Patents

Literature

31results about How to "Good viewing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

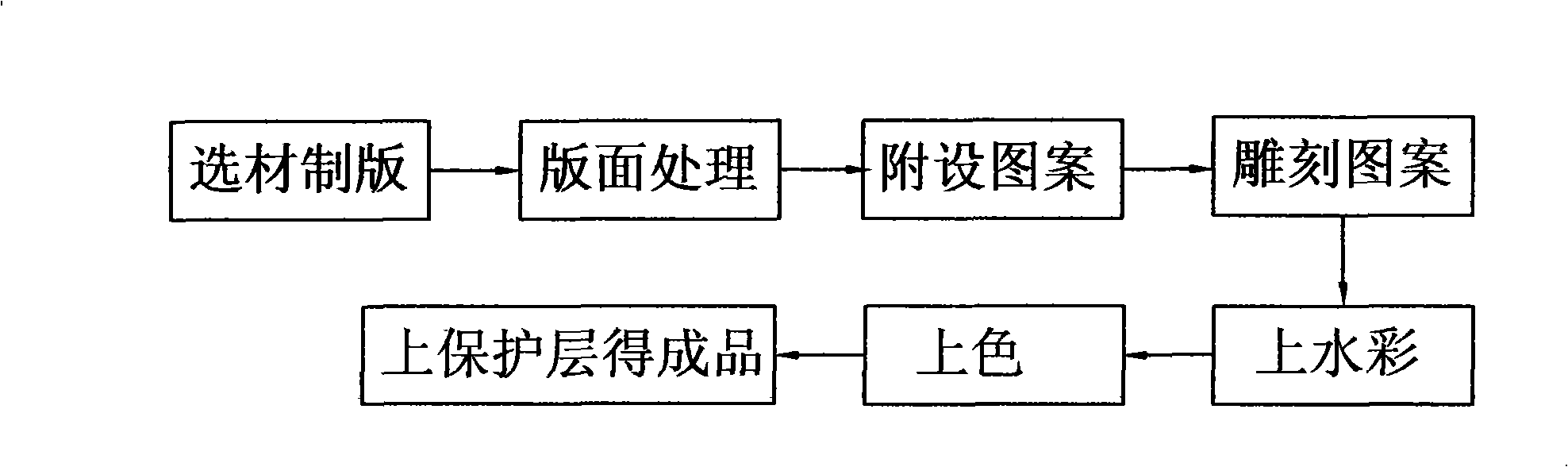

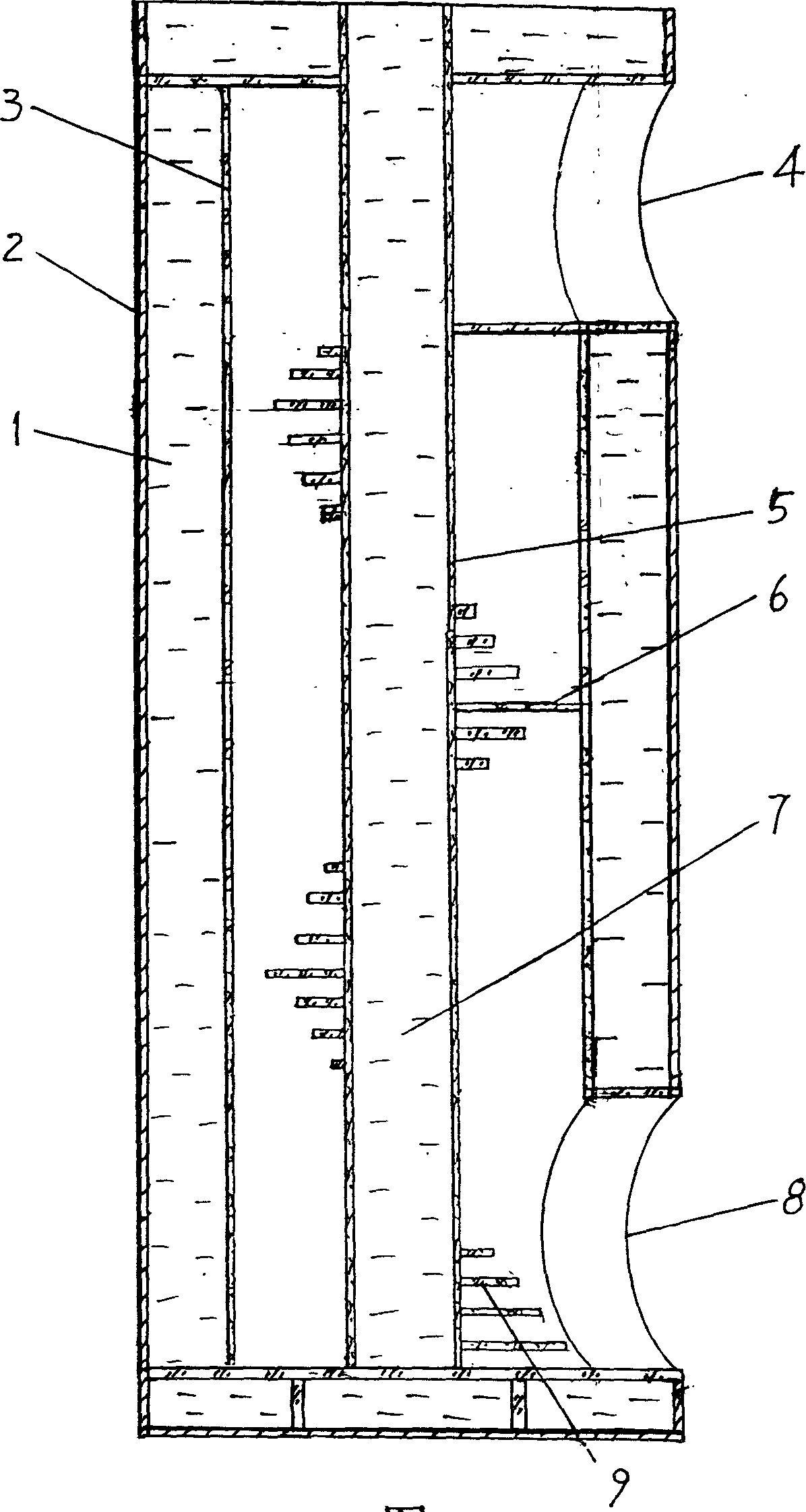

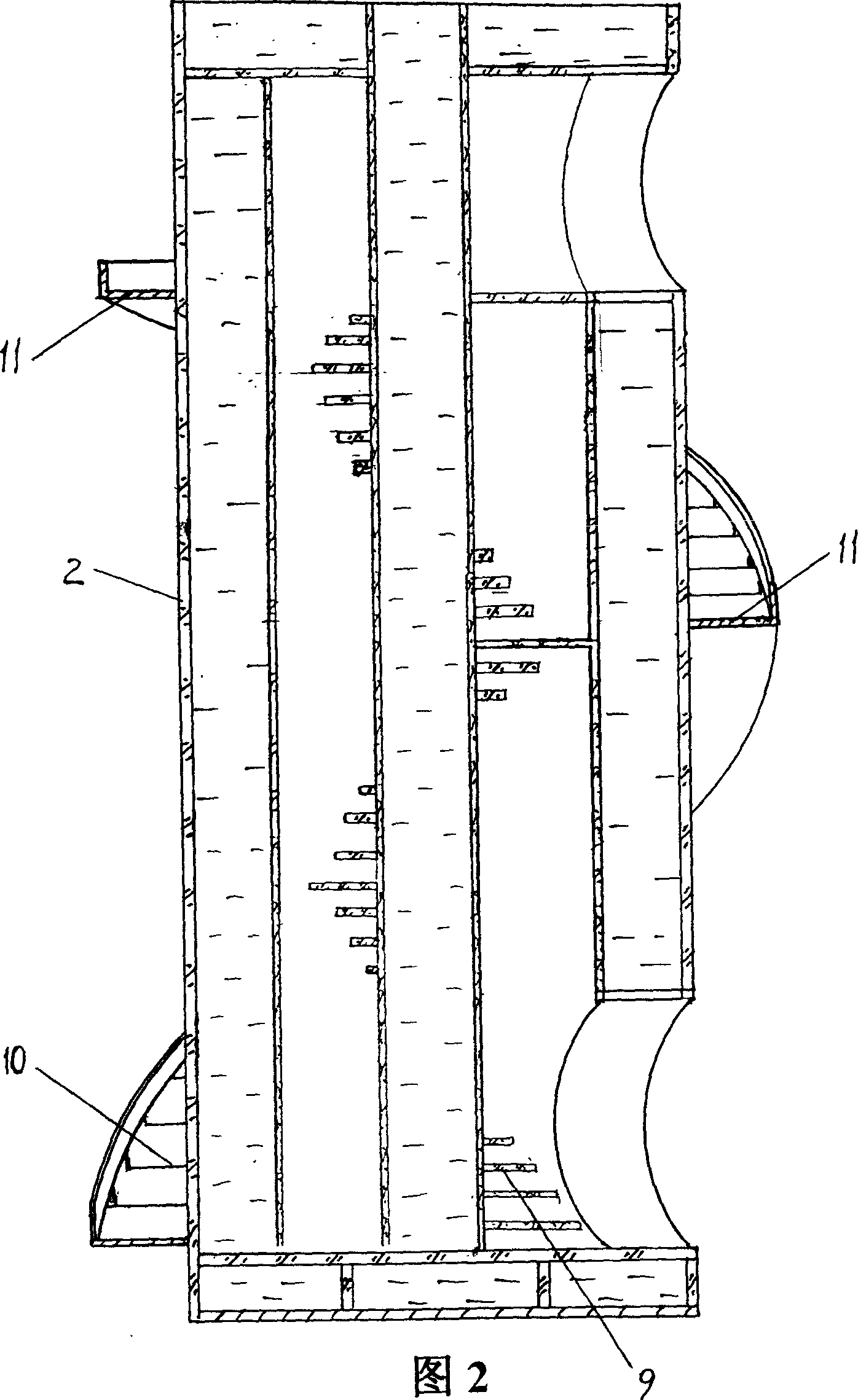

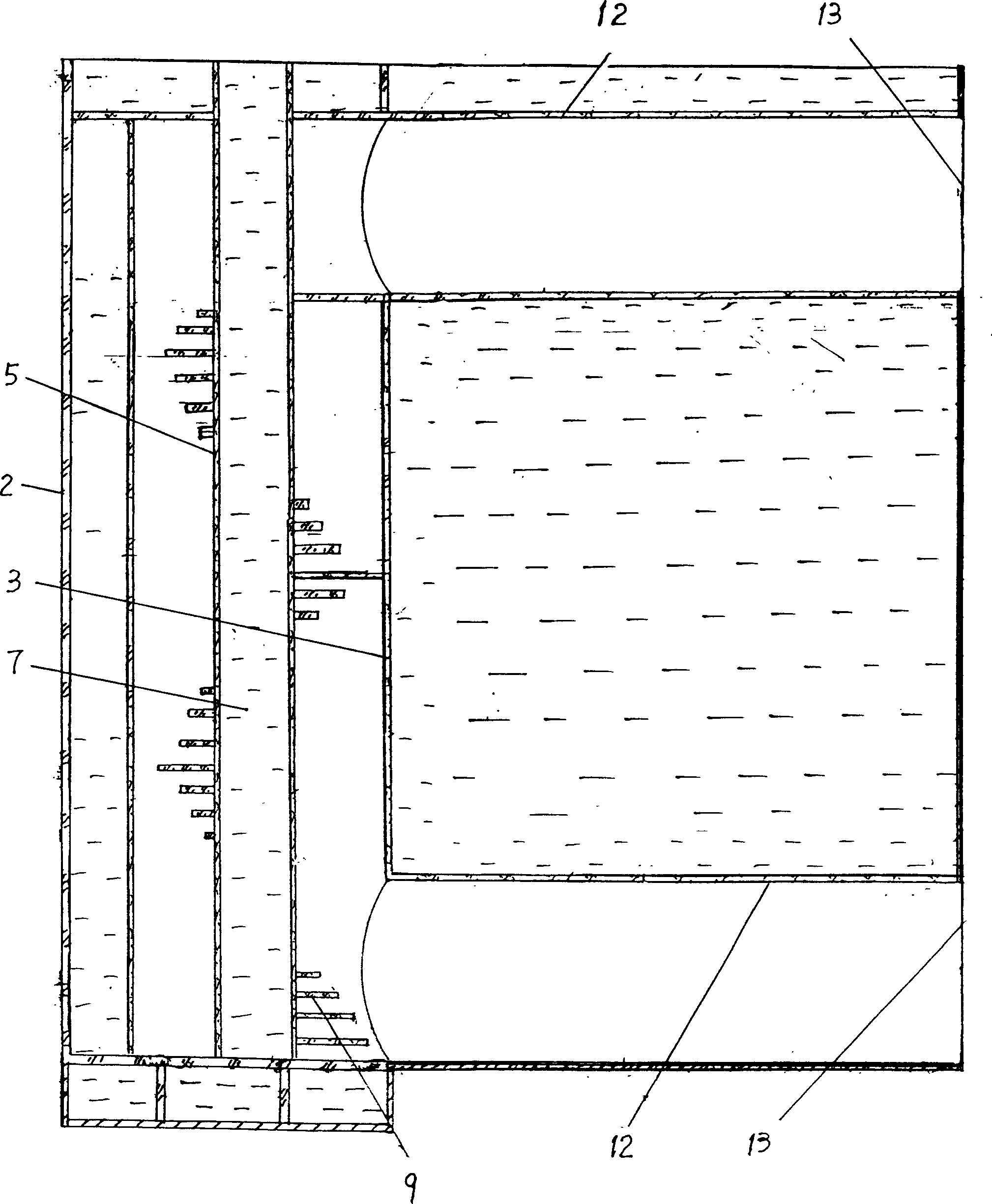

Method for making gild solid artistic print

InactiveCN101279570AThree-dimensional layered sense of protrudingGood viewing effectOrnamental structuresSpecial ornamental structuresEngineeringWetting

The invention relates to a method for manufacturing a relief sculpture three-dimensional artistic print, which mainly comprises the steps of material selecting and plate making, layout treatment, pattern affiliation, pattern carving, watercolor painting, coloring and protective layer coating, etc. The print manufactured in the method of the invention has the advantages that the picture has outstanding three-dimensional and layering sensation and excellent appreciation effect, can be easily kept and stored, is uneasily faded due to being affected with damp or damaged due to the wood-consuming of the insect, has long storage years, etc., and simultaneously solves the problems of uneasy storage, easy wetting and fading or damage due to the wood-consuming of the insect, quite limited keeping and storage years, flat painting without three-dimensional impression and bad appreciation effect existing in the existing art painting. According to requirements, the prints with various dimensions and specifications can be conveniently made to meet the requirements for the appreciation and collection by the people, various painters and collectors in the method of the invention.

