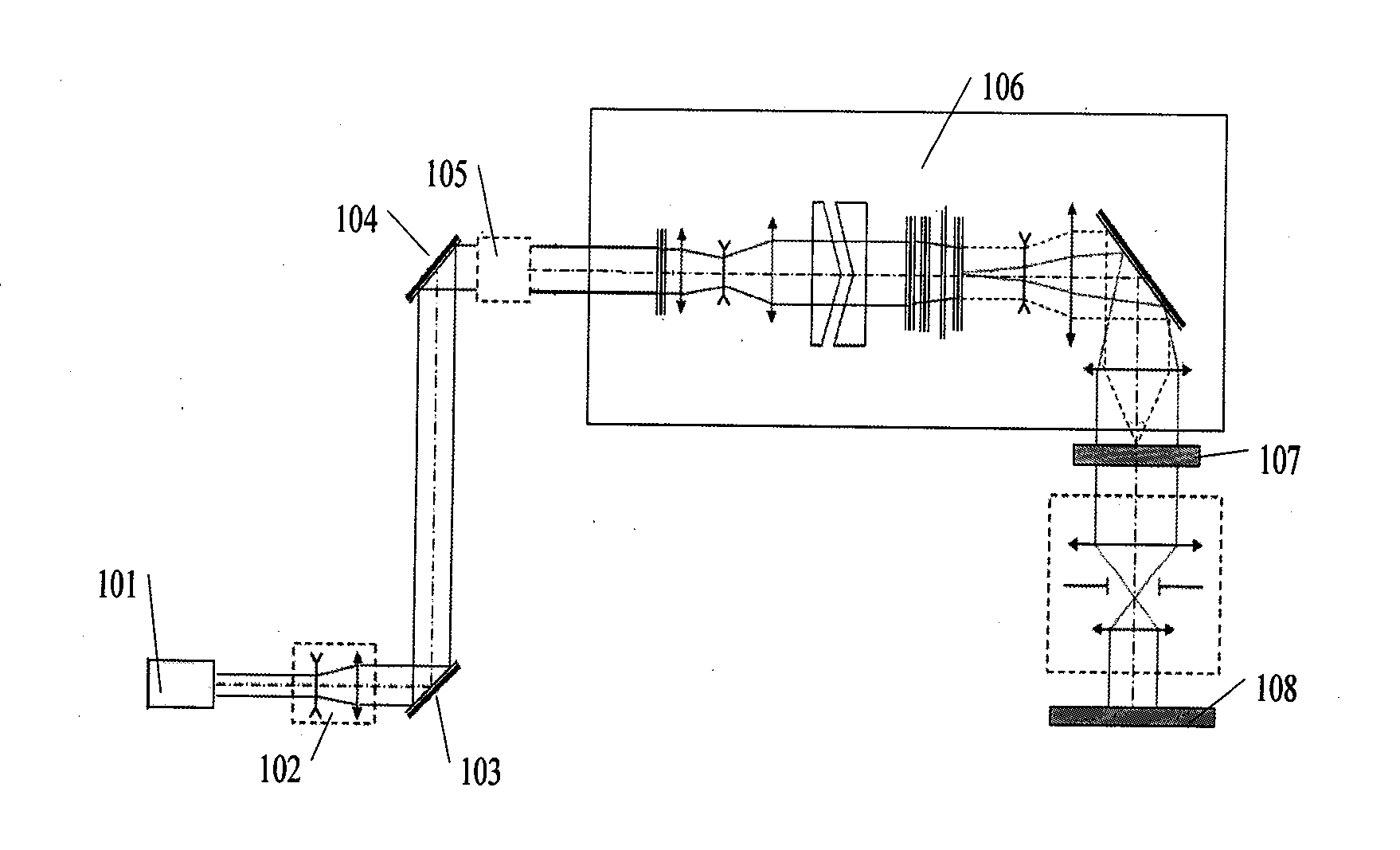

Light beam transmission apparatus and method

InactiveCN101487983AStable telecentricStable UniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splitterLight beam

The invention provides a beam transmission device which is used for transmitting beams ejected by a laser to a basic illuminating system. A beam steering unit is placed on a beam path of beams; a beam splitter is placed on the beam path of the beams; the beams are divided into a first beam and a second beam after passing through the beam splitter, a beam outlet is arranged on the beam path of the first beam, a beam measuring unit is arranged on the beam path of the second beam, the beam steering unit and the beam measuring unit are both connected with a controller. The beam transmission device of the invention can measure positions and angles of beams in real time and adjust the positions and angles of the beams according to the measurement results, thus ensuring stability of telecenter and uniformity of the illuminating system.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

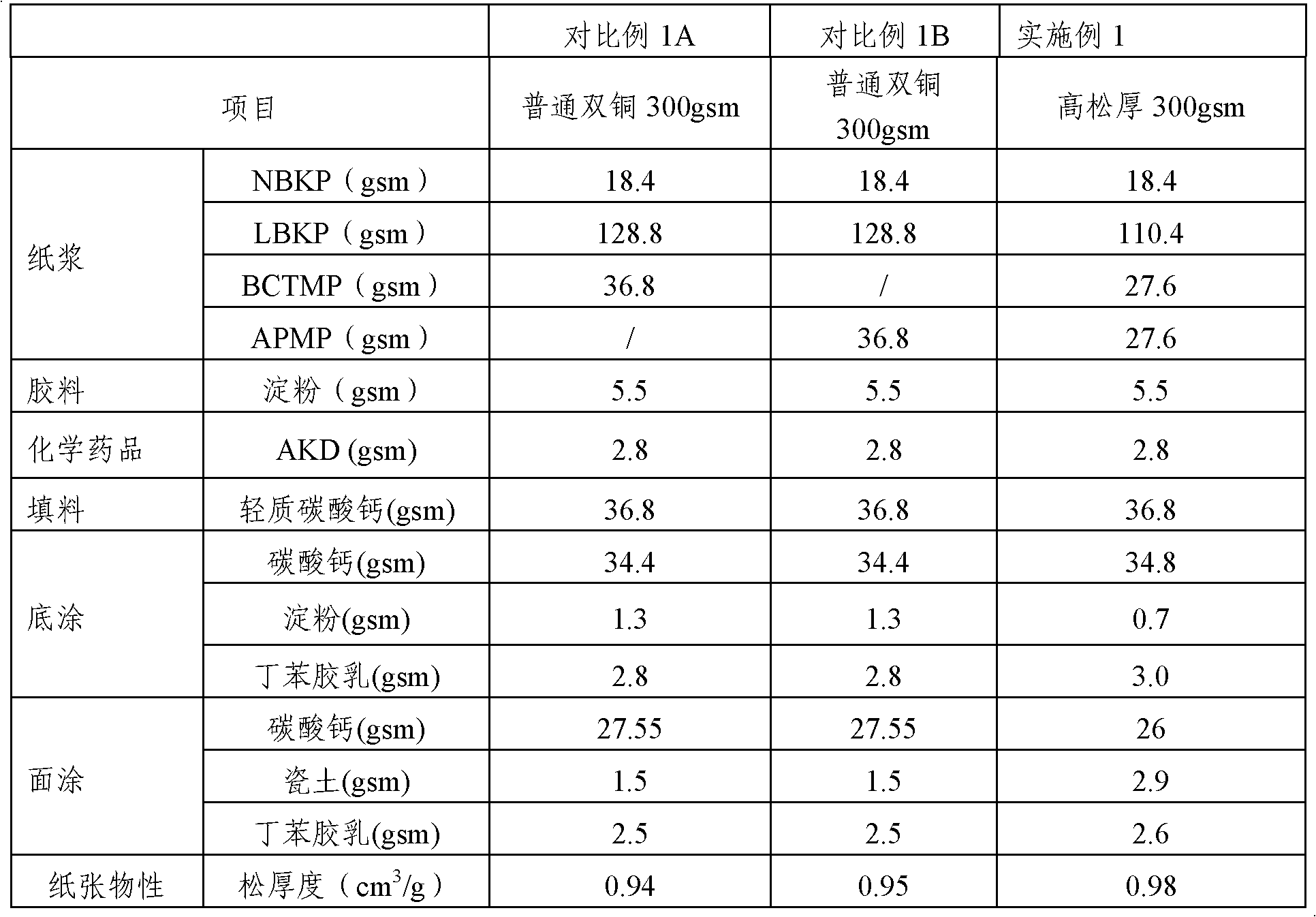

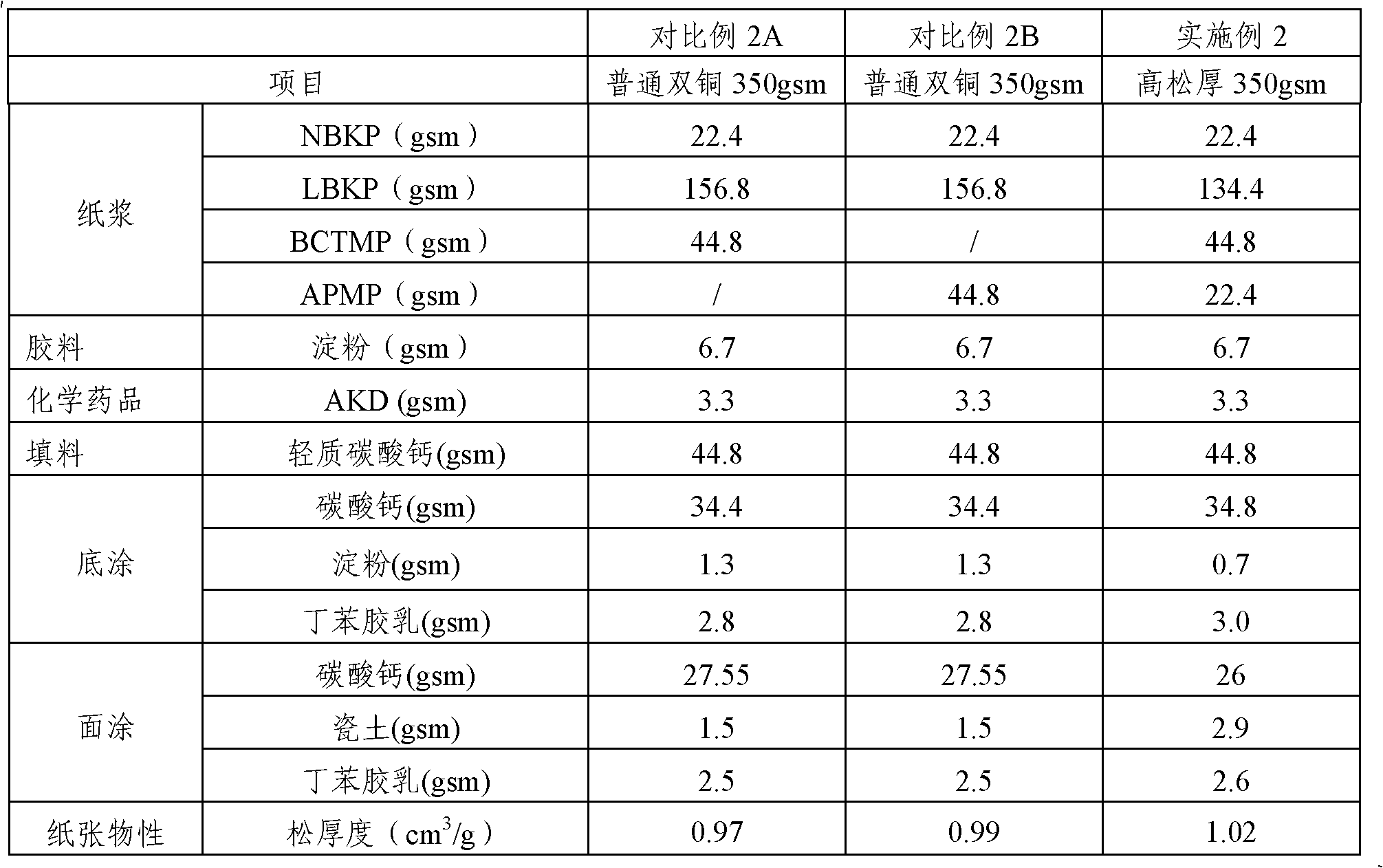

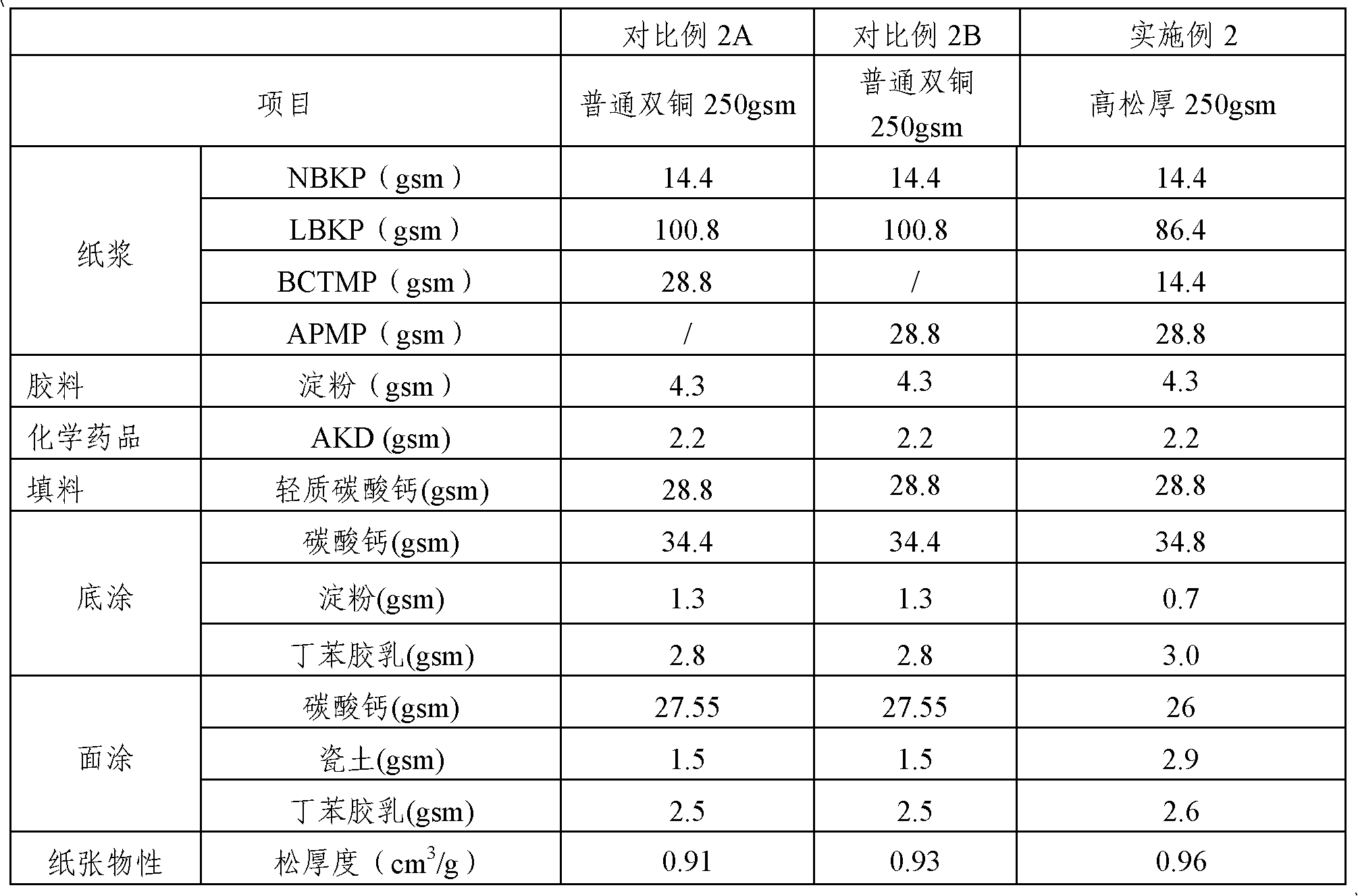

Paper pulp and high-bulk energy-saving environment-friendly card prepared from same

ActiveCN102535240AStable qualityAvoid overproductionCoatings with pigmentsSynthetic cellulose/non-cellulose material pulp/paperGramHardwood

The invention discloses paper pulp and a high-bulk energy-saving environment-friendly card prepared from the same. The paper pulp is prepared from the following components in percentage by weight: 1 to 10 percent of bleached sulfate softwood pulp, 30 to 70 percent of bleached sulfate hardwood pulp, 20 to 50 percent of chemithermomechanical pulp, and 10 to 30 percent of alkaline peroxide mechanical pulp. The invention also provides the copperplate card prepared from the paper pulp and other components. The paper made with the paper pulp is high in bulk, the gram weight of the paper is effectively controlled to be in a certain range, the paper pulp is prevented from being put into production excessively, and the defibrination energy consumption of a paper machine is reduced correspondingly, so that the effects of environment friendliness and energy saving are effectively achieved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

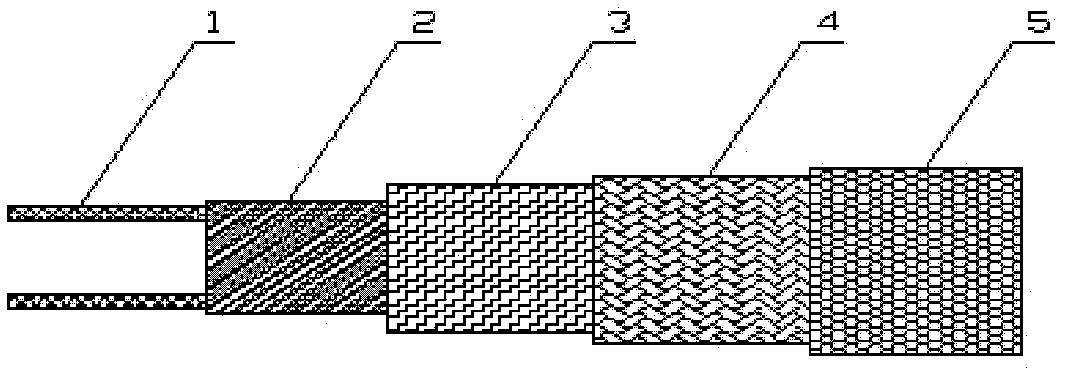

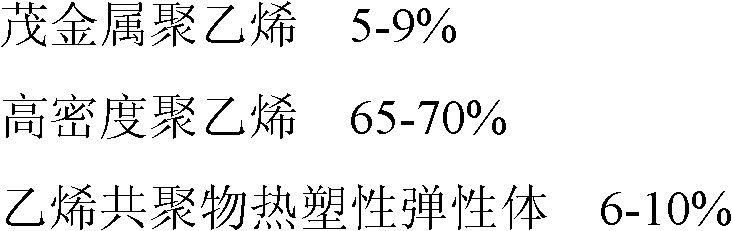

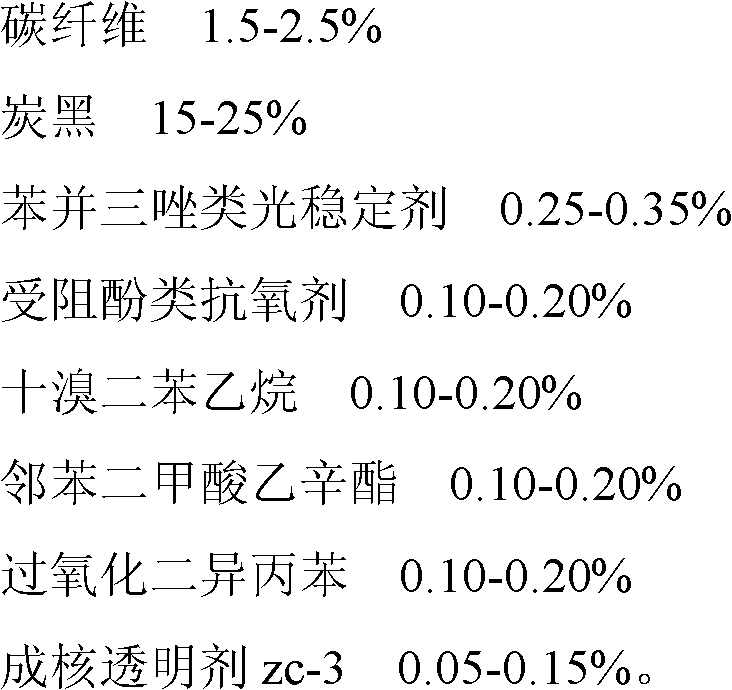

PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

InactiveCN102604189AImprove PTC StrengthImprove tensile propertiesHeating element shapesPositive temperature coefficient thermistorsFiberCarbon fibers

The invention discloses a PTC (Positive Temperature Coefficient) high polymer heating material for a self-limiting temperature electric tracing band, which is prepared from the following raw materials in percentage by weight: 5 to 9 percent of metallocene polyethylene, 65 to 70 percent of high-density polyethylene, 6 to 10 percent of vinyl copolymer thermoplastic elastomer, 1.5 to 2.5 percent of carbon fibers, 15 to 25 percent of carbon black, 0.25 to 0.35 percent of benzotriazole light stabilizer, 0.10 to 0.20 percent of hindered phenol antioxygen, 0.10 to 0.20 percent of decabromodiphenylethane, 0.10 to 0.20 percent of diisooctyl ortho-phthalate, 0.10 to 0.20 percent of dicumyl peroxide and 0.05 to 0.15 percent of nucleating transparent agent zc-3. According to the invention, the elasticity modulus of the PTC material is improved, the maximum stress and the stress of a breaking point of the PTC material are increased, so that the PTC strength and the stretch resistance performance of the PTC heating material are improved.

Owner:WUHU XUHUI ELECTRIC NEW MATERIAL

Smelting preparation method of aluminum alloy section with good stability

ActiveCN103103399AImprove performanceAffect qualitySolid state diffusion coatingAluminium preparationsSurface oxidation

The invention discloses a smelting preparation method of an aluminum alloy section with good stability. The smelting preparation method comprises the following operating steps of: (1) preparing an aluminum alloy melt which is prepared form the following raw materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of discarded aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer silica sand powder; and adding the raw materials into a smelting furnace, heating till the furnace charges begin to soften and collapse, and then spreading a layer of covering agent on the surface of the melt, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of pulverized fuel ash. According to the smelting preparation method, the performance of the aluminum section can be kept stable as the discarded aluminum material is added in components, and the probability that the quality of the aluminum section is influenced as a material is not detected during smelting of molten aluminum is reduced; and the surface of the aluminum alloy section is subjected to chromation, so that the anticorrosive capability of an oxide film on the surface of the aluminum alloy section and the binding force between the aluminum alloy section and a coating are improved.

