Device and method for preparing hollow fiber membrane

A technology of conveying device and spinning device, which is applied in the field of devices for preparing hollow fiber membranes, can solve the problems of limited spinning speed, weaving speed, uneven coating of membrane filaments, and affecting large-scale production efficiency, and achieve stable membrane filaments Tension and coating uniformity, avoiding online weaving speed limitation, and easy industrial continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

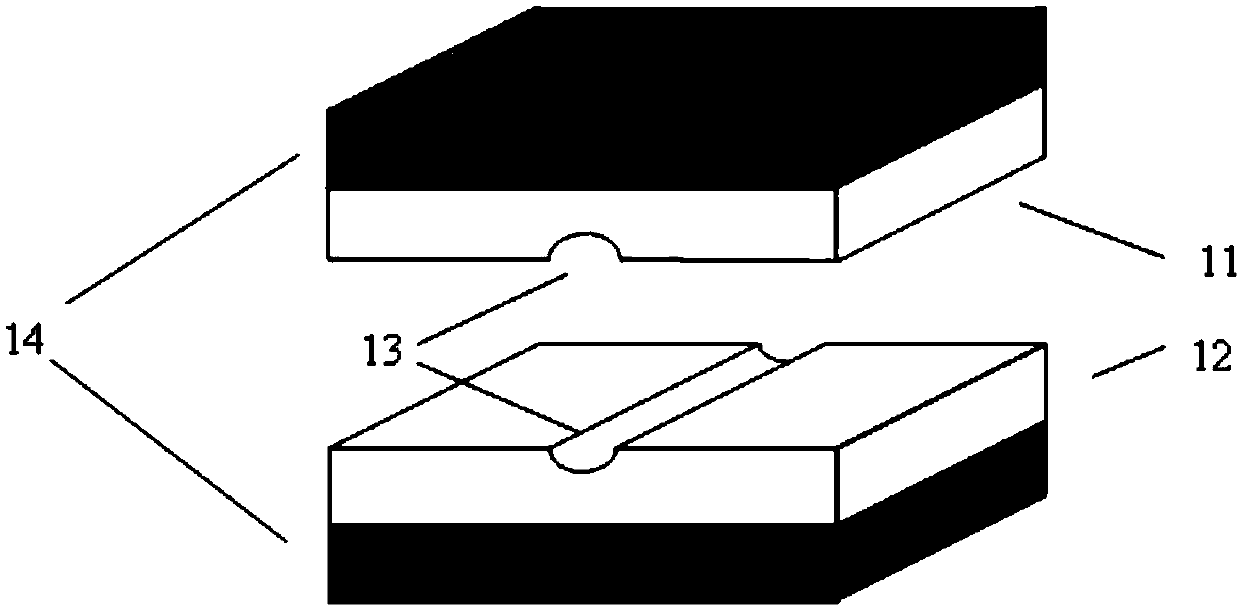

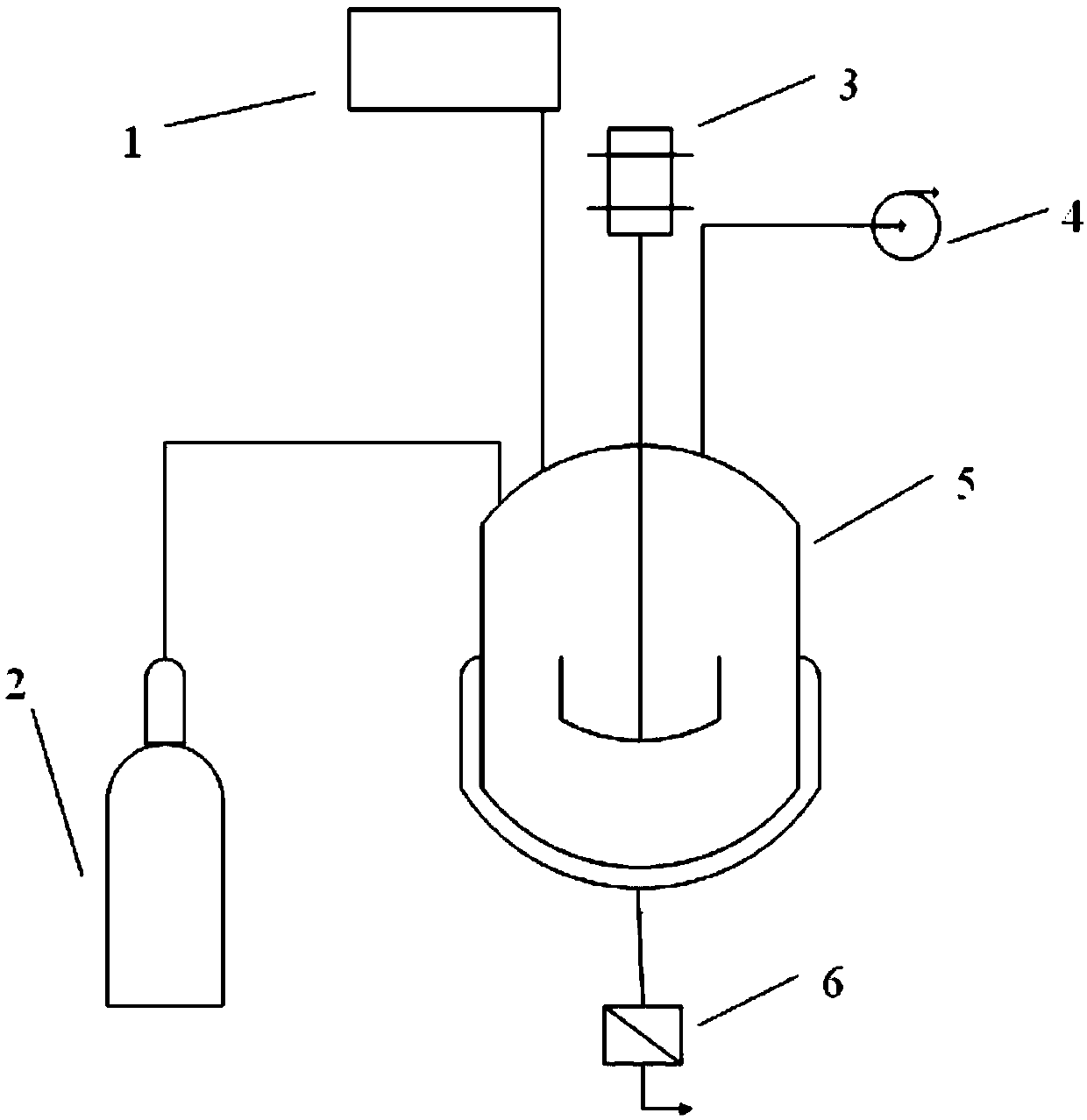

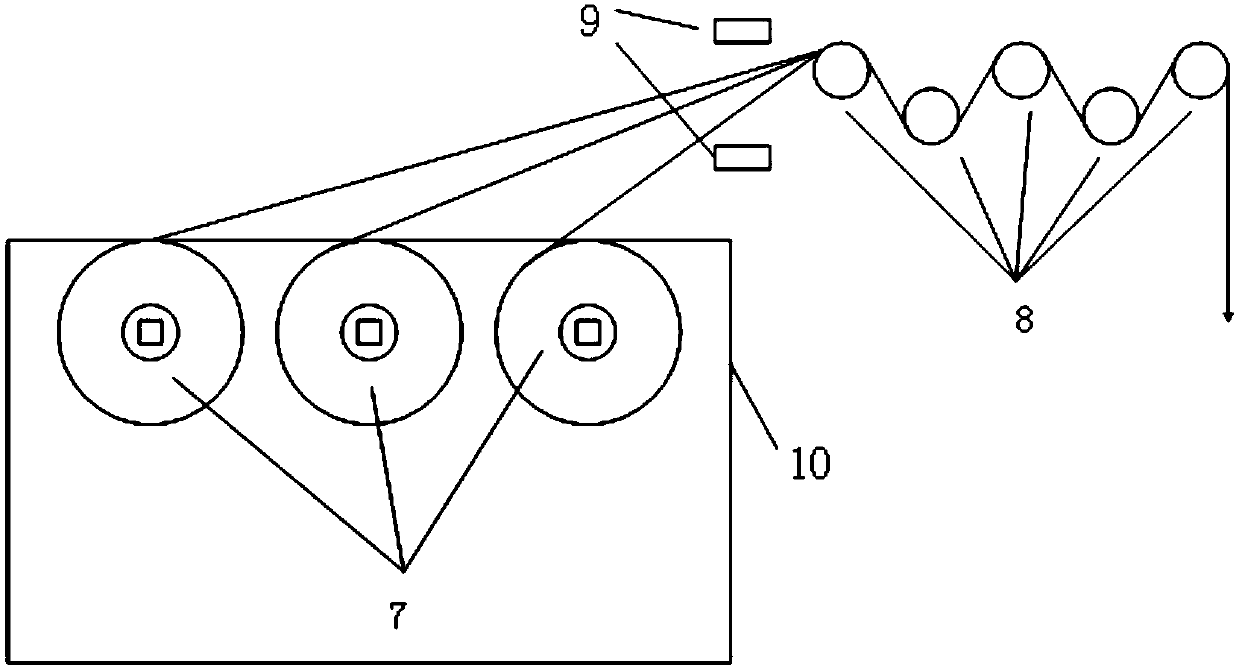

[0034] Figure 1-7 A device for preparing a reinforced hollow fiber membrane provided in some embodiments of the present invention is shown, which specifically includes a feeding device, a mixing and extrusion device, a braided tube conveying device, a spinneret device, a gelling device, and a wire collecting device.

[0035] The feeding device 1 in the preferred embodiment includes a solid weight loss metering device, a liquid weight loss metering device and a preheating tank. Wherein, the liquid raw material is added to the mixing extrusion device through the liquid weight loss metering device, and the solid raw material is added to the mixing extrusion device through the solid weight loss metering device. Specifically, the solid weight loss metering device may be configured to add the solid raw material to the In the reactor 5, the solid weight loss metering device is located above the feed port of the reactor 5, and the outlet of the solid weight loss metering device is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com