Owner:姜奕

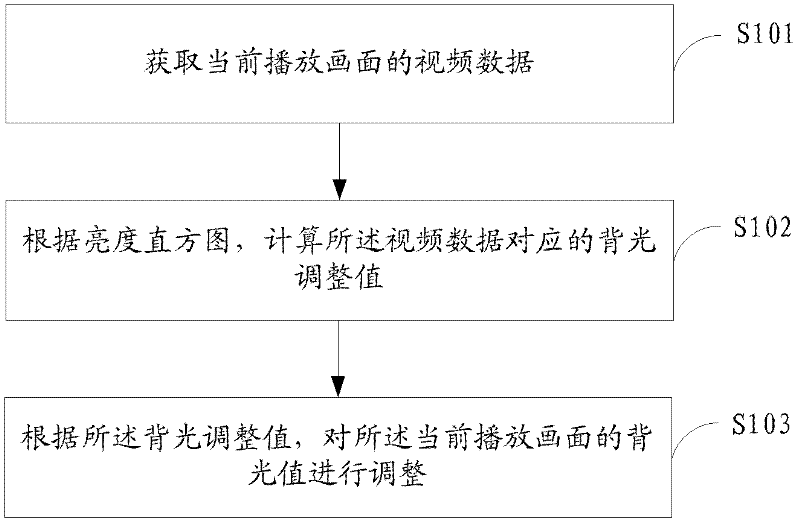

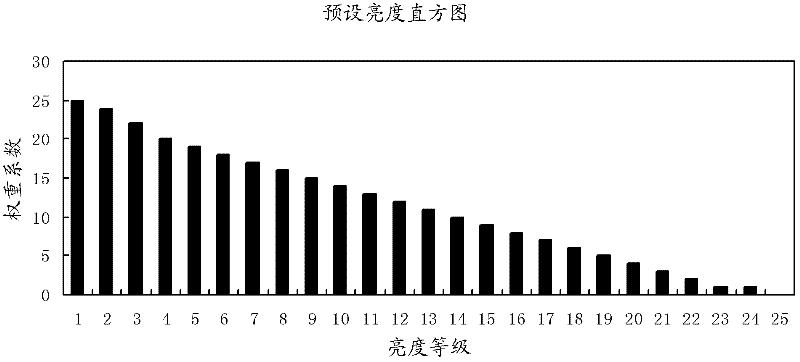

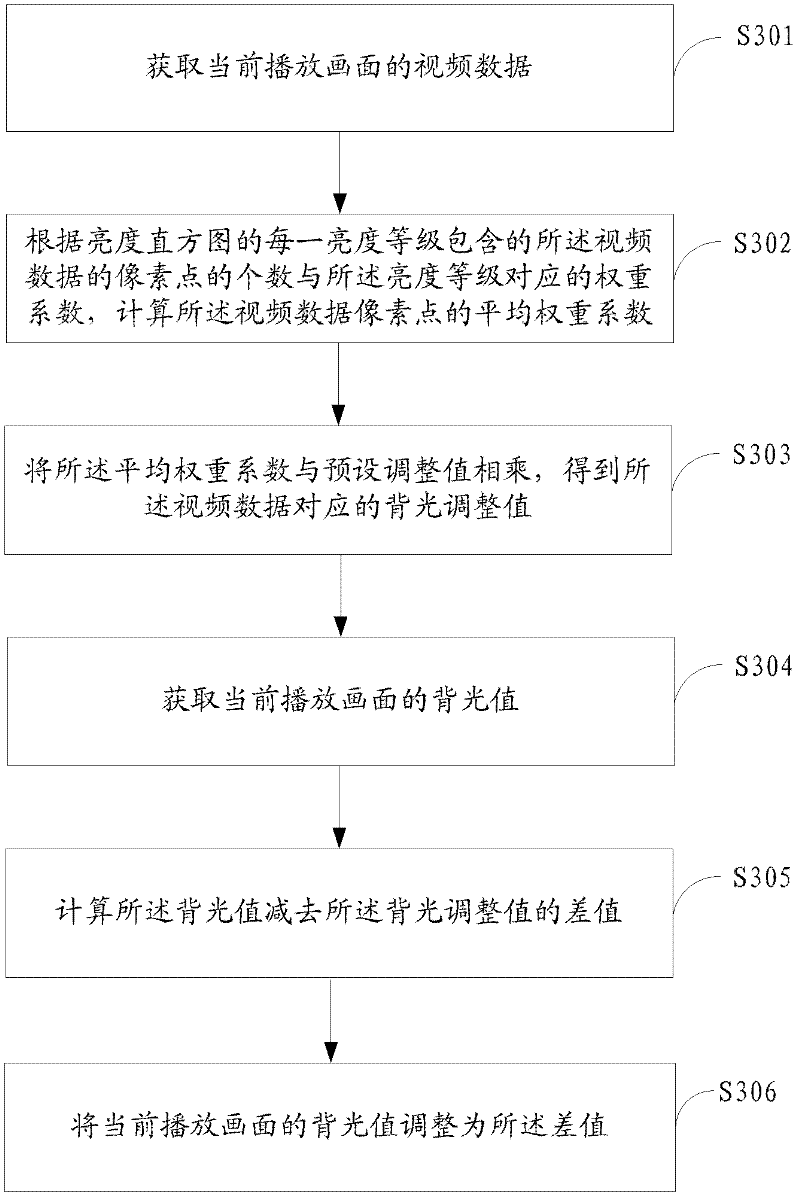

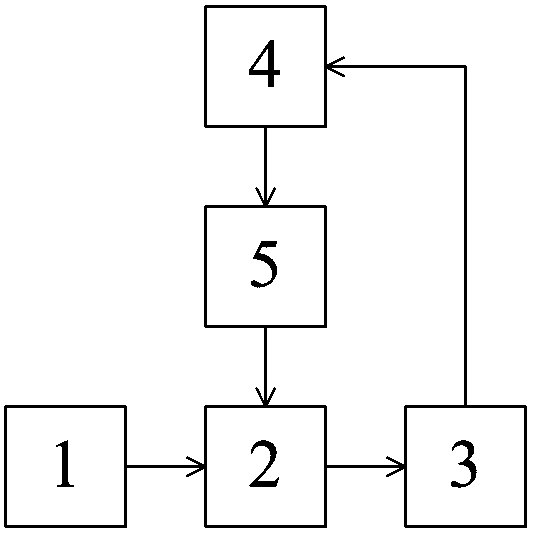

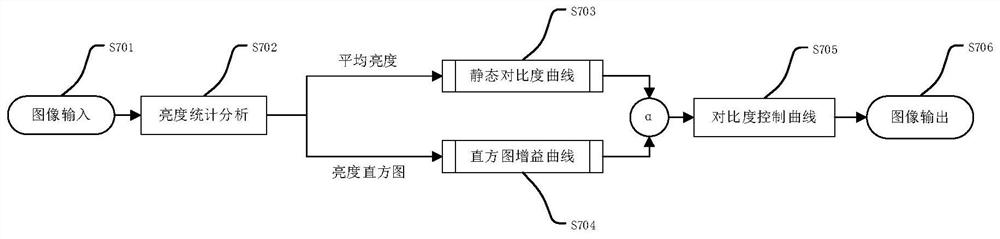

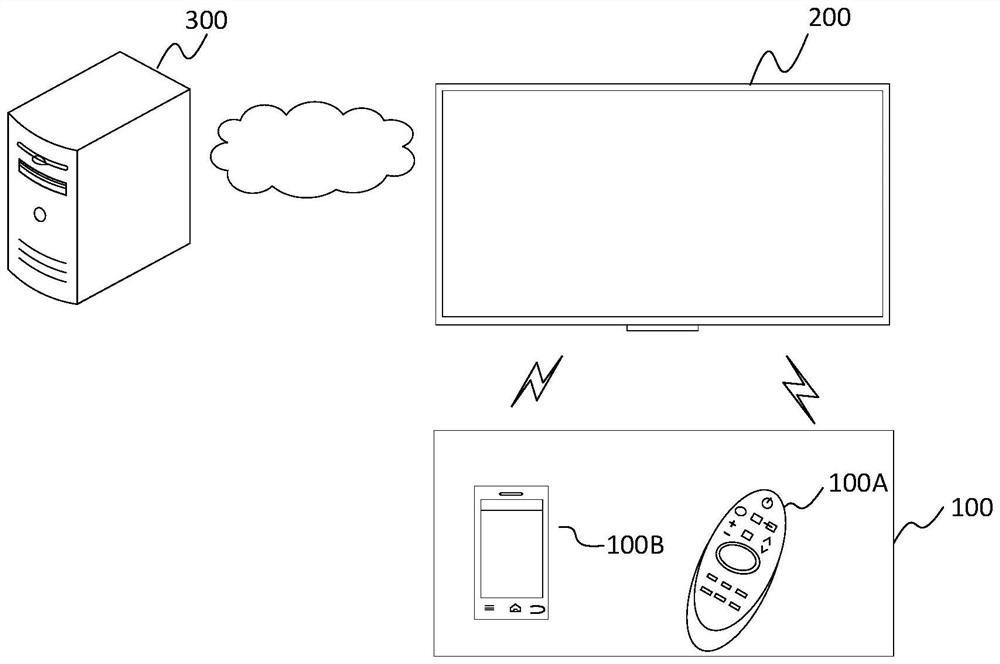

Dynamic backlight adjustment method, system and television

ActiveCN102647832AFlexible adjustment methodGood viewing effectTelevision system detailsStatic indicating devicesLiquid-crystal displayHistogram

The invention is applicable to the technical field of liquid crystal display, and provides a dynamic backlight adjustment method, system, and television. The method comprises the following steps of: obtaining video data of the current playback screen; calculating a backlight adjustment value corresponding to the video data according to a brightness histogram for dividing the brightness data of video signals into M brightness levels, wherein each brightness level corresponds to an interval of brightness data and a weight coefficient; and adjusting the backlight value of the current playback screen according to the backlight adjustment value. Through the method, different brightness of the playback screen can be adjusted by using different weight coefficients, especially, the playback screen with the same brightness average value and different brightness histogram distribution can be adjusted by using different backlight control, and the adjustment method is flexible, so that the better watching effect can be obtained by users, and the user experience is enhanced.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Holographic projection box and imaging method and interaction method thereof

InactiveCN106154697AGood viewing effectGood imaging effectProjectorsCharacter and pattern recognitionLight sourceTablet computer

The invention discloses a holographic projection box and an imaging method and an interaction method thereof. The holographic projection box comprises a box body, an imaging film arranged in the box body, and a support cover plate arranged on the top surface of the box body. An opening used for watching imaging pictures is arranged in one side of the box body. A tablet computer is arranged on the support cover plate, and an opening through which a screen of the tablet computer projects the images is arranged in the support cover plate. The tablet computer provides a light source for the imaging film through the opening. A plurality of background plates are arranged in the box body. The imaging method comprises the steps of: combining the holographic projection box and the tablet computer, imaging the images or video of the tablet computer on the background plates in the box body through the imaging film, and forming a stereo picture. The interaction method comprises the steps of: identifying a card through a scanning function of a preposition pick-up head of the tablet computer, and cooperating with an APP application program to realize the data interaction. According to the invention, the imaging and film-watching effects are good, and the operation is convenient and flexible.

Owner:SHENZHEN ZHONGSHU CREATIVE CULTURE & MEDIA TECH CO LTD

Three-dimensional display device and electronic device thereof

InactiveCN103149692AGood viewing effectStereoscopic display effect is goodStatic indicating devicesCharacter and pattern recognitionLiquid crystalThree dimensional display

The invention relates to a three-dimensional display device which comprises a display panel, a liquid crystal lens, an identification module and a driving circuit, wherein the display panel is used for outputting pictures; the liquid crystal lens is arranged on the display panel and is used for focusing the display light of the pictures on the focusing position; the identification module is used for capturing and identifying images, and outputting an identification signal according to the identification result; the driving circuit is electrically connected with the liquid crystal lens and the identification module; and the driving circuit is used for driving the liquid crystal lens to adjust the focusing position according to the identification signal.

Owner:华映视讯(吴江)有限公司 +1

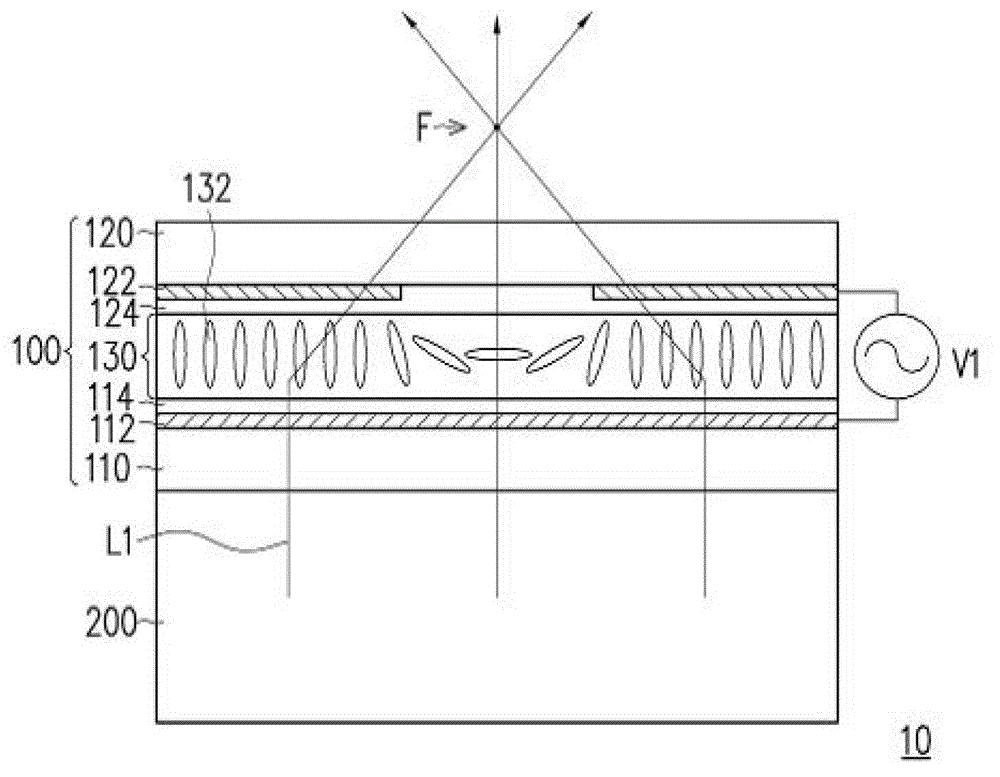

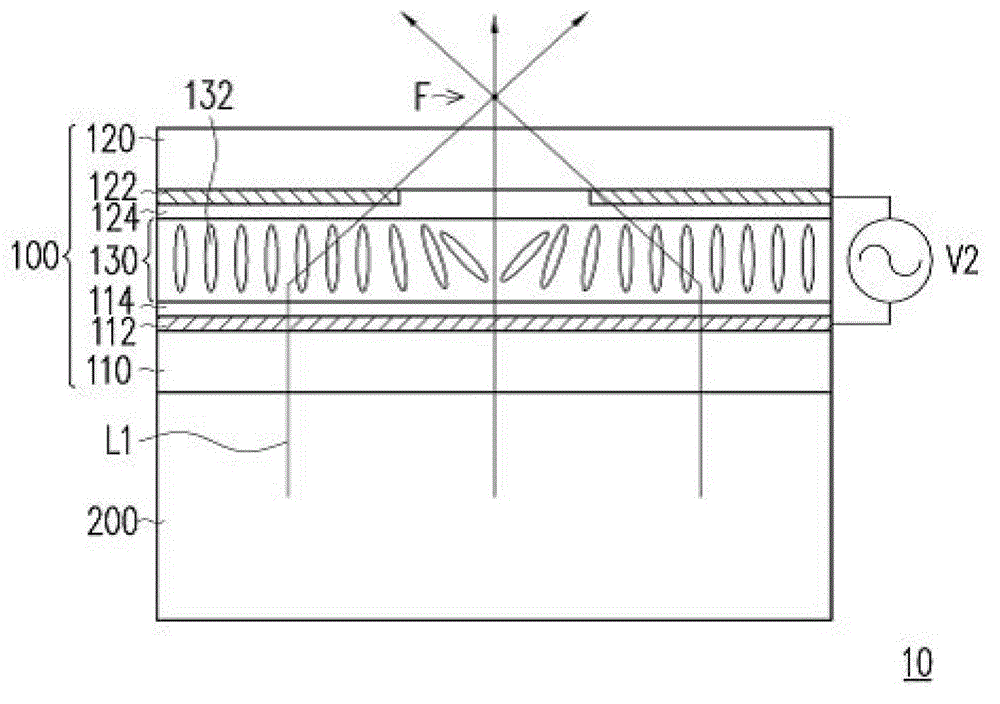

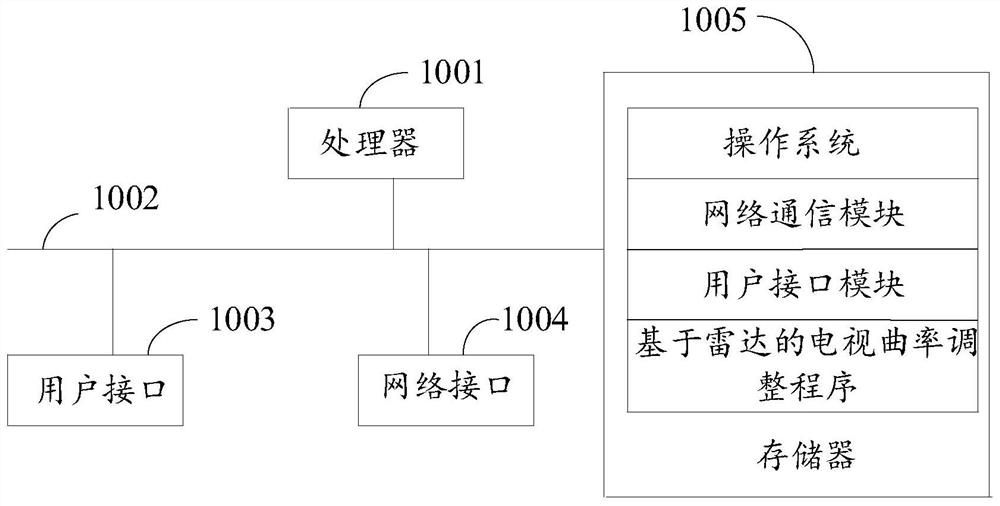

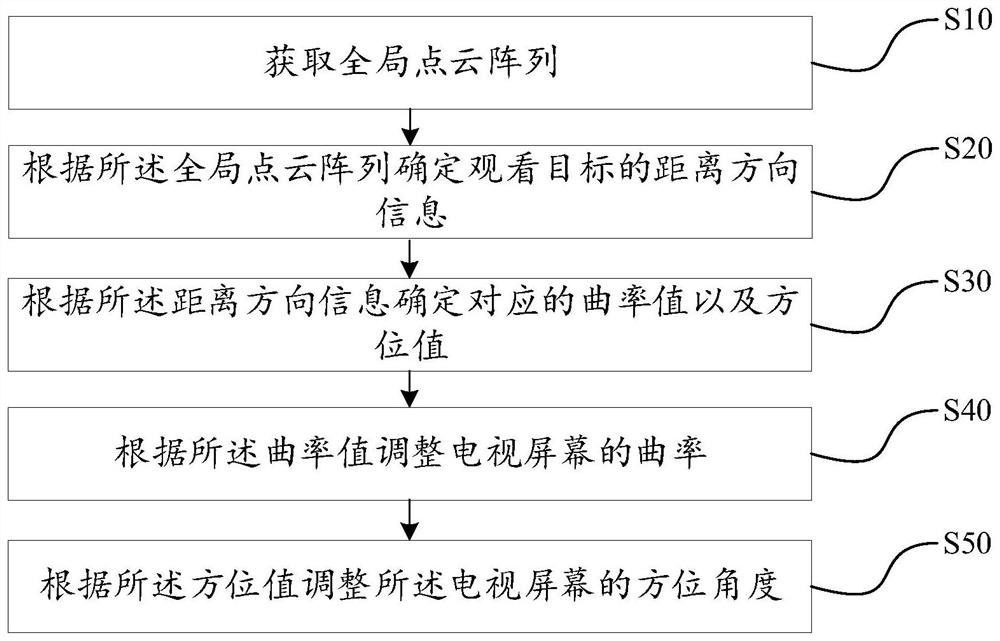

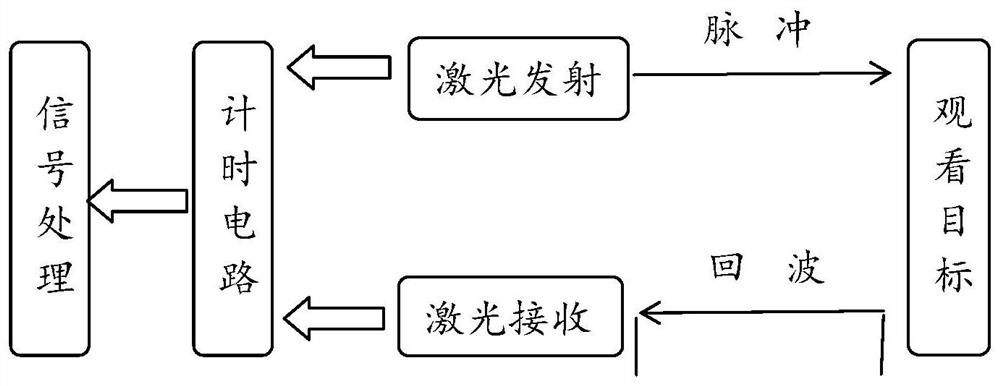

Radar-based television curvature adjustment method and device, television and storage medium

ActiveCN113794922AGood viewing effectImprove user experienceSelective content distributionRadio wave reradiation/reflectionTechnology of televisionTelevision screen

The invention belongs to the technical field of televisions, and discloses a radar-based television curvature adjustment method and device, a television and a storage medium. The method comprises the following steps of: acquiring a global point cloud array; determining distance direction information of a watching target according to the global point cloud array; determining a corresponding curvature value and an orientation value according to the distance direction information; adjusting the curvature of a television screen according to the curvature value; and adjusting an azimuth angle of the television screen according to the azimuth value. Through the above mode, the radar on the television obtains the global point cloud array in front of the television, thereby determining the distance and angle between a viewer and the television, adjusting the screen of the television to the curvature corresponding to the distance, and rotating the screen of the television according to the angle, thereby enabling the television to achieve the optimal watching effect, and improving the user experience.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Crescent cooking pan

A crescent cooking pan belongs to the technical field of kitchen utensils and comprises a pan body. The pan body comprises a pan bottom and a pan wall, wherein the pan wall encircles the arc of the pan bottom and extends upward. When the opening extends and vertical to the horizontal datum, one side surface of the pan wall stops extending, the other side surface which corresponds to the side surface drives the adjacent left and right side surface to go on extending upward and to extend to the inner side arc, the pan wall is enabled to be lower at one side and higher at the other corresponding side, the adjacent left and right sides of the pan incline from the higher position to the lower position to form a crescent structure, and the three side surface of the opening of the pan wall are curled inward. The crescent cooking pan can effectively prevent food material and edible oil from overflowing from the pan opening and ensure that the working table of the kitchen to be clean and easily washed. Meanwhile, the lower side surface enables a spatula to stir the food in the pan. The crescent cooking pan is good in viewing effect, ensures the pan bottom to be heated evenly, can avoid the situations of loosening or damages due to the fact that a handle connection column is connected with the pan wall, and prolongs the service life.