Owner:武汉鸿劲金属铝业有限公司

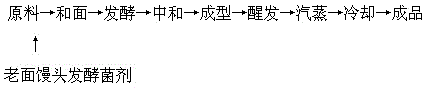

Steamed bun zymophyte, preparation method thereof and application of steamed bun zymophyte

The invention relates to steamed bun zymophyte, a preparation method thereof and application of the steamed bun zymophyte, and belongs to the field of biotechnology and food. The steamed bun zymophyte comprises the following raw materials in percent by weight: 5.00-15.00% of steamed bun yeast powder, 5.00-15.00% of lactobacillus plantarum powder, 0.10-5% of lactobacillus casei powder, 0.10-5.00% of lactobacillus acidophilus powder and 60.00-89.80% of edible glucosum anhydricum. The preparation method comprises the following steps of pre-mixing the lactobacillus plantarum powder, the lactobacillus casei powder and the lactobacillus acidophilus powder; adding the lactobacillus plantarum powder, the lactobacillus casei powder and the lactobacillus acidophilus powder in the edible glucosum anhydricum; and uniformly blending the mixture so as to obtain the steamed bum zymophyte. 2-10g steamed bun zymophyte is added in 1Kg of flour. By using the steamed bun zymophyte, the flavor and the quality of steamed buns are improved, the problem that the quantity of steamed bun processing zymophyte is insufficient is solved, and the shortcoming that the feature and the flavor of steamed buns fermented by using the existing zymophyte are not obvious is overcome.

Owner:SICHUAN GAOFUJI BIOLOGICAL TECH

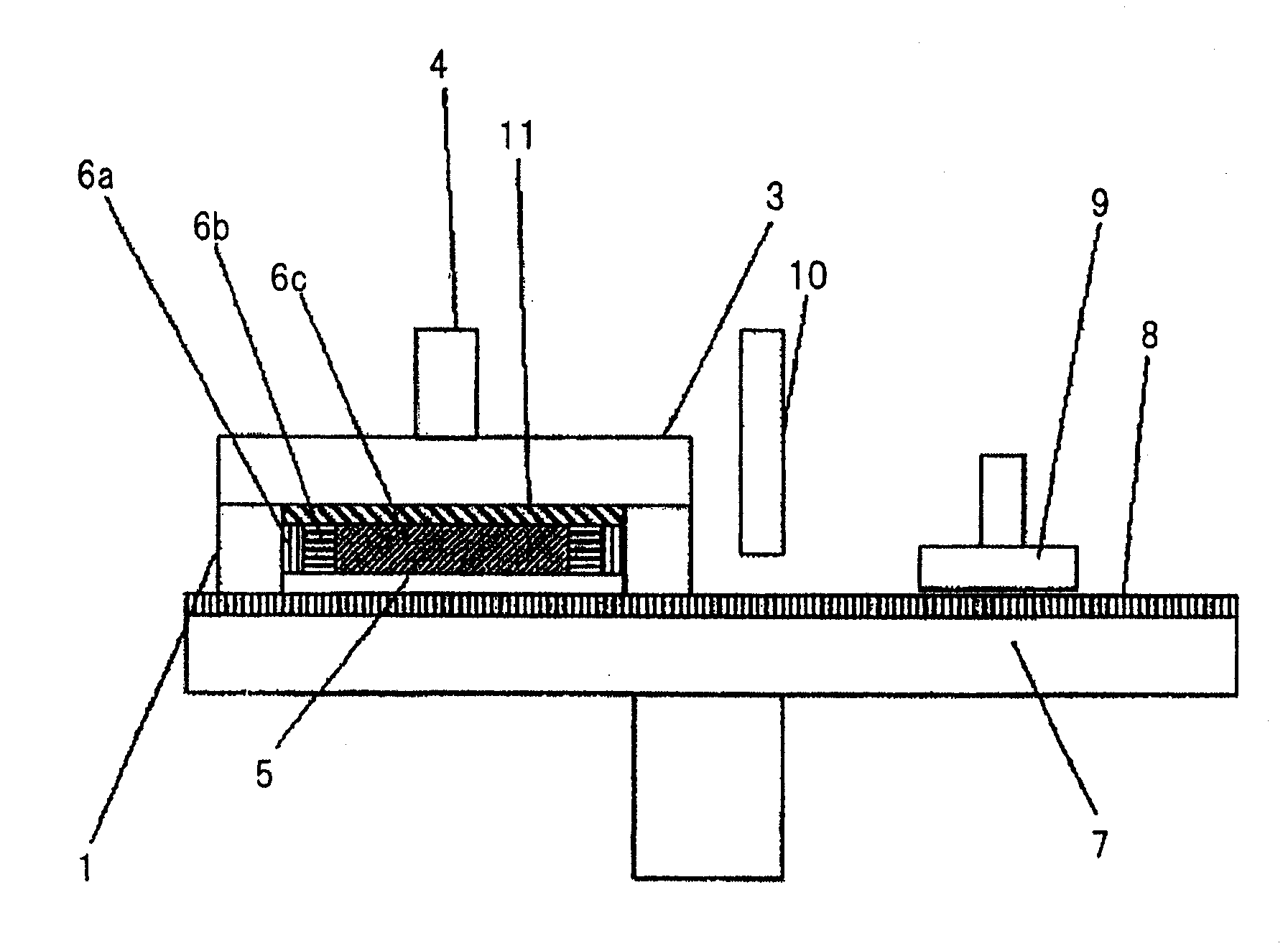

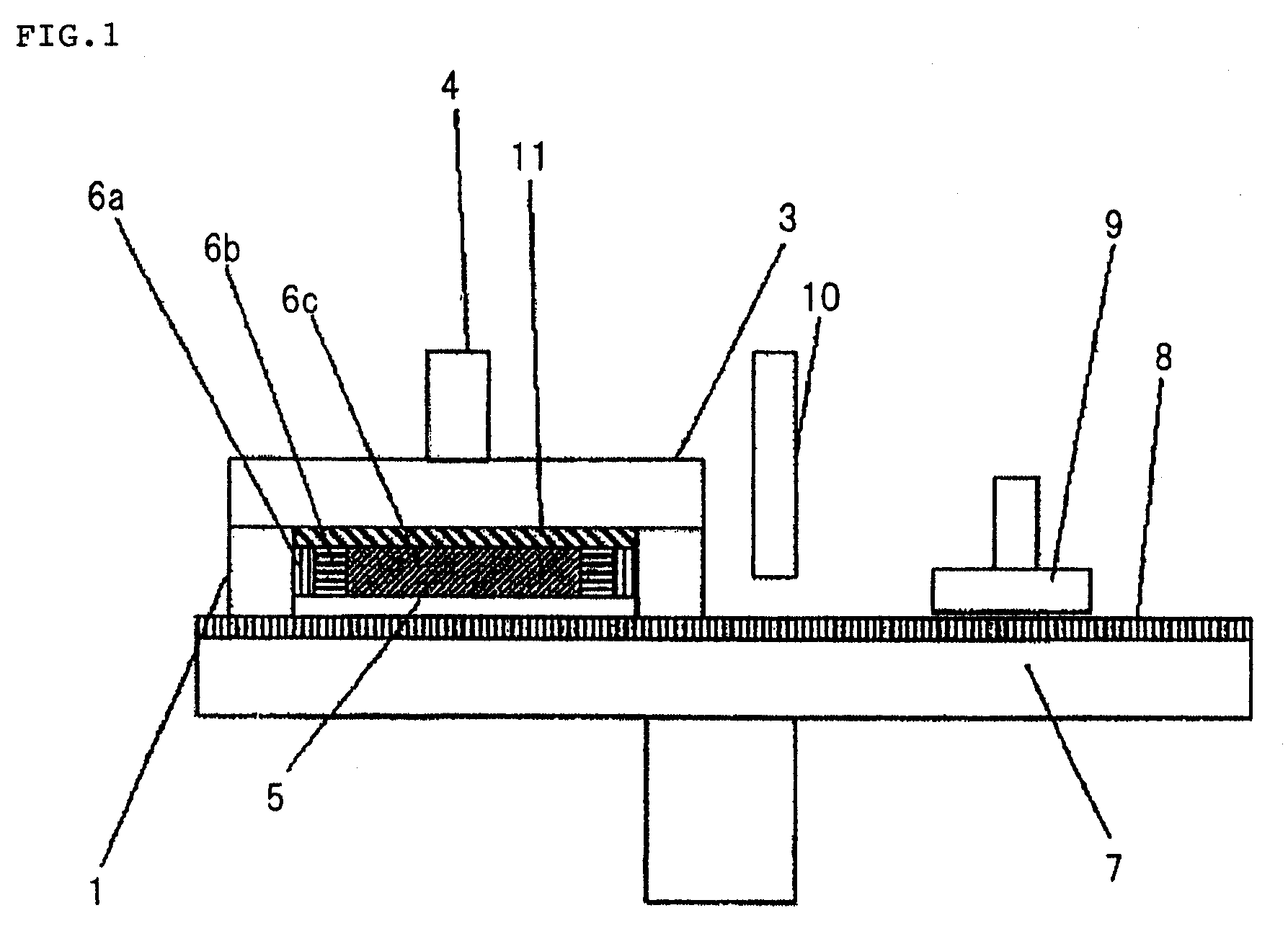

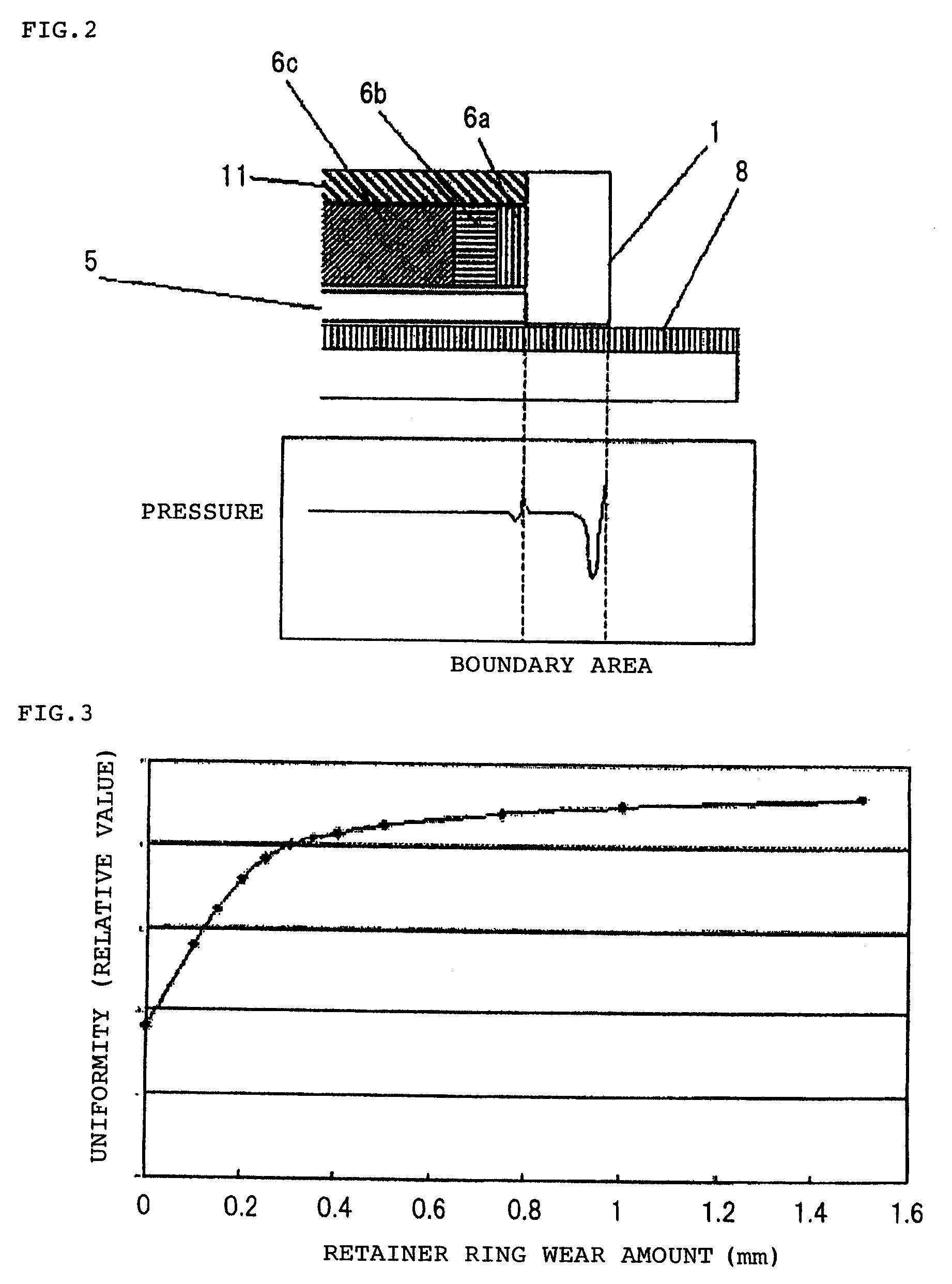

Semiconductor device manufacturing apparatus and method

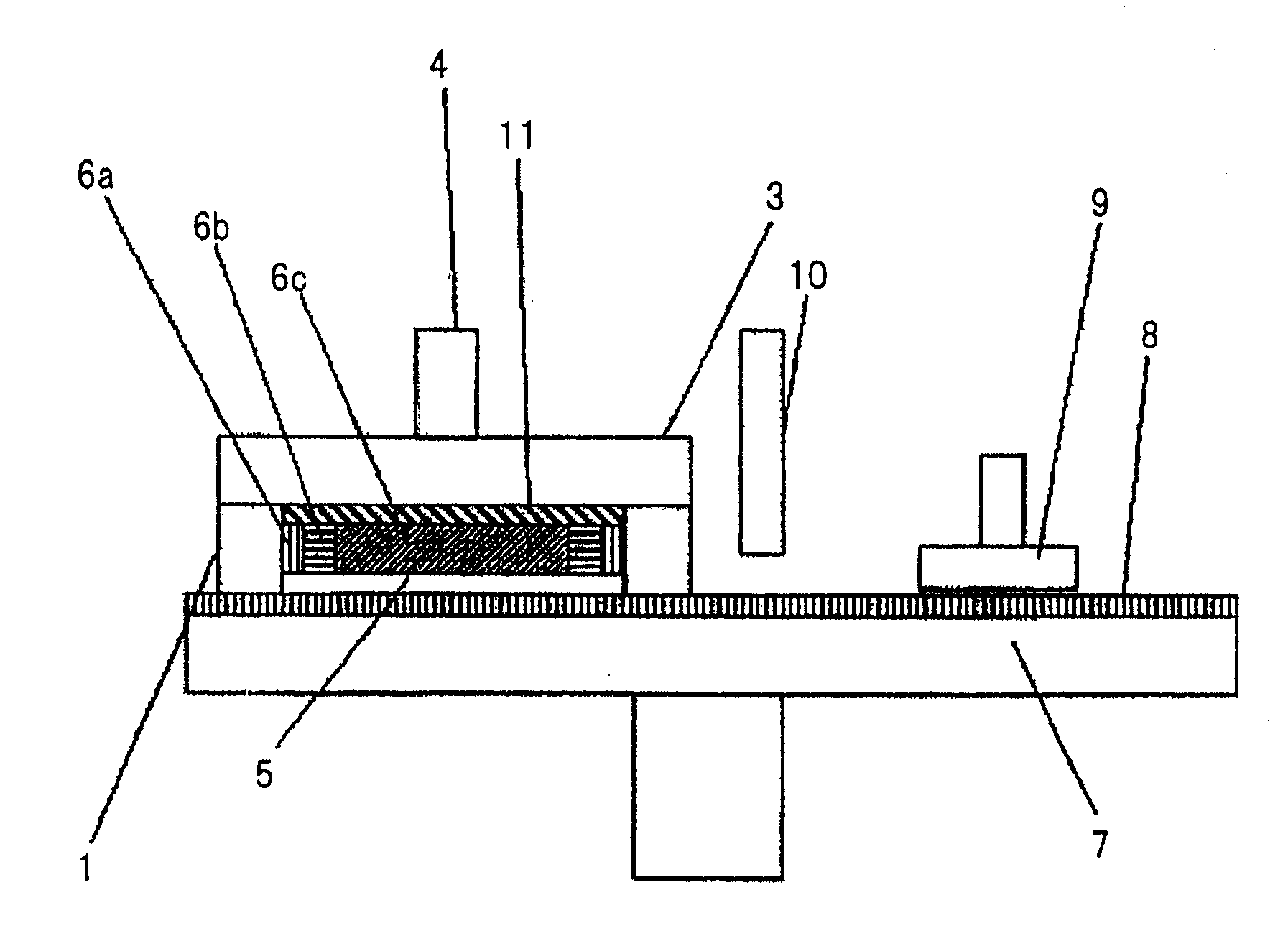

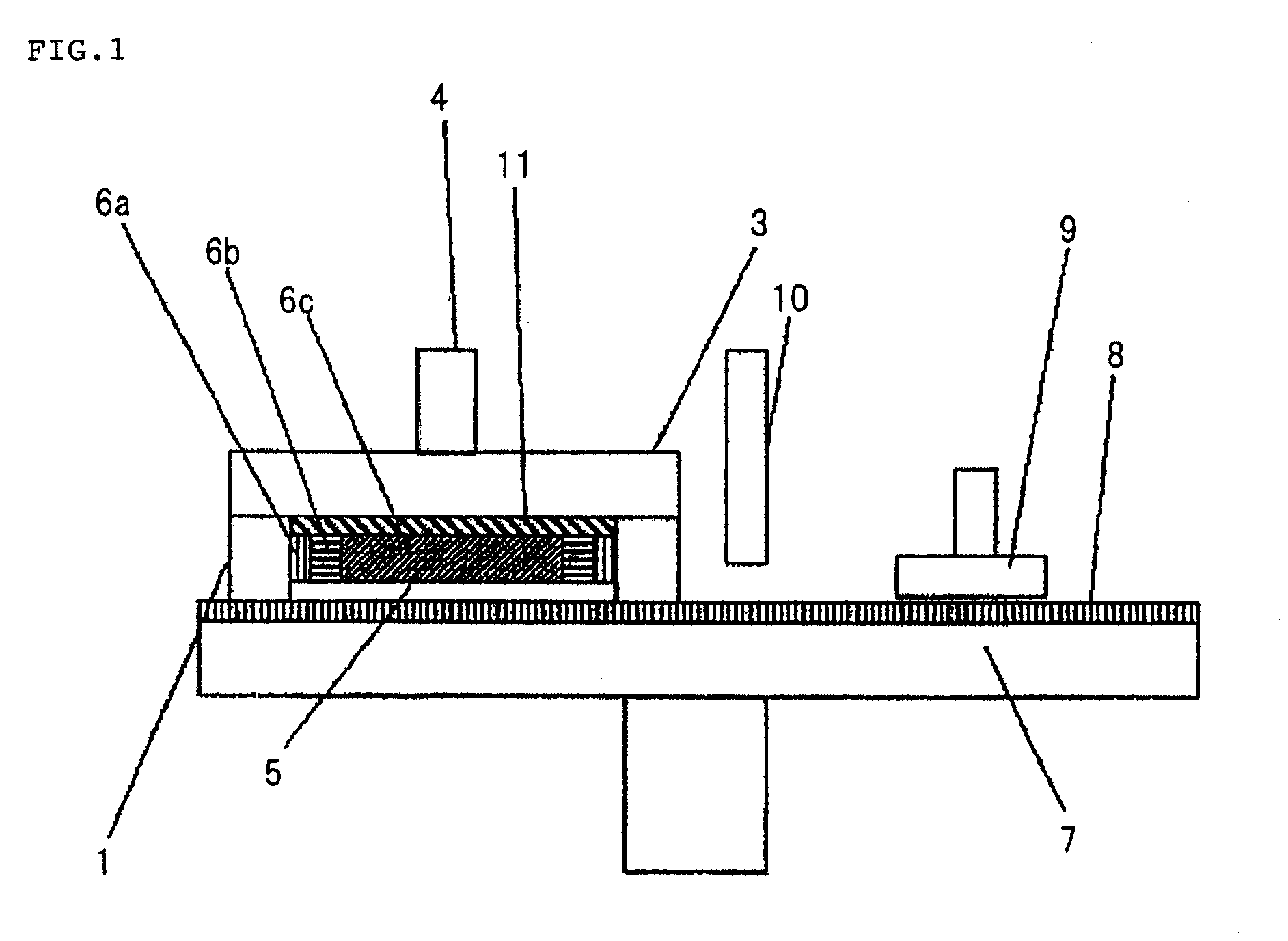

ActiveUS20080146123A1Stable UniformityAvoid heat effectsEdge grinding machinesPolishing machinesSemiconductorDevice material

A semiconductor device manufacturing apparatus according to the present invention comprises a head for holding a semiconductor wafer, a retainer ring for surrounding the outer periphery of the semiconductor wafer held by the head, and a polishing pad for polishing a polished surface of the semiconductor wafer. This apparatus presses the polished surface of the semiconductor wafer against the polishing pad together with the retainer ring to polish the semiconductor wafer. The retainer ring used in the present invention has a surface that is in contact with the polishing pad, which increases a contact area of the retainer ring against the polishing pad in accordance with wear of the retainer ring.

