Method for adjusting uniformity of ion milling

A uniformity and ion milling technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problem that small-sized ion sources cannot meet wafer cleaning and other problems, and achieve the effects of saving procurement costs, stabilizing uniformity, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

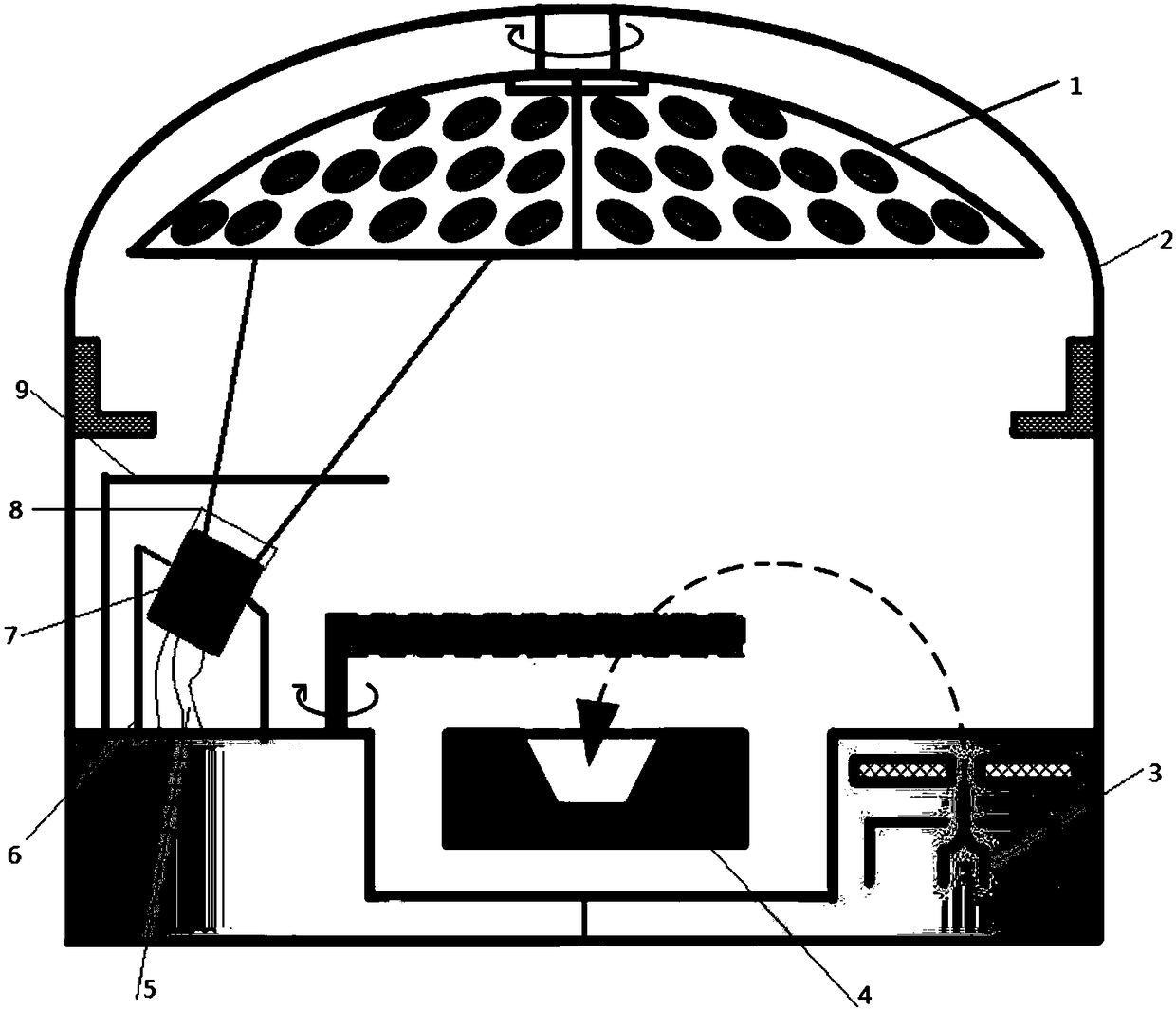

[0018] Such as Figure 1-5 shown.