Owner:CHANGSHU KASMAIN

Display panel, production method thereof and electronic device

InactiveCN107566567AGood viewing effectGood appearanceDigital data processing detailsTelephone set constructionsEngineeringElectronic equipment

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

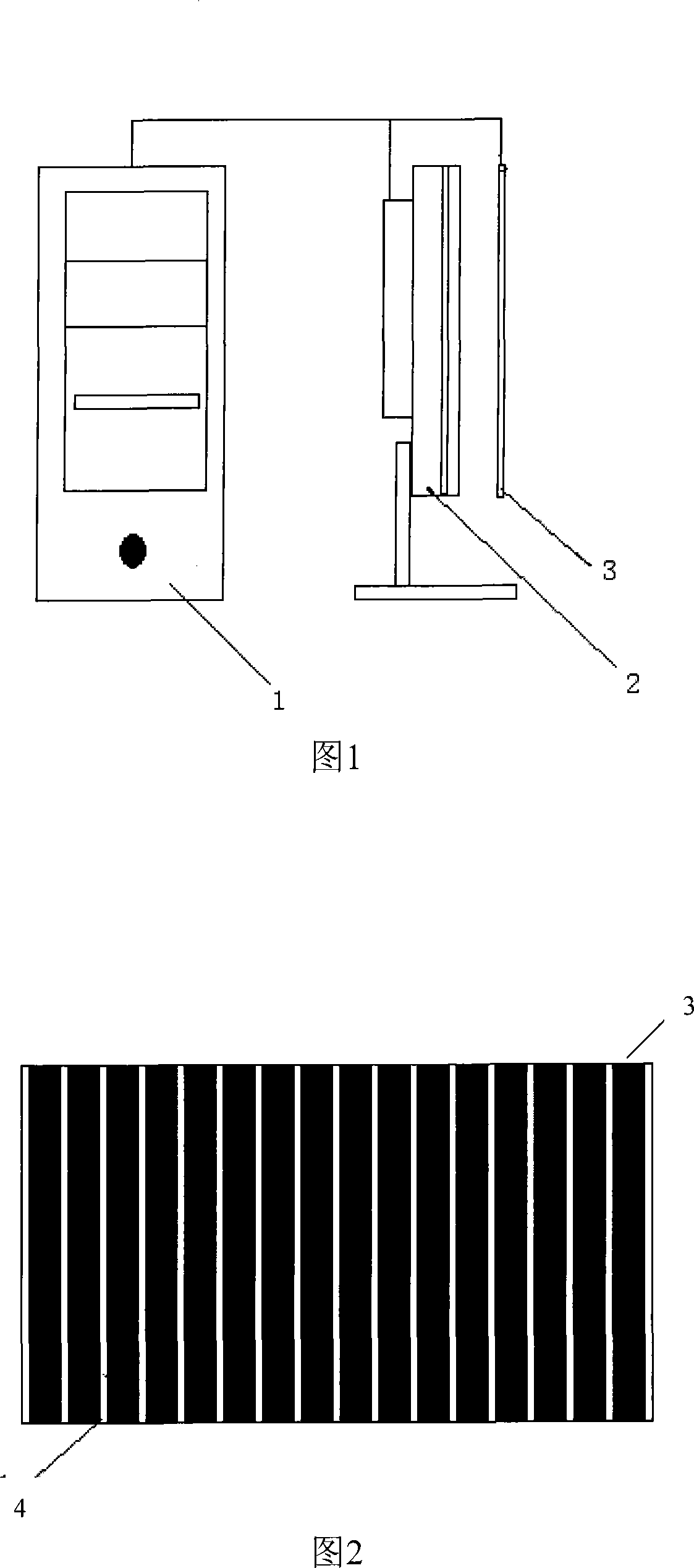

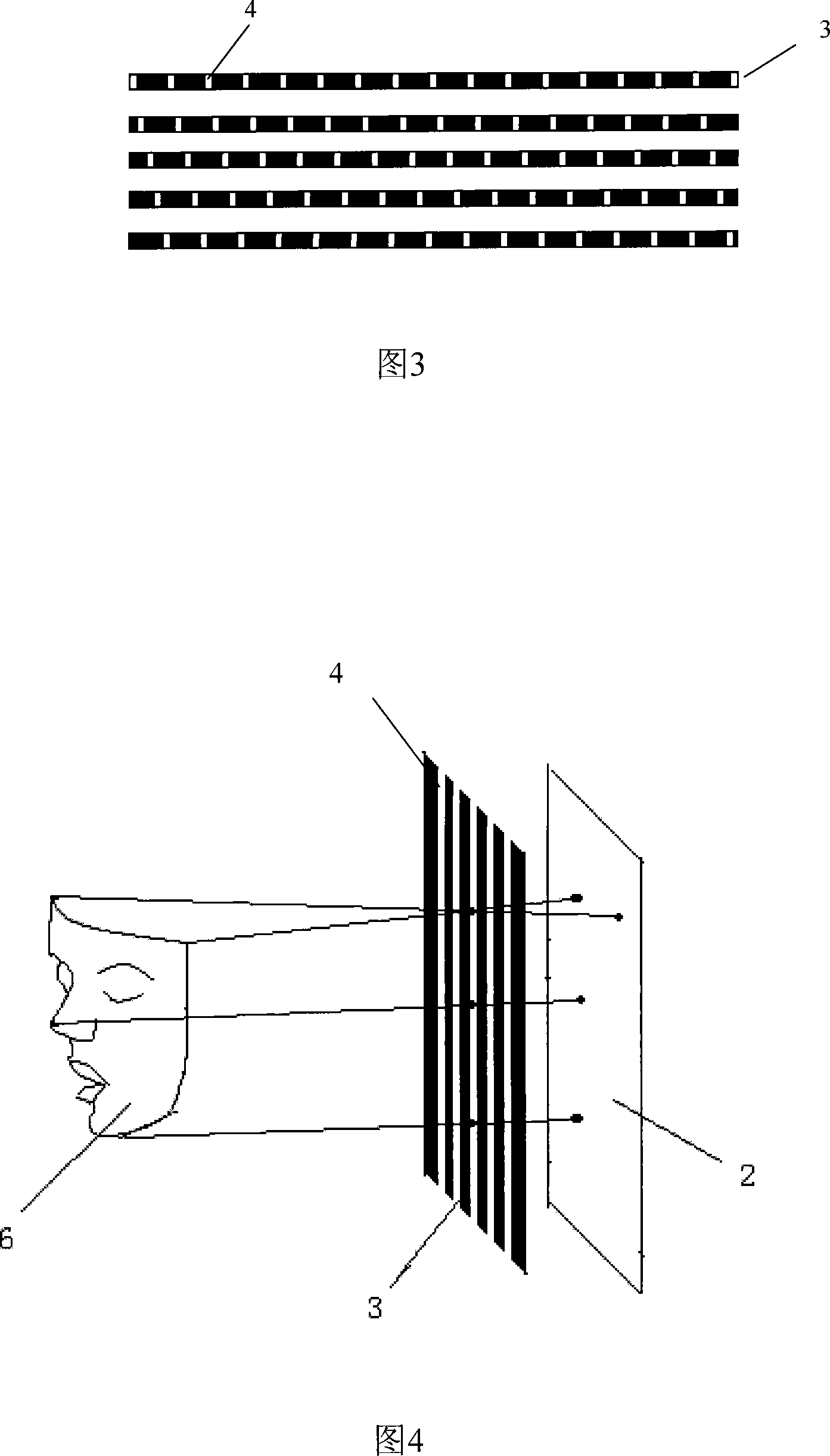

Naked eye visible stereo image liquid crystal grating time-sharing display device

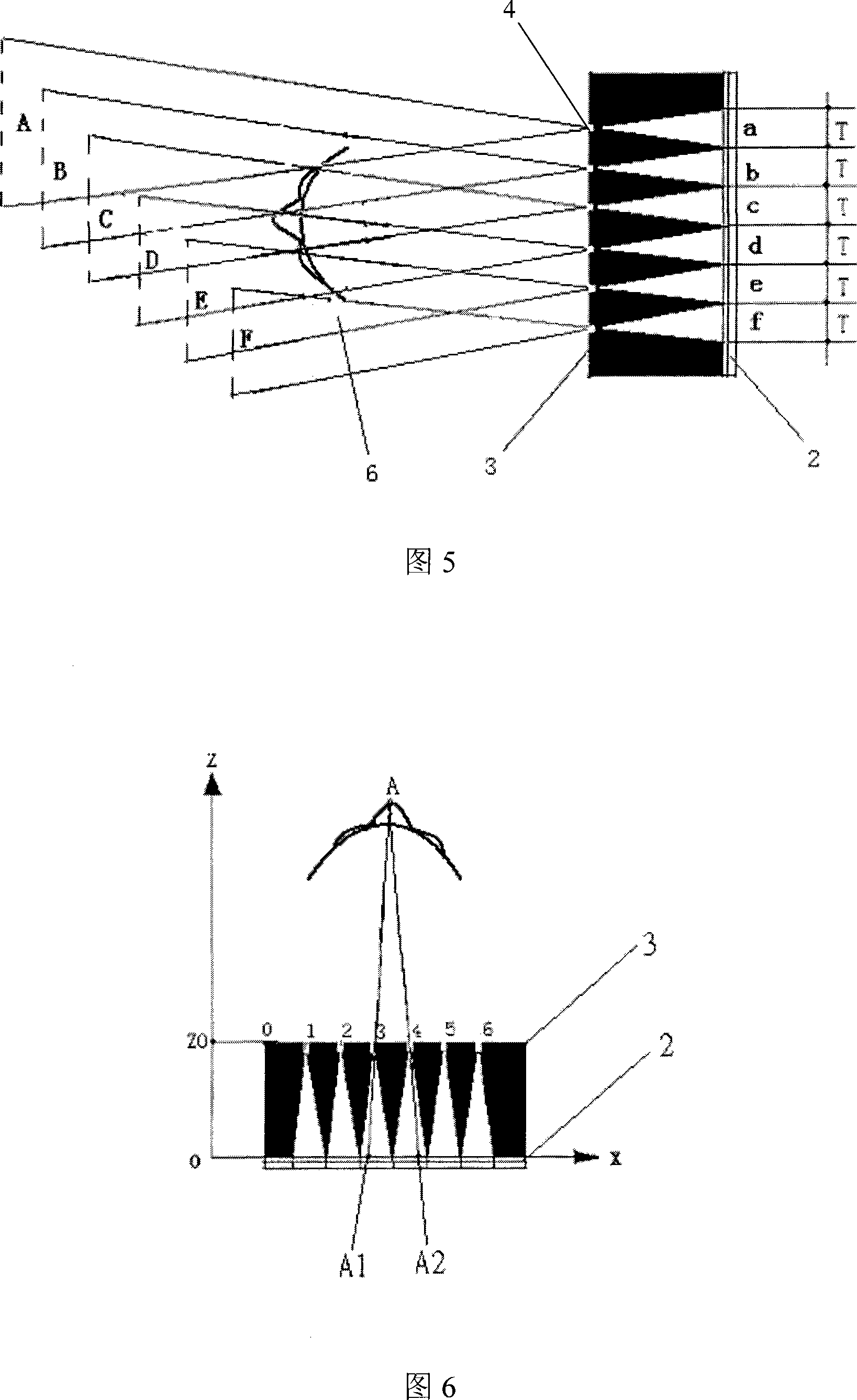

InactiveCN101169518AGood viewing effectSolve the defect of serious light interference phenomenonSteroscopic systemsNon-linear opticsTime-sharingStereo image

The invention relates to the stereo image liquid crystal grating time-sharing display device which is visual to bare eyes. The invention comprises a display and a PC host computer which is provided with a drawing card. The display comprises an image screen and a grating screen. The image screen and the grating screen are all connected with the drawing card. An angle a is formed between the X axis of the image screen and the X axis of the grating screen, and the value range of the angle a is between 0 degree and 90 degrees. The invention can satisfy bare eyes to watch the stereo images, simultaneously, the invention solves the defect that serious light interference phenomenon caused by the point-pixel distance coupling of the image screen and the grating screen in the prior art. The display can normally word and better effect of watching stereo images using bare eyes can be guaranteed. The applied range of the device is wide; thereby the device can be suitable to watch 2D / 3D images.

Owner:张凯明 +1

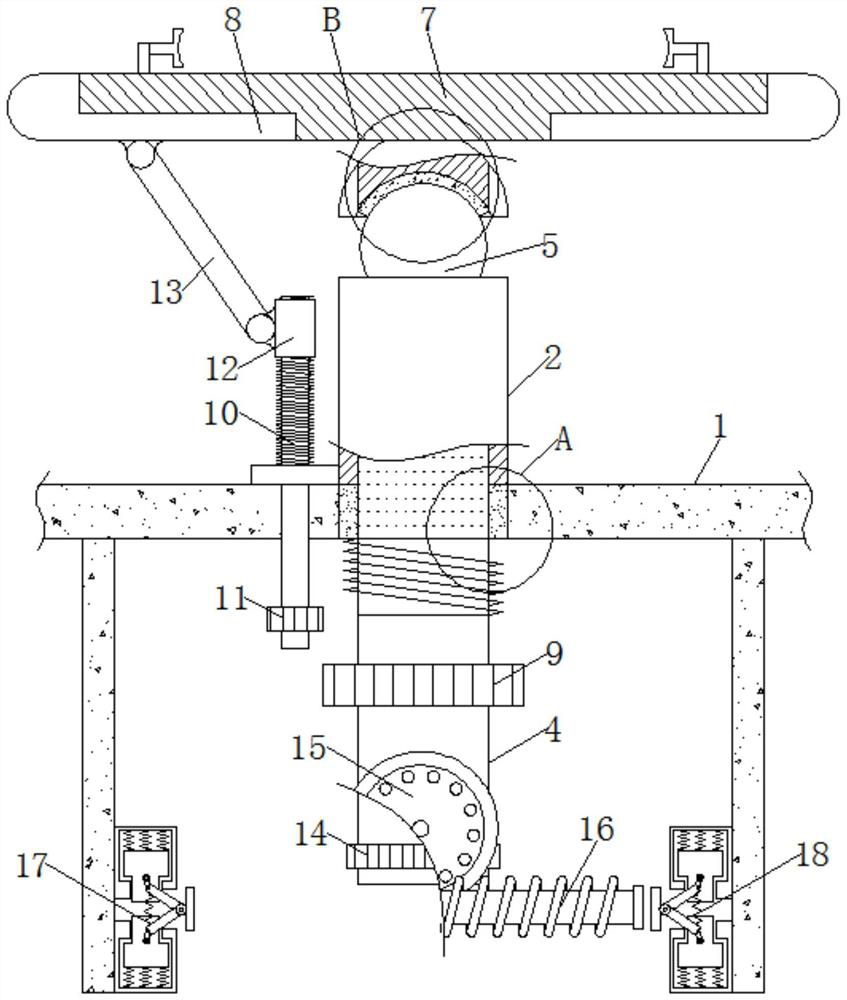

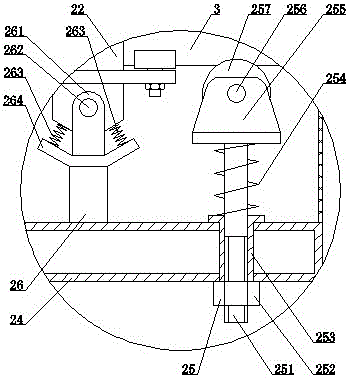

Exhibition article base adjusting mechanism for convention and exhibition

InactiveCN112006483AImprove display effectGood viewing effectShow shelvesShow hangersGear wheelEngineering

The invention relates to the technical field of conference exhibition. The invention discloses an exhibition article base adjusting mechanism for convention and exhibition. An exhibition stand is included; a shell is arranged in the exhibition stand; a threaded ring is arranged in the shell; a rotating shaft is arranged in the shell; the upper end of the rotating shaft is movably connected with aspherical part; the surface, away from the rotating shaft, of the spherical part is movably connected with a shaft seat; a base is arranged on the surface of the shaft seat; and a chassis is arrangedon the surface of the base. According to the exhibition article base adjusting mechanism for convention and exhibition, through cooperative use of the rotating shaft and the spherical part and cooperative use of the shaft seat and the base, an article can be rotated for exhibition; and through cooperative use of the rotating shaft and the threaded ring, cooperative use of a first gear and a secondgear and cooperative use of a push ring and a connecting rod, an article can be obliquely exhibited, a viewer can view the full view of the article at one position, the viewer can view the article conveniently, and the viewing experience of the viewer is improved.

Owner:广州朗天企业管理有限公司

Video image enhancement processing method and processing system, and player end

InactiveCN109688464AGood viewing experienceGood viewing effectColor signal processing circuitsSelective content distributionStrength parameterImage enhancement

The invention discloses a video image enhancement processing method and processing system, and a player end. The video image enhancement processing method comprises steps of A. decoding to obtain original playback data; B. enhancing and rendering a video image so as to obtain terminal playback data, wherein the enhancement and rendering process of the video image comprises the step of performing image enhancement on original playback data according to strength parameter value Ecur; C. playing data by the display terminal; following steps are included between A and B: D. setting a theoretical maximum and minimum of a strength parameter value, setting a subjective effective maximum and minimum of the strength parameter value; E. acquiring a current brightness value Lcur of a playback screenin real time; F. determining a strength parameter value Ecur according to Lcur; and G. checking validity of the strength parameter value Ecur and updating the strength parameter value Ecur. Strength for image enhancement is regulated adaptively in real time according to brightness of the playback screen, user interaction operation is omitted, watching effect is better and user experience is higher.