Owner:MICRON TECH INC

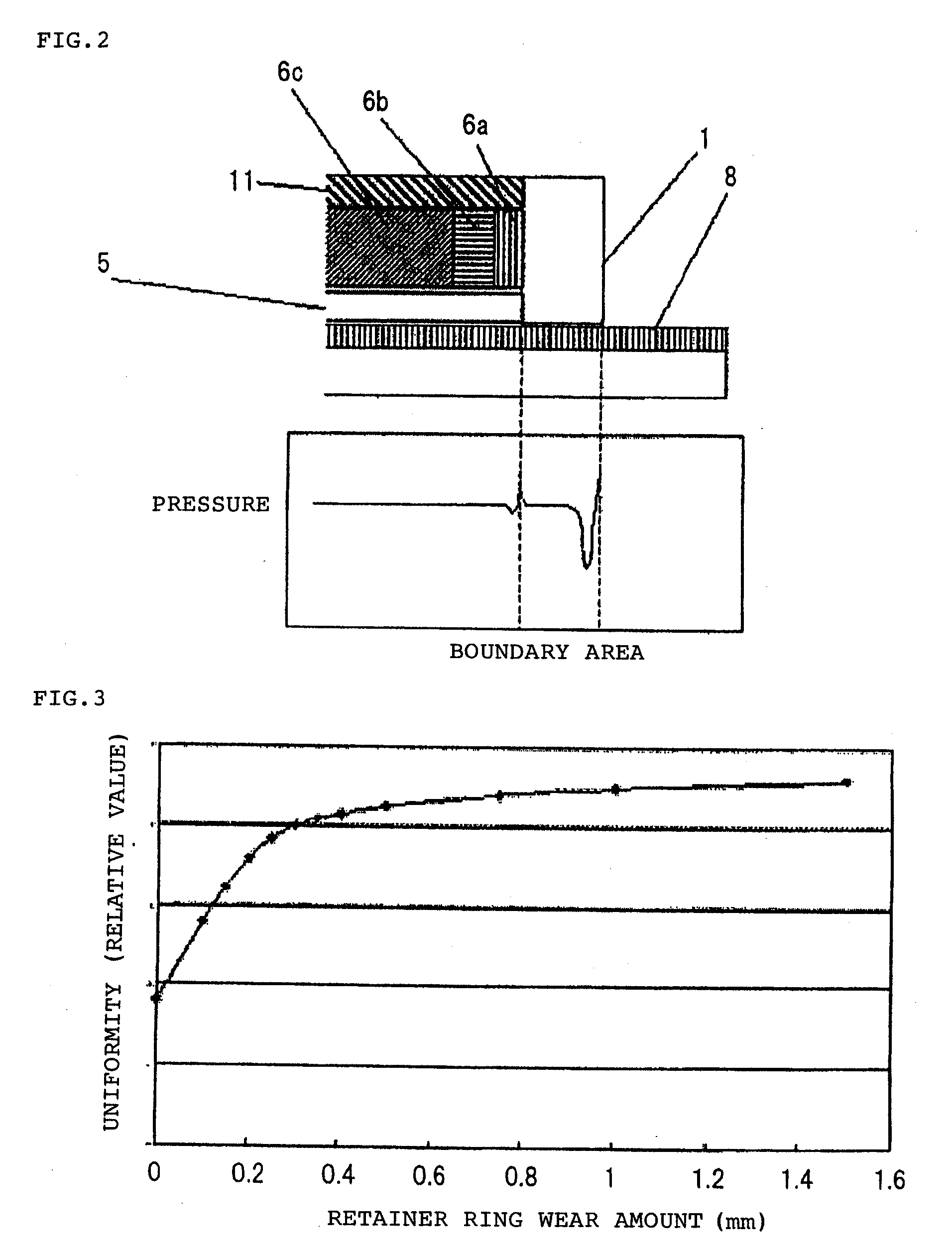

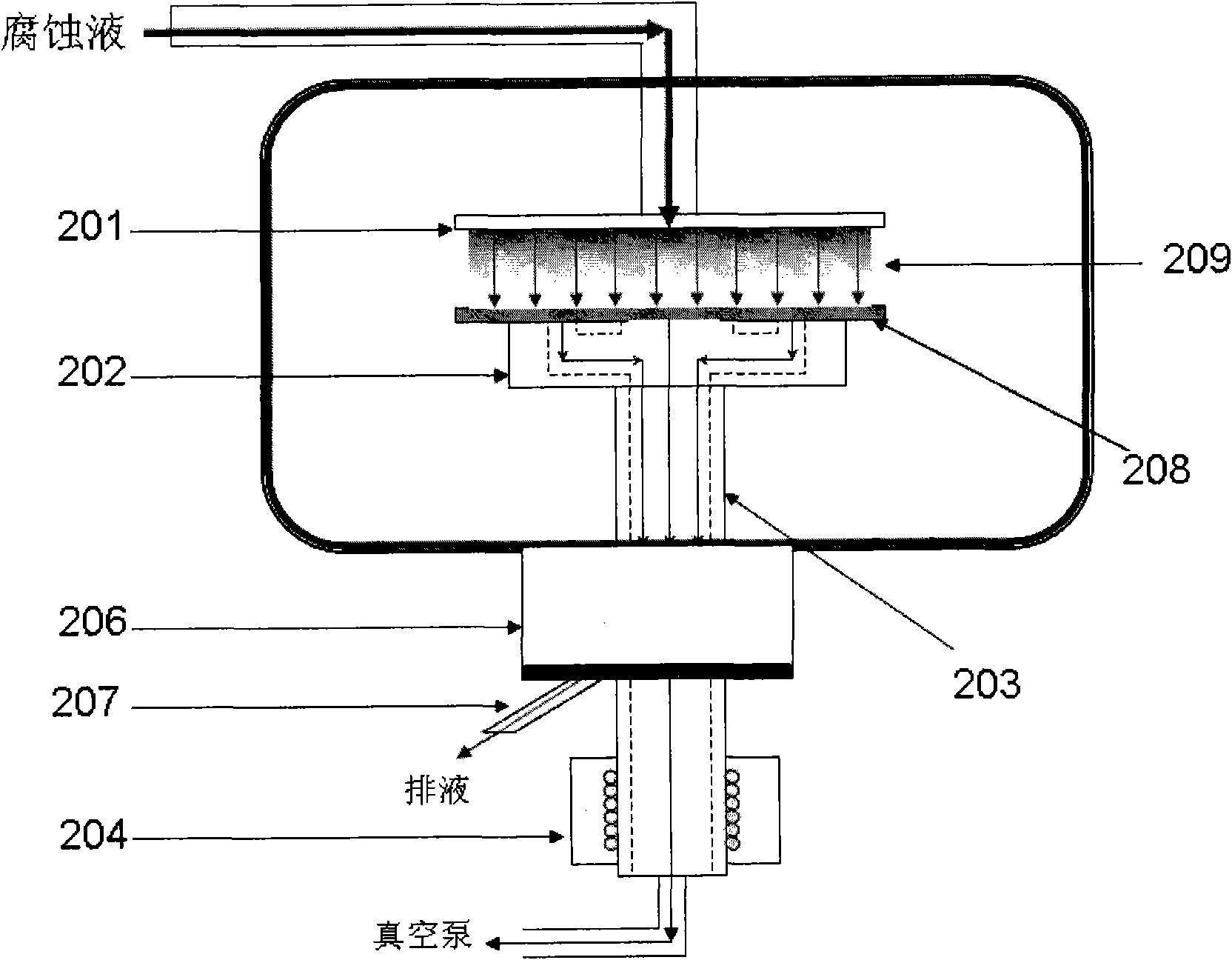

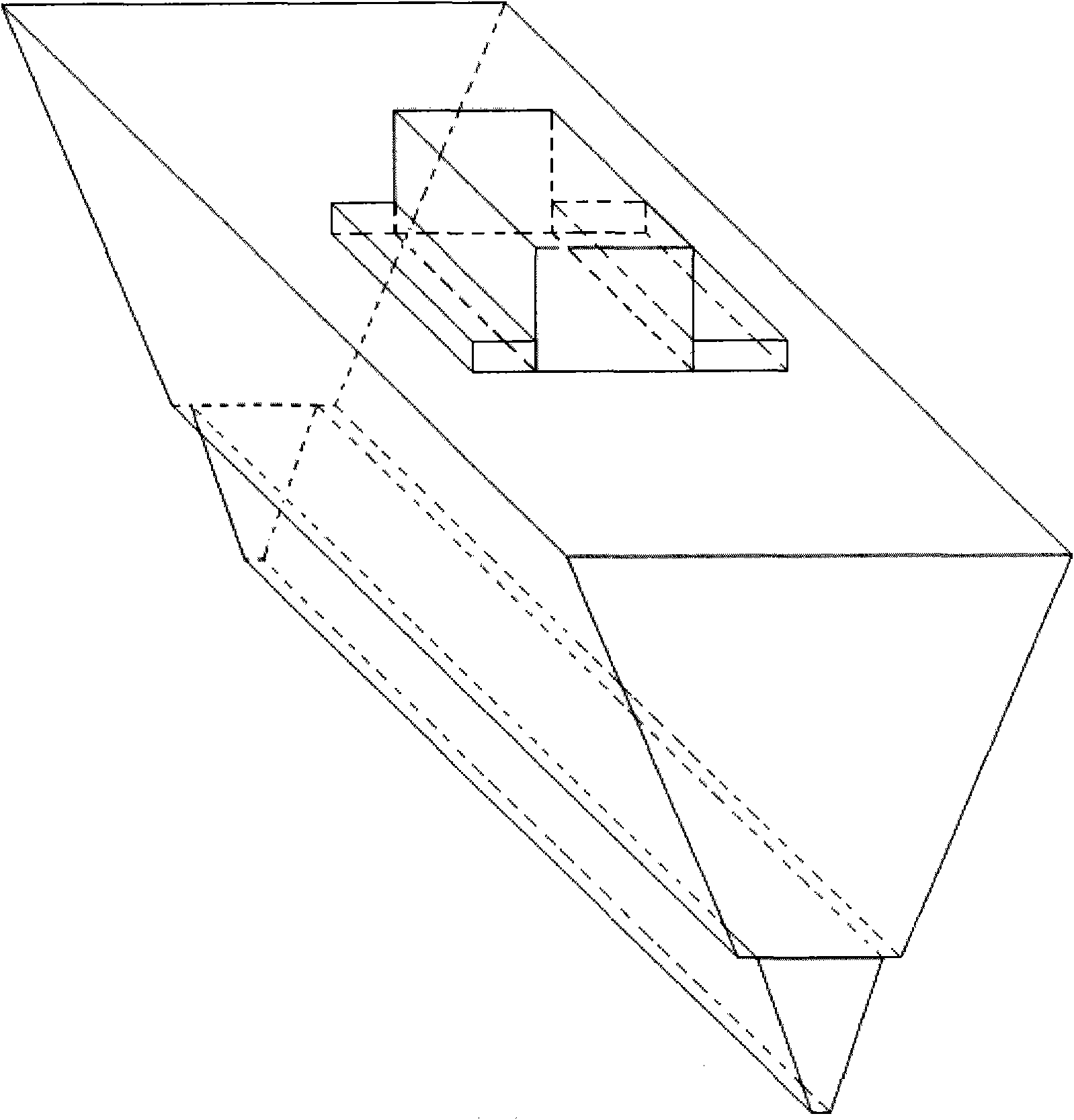

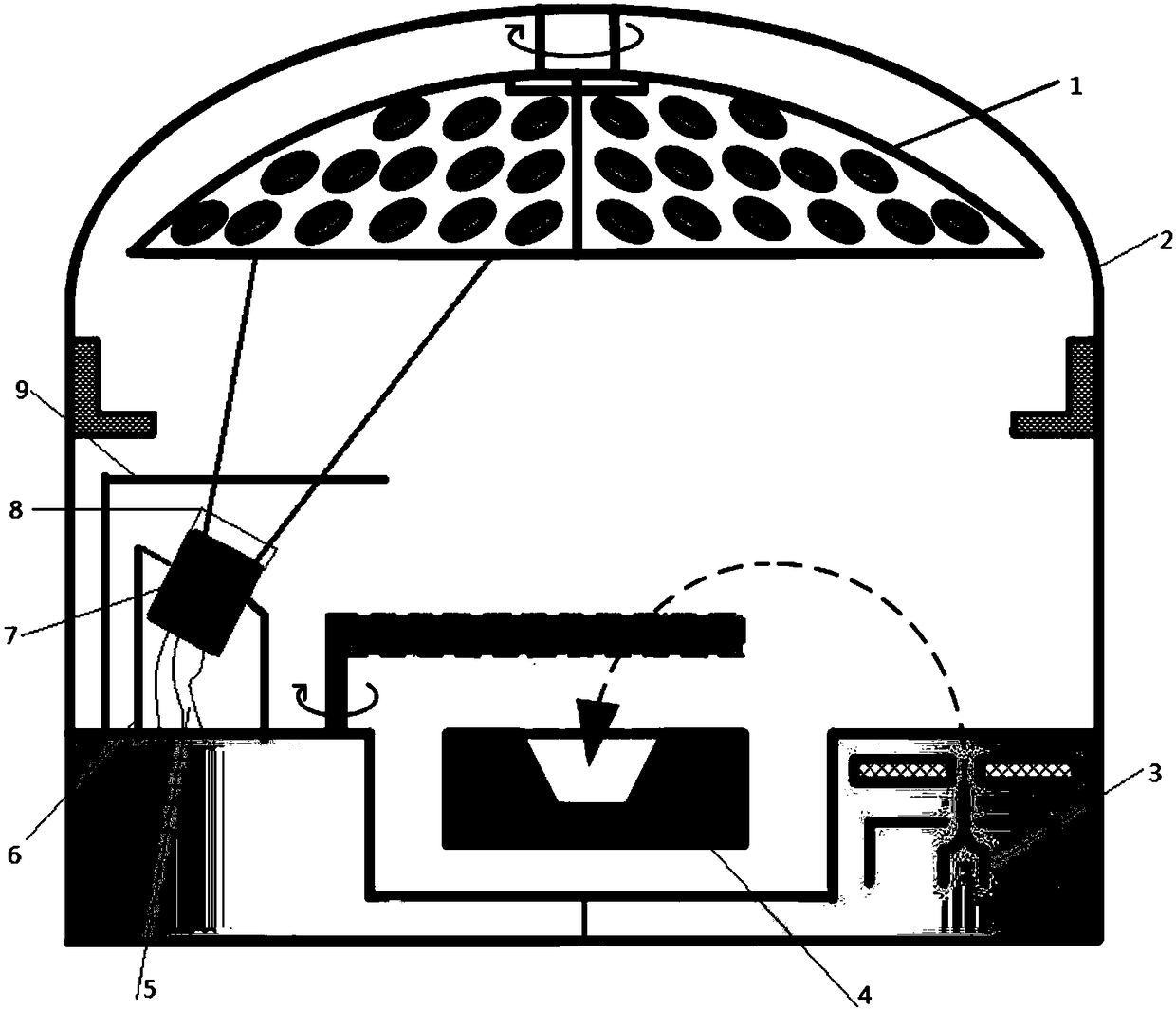

One-sided silicon wafer wet etching equipment

The invention discloses one-sided silicon wafer wet etching equipment. The equipment comprises a liquid feeding device (1), an etching chamber (2) and a remaining liquid processing device (3), wherein the liquid feeding device (1) sprays a high-temperature alkaline etching liquid onto a silicon wafer rotating on a vacuum chuck in the etching chamber (2) to carry out reaction rate and surface finish controlled anisotropic wet etching on the silicon wafer; at the same time, the silicon wafer is tightly fit with the vacuum chuck in the etching chamber (2); and the fitting surface is isolated from the etching environment to realize protection of the one-sided silicon wafer. The equipment has the following beneficial effects: one-sided wet etching is carried out by spraying the high-temperature alkaline etching liquid onto the silicon wafer rotating on the vacuum chuck and vacuum is utilized to effectively isolate the side to be protected from the etching environment, thus solving the problem that long-time one-sided protection is difficult to implement on the silicon wafer in the tradition wet etching processes.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Square billet ultra-low carbon steel continuous casting functional protection material

The invention discloses a square billet ultra-low carbon steel continuous casting functional protection material. The raw material of the functional protection material comprises the following components: wollastonite, barium carbonate, sodium carbonate, fluorite, manganese powder, alumina powder, carbon black, iron cement, bentonite and quartz powder, and the quality percentages of the components are respectively 53.5%, 1.5%, 7%, 15%, 5%, 7%, 5%, 4% and 2%. The invention innovates and improves the formula thereof, using a special composite component to ensure fast slagging speed, and can fast and timely supplement liquid slag consumption; the thickness of slag film between a crystallizer wall and a blank shell is suitable and is uniformly distributed, thereby preventing the blank shell from directly contacting with the crystallizer wall so as to reduce friction and ensure even mold heat dissipation of the crystallizer, thereby preventing the slag from sticking leakage steel and preventing the surface of a casting blanking from generating defects.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

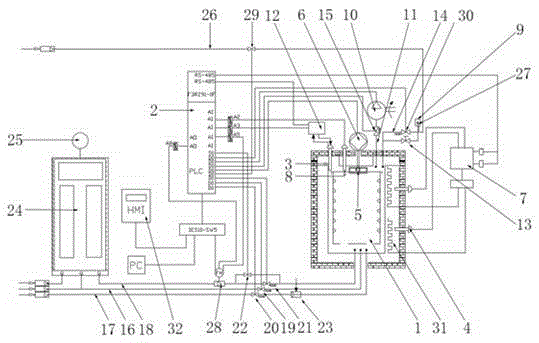

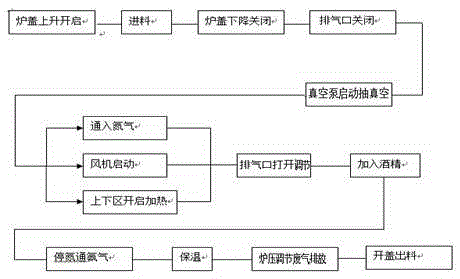

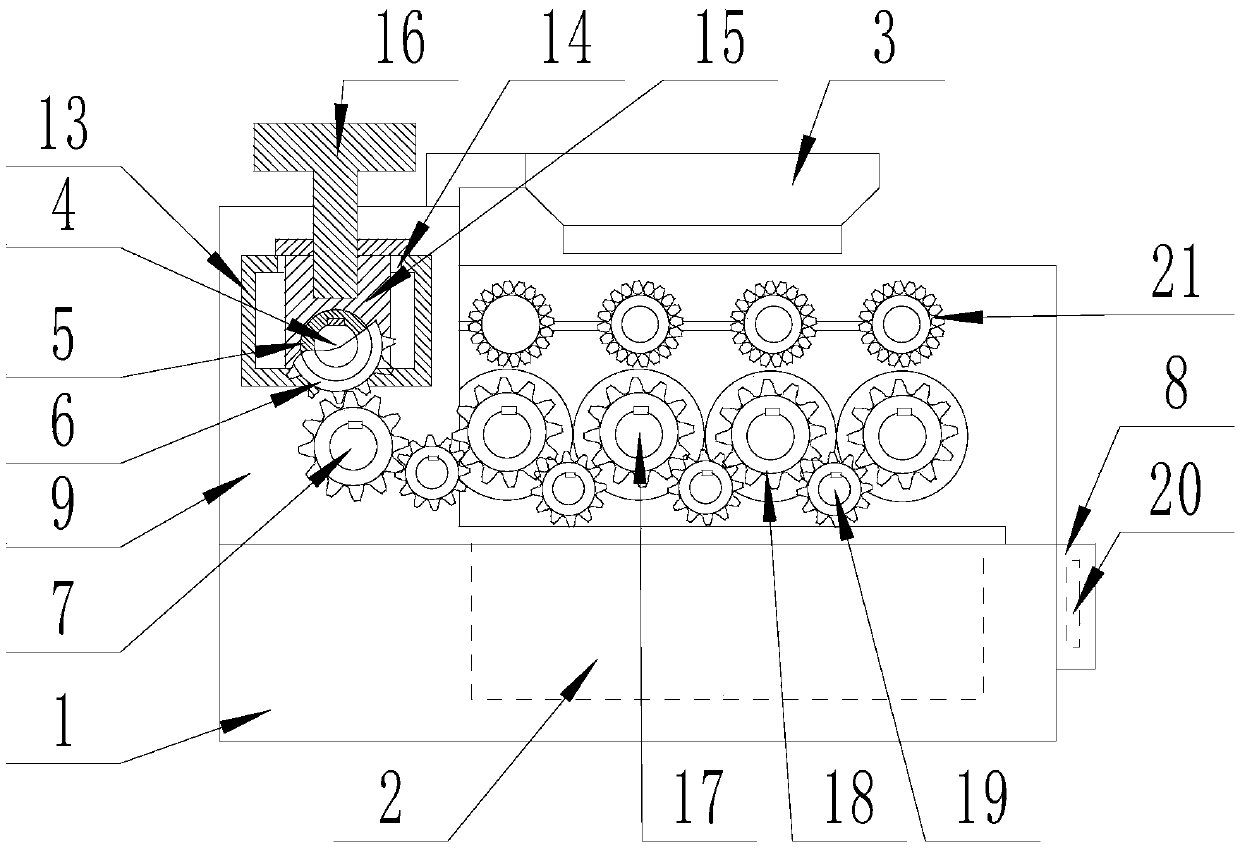

Gas carbonitriding automatic control method and device

ActiveCN105369190ADeep stabilityStable UniformitySolid state diffusion coatingAutomatic controlClosed loop feedback

The invention discloses a gas carbonitriding automatic control method and device. The device comprises nine devices, namely, a nitriding furnace 1, a PLC, a pressure sensor, a hydrogen probe, a thermocouple, a blade, a fan, a heating and temperature control device and an air exhausting device. After being subjected to degreasing, cleaning and surface treatment, a part is subjected to closed loop feedback control of a vacuum pump, nitrogen, ammonia, ethyl alcohol, temperature and pressure in the furnace, so that the nitrocarburizing of various common nitriding steel such as high-speed steel and stainless steel is achieved. The device is energy-saving and efficient in use, easy to maintain and free of pollution, the product is high in quality performance, the PLC control system is adopted to quickly confirm and control the depth of the white etching layer and the reticular layer of the part to be stable according to the number of corresponding parts and the technological parameters of the material, the uniformity of stainless steel mass production is stable, the ammonia consumption is less, the energy consumption is low, the nitridation time is short, and the efficiency is high.

Owner:XINAN TOOLS GUIZHOU PROV

Silicon carbide-carbon composite material and preparation method thereof

The invention relates to a silicon carbide-carbon composite material and a preparation method of the composite material. The technical scheme is as follows: firstly stirring and mixing 50-90wt% of graphite, 5-40wt% of high silica glass and 1-10wt% of phenolic resin, wherein the mixing time is 2-30 minutes, compressing and forming the mixture, and naturally drying the mixture for 24 hours; thermally treating the dried mixture for 8-24 hours at 110-330 DEG C, keeping the temperature for 1-12 hours in a reducing atmosphere at 1300-1700 DEG C, naturally cooling the mixture; and finally crushing the mixture to particles and powder with grain size smaller than 10mm. The preparation method has simple preparation processes and relatively low cost; the prepared silicon carbide-carbon composite material not only has good heat-conducting property and electrical conductivity, but also has excellent melt corrosion resistance performance and osmosis resistance performance.

