Vapor phase epitaxy device

A technology of vapor phase epitaxy and heating equipment, which is applied in the direction of chemically reactive gas, crystal growth, single crystal growth, etc., to achieve the effect of maintaining stable temperature uniformity and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

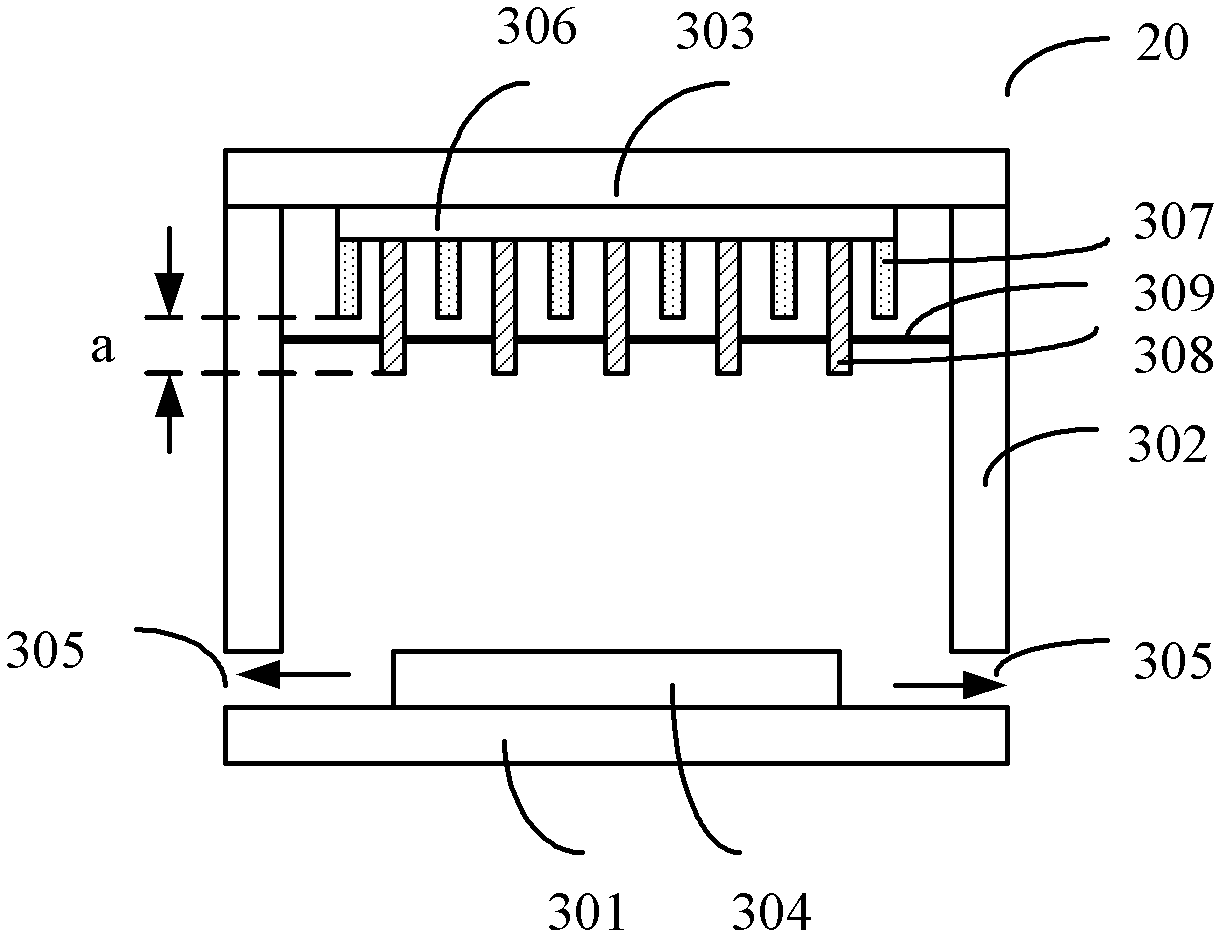

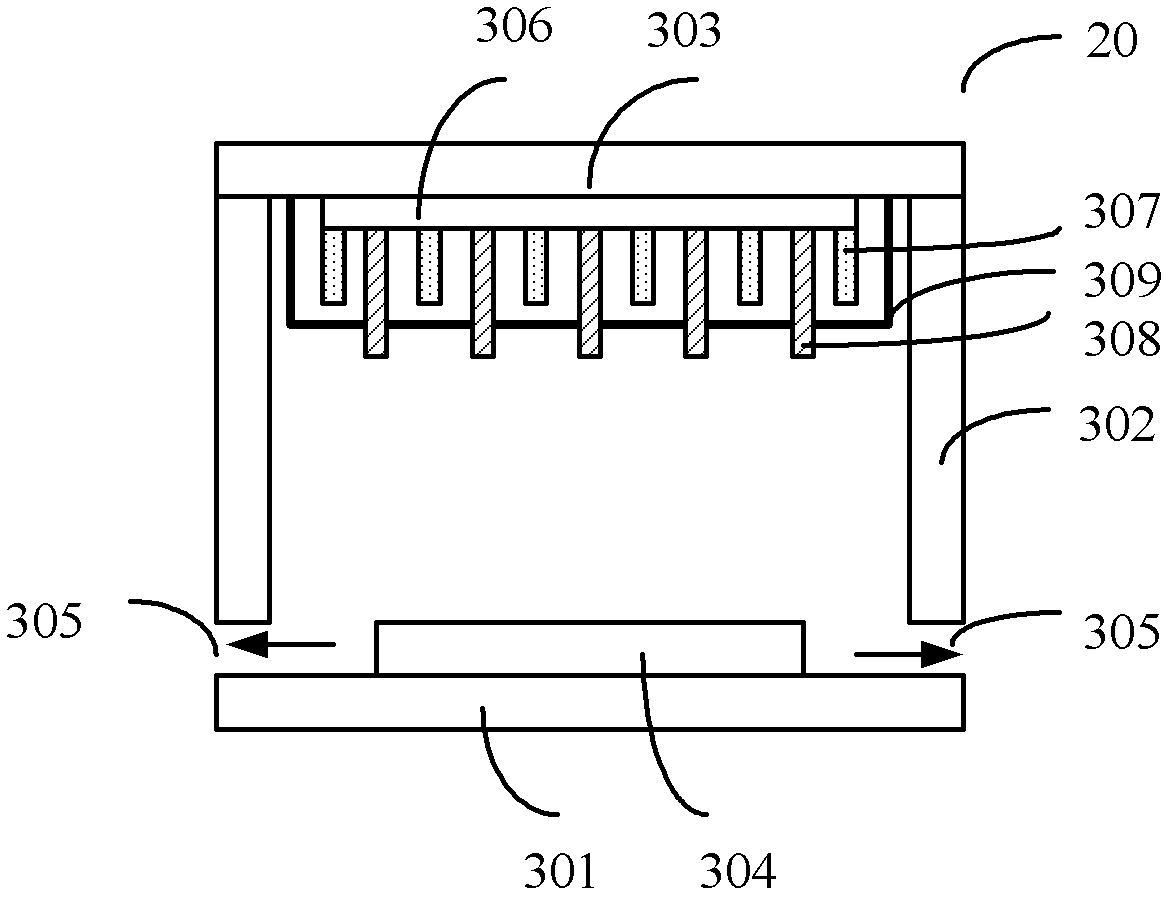

[0037] In the process of forming the epitaxial layer using the existing vapor phase epitaxy device, the inventor found that the heating device is located below the substrate, and it is difficult to adjust the uniformity of the temperature in the chamber and the temperature of the substrate to be processed. When the source gas reacts to form