Owner:HUNAN HAPPLY SUNSHINE INTERACTIVE ENTERTAINMENT MEDIA CO LTD

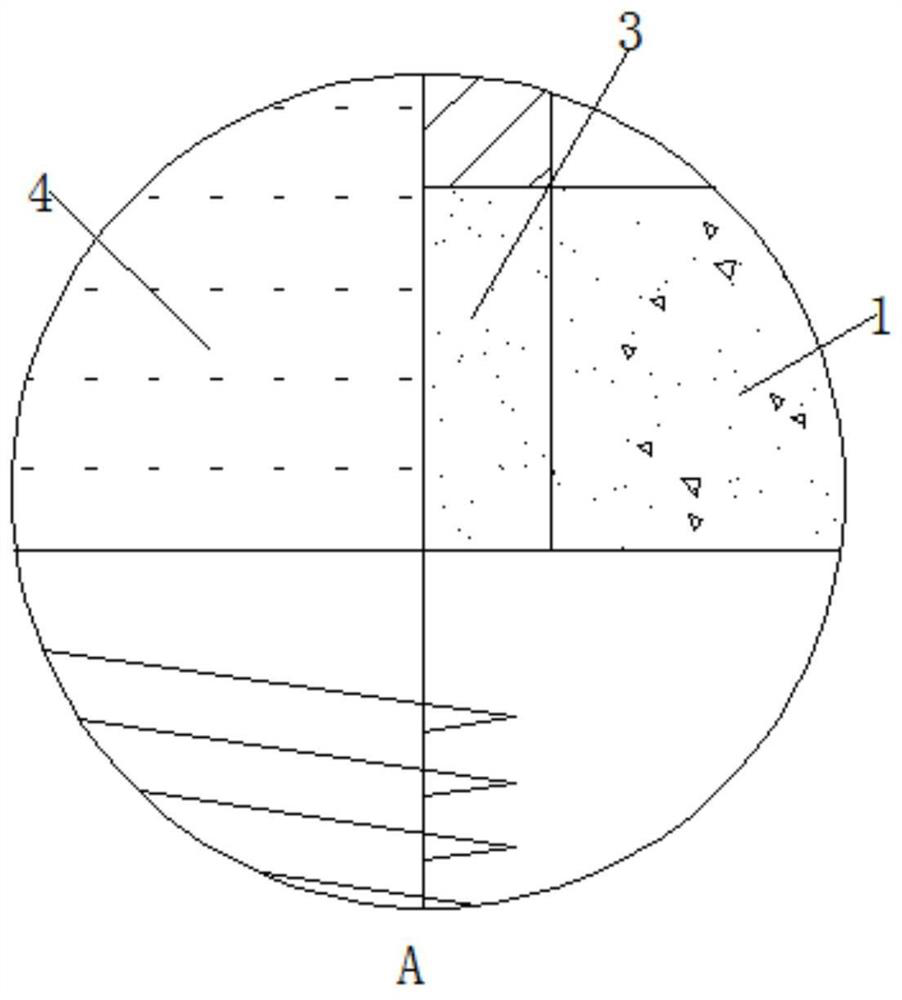

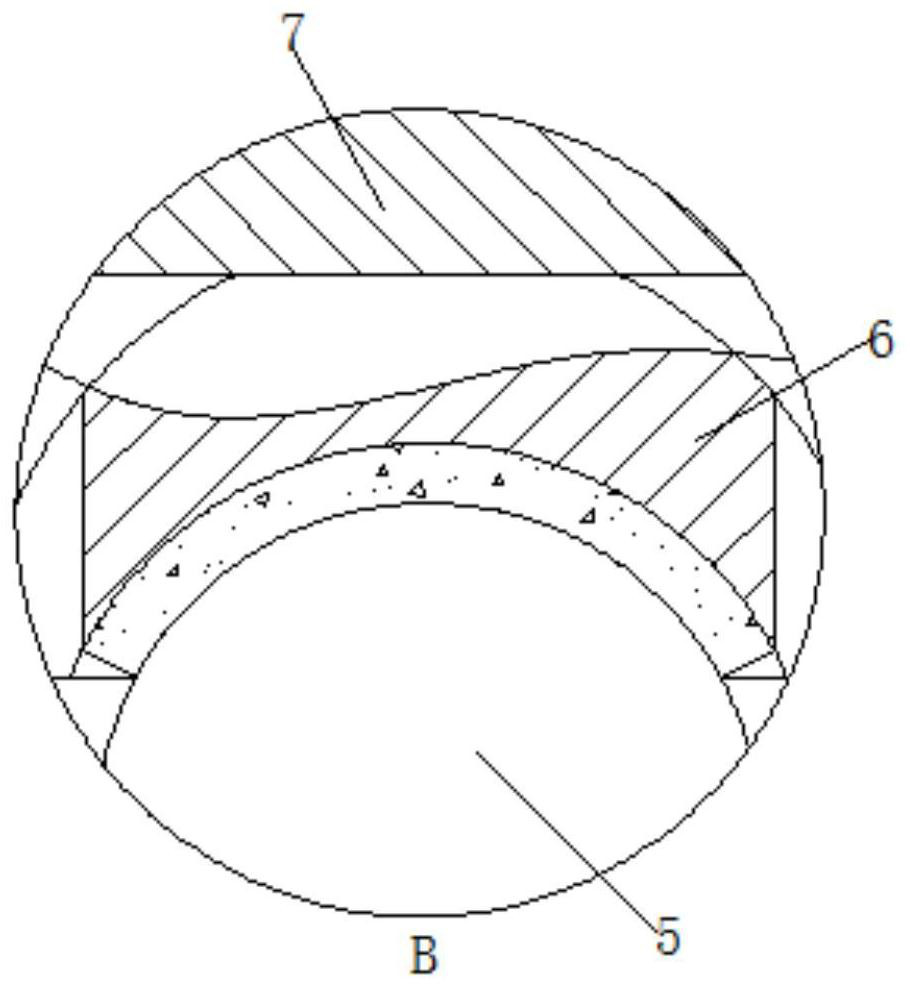

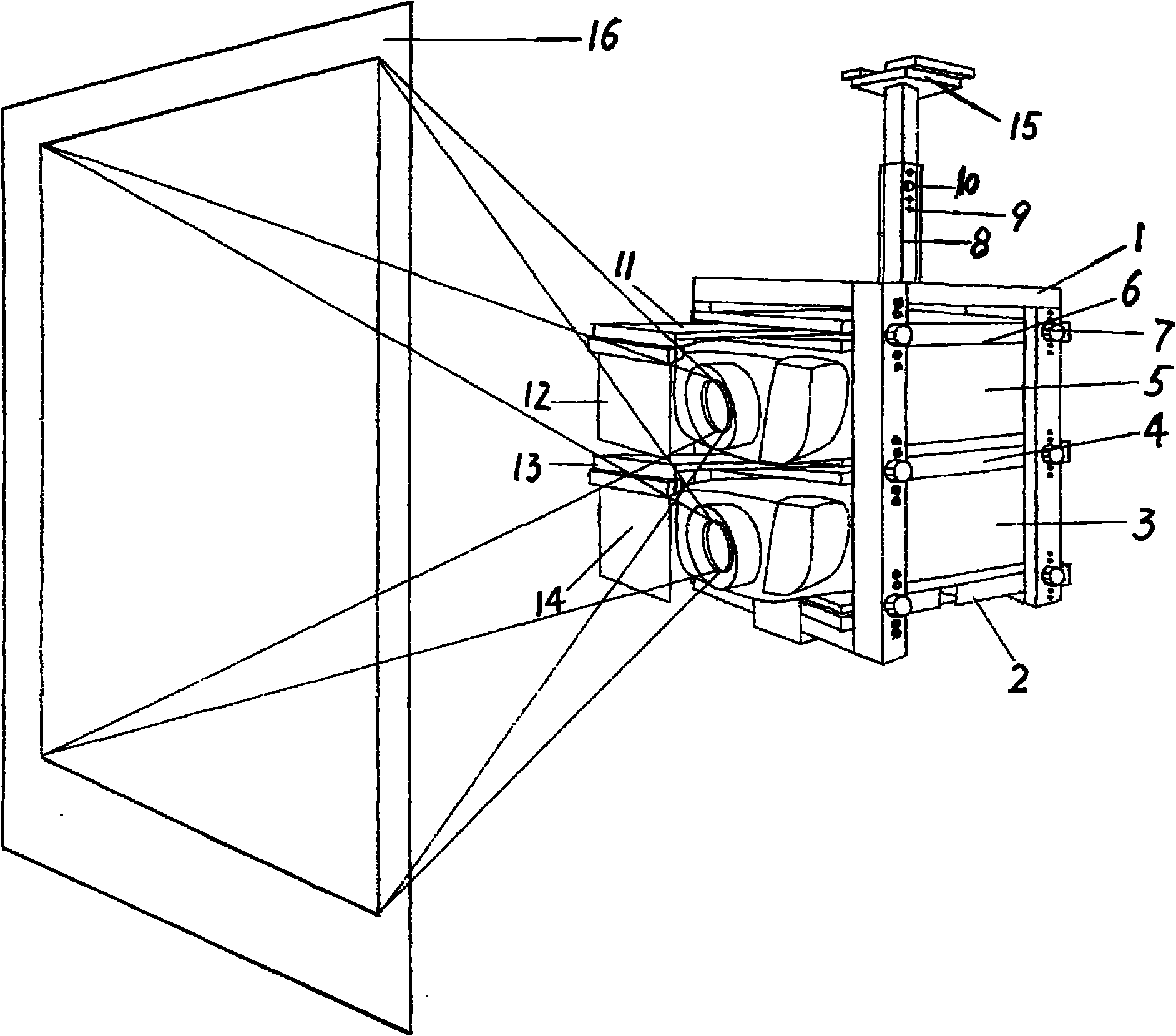

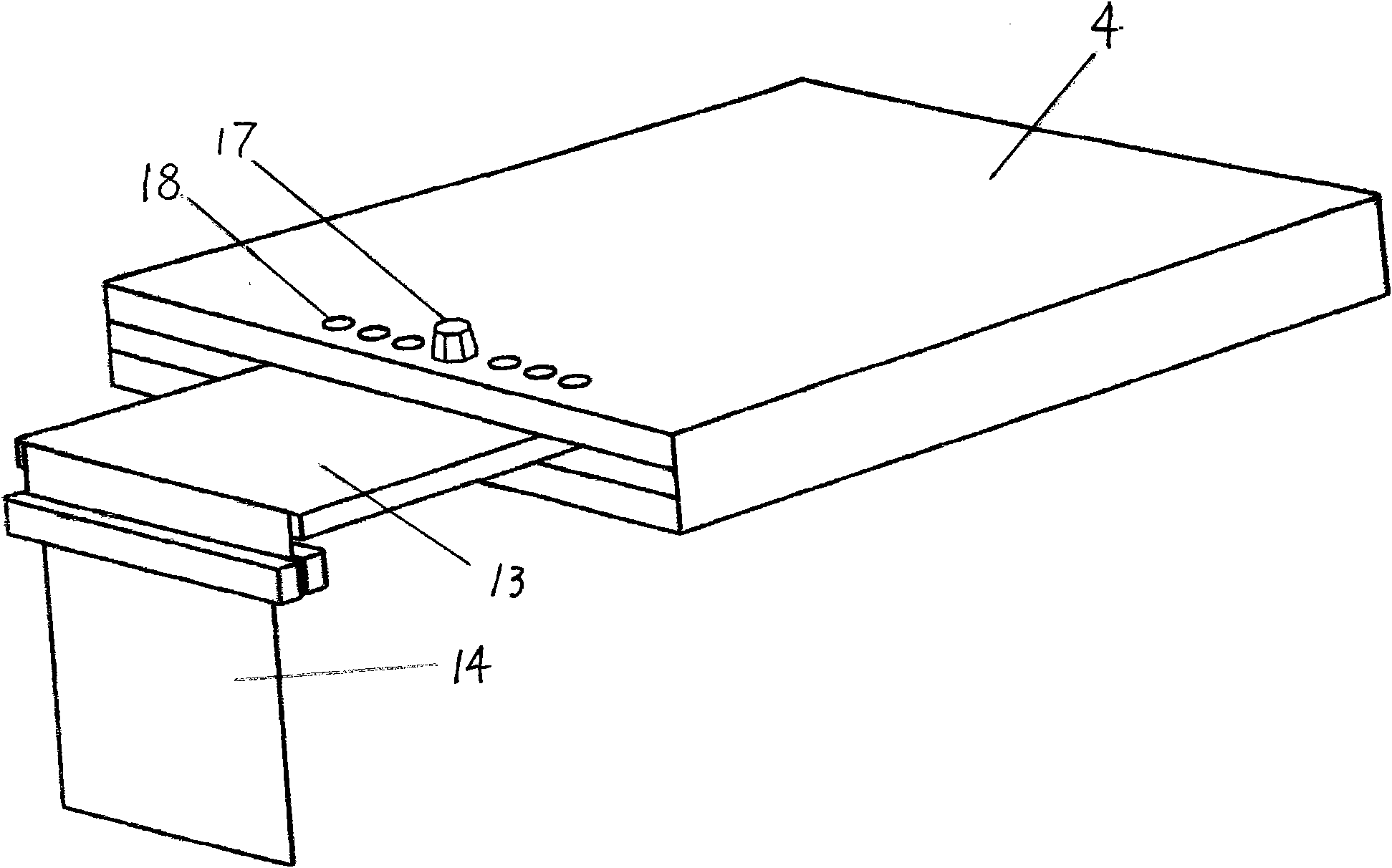

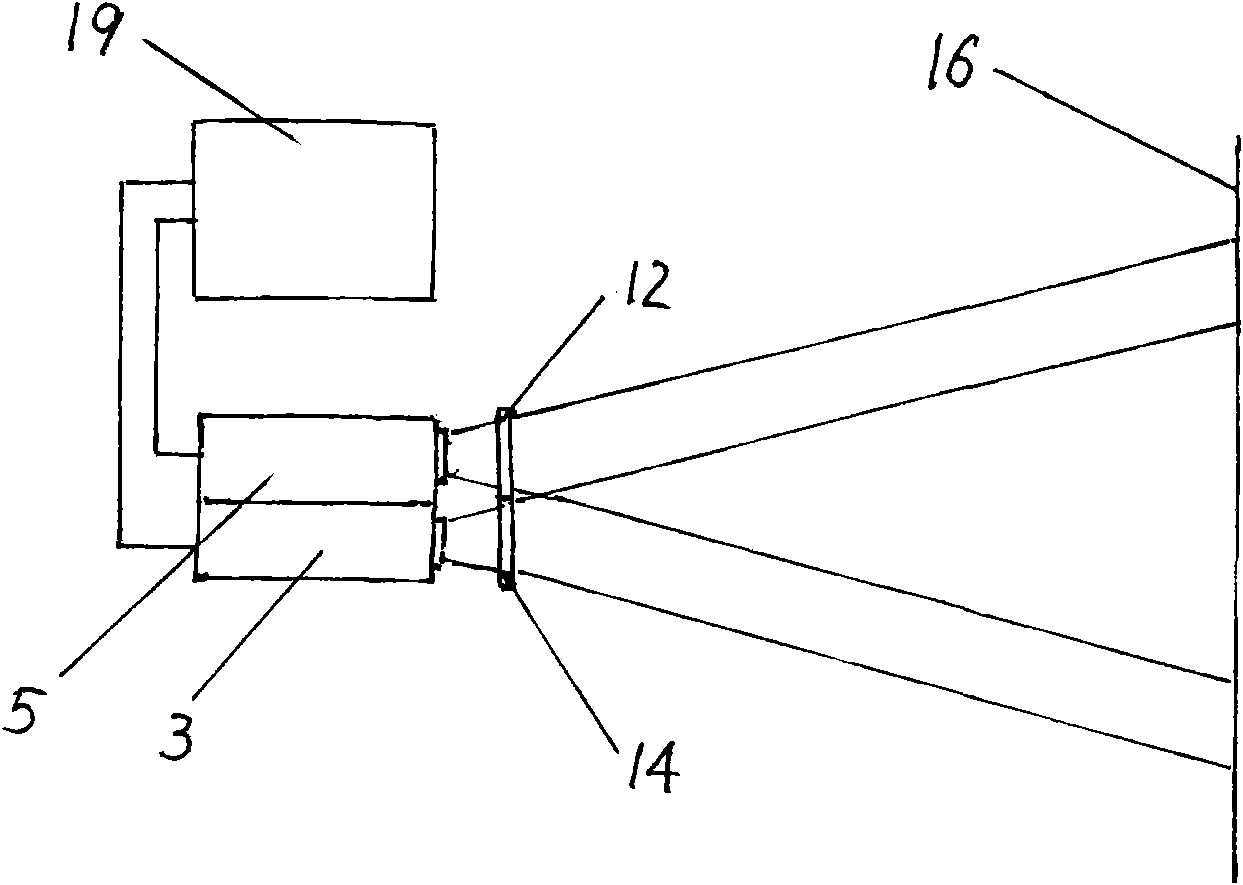

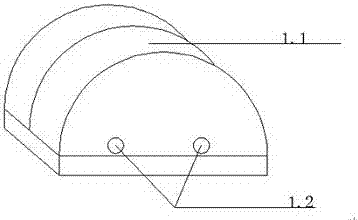

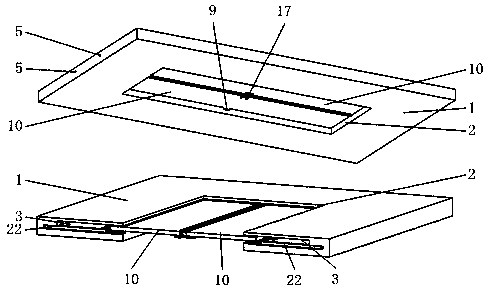

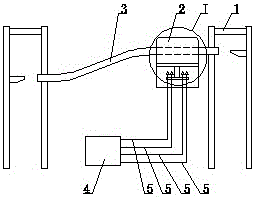

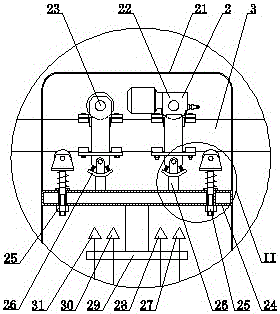

Assembly auxiliary equipment of 3D stereoscopic image projection playing system

The present invention relates to a piece of assembly auxiliary equipment of 3D stereoscopic image projection playing system, comprising a hanger frame assembly, a polarized light projection device and a metal curtain. The hanger frame assembly has a main frame, wherein three layers of tray plates with adjustable front and back pitch angles are disposed on the main frame; the upper and middle layers of tray plates are respectively used for stacking and fixing two projectors up and down; horizontal slots and location screw holes for plug-in mounting and fixing a polariscope tray are disposed on the upper and lower layers of tray frames; the polarized light projection device comprises two polariscope trays combined with the upper and middle layers of tray plates in a plug-in mounting manner; a polariscope clamping slot is disposed at a front end of the polariscope tray; the metal curtain is a hard substrate or a flexible soft base cloth standing front of the hanger frame assembly; silver inks, sliver powders, reflecting powders, light stabilizers and the like are coated on the surface of the substrate or the base cloth to obtain a metal reflecting coating. The product has the advantages of simple structure, convenient splicing and mounting, good focusing effect of polariscope, good texture display performance of the curtain and the like.