Owner:WUHAN UNIV OF SCI & TECH

Combustor for medium-high temperature solid fuel cell and application thereof

PendingCN110360555AUniform porosityUniformityBurner ignition devicsFuel cellsCombustion chamberEngineering

The invention belongs to the field of fuel cells, and particularly discloses a combustor for a medium-high temperature solid fuel cell and an application thereof. An air inlet and a fuel inlet are arranged at an inlet end of a static mixing cavity in the combustor and are used for mixing air and fuel to obtain mixed gas; a shunting orifice plate is connected with an outlet end of the static mixingcavity to provide a buffer area for the mixed gas and shunt the mixed gas; a metal mesh structure is connected with the shunting orifice plate, so that the phenomena of tempering and flamelifting areprevented; a combustion chamber is arranged on the outer side of the static mixing cavity and provides a space for mixed gas combustion; and a pulse igniter is arranged above the metal mesh structureand used for igniting the mixed gas. According to the combustor, the shunting orifice plate is utilized to provide the buffer area for the high-flow-rate mixed gas, meanwhile, flame generated by combustion is divided into a plurality of fine flame flows by utilizing the metal mesh structure, and stable gas flow and temperature gradient are formed, so that the phenomena of the tempering and flamelifting are prevented.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method for quartz crucible with high-efficiency coating

InactiveCN106986553AImprove photoelectric conversion efficiencyReduce dislocation defectsIngot castingSlurry

The invention discloses a preparation method for a quartz crucible with a high-efficiency coating. According to the preparation method, ultra-pure quartz sand is used as a raw material and undergoes ball milling and batch mixing under stirring so as to prepare slurry; the slurry is allowed to cover the inner bottom surface of the square quartz crucible by using a spraying or brush coating process; and then ultra-pure quartz sand or ultra-pure polysilicon particles are uniformly spread so as to prepare the high-efficiency coating. Thus, in the process of polysilicon ingot casting, crystal growth of an ingot is induced; dislocation defects are overcome; the photoelectric conversion efficiency of the ingot is improved; and cost for the ingot is reduced.

Owner:杭州大和江东新材料科技有限公司

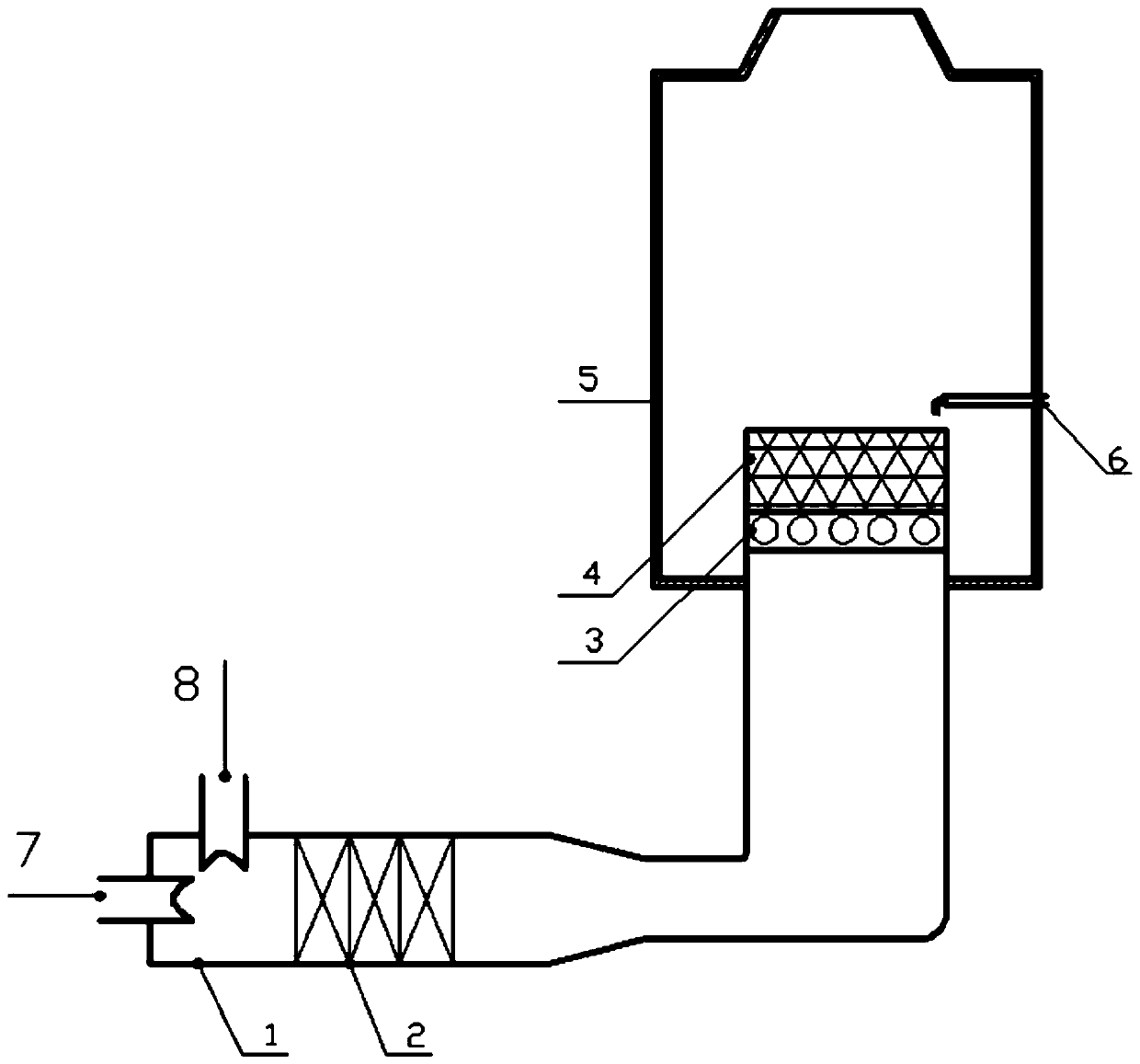

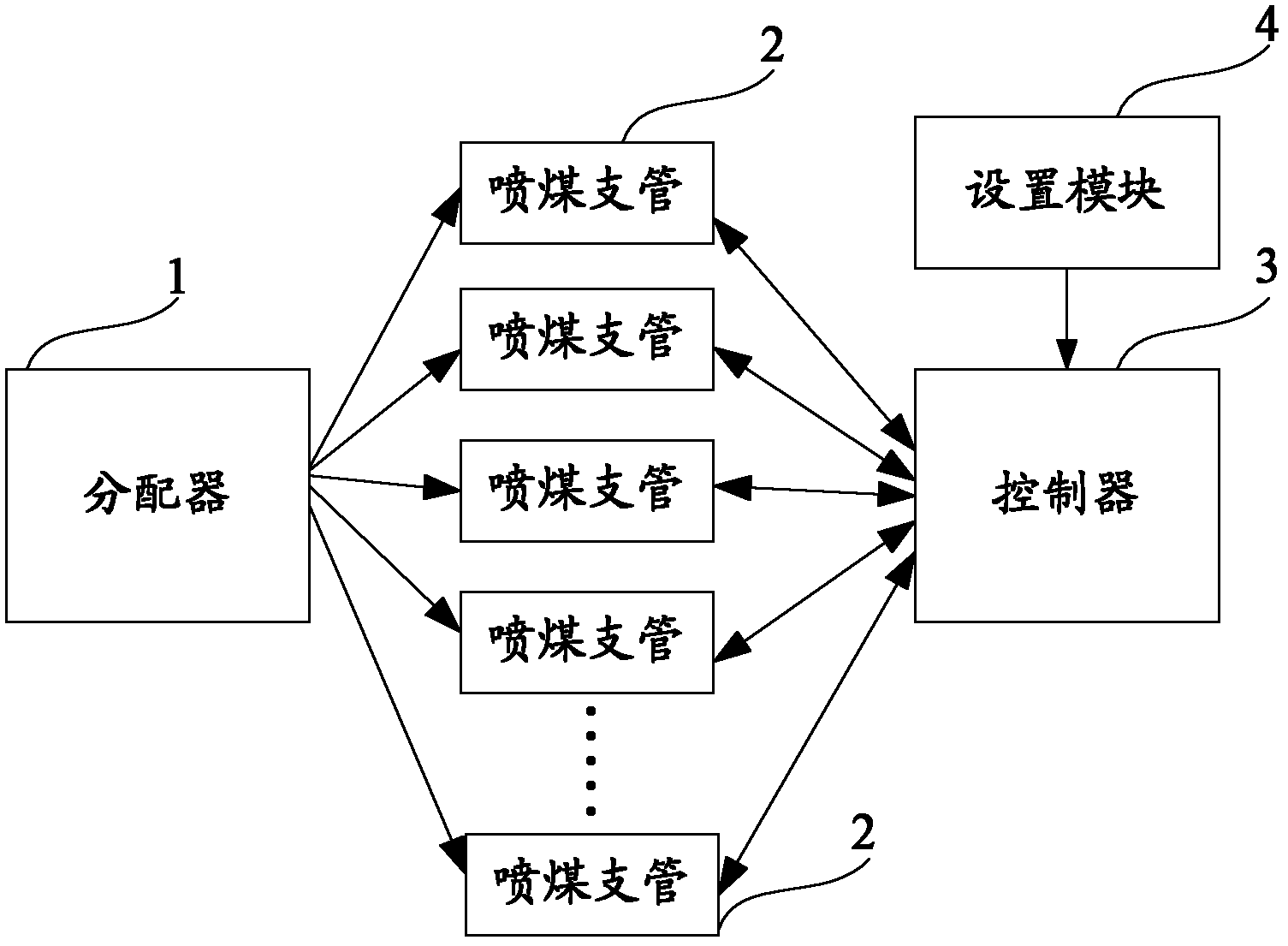

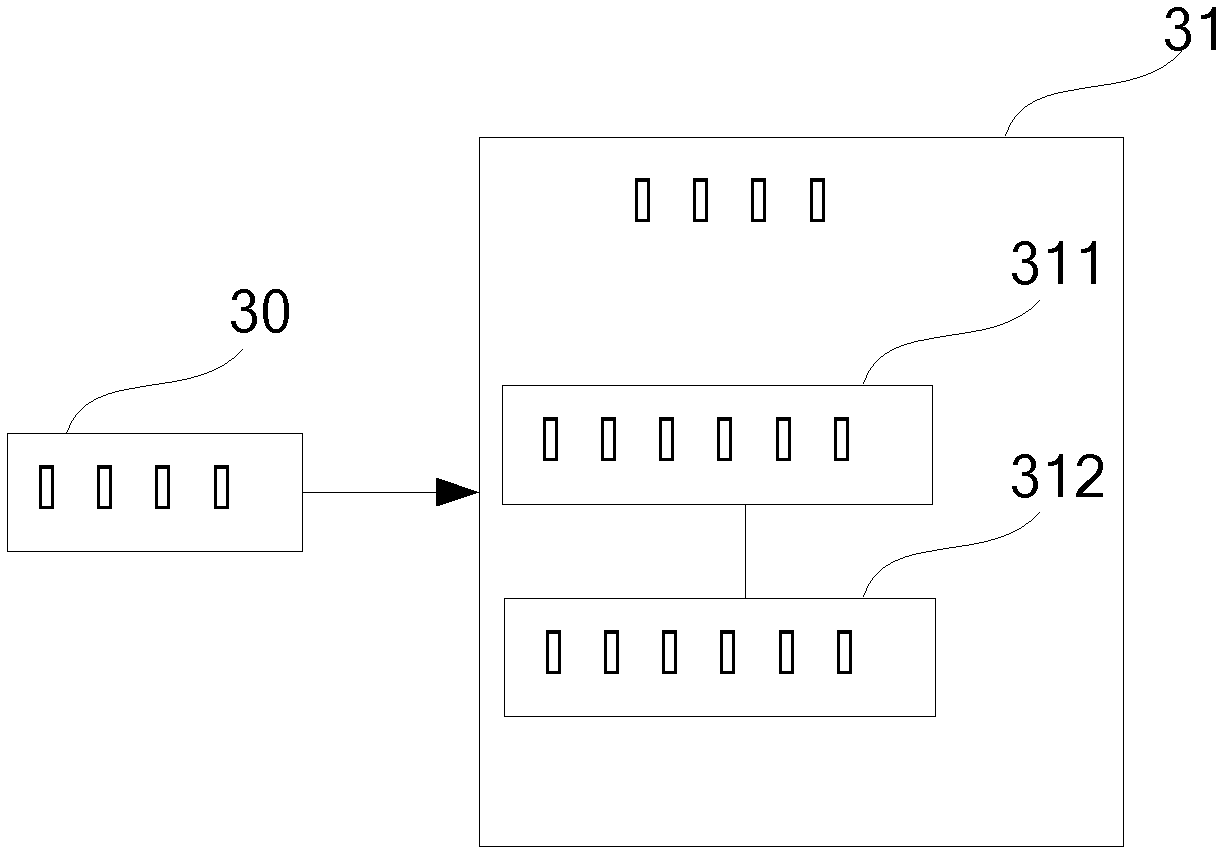

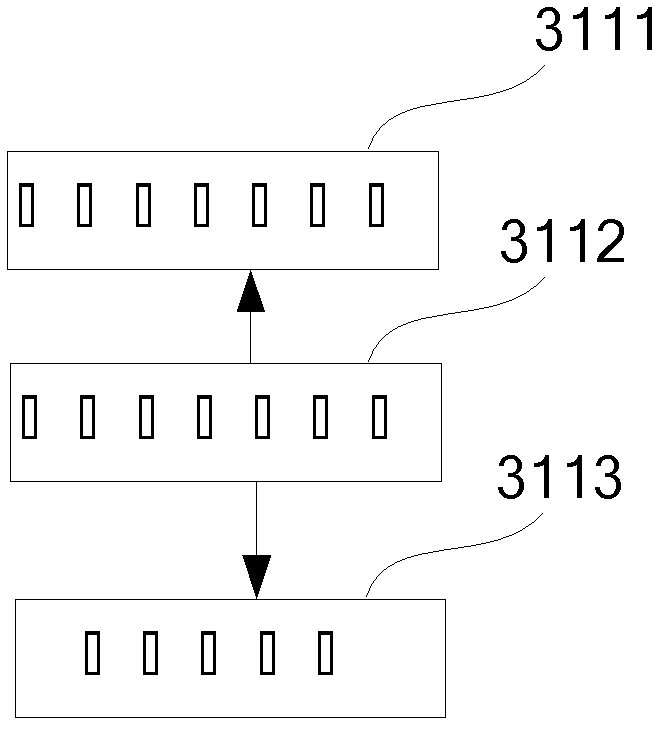

Anti-blocking control system for coal spray branch pipes of distributor of coal spray system of blast furnace

ActiveCN102220444AReduce the probability of cloggingReduce work intensityTuyeresBlast furnace detailsControl systemDistributor

The invention discloses an anti-blocking control system for coal spray branch pipes of a distributor of a coal spray system of a blast furnace, which comprises a distributor, a plurality of coal spray branch pipes and a controller, wherein the distributor is used for distributing pulverized coal from a main coal spray pipe to the plurality of coal spray branch pipes; and the plurality of coal spray branch pipes are used for sweeping through a circulating sweeping way in a circulating sweeping cycle under the control of the controller. According to the control system adopting the circulating sweeping for the coal spray branch pipes of the coal spray distributor of the blast furnace, the blocking rate of the coal spray branch pipes can be greatly reduced, the uniformity of coal spray quantity from a wind gap of the blast furnace is stabilized, the working intensity of operation staff during the production process is reduced, the level of automation is improved, the safety of production is powerfully ensured and conditions are created for stability and smooth operation of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

Semiconductor device manufacturing apparatus and method

ActiveUS7722439B2Stable UniformityAvoid heat effectsPolishing machinesRevolution surface grinding machinesSemiconductorSemiconductor device fabrication

A semiconductor device manufacturing apparatus according to the present invention comprises a head for holding a semiconductor wafer, a retainer ring for surrounding the outer periphery of the semiconductor wafer held by the head, and a polishing pad for polishing a polished surface of the semiconductor wafer. This apparatus presses the polished surface of the semiconductor wafer against the polishing pad together with the retainer ring to polish the semiconductor wafer. The retainer ring used in the present invention has a surface that is in contact with the polishing pad, which increases a contact area of the retainer ring against the polishing pad in accordance with wear of the retainer ring.

Owner:MICRON TECH INC

Hot pepper gel for treating rheumatism

A hot pepper gel for treating rheumatism is prepared from hot pepper, menthol, borneol, Na2EDTA, carbomer, nipagin ethylester, glycerine, propanediol and ethanol. Its preparing process is also disclosed.

