Method for preparing composite conductive polyethylene carbon black material with improved positive temperature coefficient performance

A conductive composite material, polyethylene carbon black technology, applied in conductive materials dispersed in non-conductive inorganic materials, fibrous fillers, dyed polymer organic compounds and other directions, can solve the problem of not producing enough steric hindrance effects to stabilize It can achieve good PTC effect stability, good dispersion stability, and the effect of inhibiting agglomeration and position shift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the polyethylene carbon black conductive composite material with improved positive temperature coefficient performance comprises the following steps:

[0043] A. Preparation of titanate hyperdispersant

[0044] First, 100 g of 12-hydroxystearic acid, 1 g of antioxidant didodecanyl thiodipropionate (DLTP), 3 g of antioxidant tetrakis[methyl-β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (1010), 8 g of catalyst stannous octoate, and 32 g of xylene were successively added to the container, and the temperature was raised to 100 ℃, after complete dissolution, heat up to 135 ℃ and keep condensing and refluxing, separate the generated water through the water separator, react until the acid value reaches 32.5 mgKOH / g, stop the reaction; add 45 g of isooctyl alcohol (to ensure that the added isooctanol The molar ratio of octanol to 12-hydroxystearic acid is greater than 1, that is, the excess alcohol is ensured) to end-cap, sti...

Embodiment 2

[0050] The preparation method of the polyethylene carbon black conductive composite material with improved positive temperature coefficient performance comprises the following steps:

[0051] A. Preparation of titanate hyperdispersant or phosphate hyperdispersant

[0052] The raw materials used are 100 g 12-hydroxystearic acid, 1 g antioxidant didodecyl thiodipropionate (DLTP), 3 g antioxidant tetrakis[methyl-β-(3,5-ditertiary Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (1010), 5 g catalyst stannous octoate, 25 g xylene, 55 g isooctyl alcohol, 40 g tributyl phosphate; Agent; Preparation steps and processing conditions are with embodiment 1;

[0053] B, preparation of modified carbon black

[0054] Described raw material is 100 g carbon black, 3 g phosphoric acid ester hyperdispersant, makes phosphoric acid ester modified carbon black, and preparation process condition is with embodiment 1;

[0055] C, preparation of polyethylene carbon black conductive composit...

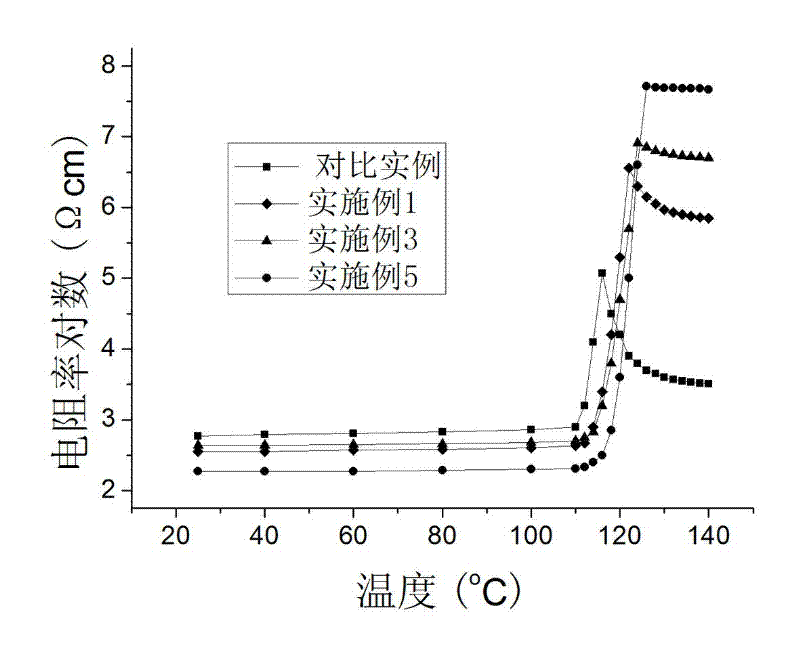

Embodiment 3

[0058] The preparation method of the polyethylene carbon black conductive composite material with improved positive temperature coefficient performance comprises the following steps:

[0059] A. Preparation of Phosphate Ester Hyperdispersant

[0060] With the preparation of phosphate ester hyperdispersant in embodiment 2

[0061] B, preparation of modified carbon black

[0062] Described raw material is 100 g carbon black, 2 g phosphoric acid ester hyperdispersant, makes phosphoric acid ester modified carbon black, and preparation process condition is with embodiment 1;

[0063] C, preparation of polyethylene carbon black conductive composite material

[0064] The raw material used is a blend of 100 g of high-density polyethylene and low-density polyethylene, the mass ratio of high-density polyethylene and low-density polyethylene is 2:1, 35 g of phosphate-modified carbon black, 0.5 g of antioxidant Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com