Owner:XIAN SHENGSHI NETWORK INFORMATION

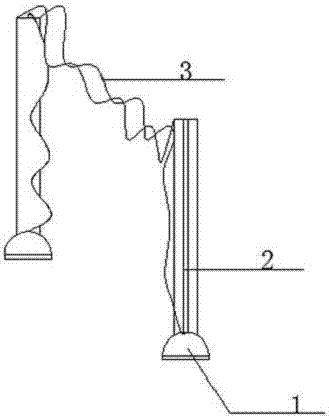

Stereo observation tunnel of Ocean aquarium

The invention relates to a solid viewing tunnel of ocean aquatic animal, which comprises a water container of outer wall and transparent viewing wall. And it is characterized in that it uses vertical cylinder transparent viewing wall as the vertical viewing tunnel; it arranges a integrated posts in the center of said tunnel; arranges up-to-down lift between the post and vertical cylinder transparent viewing wall; the vertical viewing tunnel is connected to the horizontal viewing tunnel formed by horizontal transparent viewing wall; and the horizontal viewing tunnel has outlets. The invention has the advantages that the vertical and horizontal viewing tunnels are connection to realize up-and-down and horizontal walking and viewing, with full-directional view angle, while it can fully utilize space, reduce accommodation area. And the vertical cylinder transparent viewing wall has better anti-compression strength, lower cost and higher water container. In addition, it can be mounted between floors.

Owner:王德芙

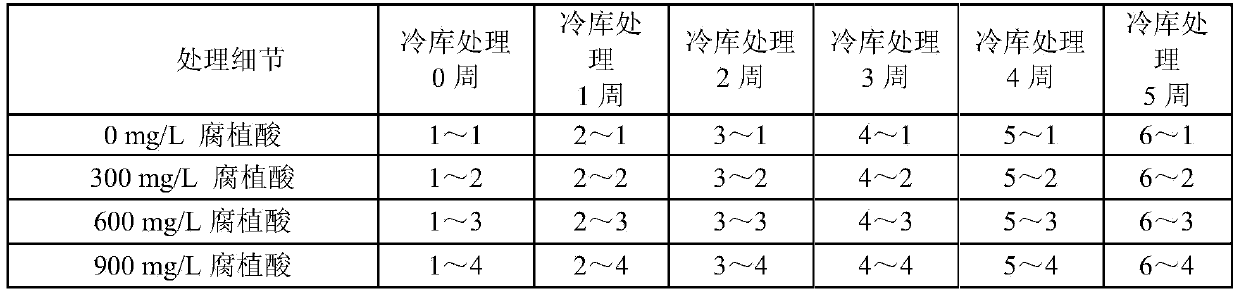

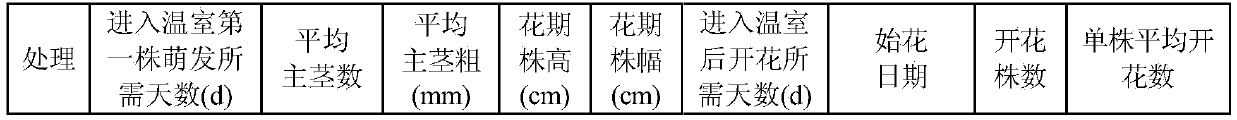

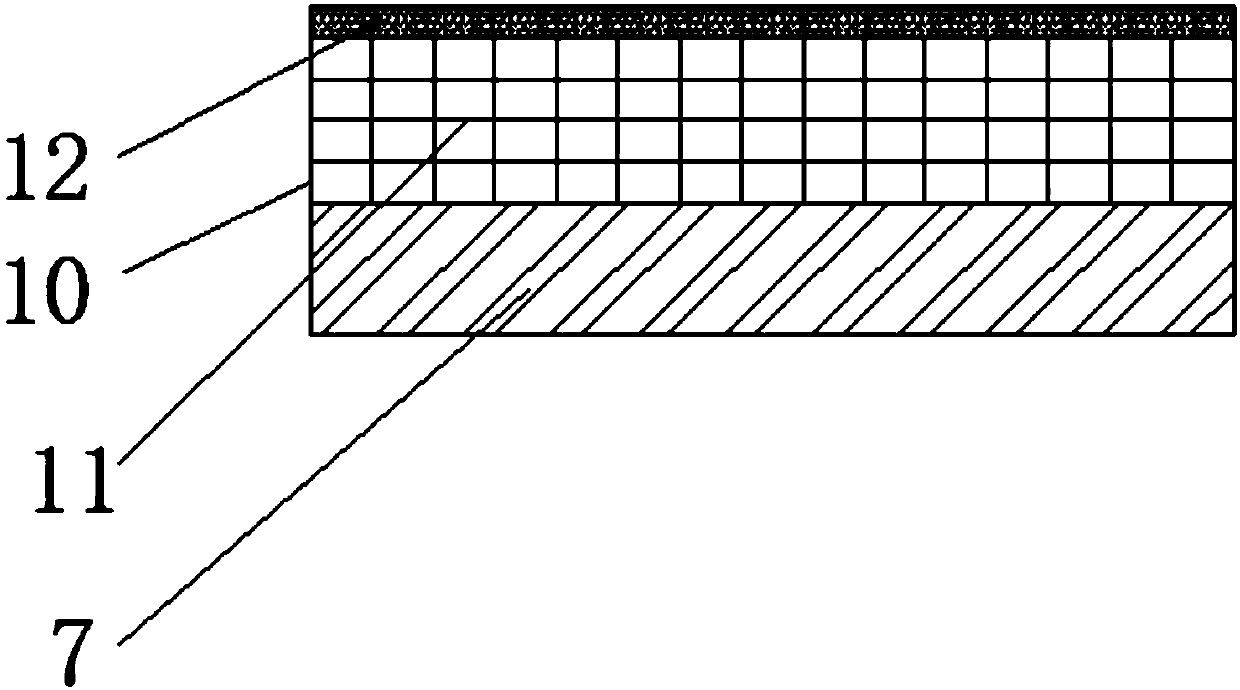

Hangzhou white peony potted flower cultivation method

InactiveCN105359778AGuaranteed to flourishPromote growthSeed and root treatmentFertilising methodsPlant rootsGreenhouse

The invention relates to plant florescence regulation and control technology, and provides a Hangzhou white peony potted flower cultivation method. The method comprises the steps of selecting a mother plant root tuber of a Hangzhou white peony that is 3-5 years old; transplanting the root tuber to a pottery after ramet; placing the pottery to a cold storage in 0-4 DEG C for refrigeration for 1-5 weeks; transplanting the root tuber to a greenhouse for routine culture, and applying a humic acid suspending liquid since the day being transplanted to the greenhouse, and applying the humic acid suspending liquid twice a week and 250ml to each pottery until a full flowering stage. The quality concentration of the humic acid suspending liquid is 300-900mg / L, and is prepared by mixing ore source humic acid raw powder and water evenly. By selecting the local Hangzhou white peon, the potted florescence is 60-75 days before routine florescence; the potted Hangzhou white peony in 1 gallon can be guaranteed to grow leafy; each plant grows 4-5 flowers on average and part can grow 7 flowers; the flowers cover the plant body largely; and a good flower viewing effect and goods value are provided. At the same time, the problems of spindling and lodging of the forcing Chinese herbaceous peony is greenhouse is solved.

Owner:ZHEJIANG UNIV

A display stand based on ecological garden landscape

InactiveCN109864506AImprove practicalityGood viewing effectCultivating equipmentsSeaweed cultivationElectricityEngineering

Owner:张轶皓

Video editing method based on artificial intelligence technology

PendingCN114727129AGood viewing effectImprove viewing effectSelective content distributionImage resolutionEngineering

The invention discloses a video editing method based on an artificial intelligence technology, and the method comprises the following steps: S1, reading a target video file, and recognizing the resolution and the frame number of the target video file; s2, reading a material video file, identifying the resolution ratio and the frame number of the material video file, and editing an image of the material video file and a corresponding frame image; s3, comparing the resolution ratio and the frame number of the edited material image segment with the resolution ratio and the frame number of the target video file, and performing resolution ratio adjustment and frame compensation; s4, synthesizing the edited video, and synthesizing the edited material video image and the target video image to obtain an edited video; s5, exporting the edited video, and selecting the resolution and the frame number of an exported video file; and S6, carrying out intelligent resolution modification and intelligent frame supplementation on the exported video file. According to the invention, the resolution and the frame number of the material video file are adjusted through the artificial intelligence system, so that the resolution and the frame number are consistent, and a better video editing effect is achieved.

Owner:武汉热榜科技有限公司

Biological scene display

InactiveCN109907601AImprove practicalityGood viewing effectShow cabinetsShow shelvesEngineeringDisplay device

The invention discloses a biological scene display which comprises a platform; a moveable end is fixedly connected with the top of the platform; a vertical rotating shaft is arranged in the moveable end; a moveable starter is arranged at the center of platform bottom; a moveable ring is fixedly jointed in the moveable starter; an output shaft of the moveable ring is penetrated through the moveablestarter and is in driving connection with the rotating shaft; a liquid storage area is fixedly connected with the upper surface of the moveable end; a first display surface is fixedly connected withthe upper surface of the liquid storage area; a second display surface is fixedly connected with the upper surface of the first display surface. Through the arrangement of first display surface, second display surface and third display surface, the practicability of biological scene display is promoted; through the arrangement of landscape lamp, the ornamental effect of biological scene display isbetter and is promoted; change on ecological landscape can be more comprehensively displayed.

Owner:张勇

Two-color and multi-color patterned coins

InactiveCN111301047AAdd product colorGood viewing effectDecorative surface effectsSpecial ornamental structuresCoinEngineering

The invention relates to two-color and multi-color patterned coins. Each coin is composed of an outer outline part, a local seal and an inner outline part; an annular groove is formed in the inner side face, perpendicular to the front and back faces of the annular outer outline part, the inner diameter of the outer outline part is the same as the size of the outer diameter of the local seal, and the outer outline part and the local seal are the same in shape; the size of a local seal inner hole is the same as the size of an inner outline part outer periphery, and the local seal inner hole andthe inner outline part outer periphery are the same in shape; and the outer outline part, the local seal and the inner outline part are made of metal raw material of different colors. A preparation process of the coin comprises the following steps of firstly, separately manufacturing punching dies and an assembly die of the outer outline part, the local seal and the inner outline part of the patterned coin according to design requirements, separately punching the outer outline part, the local seal and the inner outline part, placing the outer outline part, the local seal and the inner outlinepart into the assembly die on a punch press according to requirements, and performing punching connection to enable the parts to be closely combined into a whole; then, adopting the process combininghand engraving and mechanical punching to manufacture relief marks and text or patterns of the front and back faces of the patterned coin; and performing correcting and polishing treatment to obtain afinished product.

Owner:陈阳

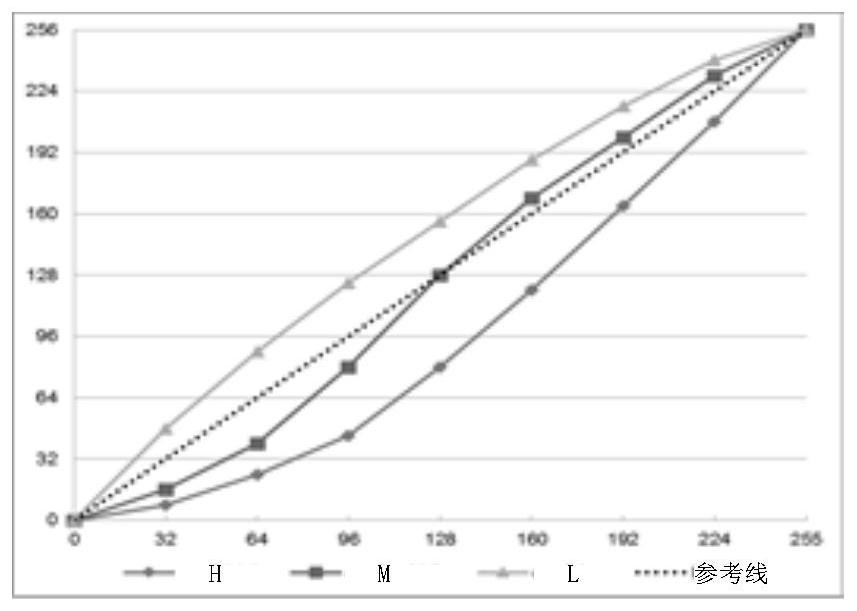

Display device and display method

ActiveCN113015006ARaise the proportionGood viewing effectSelective content distributionPhysicsHistogram

The embodiment of the invention provides a display device and a display method, the display device comprises a display and a controller, the controller is connected with the display, and the controller is configured to obtain the average brightness of a to-be-displayed image and a brightness histogram of the to-be-displayed image. The method comprises the steps of: if the serial number of the first target interval is different from the serial number of the second target interval, obtaining a first proportion; correcting a contrast control curve of the to-be-displayed image according to the first proportion; correcting the to-be-displayed image by using the contrast control curve to obtain a corrected to-be-displayed image; and controlling a display to display the corrected image to be displayed. The first proportion can represent that the distribution condition of the brightness of the to-be-displayed image is in concentrated distribution or discrete distribution. Therefore, the contrast control curve of the to-be-displayed image can be corrected based on the first proportion, and then the contrast of the to-be-displayed image is corrected, so that the to-be-displayed images with different brightness distributions can obtain a better viewing effect.

Owner:HISENSE VISUAL TECH CO LTD

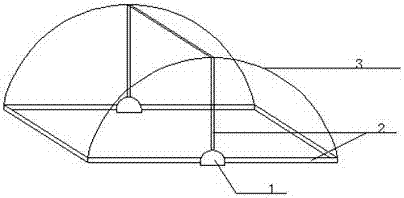

Foldable small warm shed

InactiveCN107182628AImprove survival rateGood viewing effectClimate change adaptationGreenhouse cultivationOrnamental plantEngineering

The invention discloses a foldable small warm shed. The concrete structure comprises a connection piece, a shed frame, and shed film. The connection piece is semicircle in shape, the upper side of the connection piece is provided with rotation grooves, the inner side of the connection piece is provided with two fixed axles; the shed frame is a square box body with no bottom, there are three pieces in total, the middle piece is fixed on the connection piece and used for supporting a shed body, the end parts of the remaining two pieces are provided with round holes and are respectively pierced in the two fixed axles of the connection piece and used for the expansion of the shed body; the shed film is fixed on the shed frame and used for the protection of the top and two side faces of the shed body in an enveloping mode. The foldable small warm shed has the advantages that the shed is used for the cultivation of home ornamental plants, is light and convenient, foldable, provides help for plants to resist coldness and bird and insects, and has the effects of increasing the survival rate of plants, the shed body is semicircle in shape after the unfolding and provides a good ornamental effect.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

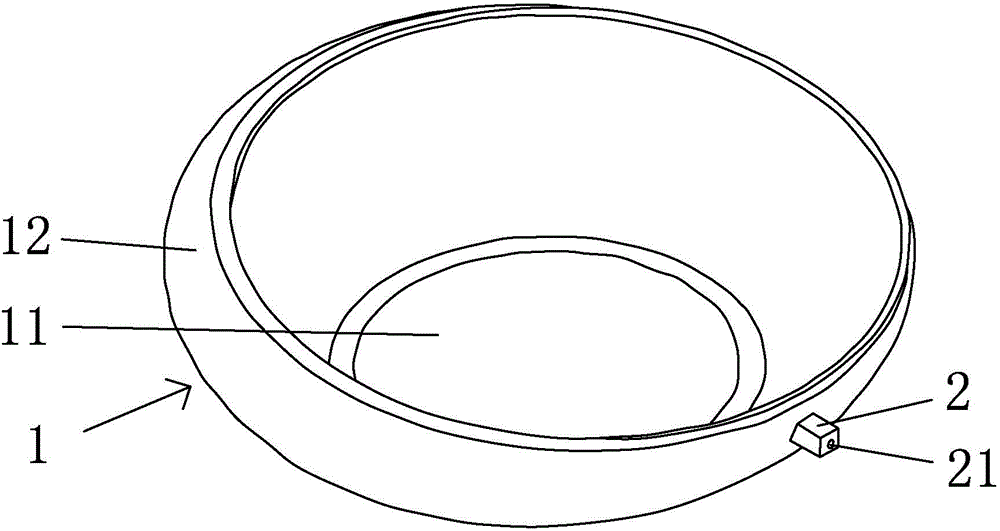

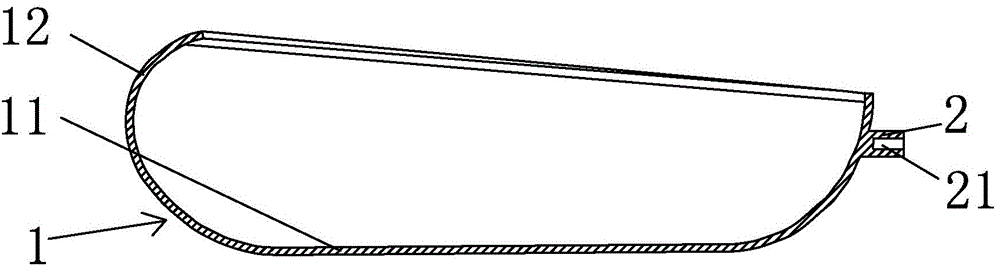

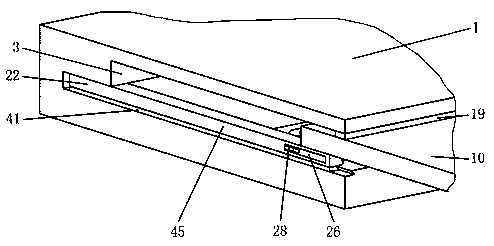

Automobile panoramic sunroof

ActiveCN111137116AWide field of viewGood viewing effectEngine sealsVehicle sealing arrangementsAutomotive engineeringMechanical engineering

The invention belongs to the field of automobile panoramic sunroofs, and particularly relates to an automobile panoramic sunroof which comprises sunroof glass, a C-shaped block, a sealing strip and adriving mechanism, a sliding groove A is formed in the inner wall of a sunroof opening in the top of a carriage, and the two pieces of sunroof glass symmetrically sliding in the sliding groove A openor close the sunroof opening from the two sides; the two pieces of sunroof glass are opened and closed from the two sides of the top of the carriage, and the front and rear lengths of the two pieces of sunroof glass contain and cover the front and rear rows of seats; after the two pieces of sunroof glass are completely closed, the two pieces of sunroof glass in the panoramic sunroof cover the front row of seats and the rear row of seats; the driving mechanism can automatically complete retraction after driving the sunroof glass to be closed; the driving mechanism in the automobile panoramic sunroof may automatically complete the withdrawal after driving the sunroof glass to close, the closed sunroof glass is not partially shielded, the visual field range is wider, the viewing effect is better, circulation of air inside and outside a vehicle can be achieved while the panoramic sunroof in the real sense is achieved, oppressed feeling caused by the fact that a person is located in the closed vehicle for a long time is avoided, and riding is more comfortable.