Owner:马宏英

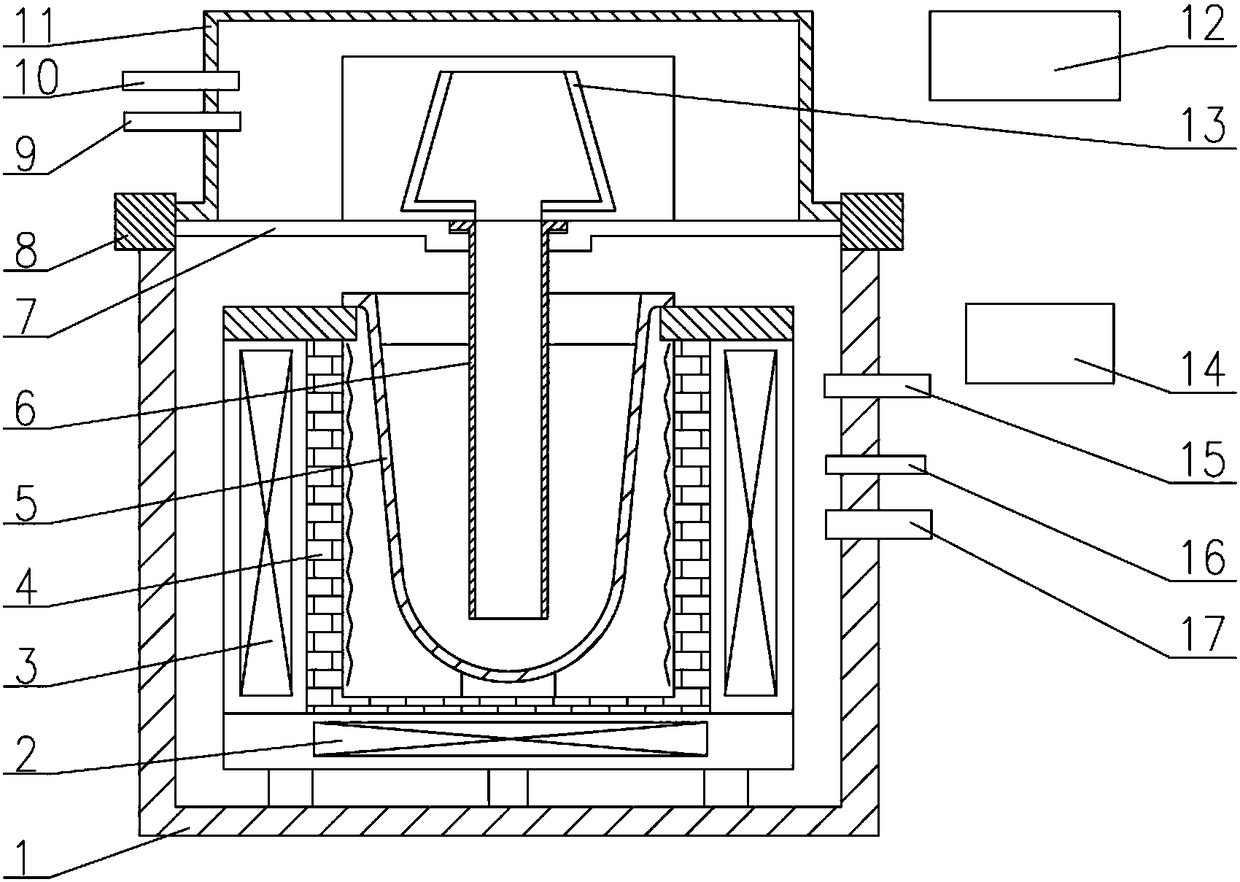

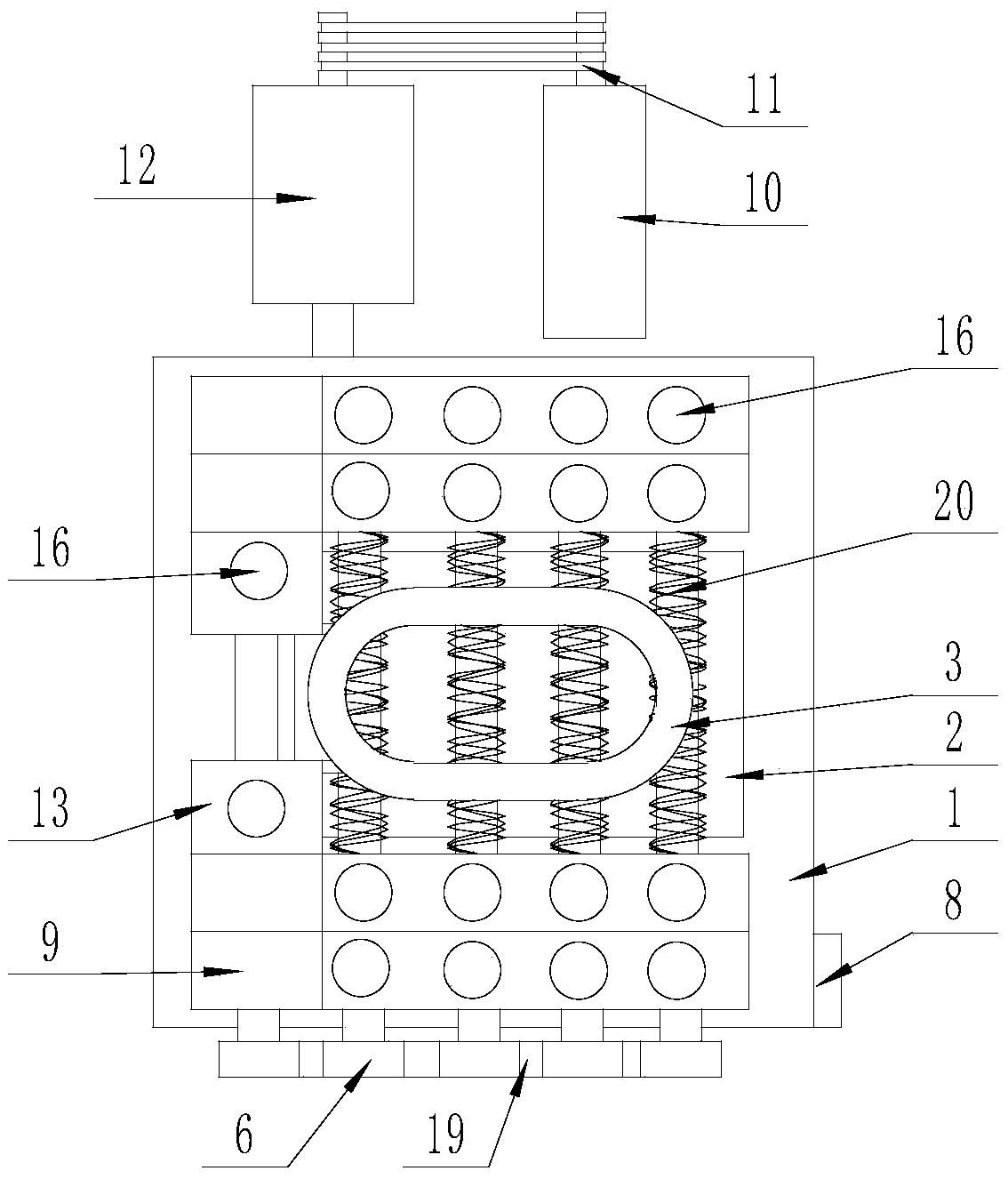

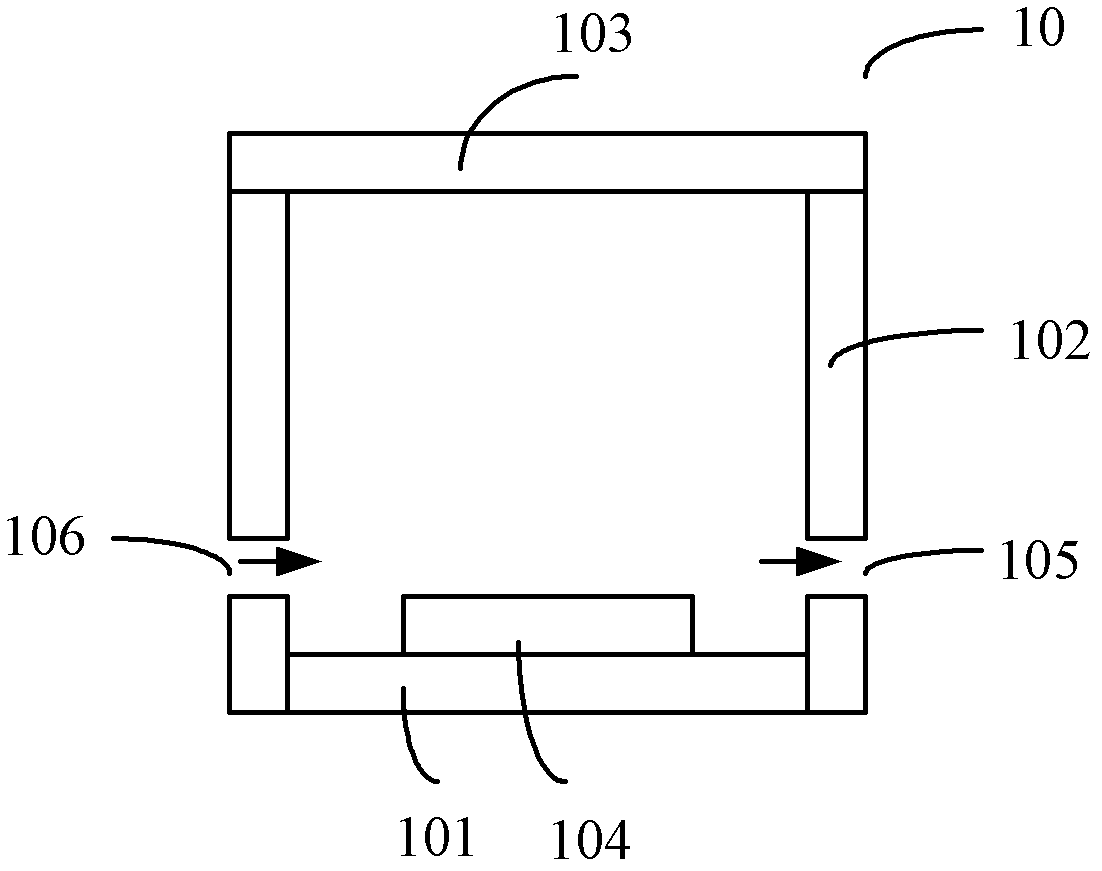

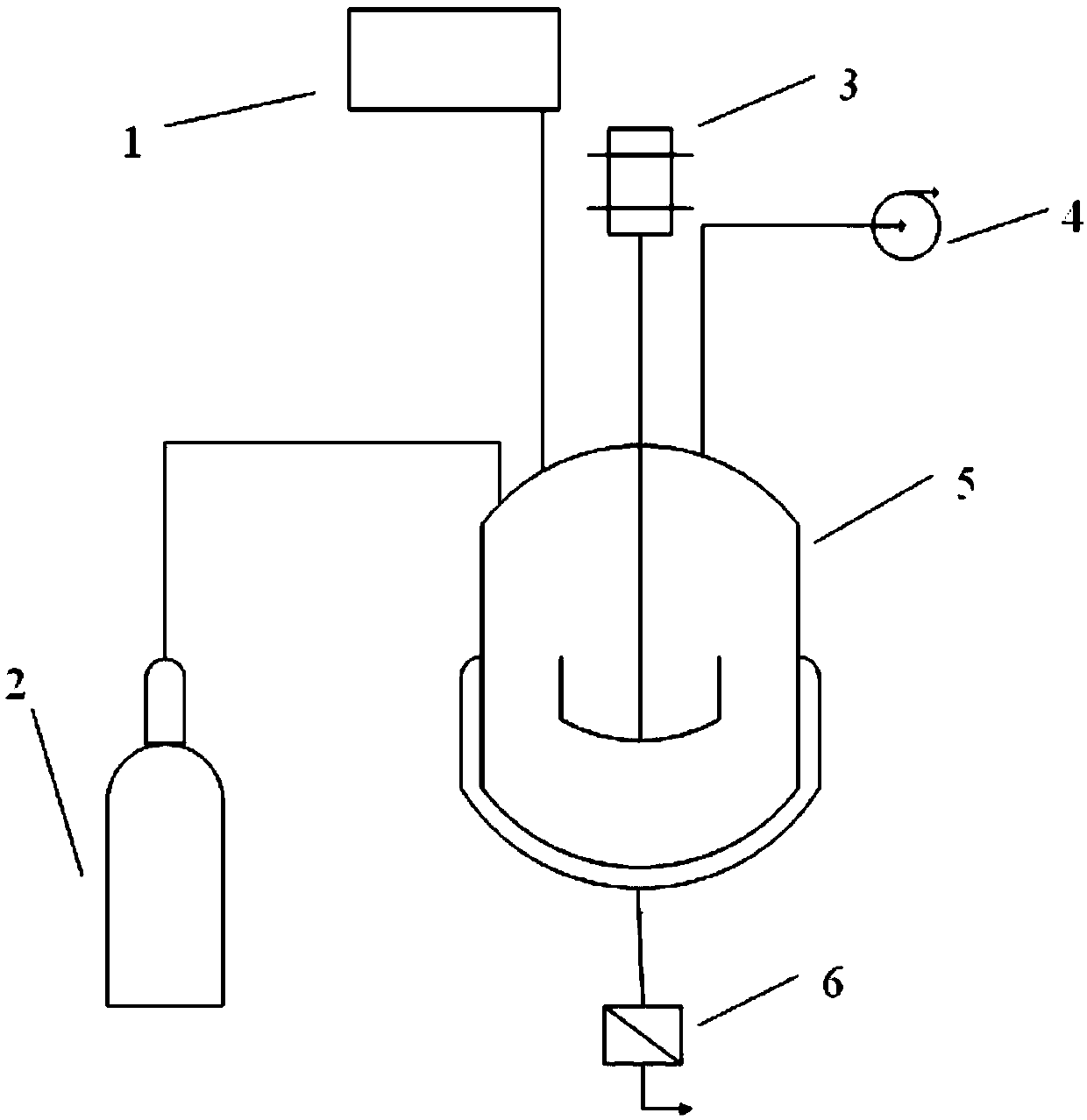

Melt stirring type multifunctional anti-gravity casting device and casting method

The invention relates to a melt stirring type multifunctional anti-gravity casting device and a casting method. The melt stirring type multifunctional anti-gravity casting device comprises a lower pressure tank, a melting furnace, strong magnets, a variable-frequency power source, a middle separation plate, an upper pressure tank and the like. The method comprises the steps that the melting furnace melts metal materials, the lower pressure tank is sealed, the variable-frequency power source applies an alternating magnetic field to melts through the strong magnets, vacuum stirring degassing treatment of the melts is realized, electromagnetic stirring is continuously applied to the melts in the anti-gravity casting preparation process and the pouring process, and casting of different anti-gravity casting methods is completed through a control system. According to the casting device and the casting method, not only can vacuum stirring degassing treatment be conducted during metal materialmelting, but also alternating electromagnetic stirring force can be applied to the melts in the pouring preparation process and during pouring, and the effects of reducing the gas content of the interiors of the melts, stabilizing the uniformity of melt compositions and improving the casting quality and performance are played.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Spray nozzle device, in particular for spraying a cast strand

Spray nozzle device comprises a mixing chamber (2) which acts as a diffuser and has a mixing body (1). The mixing chamber is provided with an air inlet (3), a water inlet (4), and a nozzle outlet (5) oriented approximately in alignment with the air inlet through which an air or water mixture exits. The air inlet comprises a region projecting in the mixing chamber, and at least one air outlet hole, which is perpendicular to the longitudinal axis of the mixing chamber. The water enters near the tip through at least one water outlet hole, which is oriented perpendicular to the longitudinal axis.

Owner:SMS CONCAST

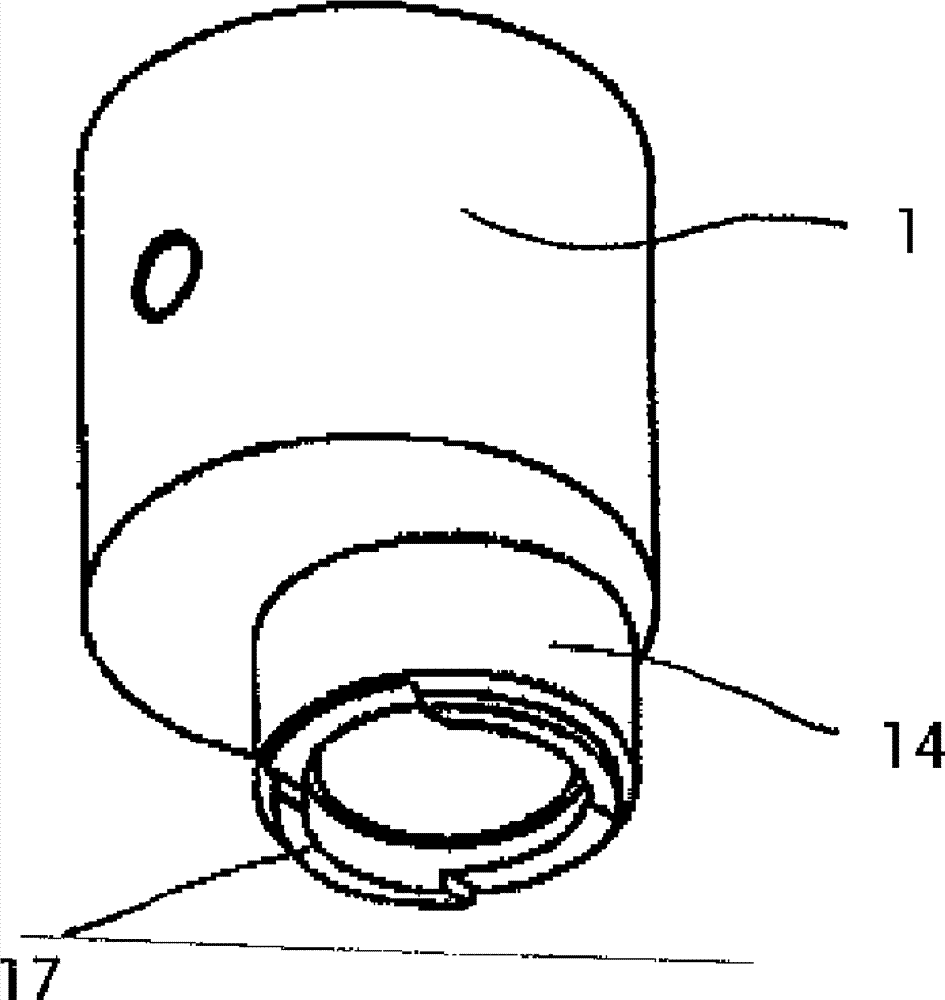

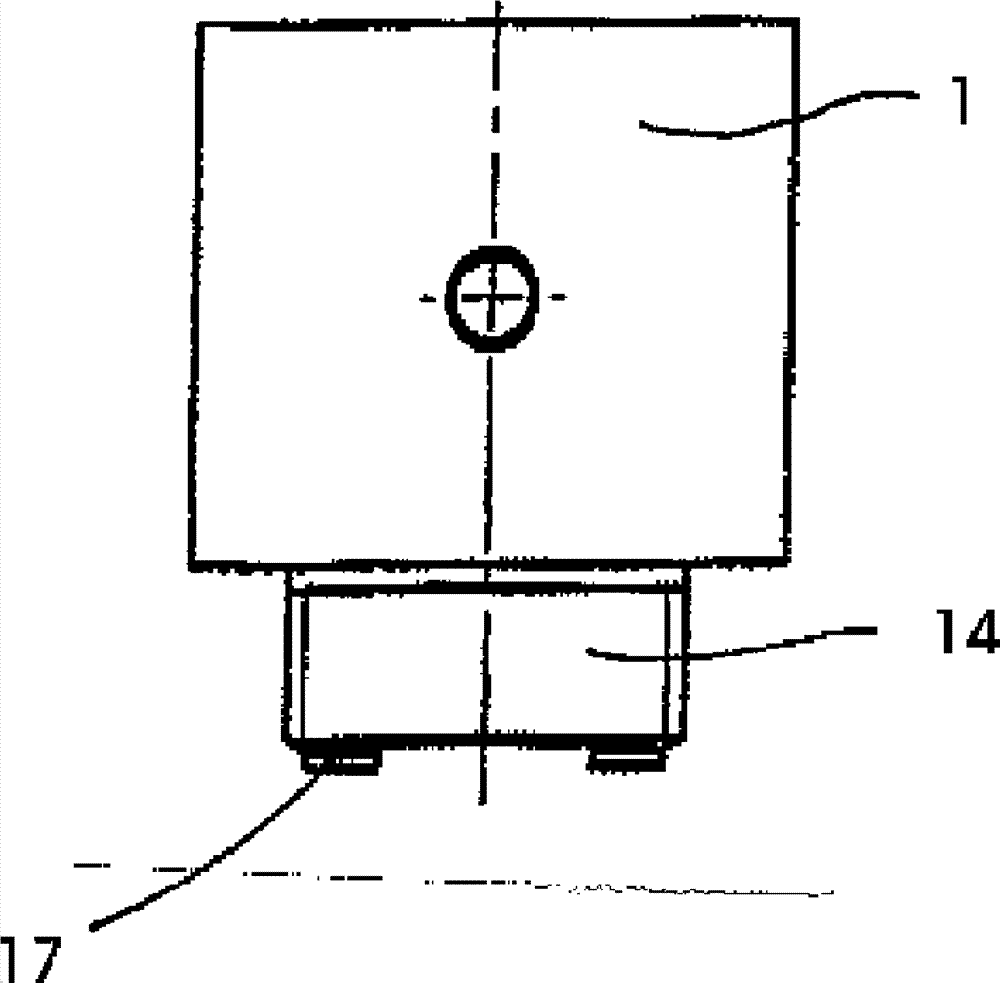

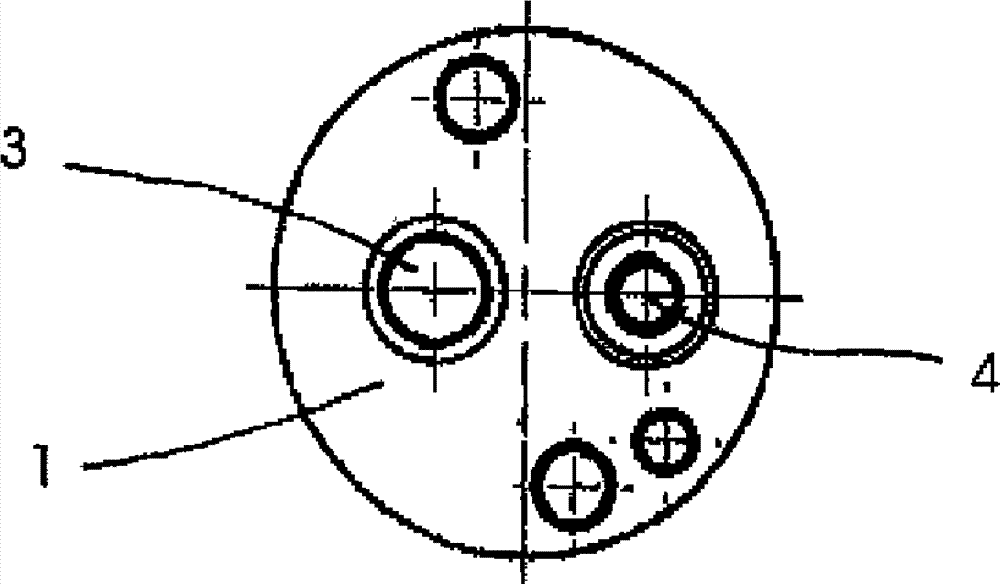

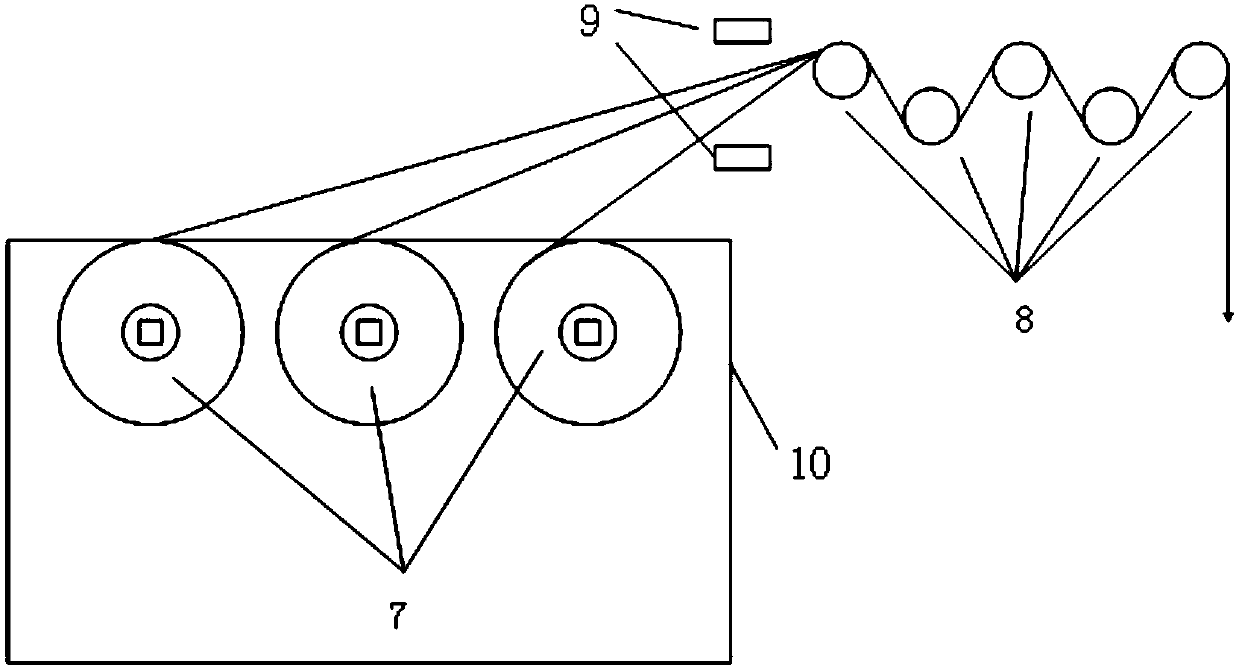

Grain grinding device

InactiveCN105498899AStable UniformityEasy to clean and maintainGrain treatmentsGrain storageEngineering

The invention discloses a grain grinding device. The grain grinding device comprises a workbench and a groove formed in the workbench, wherein a grain storage hopper is arranged above the groove; wheel carrier groups are arranged at the left and right sides of the workbench respectively; grinding units are arranged on the two wheel carrier groups and are connected with the groove in the workbench in a lapping manner; driving units driving the grinding units to move are arranged at the front and rear sides of the workbench; the grinding units are jointly formed by driving grinding mechanisms and driven grinding mechanisms, which are arranged on the wheel carrier groups; a controller is arranged on the workbench and is electrically connected with the driving units. The grain grinding device has the beneficial effects of simple structure and strong practicability.