the epitaxial layer, the chamber The uniformity of the temperature in the chamber and the temperature of the substrate to be processed is not good, which affects the uniformity of the epitaxial layer formed on the substrate to be processed.

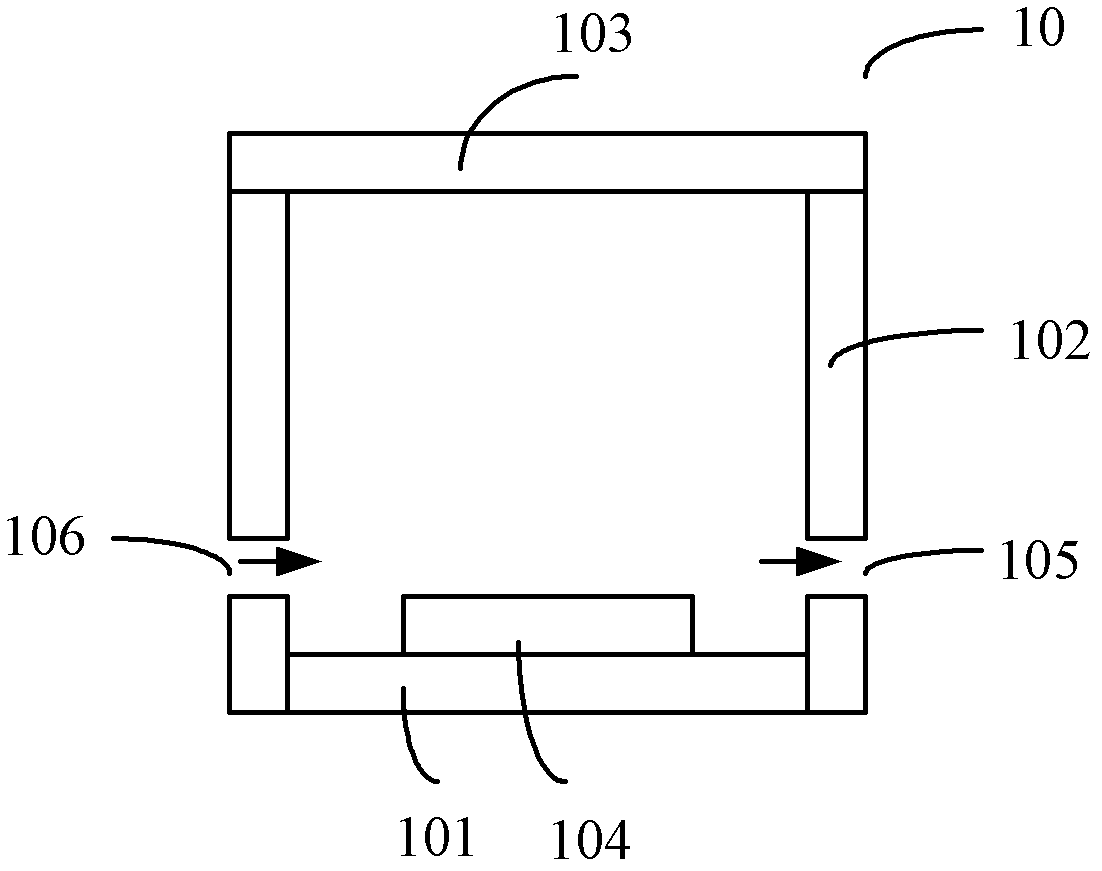

[0038] refer to figure 1 , the inventor further researched and found that the gas inlet 106 and the exhaust outlet 105 of the existing vapor phase epitaxy device are located at the lower end of the side wall 102 of the reaction chamber 10, and the source gas is passed into the reaction chamber 10 parallel to the direction of the substrate, which is easy to produce Thermal convection vortex, the flow ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com