High-modulus permeable environment-friendly mortar used for sponge city and produced by utilizing construction waste and preparation method thereof

A construction waste and sponge city technology, which is applied in the field of building materials, can solve the problems such as the rare application of permeable pavements, and achieve the effects of stabilizing mechanical properties and uniformity, improving bending strength, and improving modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

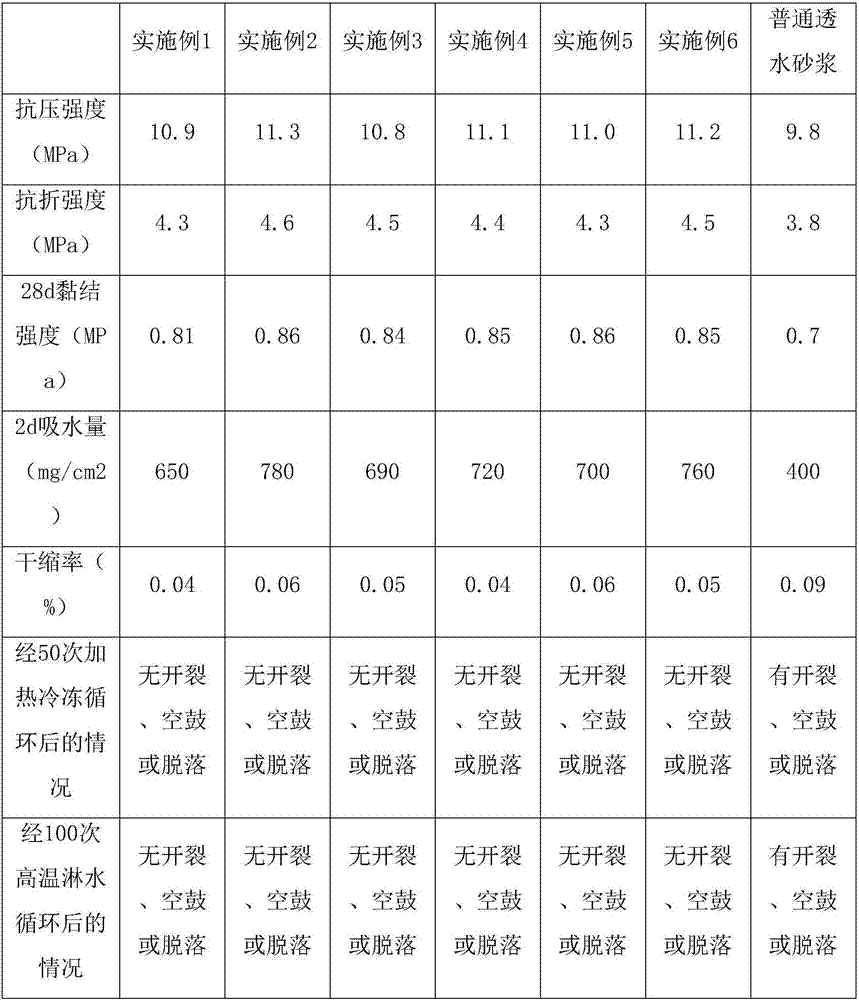

Examples

Embodiment 1

[0026] (1) Artificially crush waste bricks and waste concrete from construction waste, and sieve them into two ranges of 15-20mm and 20-30mm, wash and dry to form recycled aggregates, and soak the recycled aggregates in sodium aluminosilicate solution for 2 hours , take it out and dry it in the air, heat and activate it at 500°C for 2 hours to obtain the regenerative active construction waste aggregate.

[0027] (2) Sandstone, granite and limestone with a mass ratio of 1:1:1 are used as raw materials, soil is removed, mechanically crushed, screened into three ranges of 1-2mm, 2-5mm, and 5-10mm, and formed by washing and drying Machine-made sand aggregate.

[0028] (3) In parts by weight, 5 parts of carbon fiber mesh with an area not less than 5×5 cm, 3 parts of rubber powder, 5 parts of quaternary ammonium salt modified bentonite, 10 parts of dispersible latex powder, 8 parts of cellulose ether, wood Mix 6 parts of cellulose and 3 parts of water reducer evenly to form an admi...

Embodiment 2

[0031] (1) Artificially crush waste bricks and waste concrete from construction waste, and sieve them into two ranges of 15-20mm and 20-30mm, wash and dry to form recycled aggregates, and soak the recycled aggregates in sodium aluminosilicate solution for 6 hours , take it out to dry, heat and activate at 800°C for 3 hours, and obtain the regenerative active construction waste aggregate.

[0032] (2) Sandstone, granite and limestone with a mass ratio of 1:1:1 are used as raw materials, soil is removed, mechanically crushed, screened into three ranges of 1-2mm, 2-5mm, and 5-10mm, and formed by washing and drying Machine-made sand aggregate.

[0033] (3) In parts by weight, 10 parts of carbon fiber mesh with an area not less than 5×5 cm, 7 parts of rubber powder, 10 parts of quaternary ammonium salt modified bentonite, 15 parts of dispersible latex powder, 15 parts of cellulose ether, wood 10 parts of cellulose and 5 parts of water reducing agent are evenly mixed to form an adm...

Embodiment 3

[0036] (1) Manually crush waste bricks and waste concrete from construction waste, and sieve them into two ranges of 15-20mm and 20-30mm, wash and dry to form recycled aggregates, and soak the recycled aggregates in sodium aluminosilicate solution for 4 hours , take it out to dry, heat and activate at 600°C for 2.5h, and obtain the regenerative active construction waste aggregate.

[0037] (2) Sandstone, granite and limestone with a mass ratio of 1:1:1 are used as raw materials, soil is removed, mechanically crushed, screened into three ranges of 1-2mm, 2-5mm, and 5-10mm, and formed by washing and drying Machine-made sand aggregate.

[0038] (3) In parts by weight, 8 parts of carbon fiber mesh with an area not less than 5×5 cm, 5 parts of rubber powder, 7 parts of quaternary ammonium salt modified bentonite, 13 parts of dispersible latex powder, 10 parts of cellulose ether, wood Mix 8 parts of cellulose and 4 parts of water reducer evenly to form an admixture.

[0039] (4) M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com