Owner:王晓晓

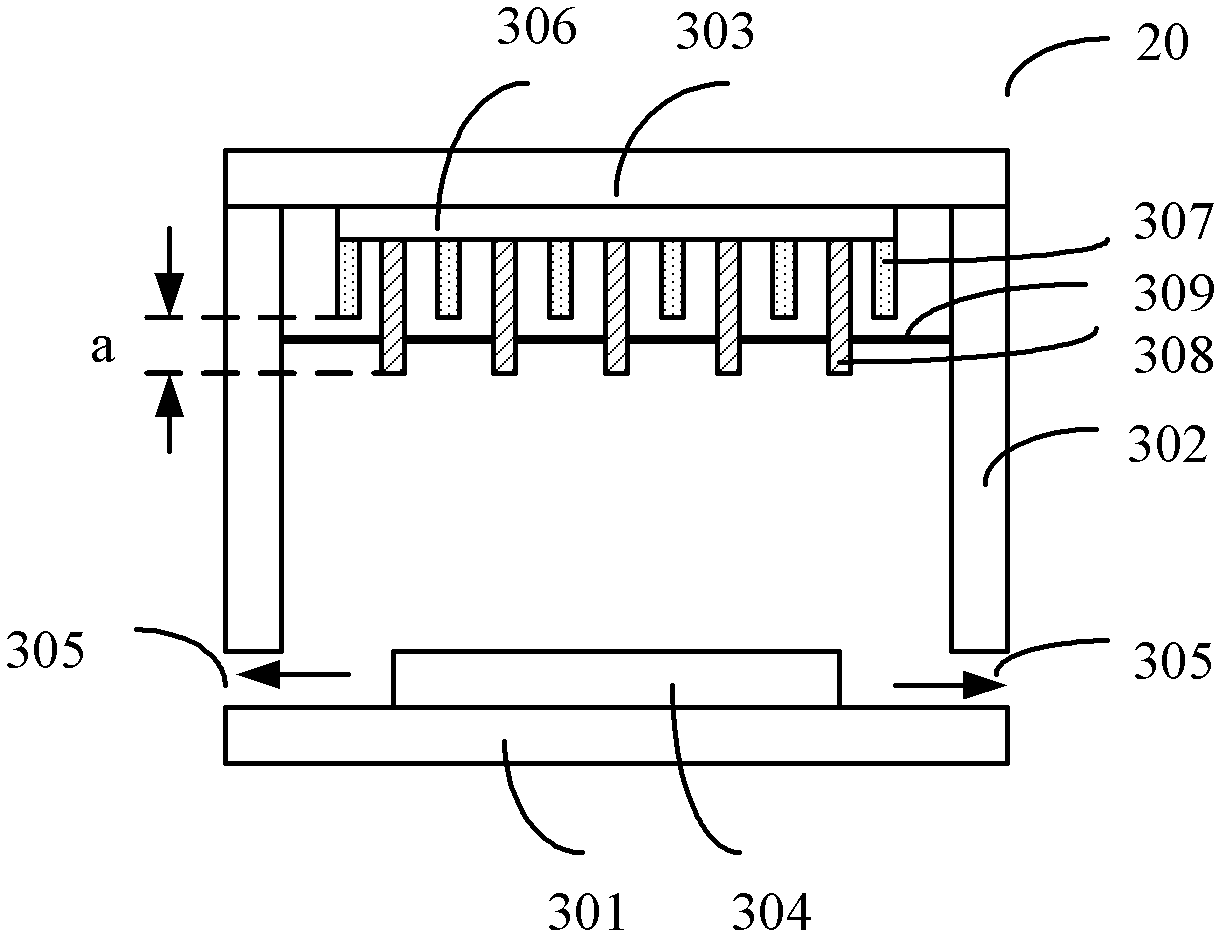

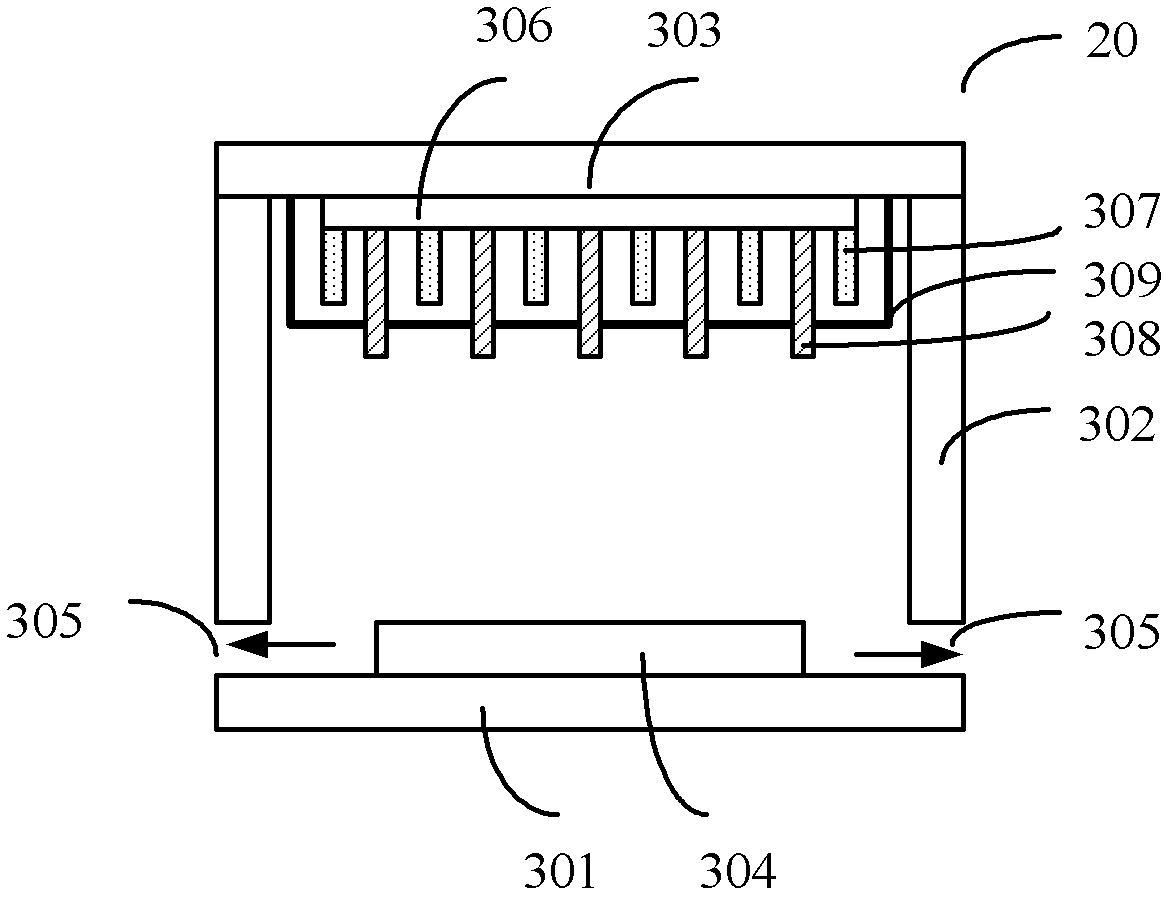

Vapor phase epitaxy device

ActiveCN103132138AImprove uniformityUniform flow rateFrom chemically reactive gasesVapour phase epitaxyGas phase

A vapor phase epitaxy device comprises a bottom plate, an upper cover plate, side walls located between the bottom plate and the upper cover plate and a substrate on the bottom plate. The bottom plate, the upper cover plate, the side walls and the substrate constitute a reaction cavity. The vapor phase epitaxy device further comprises at least four air discharge ports distributed at lower ends of the side walls at equal included angles, and a heating device located on the upper cover plate and opposite to the substrate, wherein the at least four air discharge ports are used for discharging air in the reaction cavity, and a plurality of heating lamp tubes are distributed on the heating device. The vapor phase epitaxy device improves uniformity of an epitaxy layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

IZO sintered compact sputtering target and method for producing same

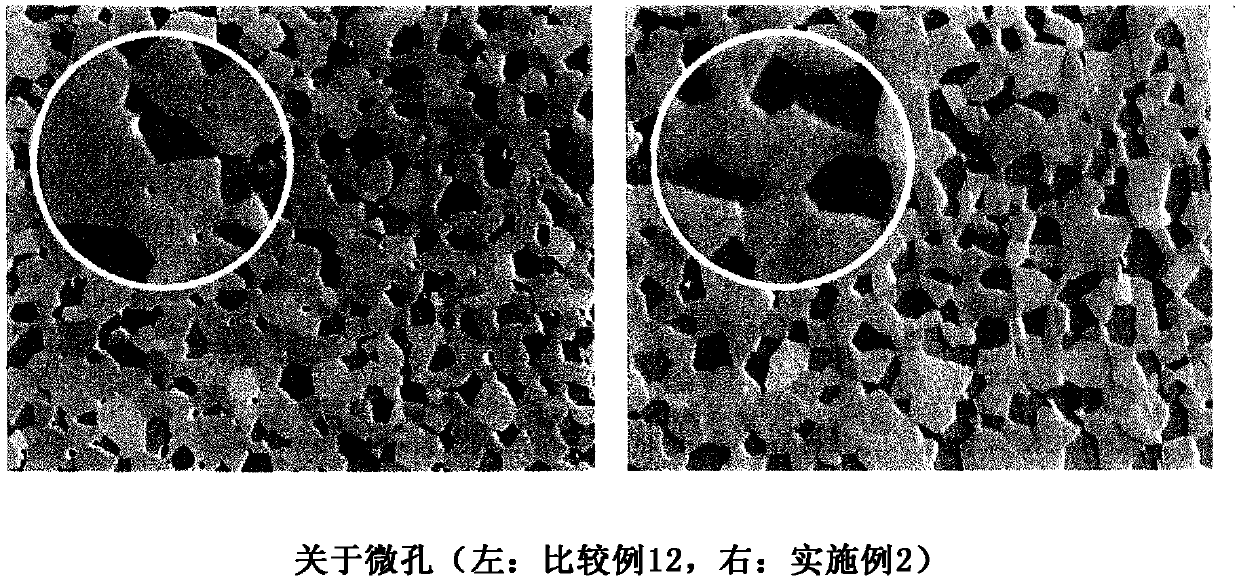

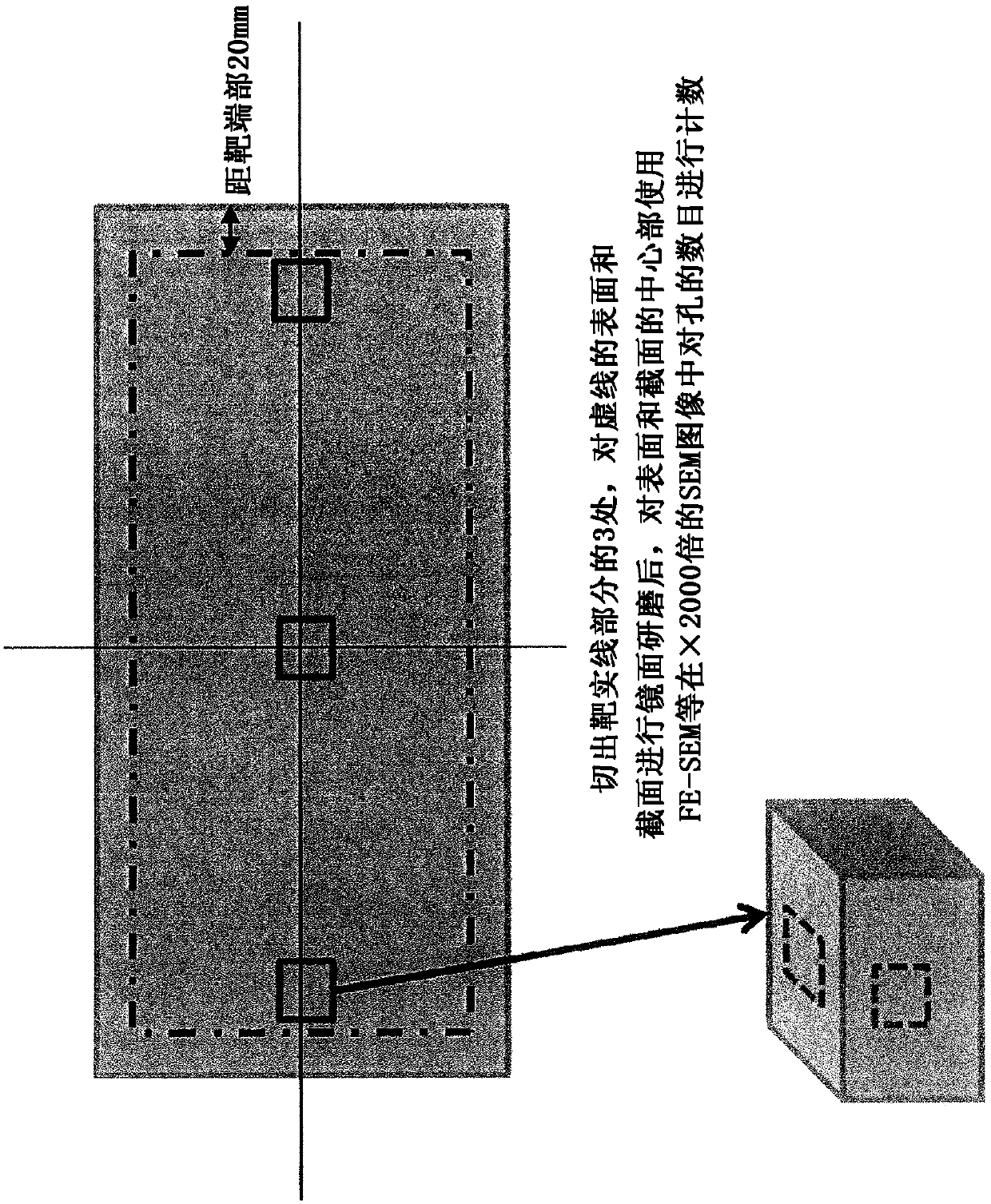

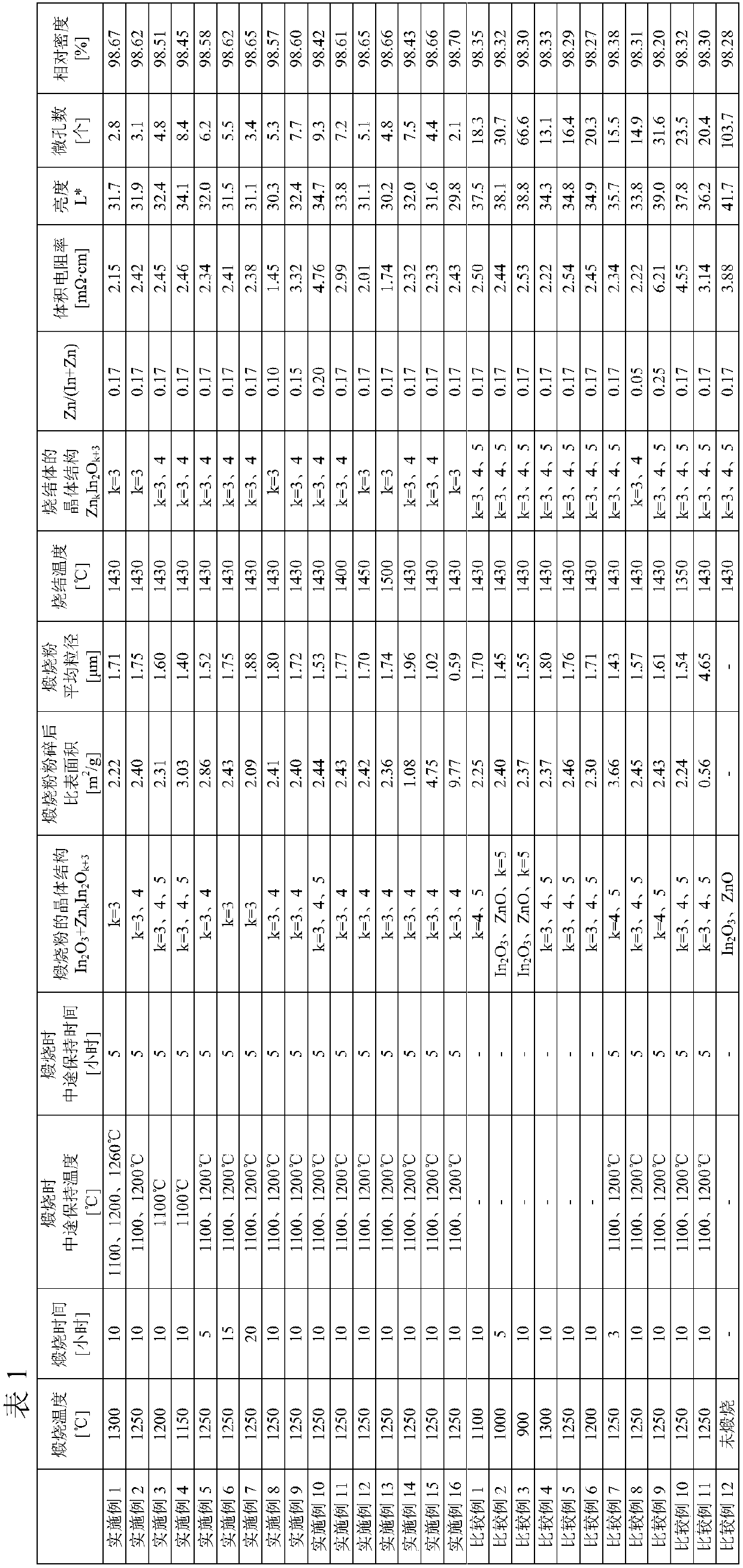

ActiveCN107614741AInhibit nodulationReduce grindingVacuum evaporation coatingSputtering coatingIndiumComposite oxide

Provided is an indium oxide-zinc oxide-based oxide (IZO) sintered compact target that is characterized in that an oxide that constitutes the target is a composite oxide of In2O3 and ZnkIn2Ok+3 (k=3, 4or 5) and that the relative density of the target is 98.4% or more. The present invention addresses the problem of increasing the density of an IZO sintered compact and reducing the number of fine holes (micropores) remaining between crystal grains so as to improve the quality of a formed film.