Owner:山东菏益科技有限公司

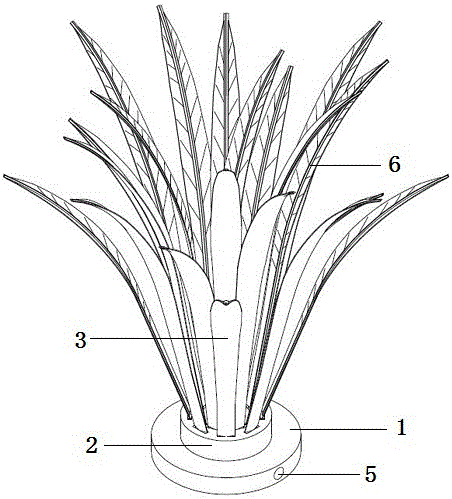

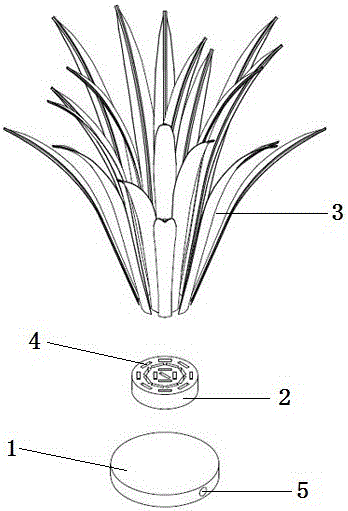

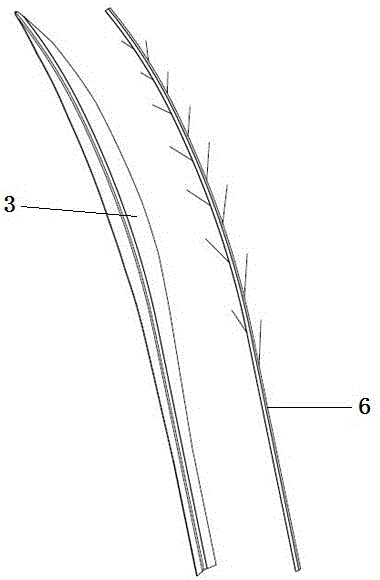

Artificial heat-dissipation bonsai

ActiveCN106617430AStrong plasticityGood viewing effectArtificial flowers and garlandsCooling/ventilation/heating modificationsBonsaiEngineering

The invention discloses an artificial heat-dissipation bonsai which comprises a metal base having a heat conducting function, a fixing base and multiple heat-dissipation blades made of a thin aluminum material. The base is fixedly connected with the fixing base, insertion holes are formed in the fixing base, and the heat-dissipation blades are fixed to the heat-dissipation base through the insertion holes. A light source is further arranged in the fixing base. The heat-dissipation blades are covered with a layer of transparent film. The transparent film is provided with veins made from light-guiding fiber. The light-guiding fiber conducts out light from the light source. The transparent film and the light-guiding fiber are arranged on the surfaces of the heat-dissipation blades, the light from the light source is conducted and extends, so that the light irradiated on the heat-dissipation blades is uniform, and the whole artificial heat-dissipation bonsai simultaneously has heat dissipation and light-emitting functions and a good ornamental effect.