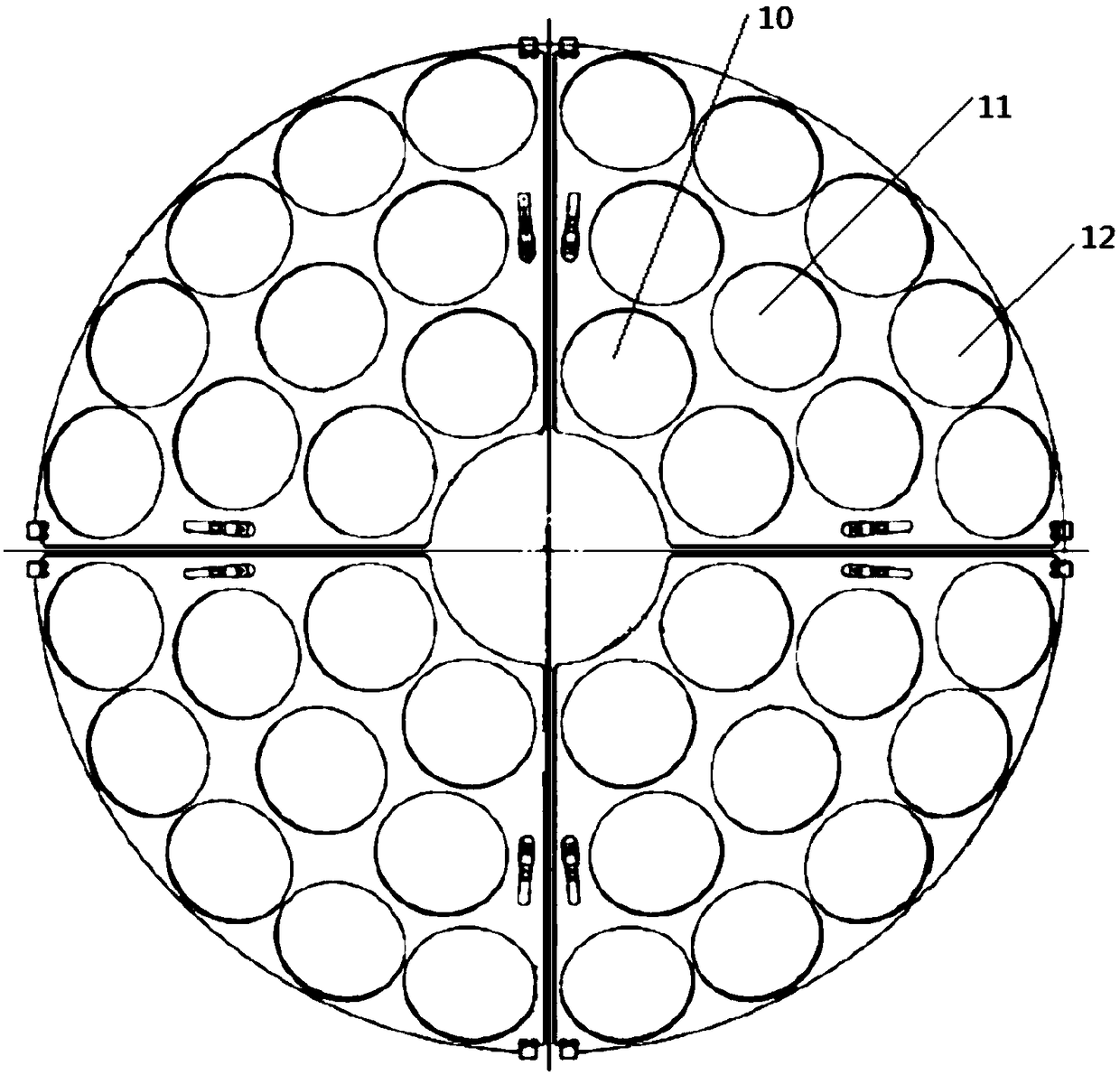

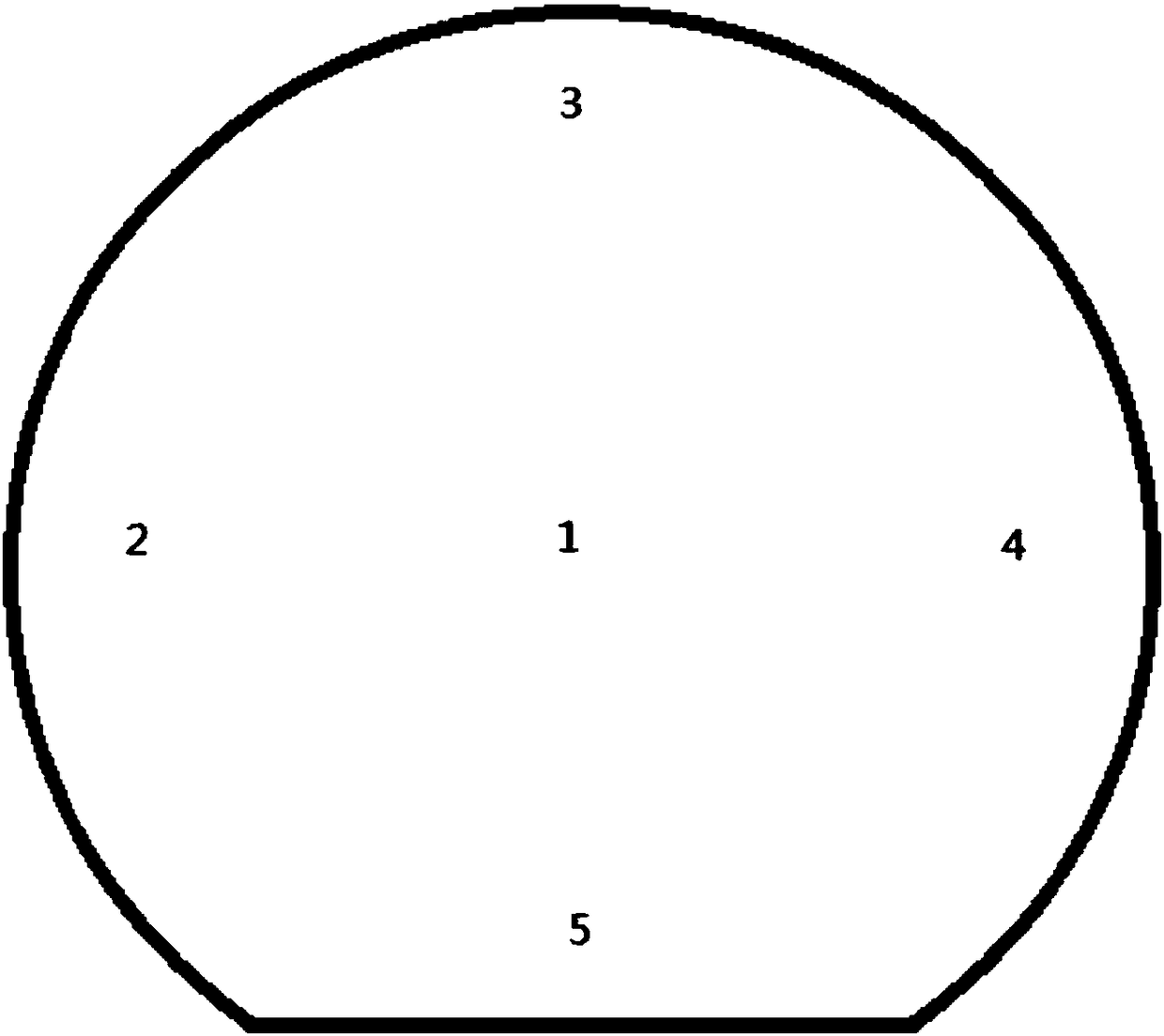

[0019] A method to adjust the uniformity of ion milling, first of all Figure 5 The ion milling source 7 shown is installed on an ion milling fixed bracket 6 with adjustable height and angle, and secondly, a uniformity baffle 8 is added outside the graphite grid 16 of the ion milling source 7; the ion milling source 7 is tilted The adjustment of angle, height and the function of uniformity baffle 8 realize the planetary disc ( figure 2 ) The ion milling uniformity of the wafers on the middle circle 11 and the outer circle 12 meets the uniformity within the wafer, between wafers and between wafer batches ≤ 10%, and at the same time ensures that the ion milling speed is greater than 0.9 nm / min. Wherein the shape of the through hole of the uniformity baffle plate 8 is a corrected fan shape, such as Figure 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com