Owner:JX NIPPON MINING & METALS CO LTD

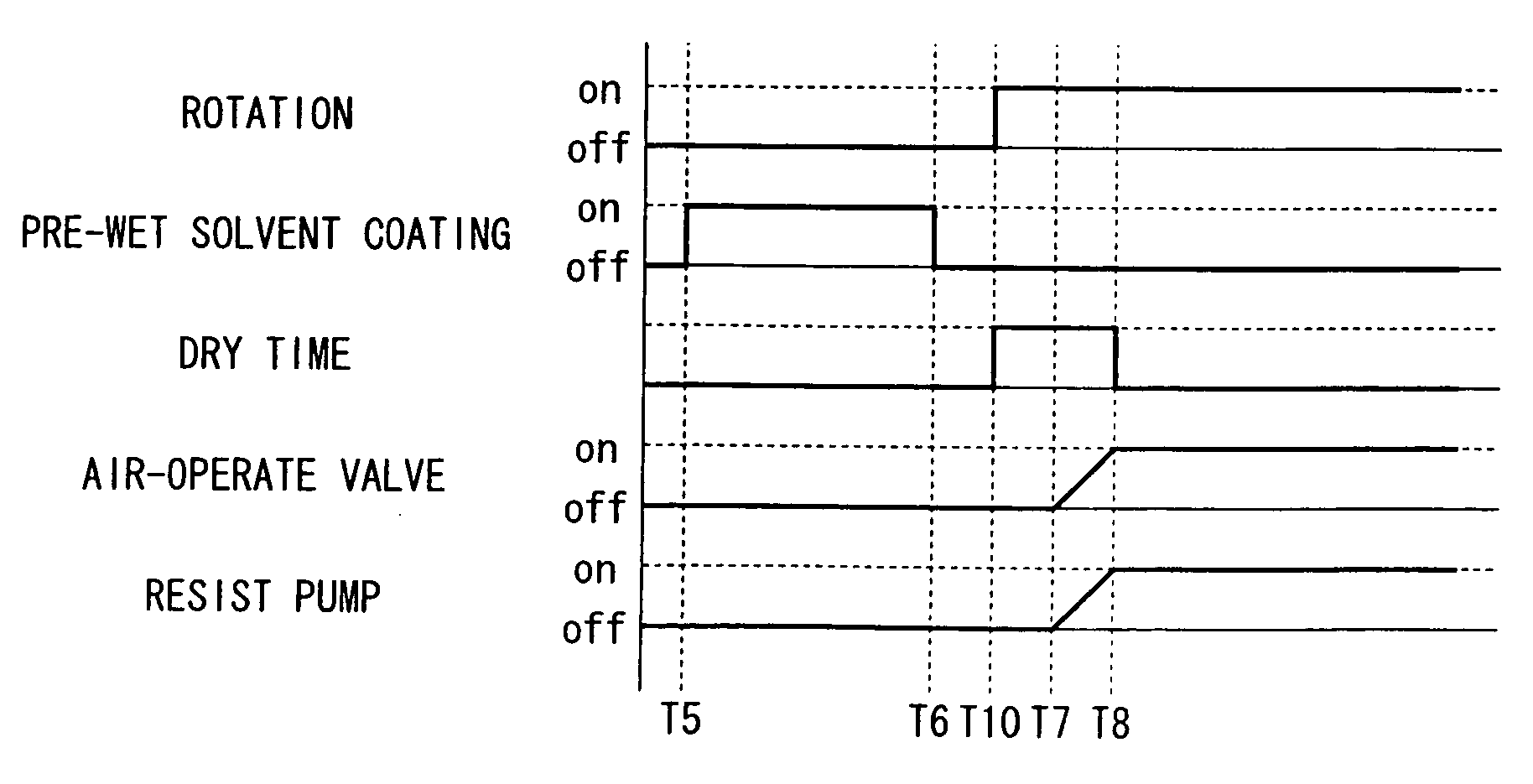

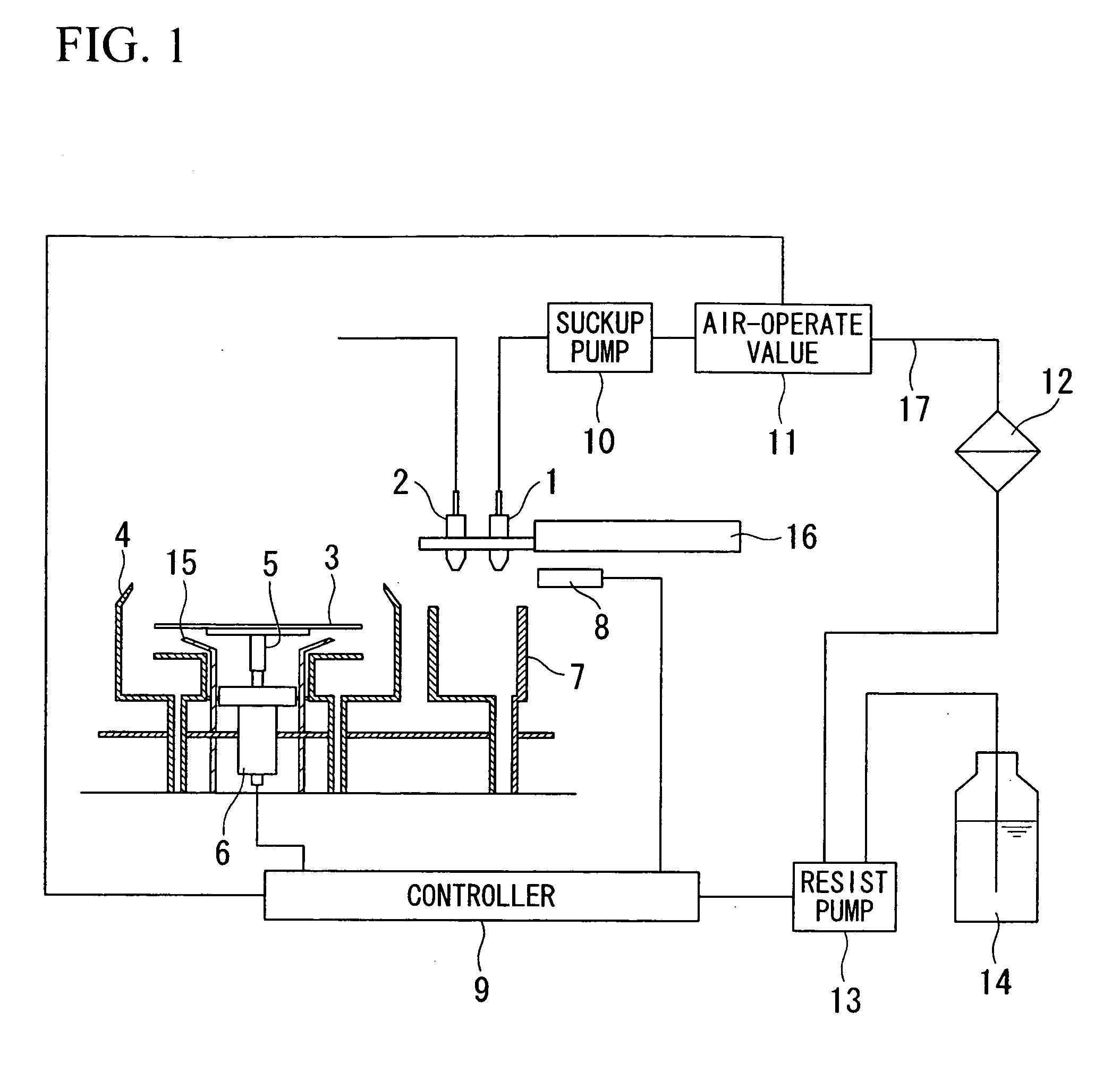

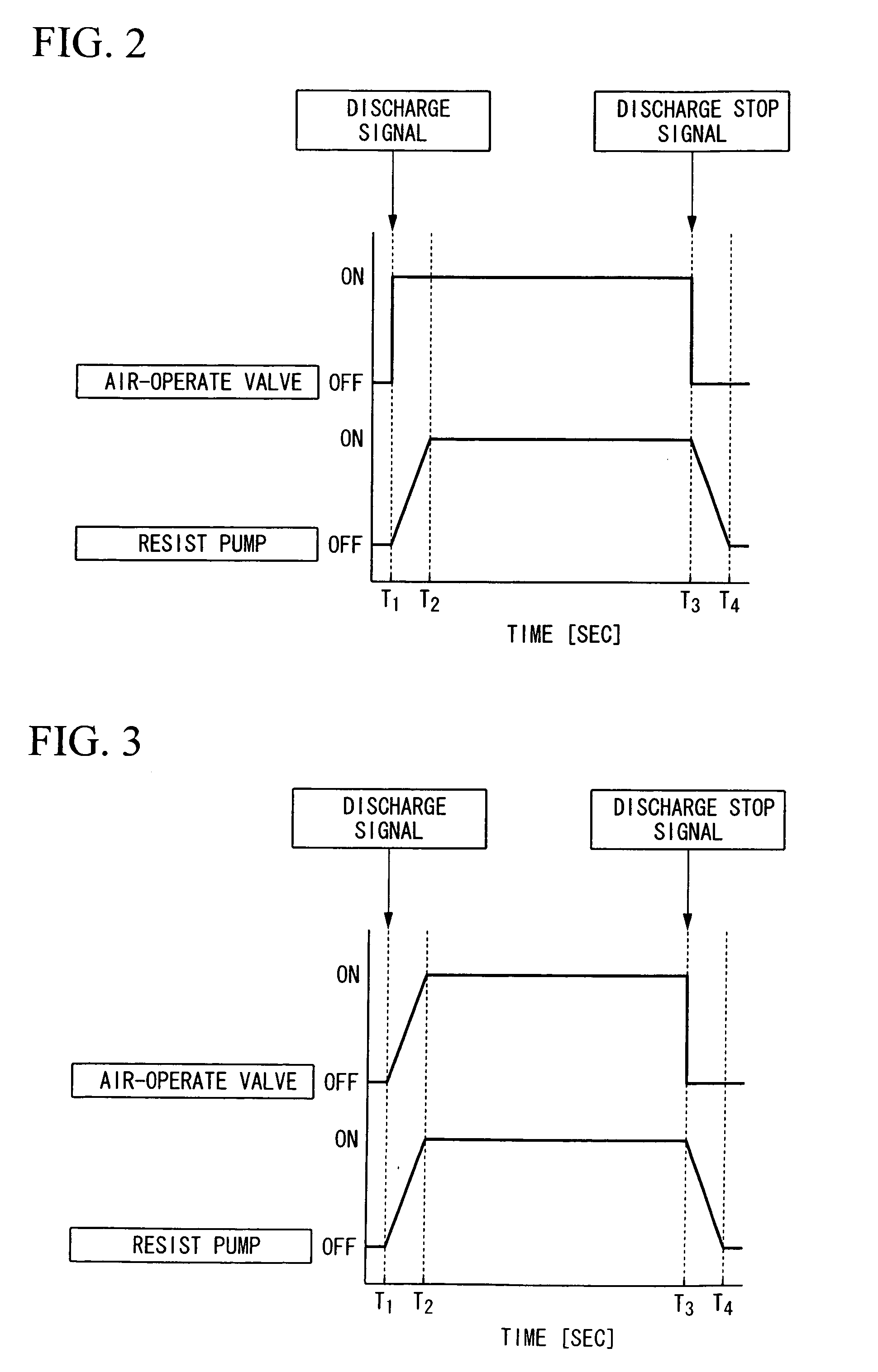

Resist coating method and apparatus

InactiveUS20080216740A1Stable productionStable UniformityLiquid surface applicatorsPhotomechanical apparatusResistDelayed time

A resist coating method includes a dummy dispensation step for discharging a resist onto a semiconductor substrate in response to a dummy discharge signal, a pre-wet step for applying and then drying a pre-wet solvent on the semiconductor substrate, and a resist coating step for applying the resist onto the semiconductor substrate in response to a resist discharge signal. The resist discharge signal is output at a timing that precedes a predetermined dry time being elapsed by a delay time, which is calculated between the timing for outputting the dummy discharge signal and the timing for actually discharging the resist, thus normally maintaining the predetermined dry time constant. This makes it possible to stably produce pre-wet effects, to improve the uniformity regarding the thickness of a resist film formed on the semiconductor substrate, and to reduce dispersion regarding pre-wet effects between resist coating apparatuses.

Owner:ELPIDA MEMORY INC

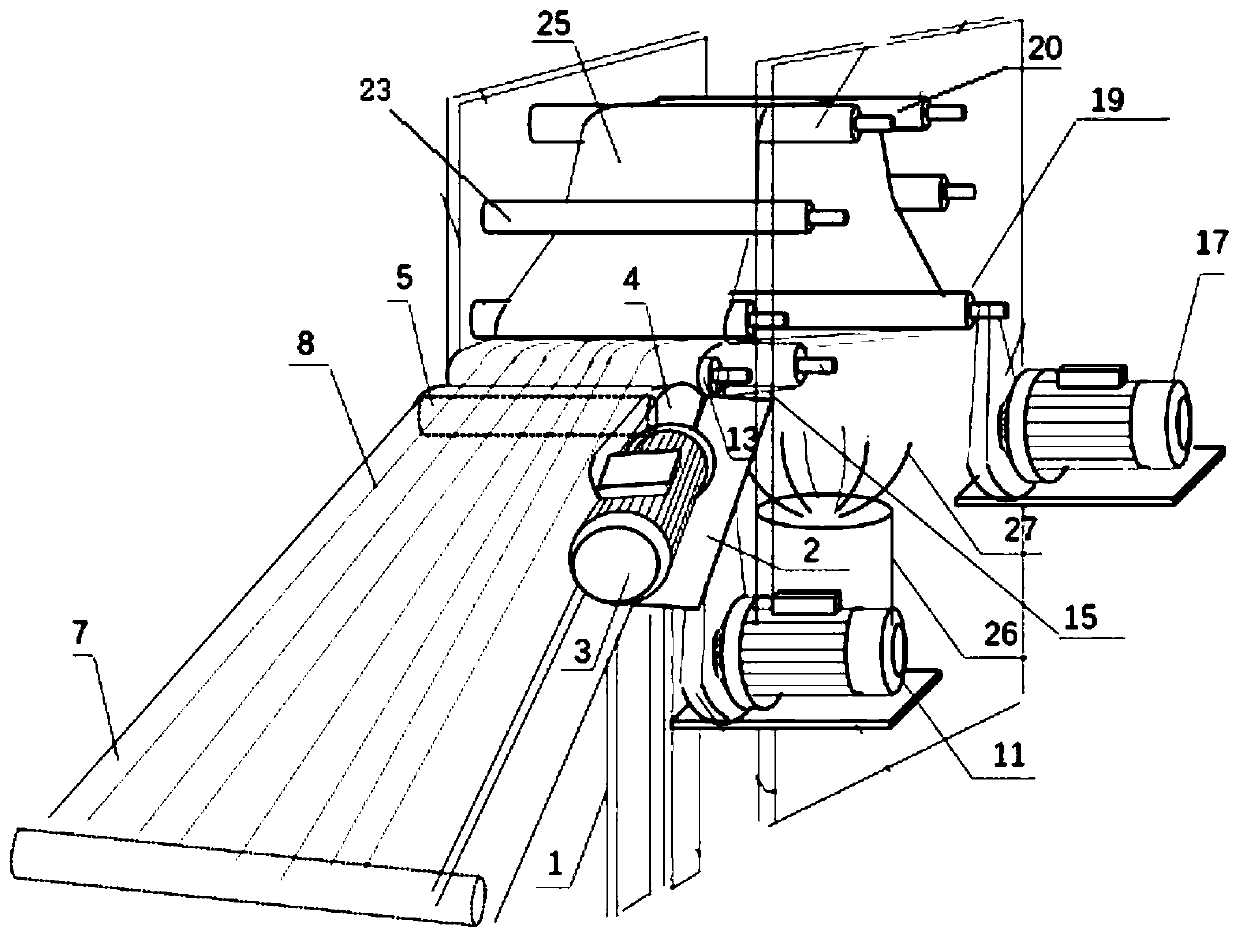

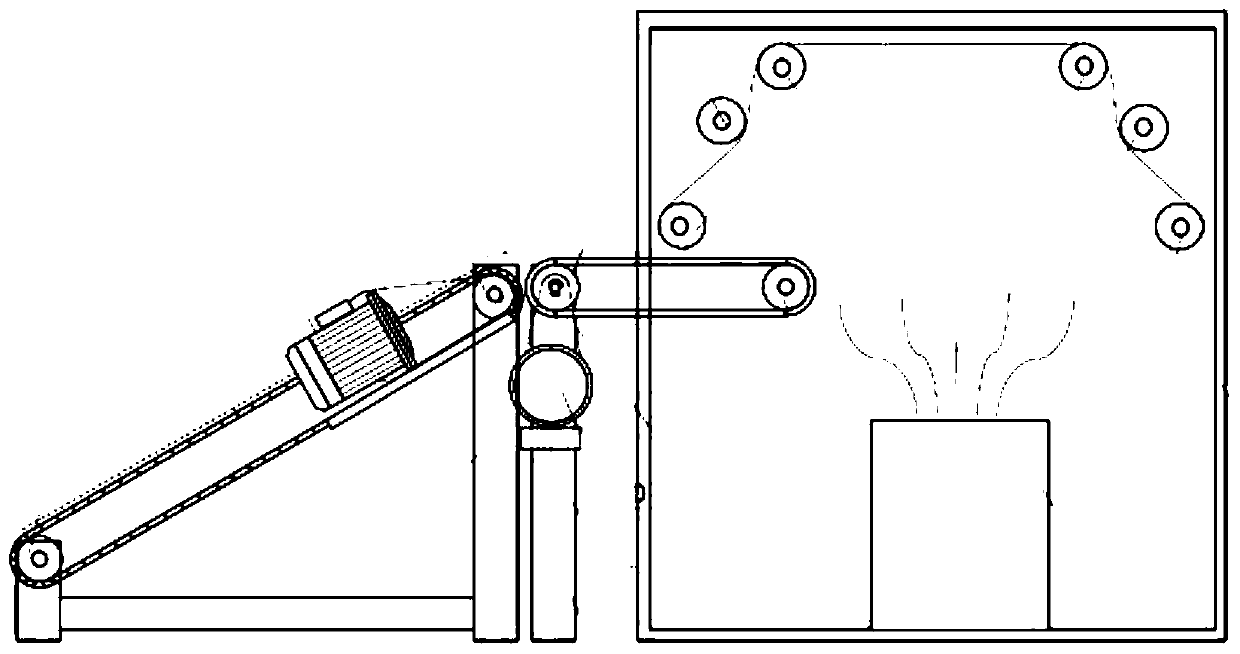

Uniform transition cotton net transmission device

The invention relates to a uniform transition cotton net transmission device. The device comprises a supporting and fixing iron support, wherein the front end of the supporting and fixing iron support is obliquely provided with a cotton net feeding conveyor belt, the upper side of the cotton net feeding conveyor belt is in horizontal butt joint with a cotton net transition transmission belt, the upper side of one end of the cotton net transition transmission belt is provided with a copper net through cyclic rolling of a plurality of copper net transmission shafts, the lower side of the copper net is horizontal, an electrospinning device spraying submicron fibers upward is arranged below the copper net, and the cotton net feeding conveyor belt, the cotton net transition transmission belt and the copper net transmission shafts are driven to rotate by a first motor, a second motor and a third motor which are located at one side of the supporting and fixing iron support respectively. The uniform transition cotton net transmission device has the advantages that a carding net can maintain uniform and smooth running to directly under the copper net in the transmission process, so that the submicron fibers sprayed by the electrospinning device act on the uniform cotton net, and the derived length and uniformity of the cotton net are increased through a conduction linkage device, so that the subsequent strip forming performance achieves the best effect.

Owner:DONGHUA UNIV +1

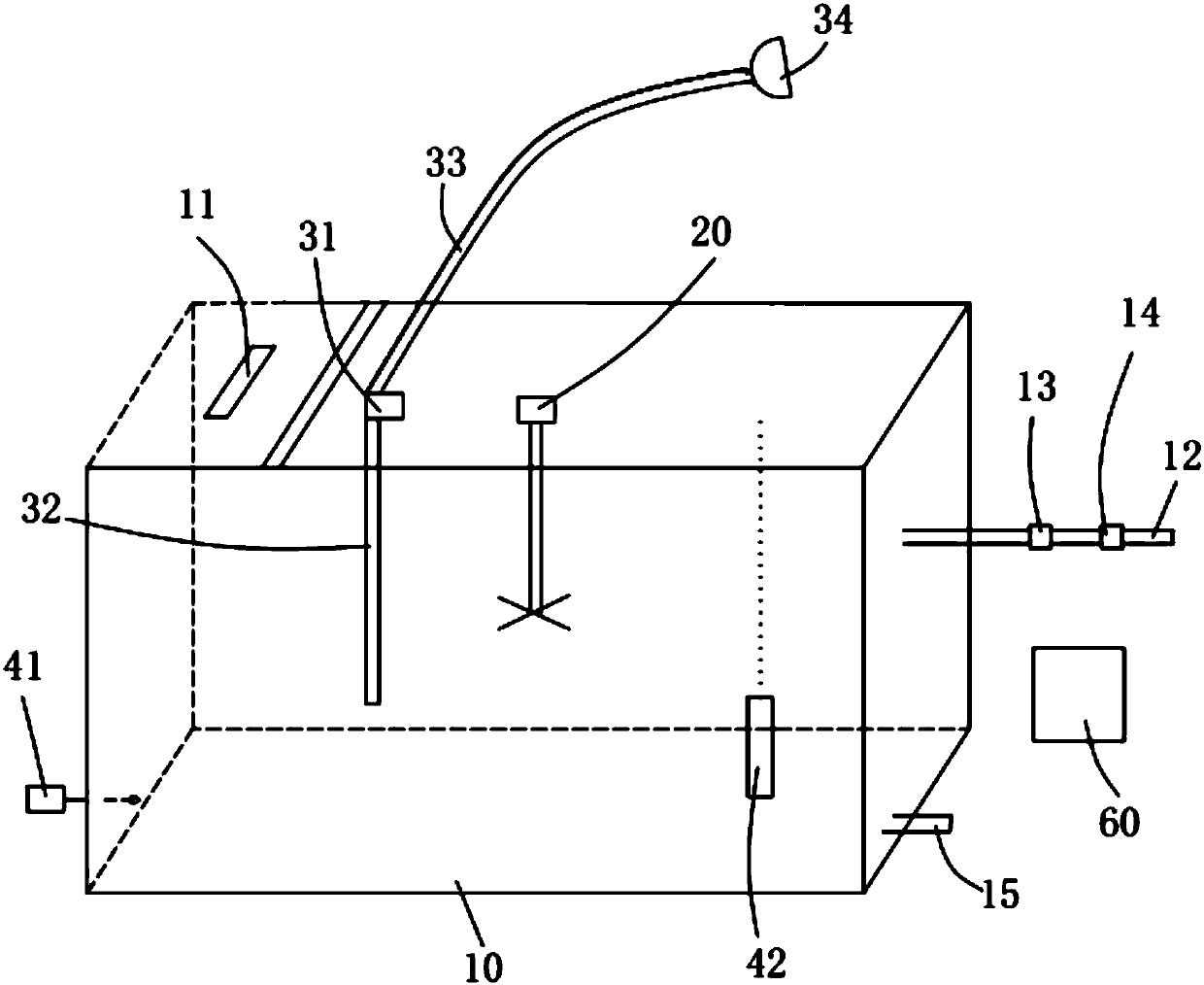

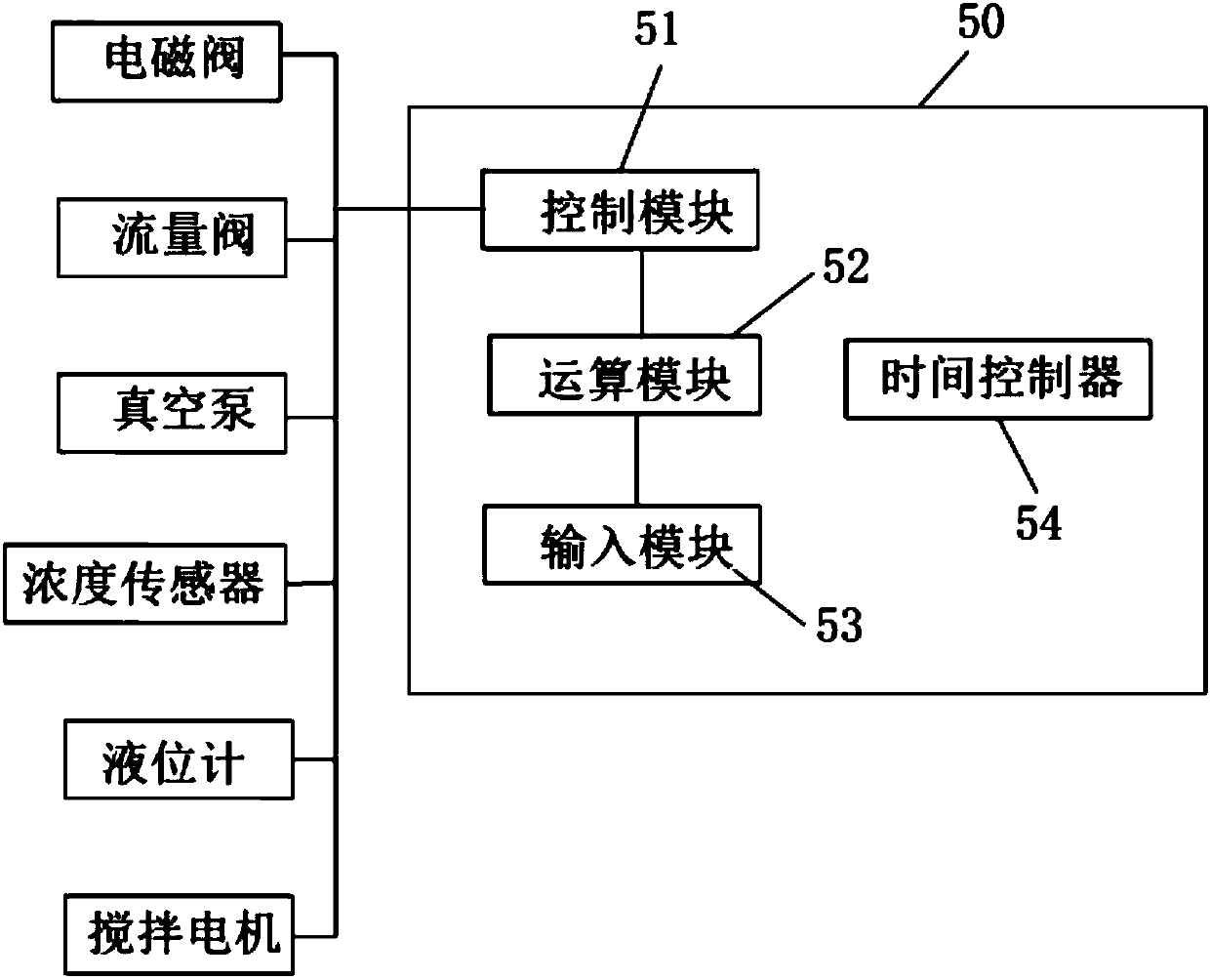

Magnetic suspension automatic preparation apparatus

InactiveCN107844064AStable concentrationStable UniformityProgramme control in sequence/logic controllersSimultaneous control of multiple variablesSolenoid valveDisplay device

The invention relates to a magnetic suspension automatic preparation apparatus. The apparatus includes a box body, a stirring device, a spraying device, a detection device, a control device, and a display device; the stirring device includes a stirring motor, a connecting rod, and blades; the spraying device includes a vacuum pump, a connection hard pipe, a connection flexible pipe and a sprayinghead; the detection device includes a concentration sensor and a liquid level gauge, wherein the detection head of the concentration sensor extends into the box body, and the liquid level gauge is located in the box body; the control device includes a main controller and a time controller, wherein the main controller is connected with a flow valve and a solenoid valve, and the time controller is connected with the stirring motor so that the stirring motor performs stirring actions according to the control of the time controller; and the display device is connected with the concentration sensorand the liquid level gauge. Compared with a conventional preparation mode, the magnetic suspension automatic preparation apparatus of the invention can save 60% to 70% of working time. Compared witha conventional preparation device, the apparatus of the invention can realize control in key links such as time, water injection quantity, magnetic suspension concentration, discharge quantity and residual liquid quantity and realize automatic operation.

