Cathode slurry and manufacturing method thereof, and lithium ion battery

A technology of negative electrode slurry and negative electrode, applied in the field of negative electrode slurry and preparation, can solve the problems of inability to carry out industrialization and low efficiency, and achieve the effect of reducing weight and thickness and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

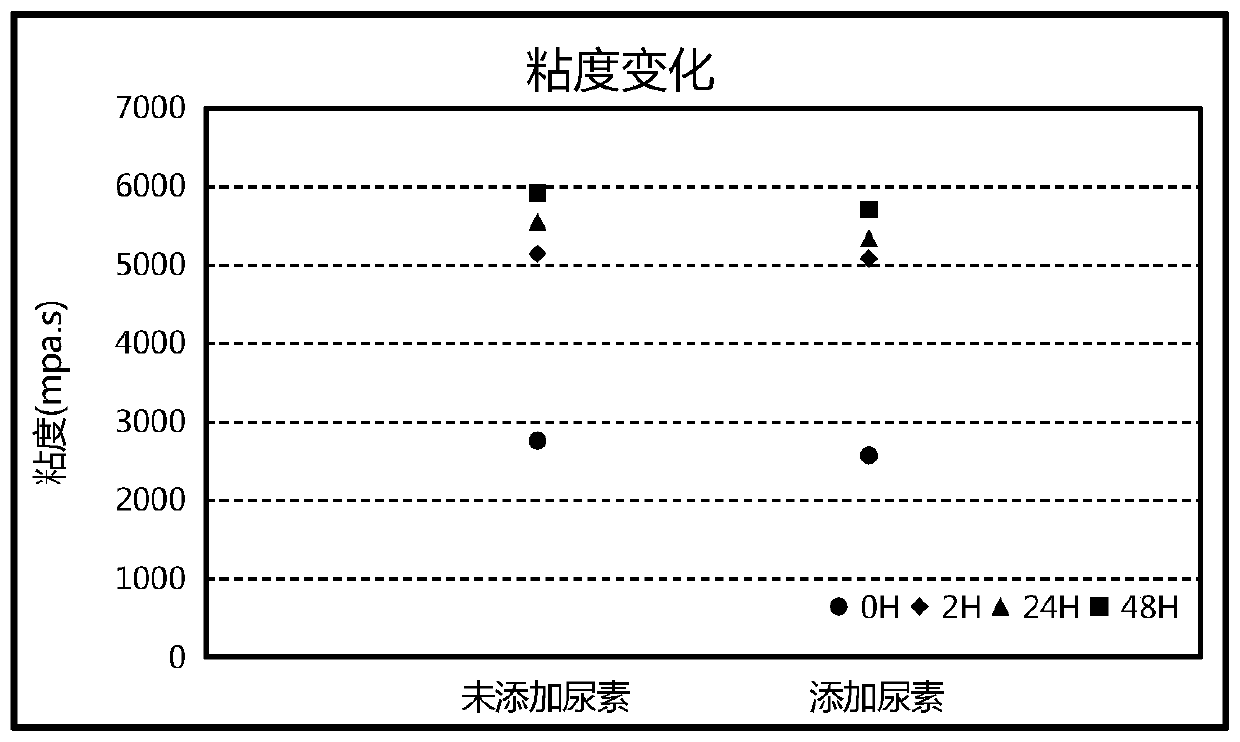

[0040] Preparation of negative electrode slurry (addition of urea)

[0041] Step 1) Mix 0.75kg sodium carboxymethyl cellulose and 50kg deionized water, and first apply glue to a 60L glue machine, the specific method is as follows: first add 50kg deionized water, add 0.75kg sodium carboxymethyl cellulose , at a revolution stirring speed of 25rpm, and at a dispersion speed of 2100rpm, stir for 180 minutes;

[0042] Step 2) 50kg graphite and 0.5kg Super-P are mixed, and specific method is as follows: first add 20kg graphite in 100L mixing tank, add Super-P again, stir 20 minutes under the revolution stirring speed of 20rpm; Then, add remaining 30kg of graphite was stirred for 20 minutes at a revolution stirring speed of 20rpm.

[0043] Step 3) Add 30kg of the mixture prepared in step 1) to the mixture prepared in step 2), then add 4.8kg of deionized water, and stir for 60 minutes at a revolution stirring speed of 25rpm and a dispersion speed of 800rpm .

[0044] Step 4) join 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com