PTC (Positive Temperature Coefficient) high polymer heating material for self-limiting temperature electric tracing band

A technology of electric heating cable and heating material, applied in heating element material, resistor with positive temperature coefficient, shape of heating element, etc., can solve the problem of unstable resistance of PTC heating material, decrease of PTC characteristic repeatability, tensile strength The problem of low performance, etc., achieves the effects of stable PTC characteristic repeatability, perfect conductive network, uniformity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

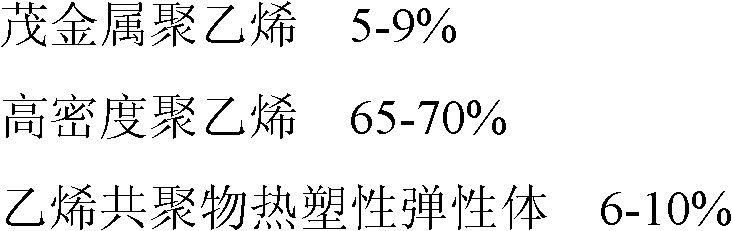

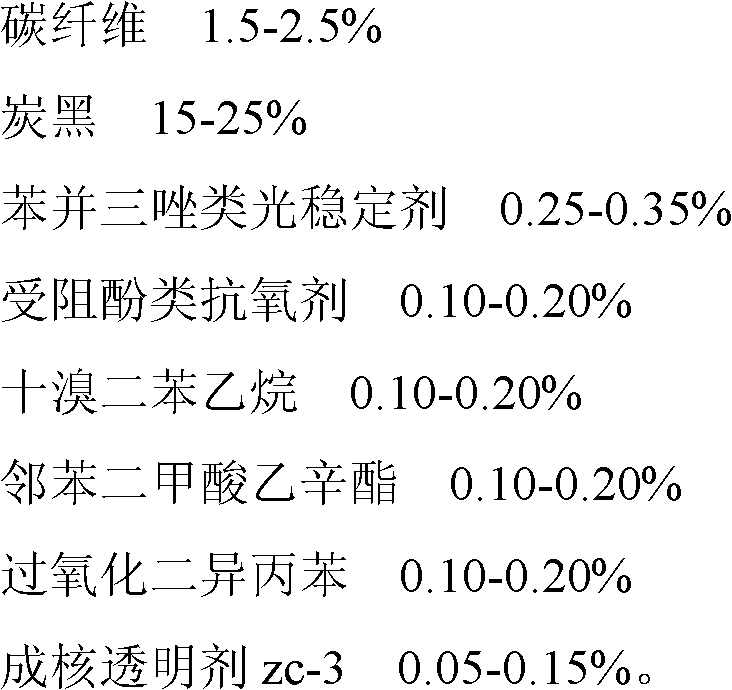

[0021] A PTC polymer heating material for self-limiting temperature electric heating cables, characterized in that: it is made of the following raw materials in weight percentage:

[0022]

[0023] The PTC polymer heating material used for self-limiting temperature heating cables is prepared by mixing all raw materials evenly with a high-speed mixer according to the weight percentage, stirring for one minute each time, and adopting a twin-screw granulation method after stirring for 3 times The product is obtained by granulating in a twin-screw extruder. The self-limiting temperature heating cable prepared therefrom includes two wires, the wires are wrapped with extruded PTC heating material in the middle, and the middle extruded PTC heating material is wrapped with an insulating inner sheath, a metal braided shielding layer, and an insulating outer layer. jacket.

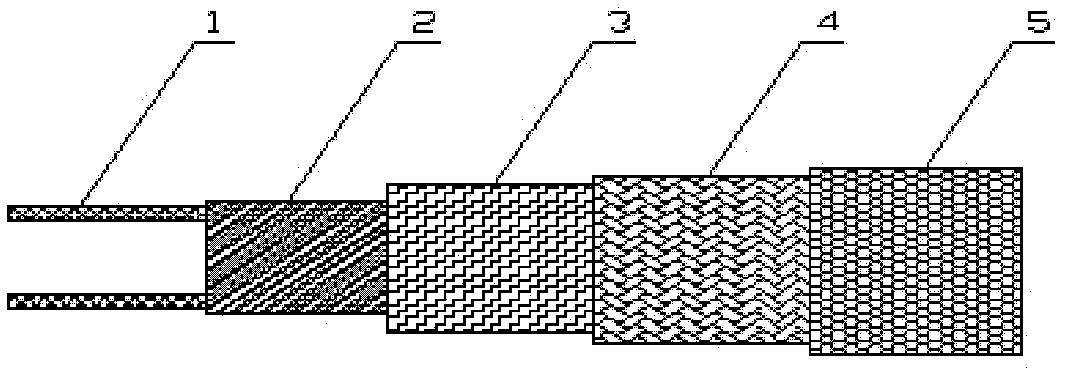

[0024] like figure 1 As shown, the high-performance self-limiting temperature heating cable includes two tin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com