Owner:KOCEL EQUIP

Device and method for preparing hollow fiber membrane

InactiveCN111054221AOvercoming problems such as low utilization rate and unstable windingStabilized membrane filament tensionSemi-permeable membranesSpinningEngineering

The invention discloses a braided tube conveying device, which comprises a braided tube connector, a wire guide wheel and a braided tube disc mounting frame, and the braided tube connector is arrangedbetween the braided tube disc mounting frame and the wire guide wheel. The device provided by the invention avoids the problems of midway connection traction and online knitting speed limitation of aknitting pipe in the original process, stabilizes the spinning tension and speed, is convenient to operate in the process, is easy for industrial continuous production, and reduces the production anduse cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

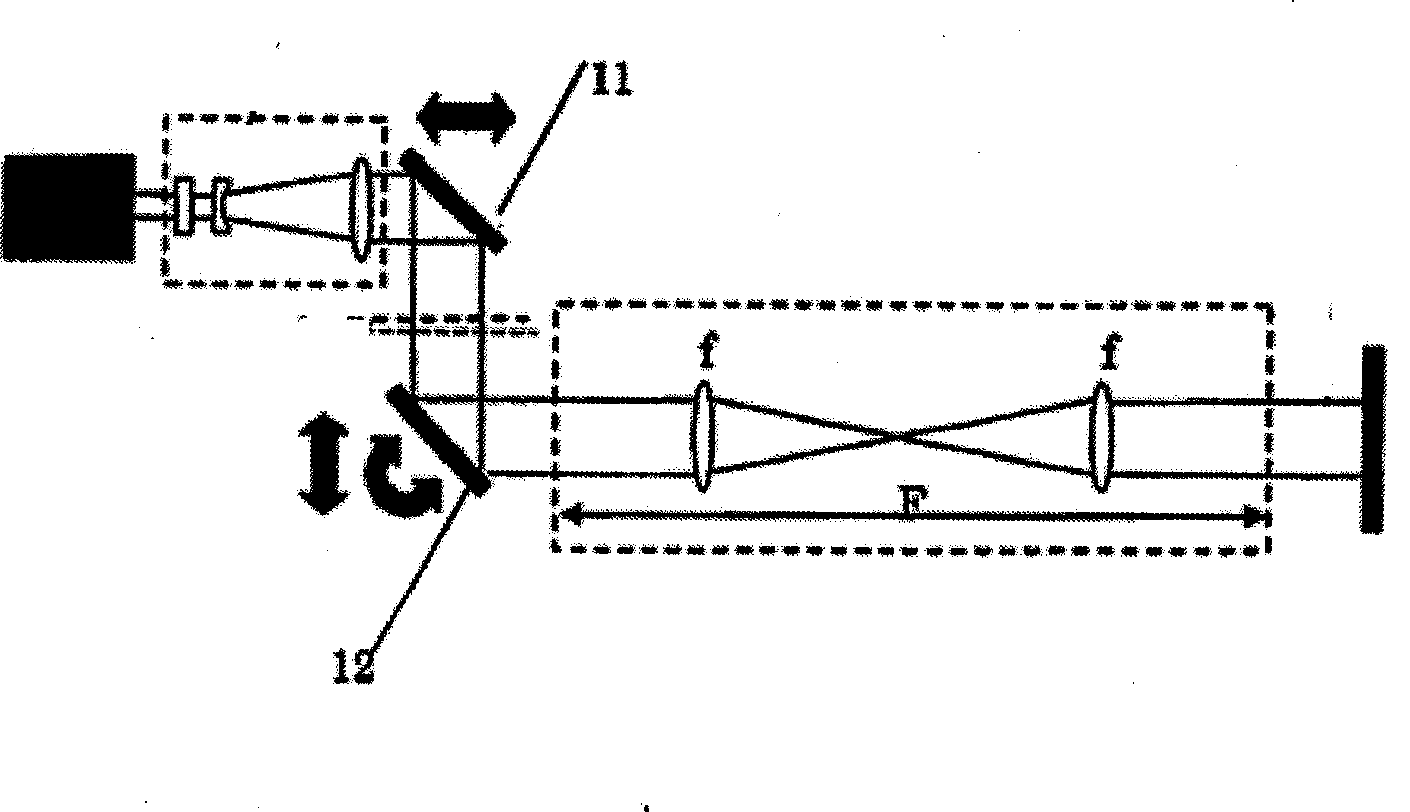

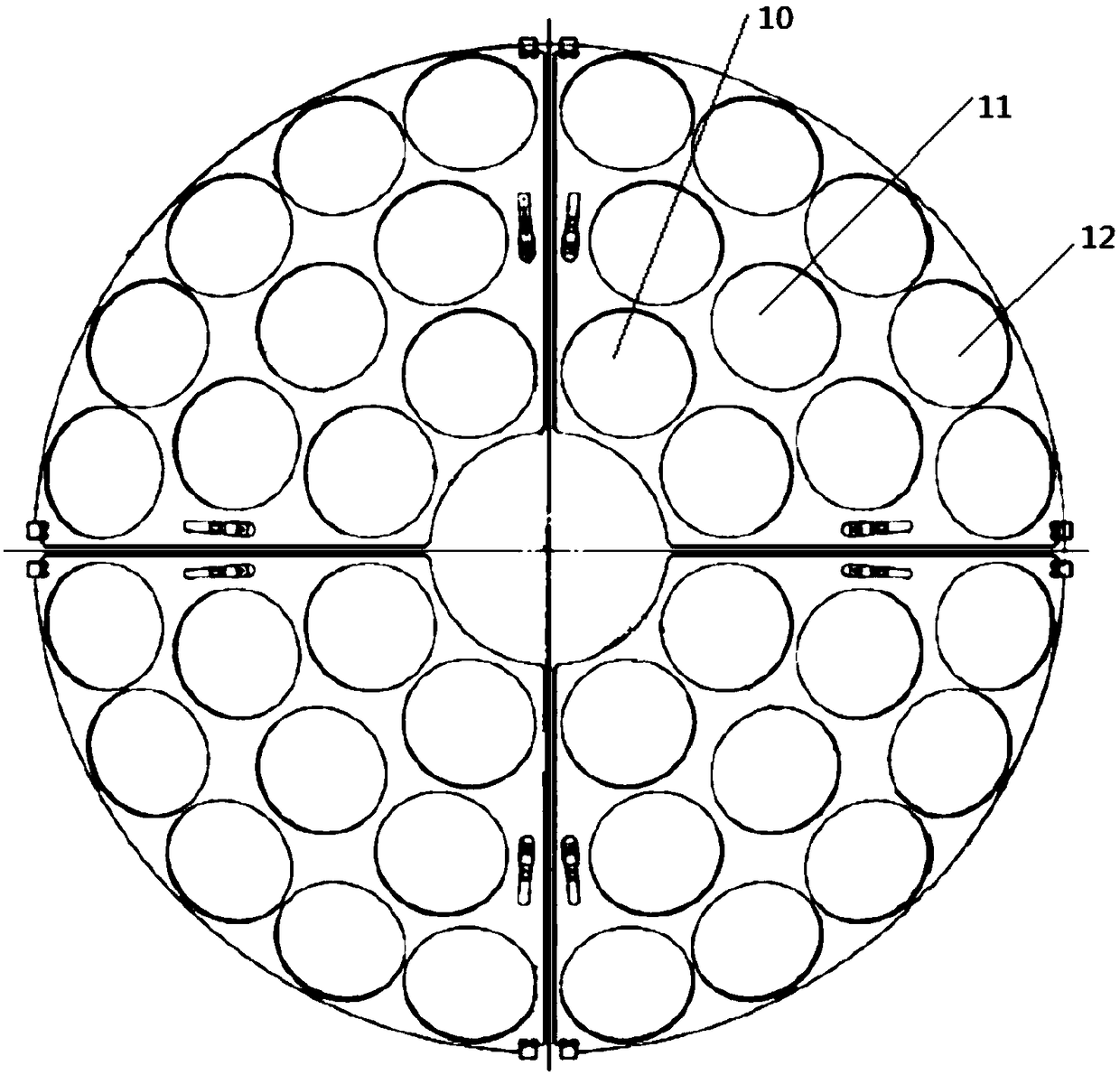

Method for adjusting uniformity of ion milling

The invention relates to a method for adjusting the uniformity of ion milling, which is characterized in that the ion milling uniformity of wafers on a planetary disk middle ring 11 and a planetary disk outer ring 12 through adjusting the height and inclination angle of a cylindrical ion source and adding a uniform baffle. The method not only stabilizes the uniformity of ion milling, but also improves the productivity and the utilization ratio of equipment and meets the requirements of process production.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

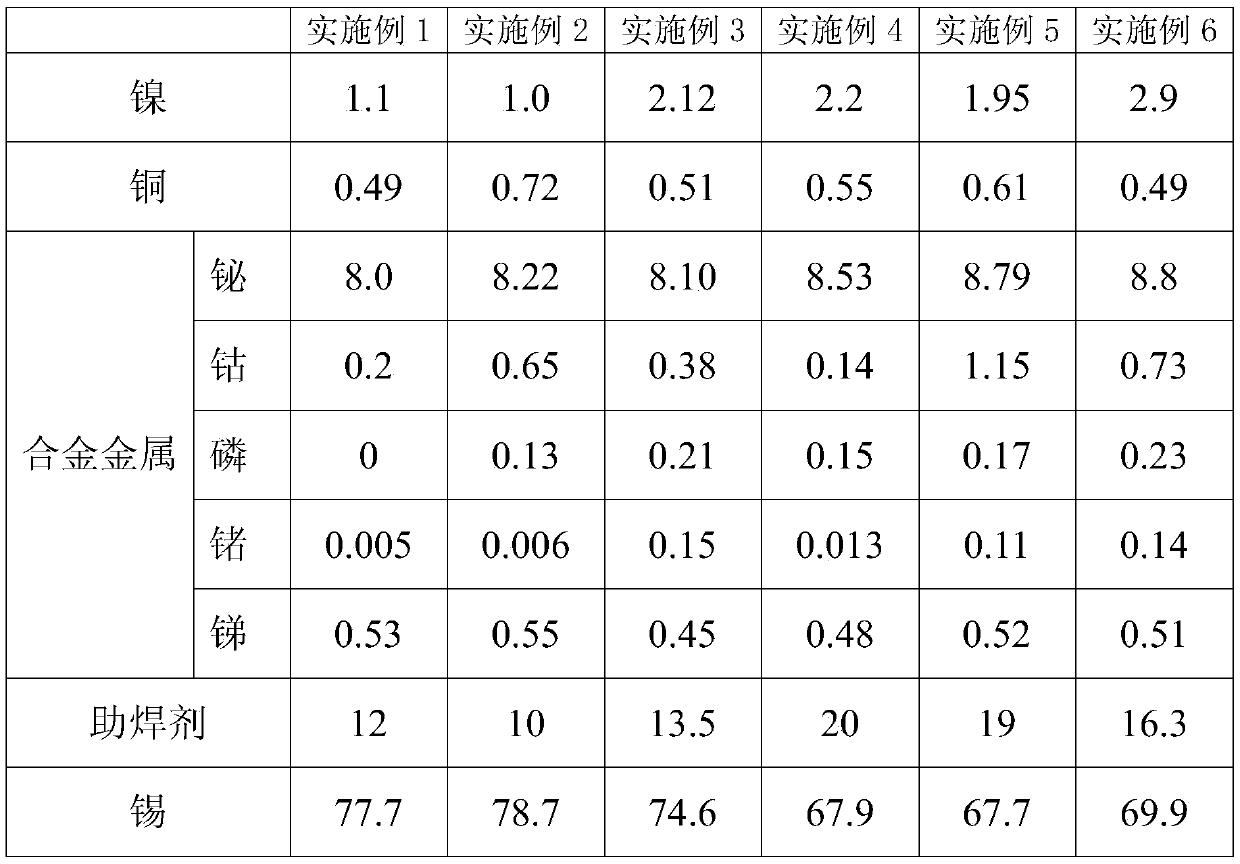

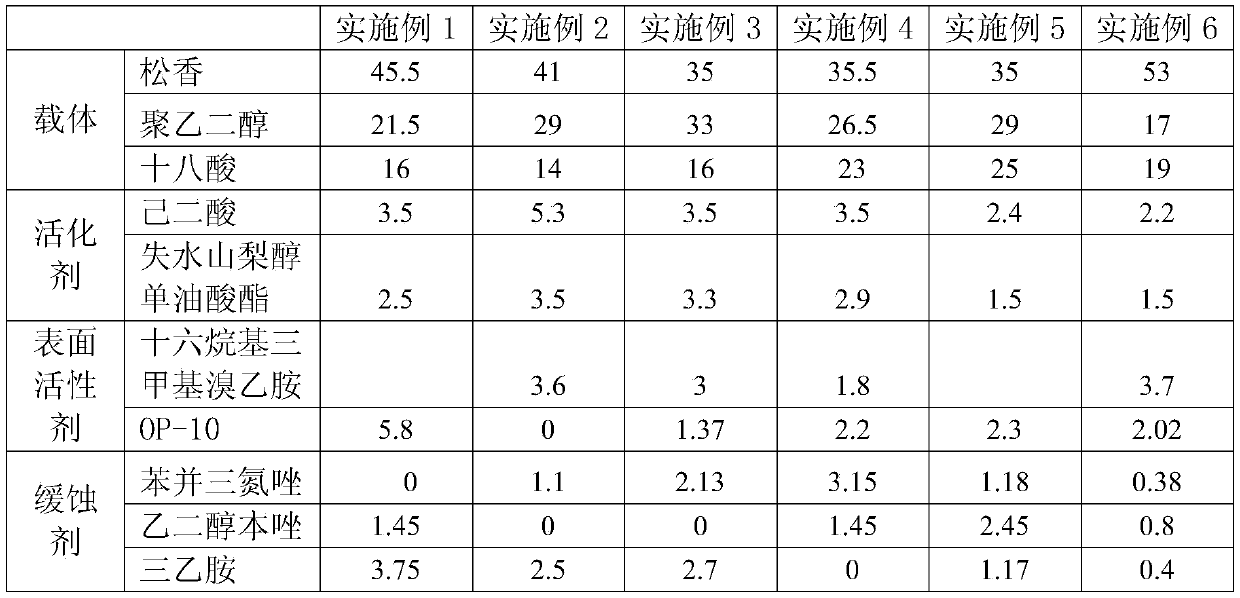

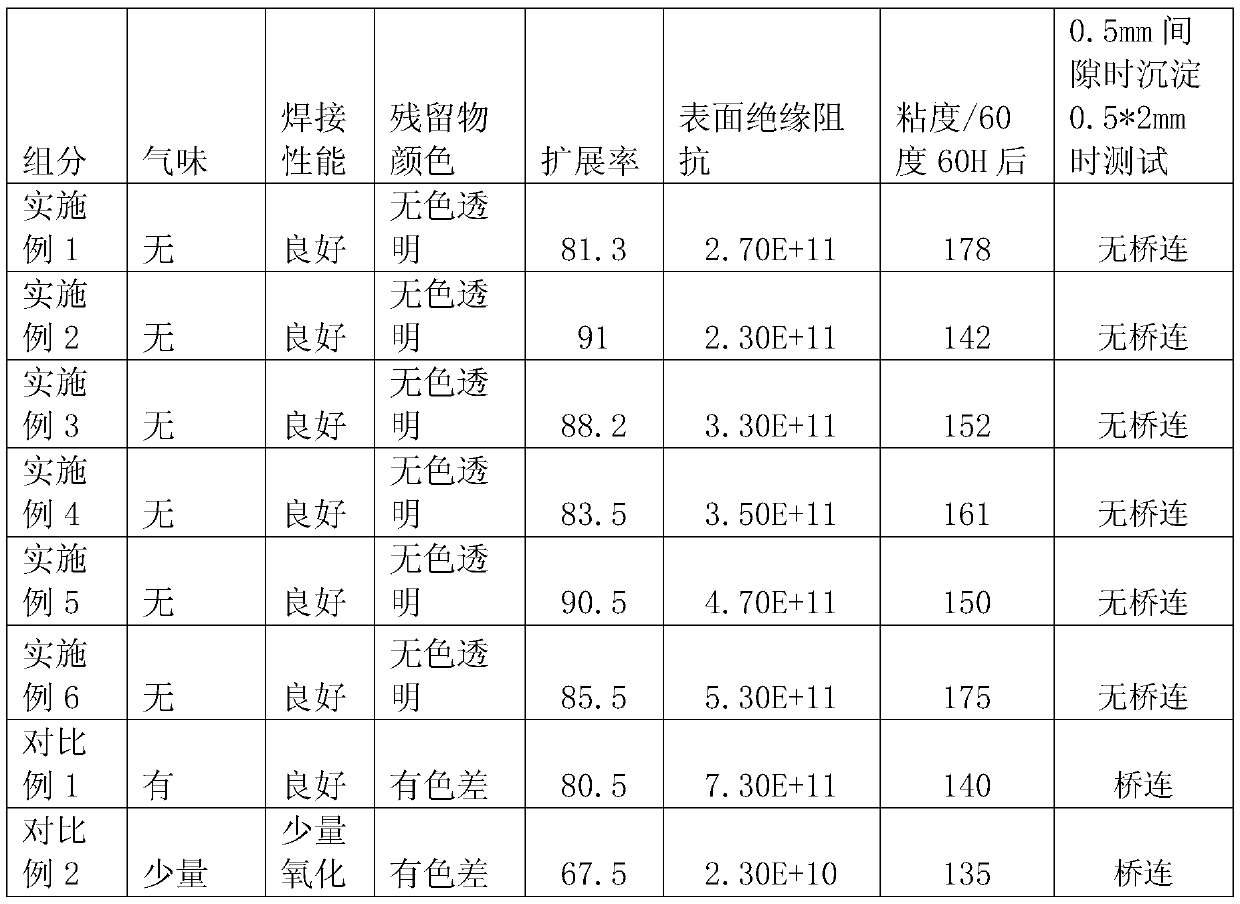

Lead-free anti-oxidation tin paste and preparation method thereof

ActiveCN109955001AThe process is gentle and environmentally friendlyStable qualityWelding/cutting media/materialsSoldering mediaMetalMaterials science

The invention discloses a lead-free anti-oxidation tin paste and a preparation method thereof. According to main points of the technical scheme, the tin paste is prepared from the following componentsin percentage by weight: 1% to 3% of Ni, 0.4% to 0.8% of Cu, 8% to 11% of alloy metal, 10% to 20% of scaling powder, and the balance of Sn; and the scaling powder is prepared from the following components in percentage by weight: 80% to 90% of a carrier, 3% to 9% of an activating agent, 2% to 6% of a surface activating agent, and 1.5% to 5.5% of an inhibitor. The lead-free anti-oxidation tin paste is good in halogen-free anti-oxidation, activity and printing durability of the tin paste are improved, wetting performance of solders to substrates is improved, and a certain collapse resistance performance is provided.

Owner:中山翰华锡业有限公司

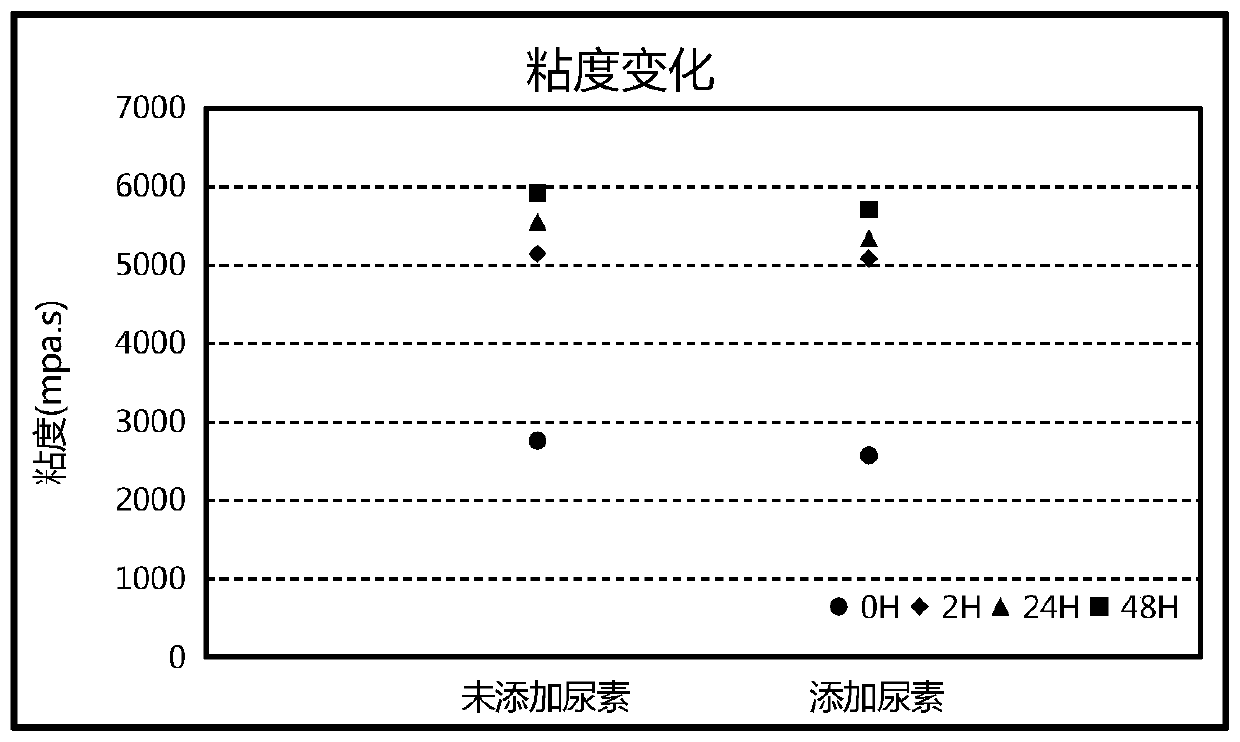

Cathode slurry and manufacturing method thereof, and lithium ion battery

InactiveCN109830658AHigh viscosityStable UniformityCell electrodesSecondary cellsActivated carbonMetallurgy

The invention relates to a cathode slurry and a manufacturing method thereof. The cathode slurry comprises, by weight, 100 parts of a cathode activated carbon material, 0.5 to 2 parts of a conductiveagent, 1 to 5 parts of urea, 0.5 to 2 parts of a binder, 1 to 1.5 parts of a thickener and 110 to 125 parts of water. The cathode slurry can be coated on a thinner current collector substrate withoutaffecting coating efficiency so that the weight of the substrate can be reduced and simultaneously the coating efficiency is improved. The slurry and the method can be applied to industrial production.

Owner:蜂巢能源(武汉)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com