Owner:济宁高新科达科技项目服务有限公司

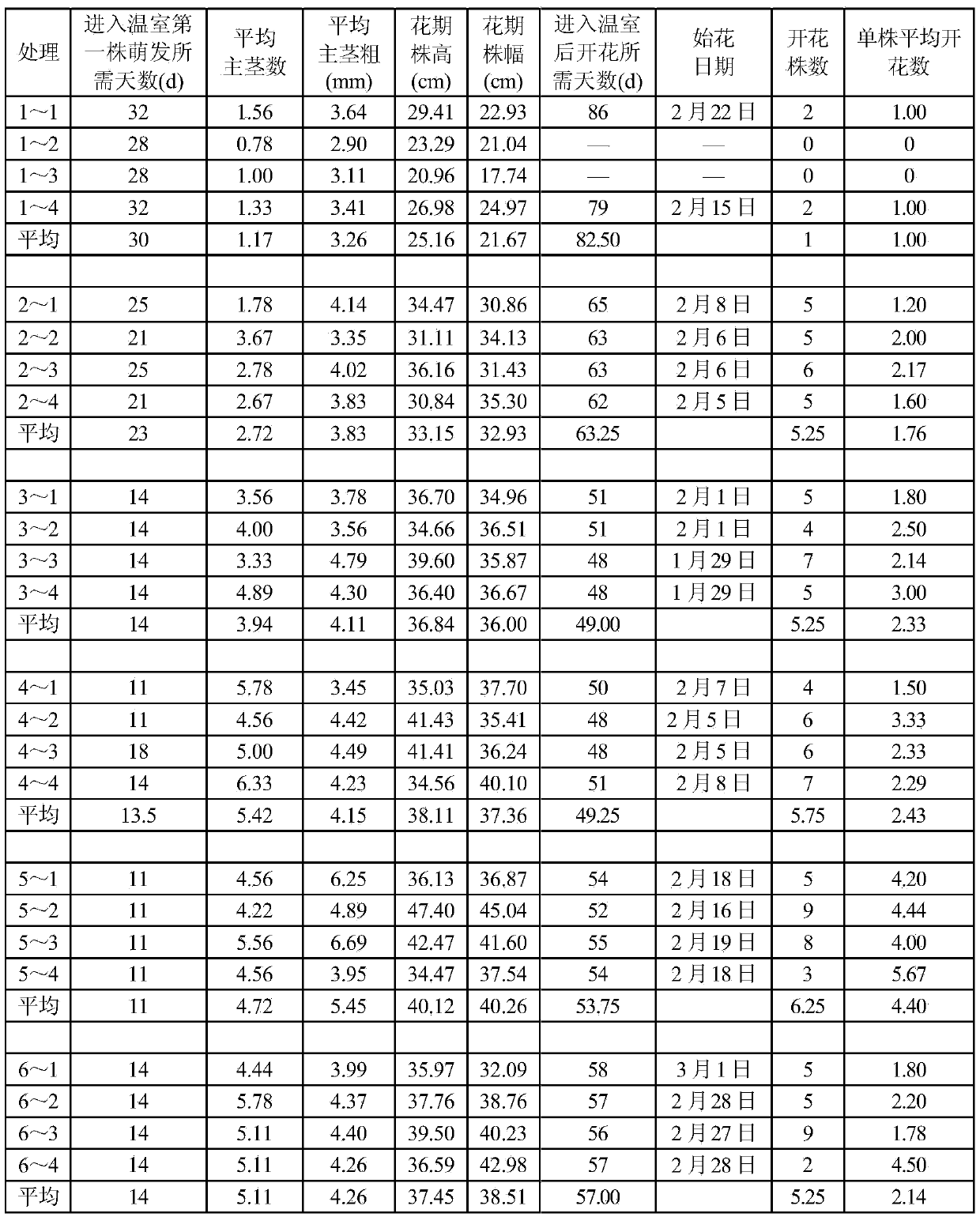

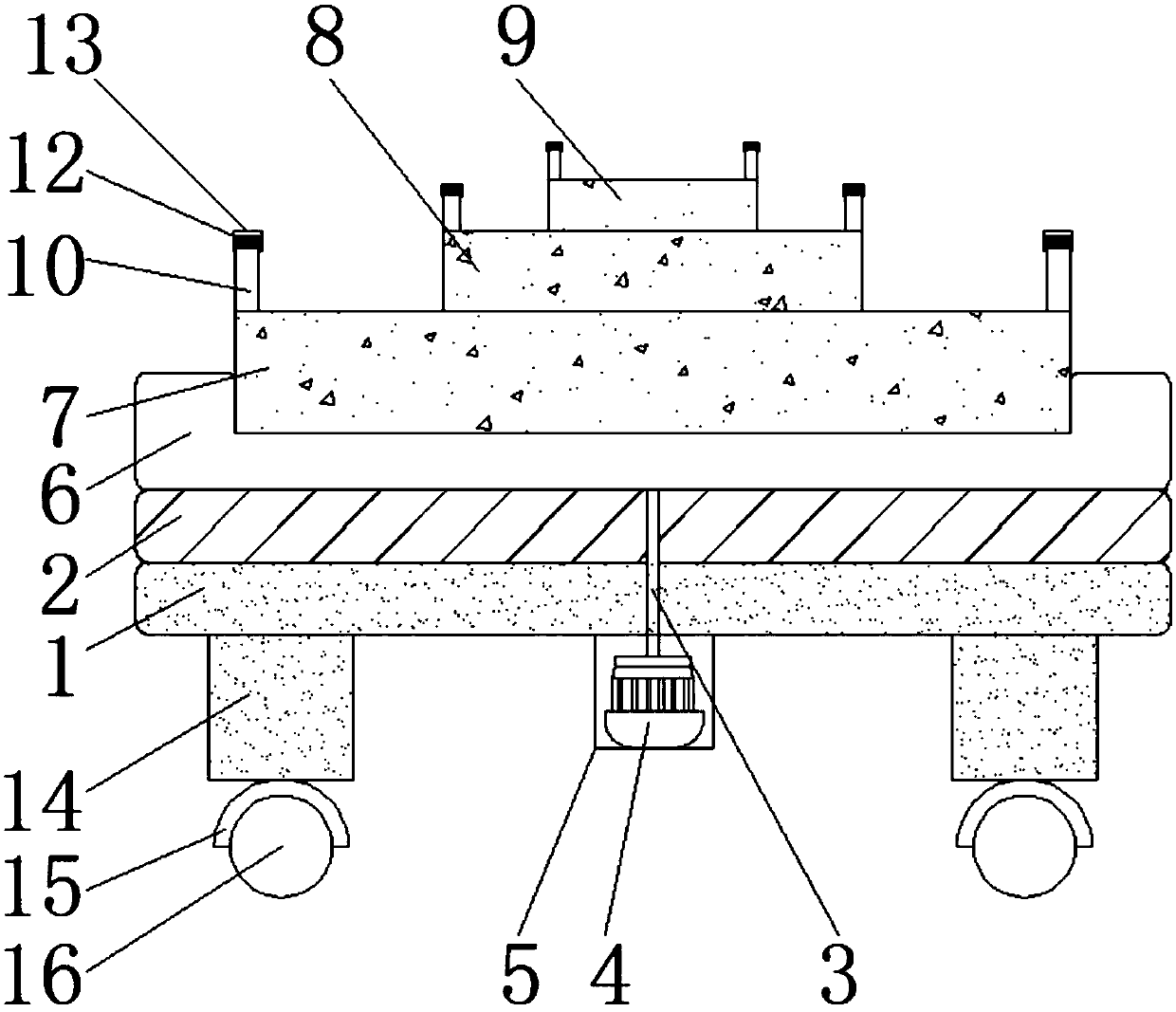

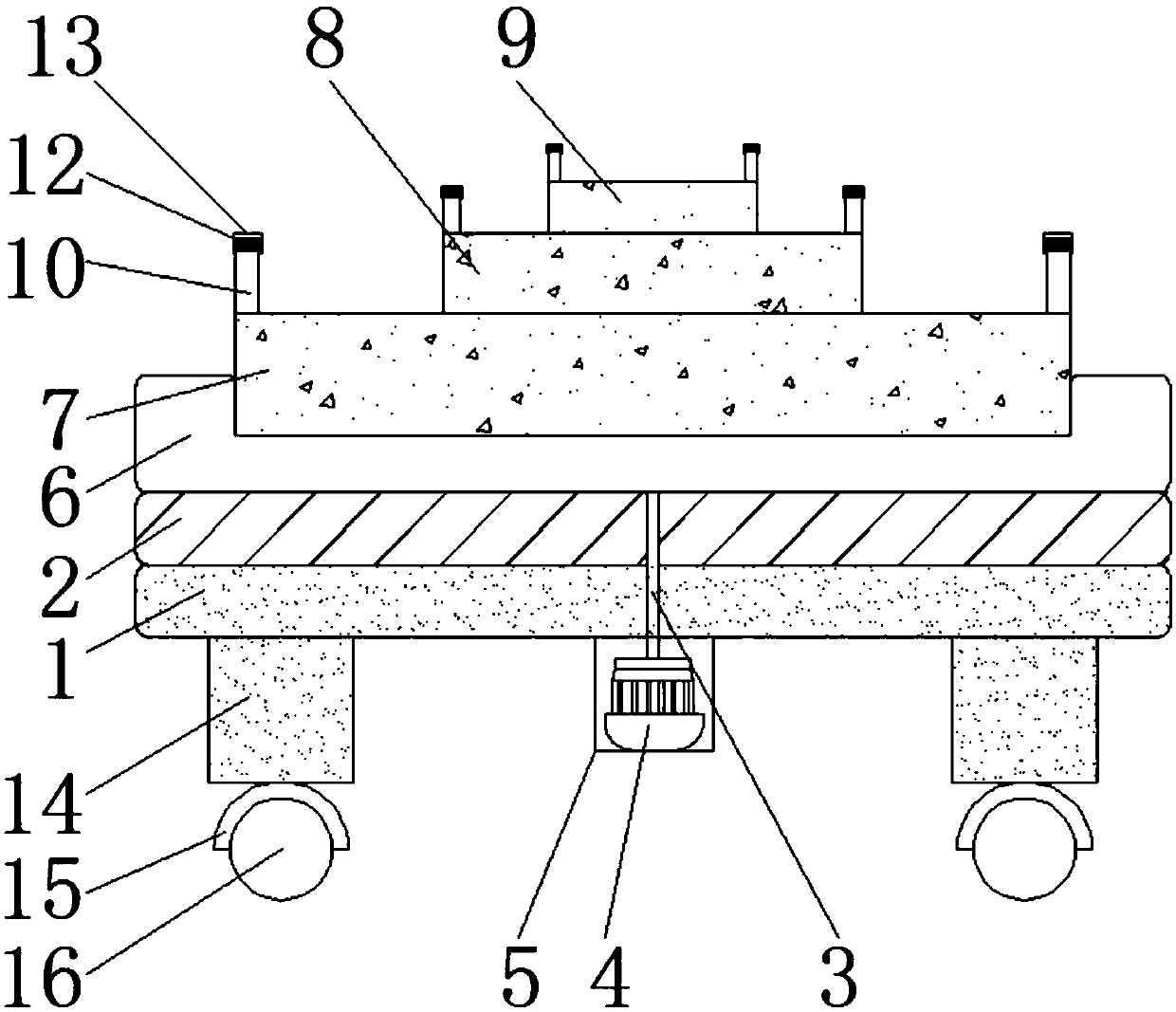

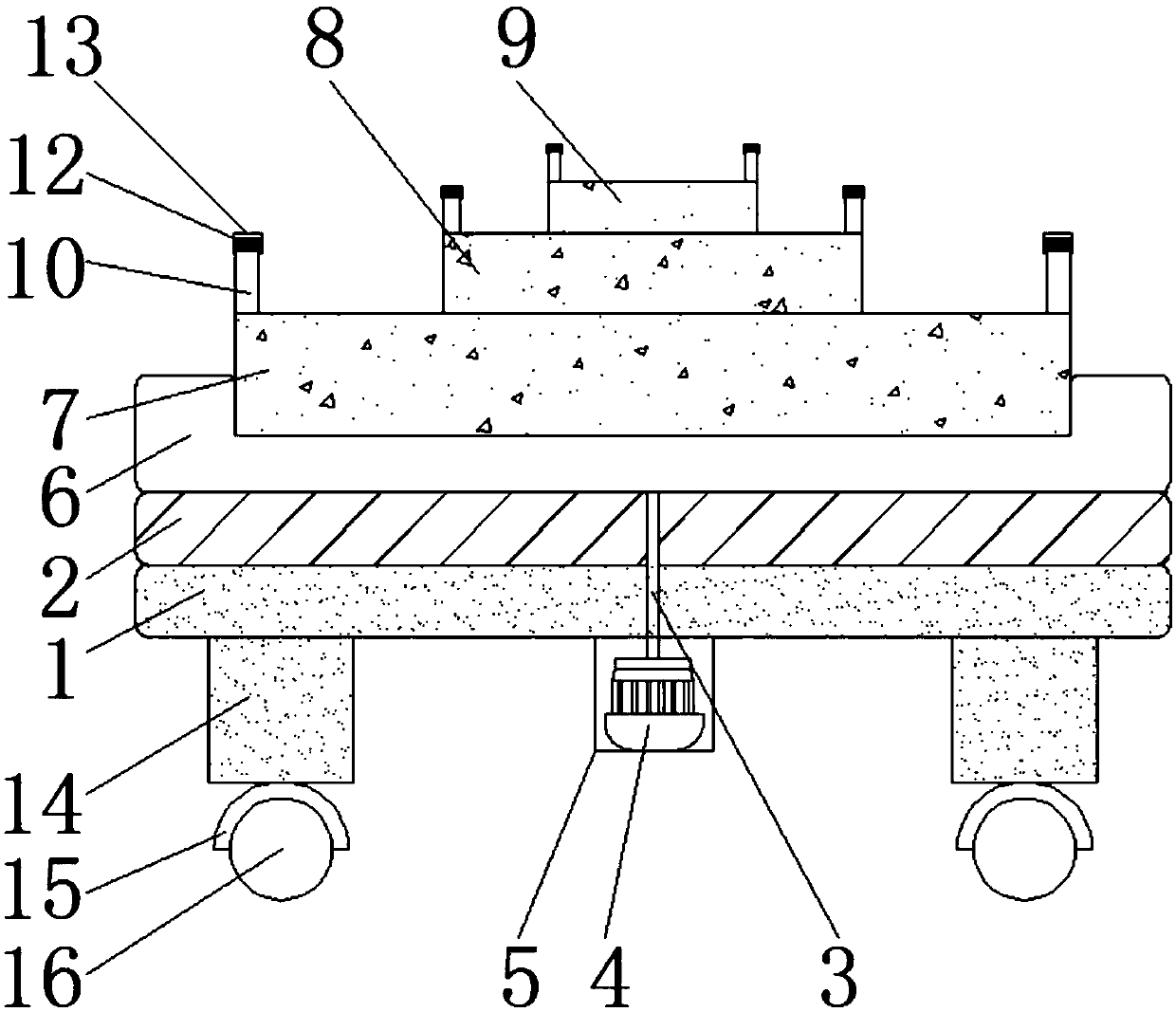

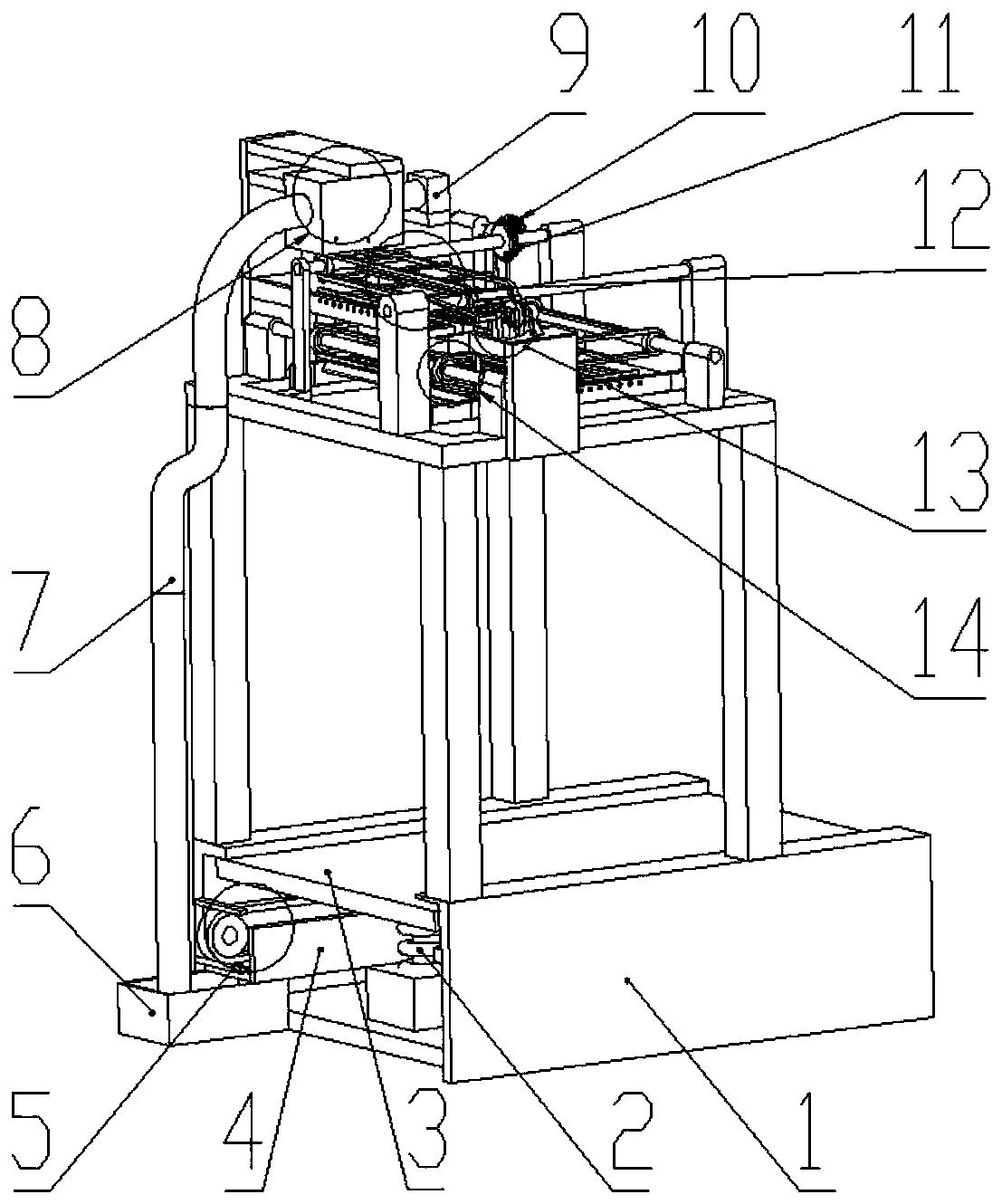

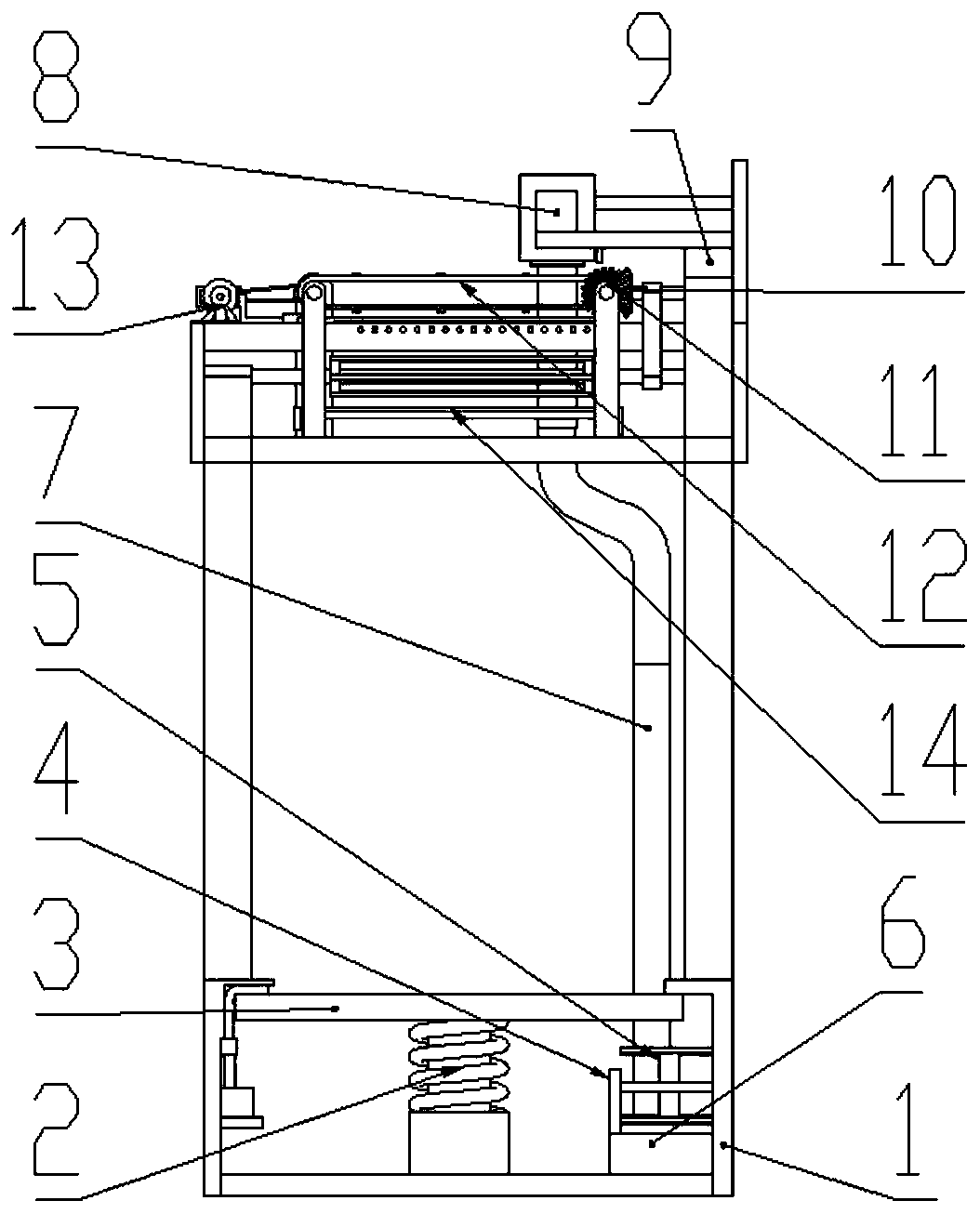

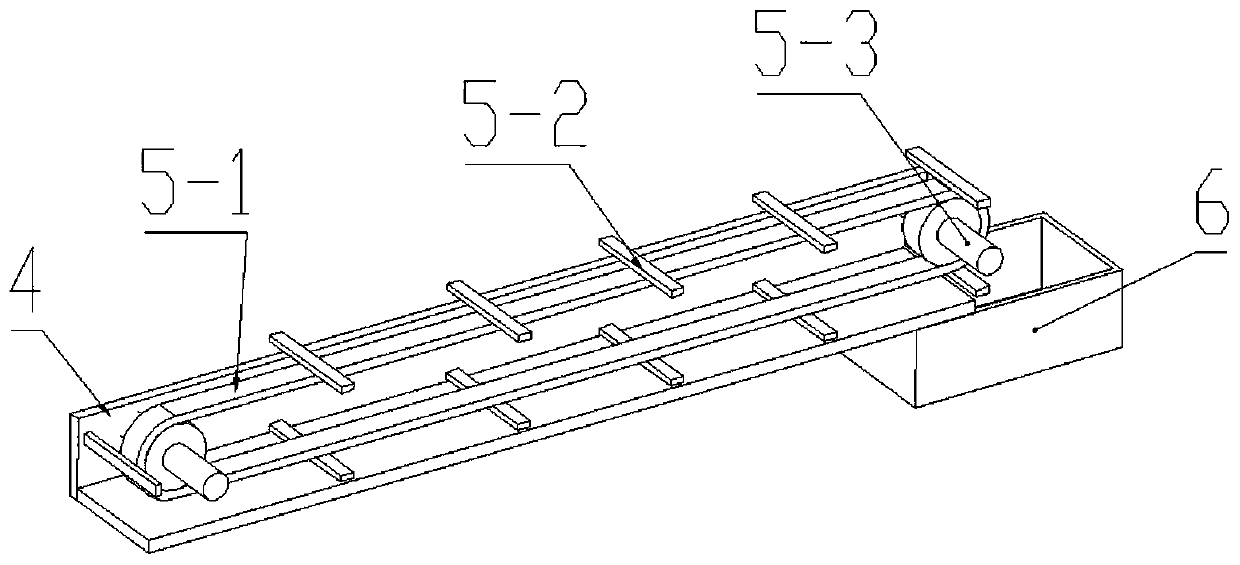

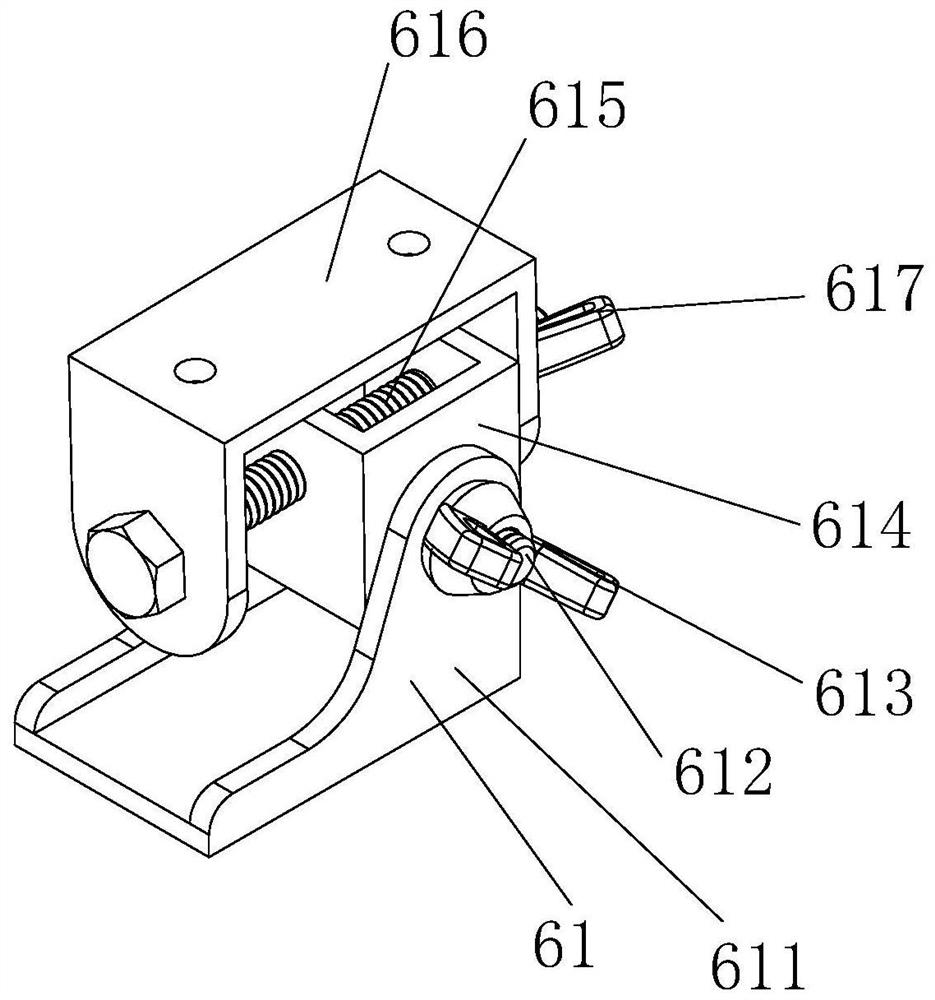

Self-propelled trolley conveying line polling device

ActiveCN105905545ANovel structureGood viewing effectElectromagnetic wave reradiationMechanical conveyorsEngineeringMechanical engineering

The invention discloses a self-propelled trolley conveying line polling device. The device comprises an auxiliary beam and a rail; and the rail is mounted on the auxiliary beam. The device is characterized by further comprising a polling trolley; the polling trolley includes a transparent cover, a main trolley, a secondary trolley, a balance beam, a laser anti-collision sensor, a temperature sensor, a sensor bracket, a combustible gas sensor, a camera, a control center, a signal wire, two balance beam stabilizing devices and two trolley body stabilizing devices; each balance beam stabilizing device includes a guide rod, a nut, a guide sleeve, a large compression spring, a roller base, a roller rotating shaft and a roller; the guide sleeve is mounted in a hole of the balance beam; the roller is mounted on the roller base through the roller rotating shaft; the upper end of the guide rod is welded on the bottom surface of the roller base; and the compression spring coats the guide rod, and is mounted between the bottom surface of the roller base and the upper end surface of the guide sleeve. The device is novel in structure, excellent in polling effect, safe, reliable, low in labor intensity and capable of prominently improving the labor conditions.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

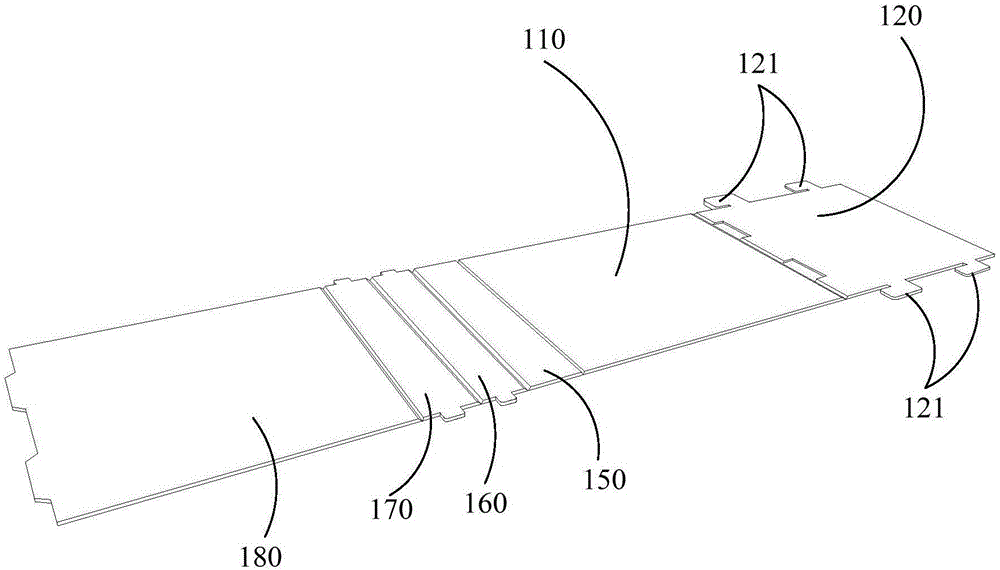

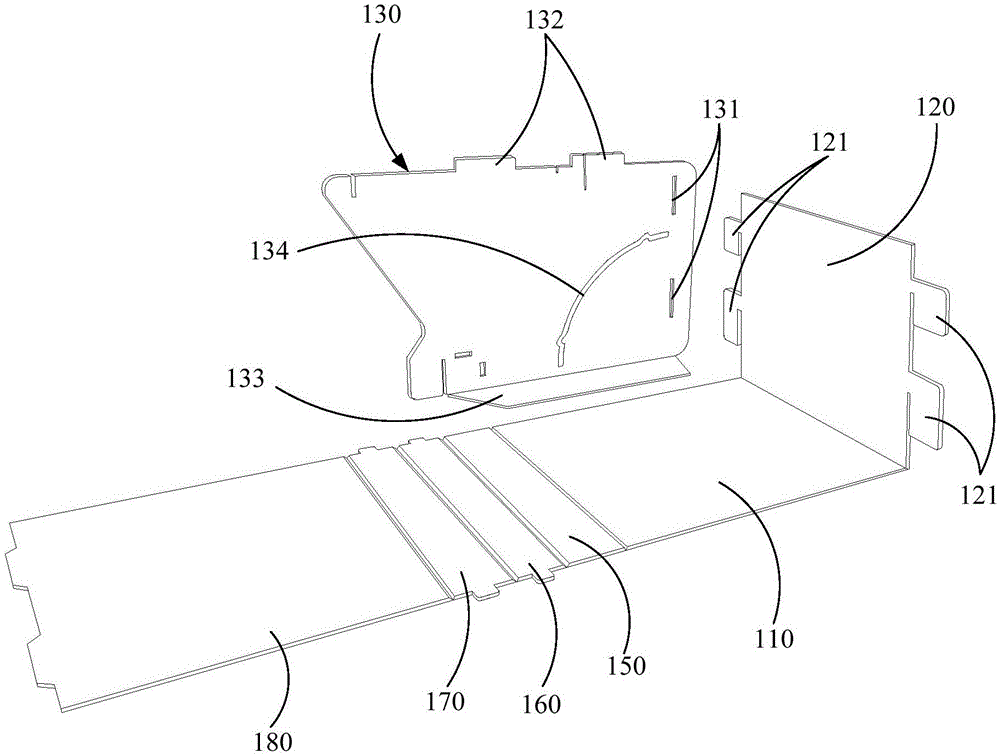

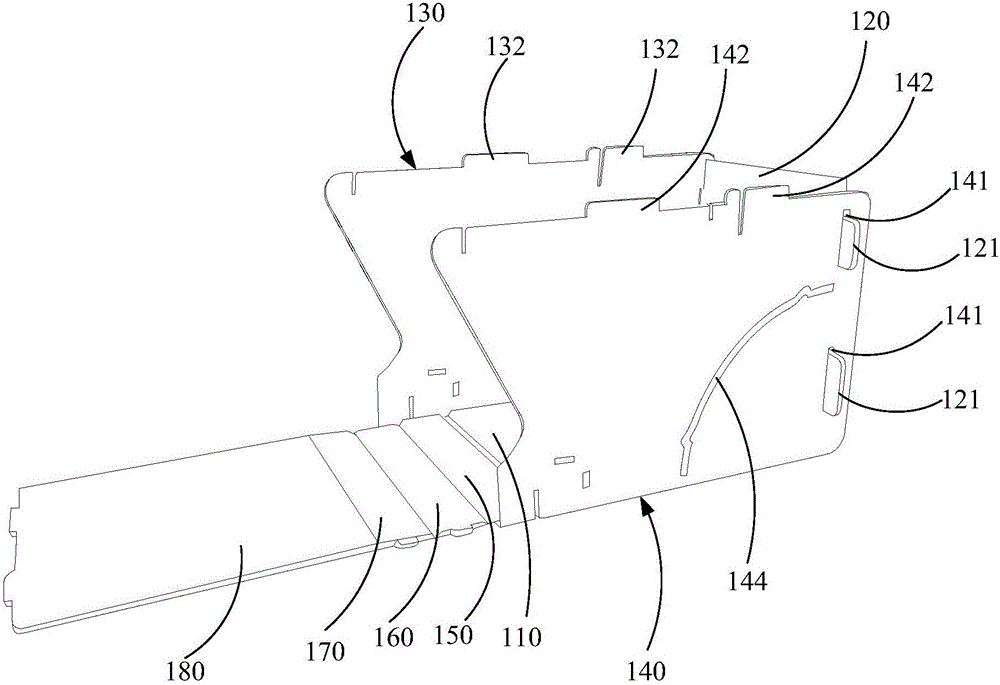

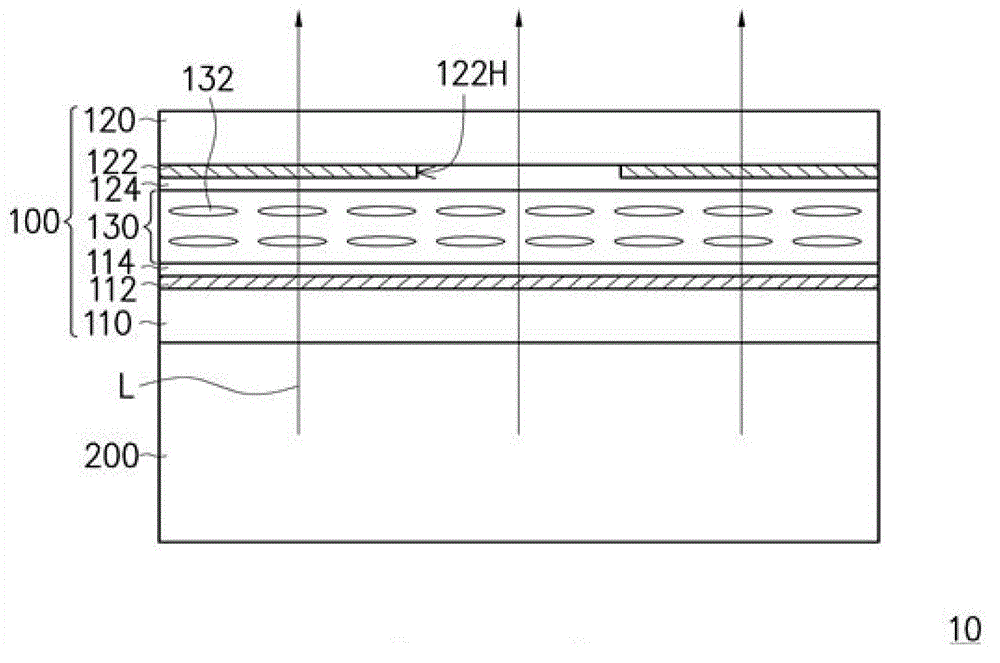

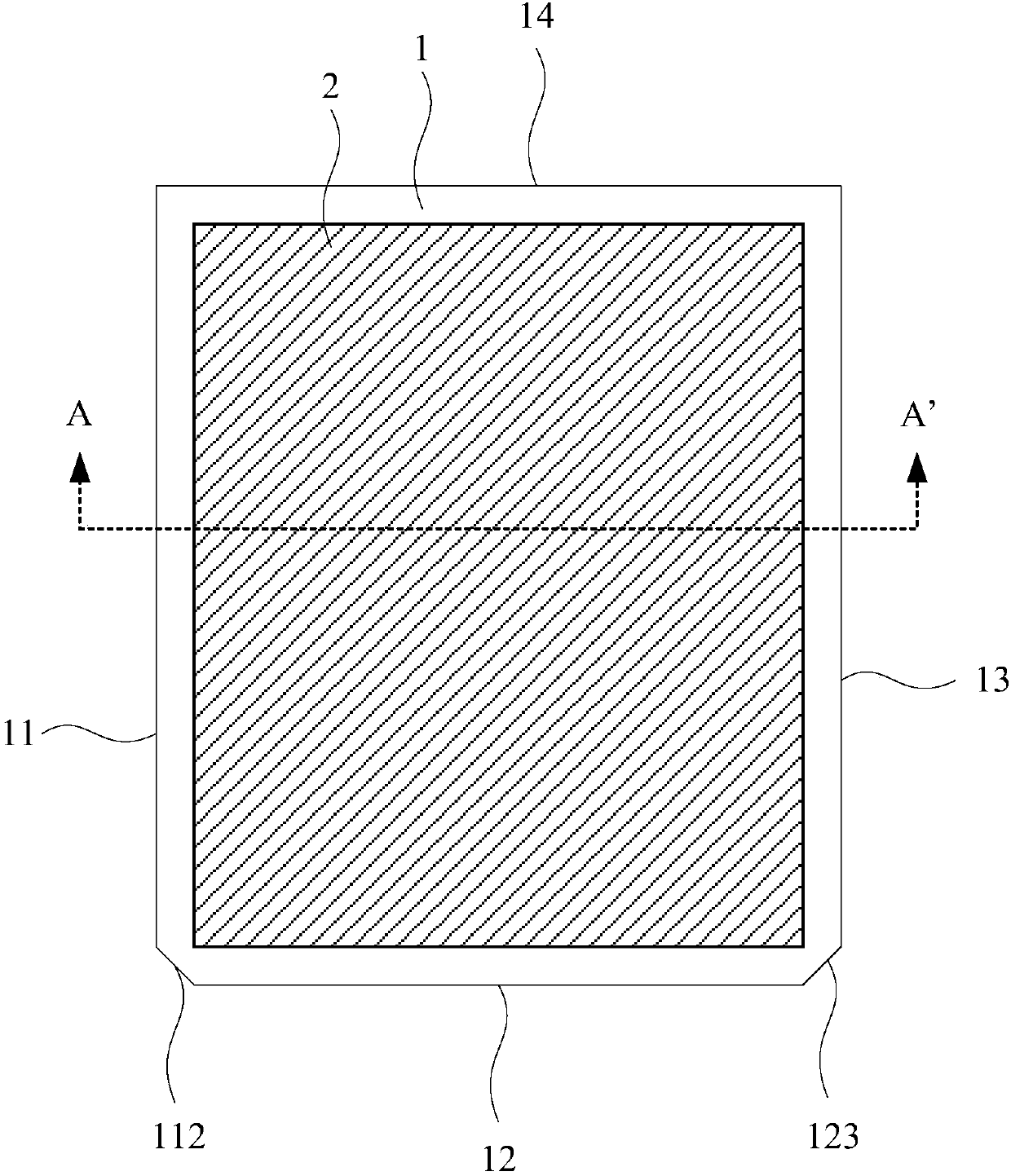

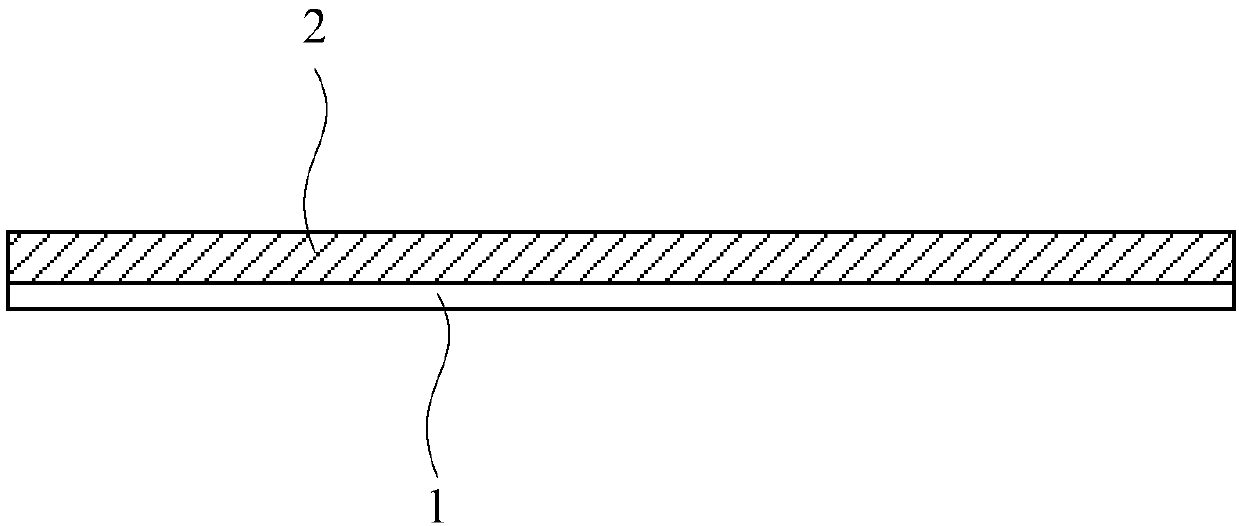

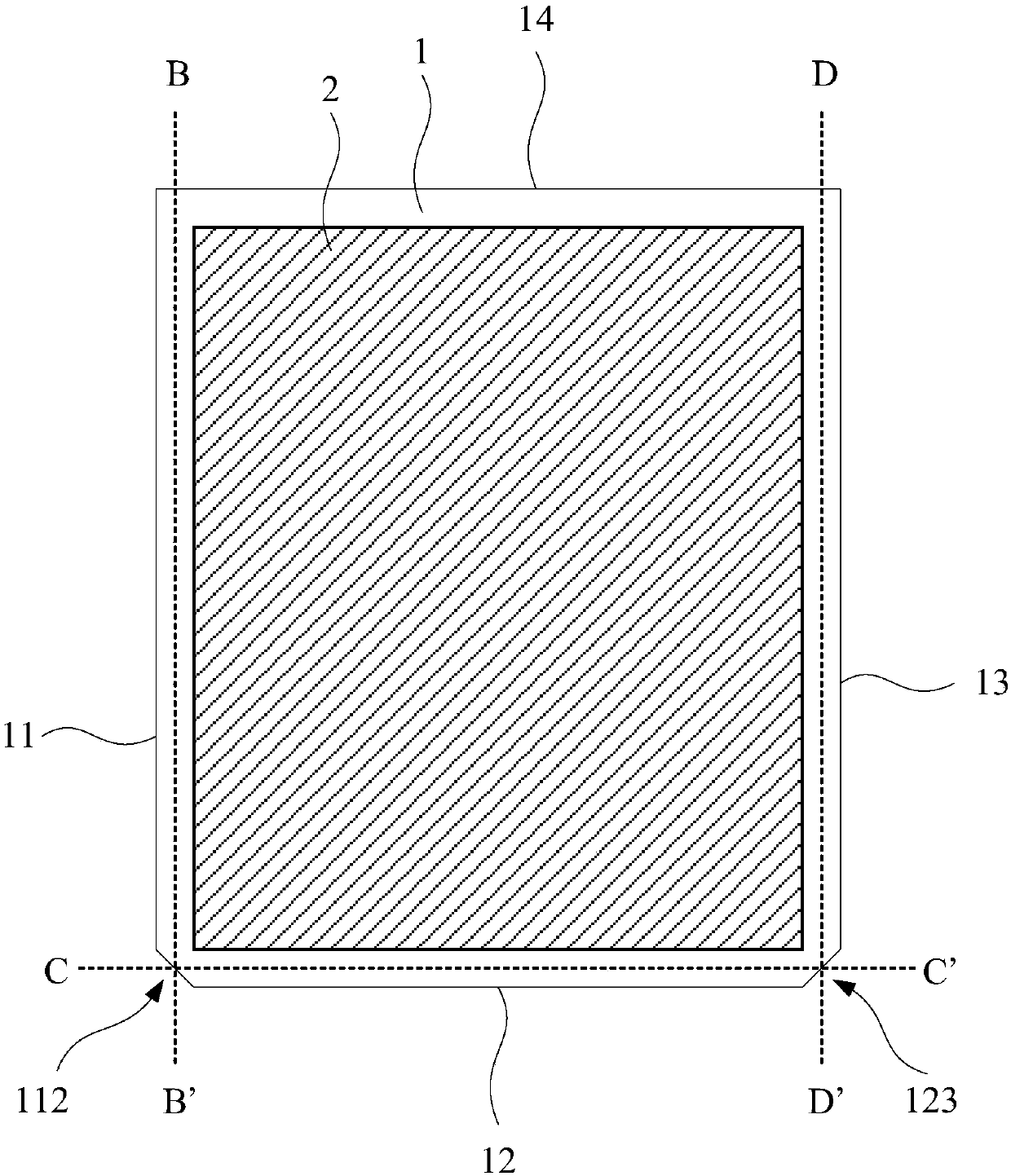

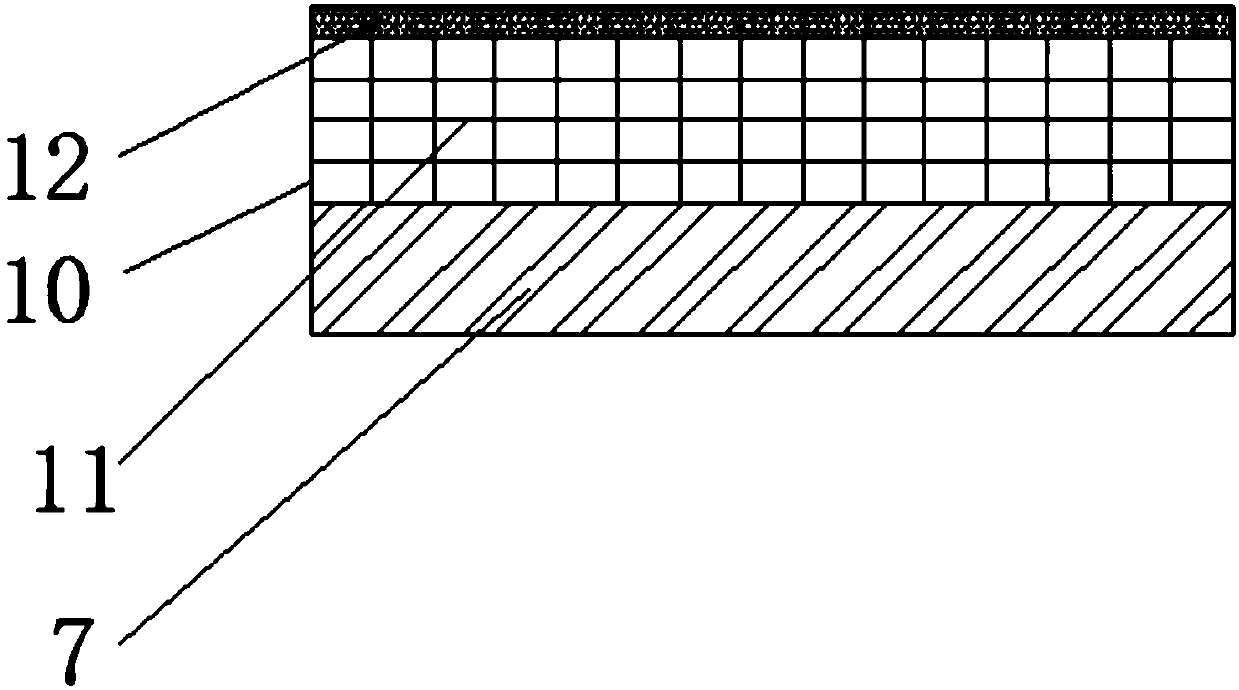

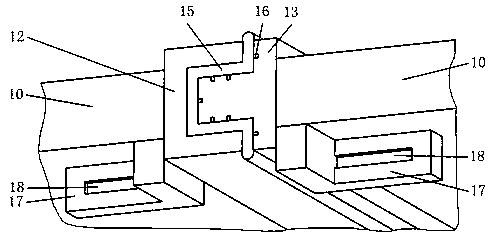

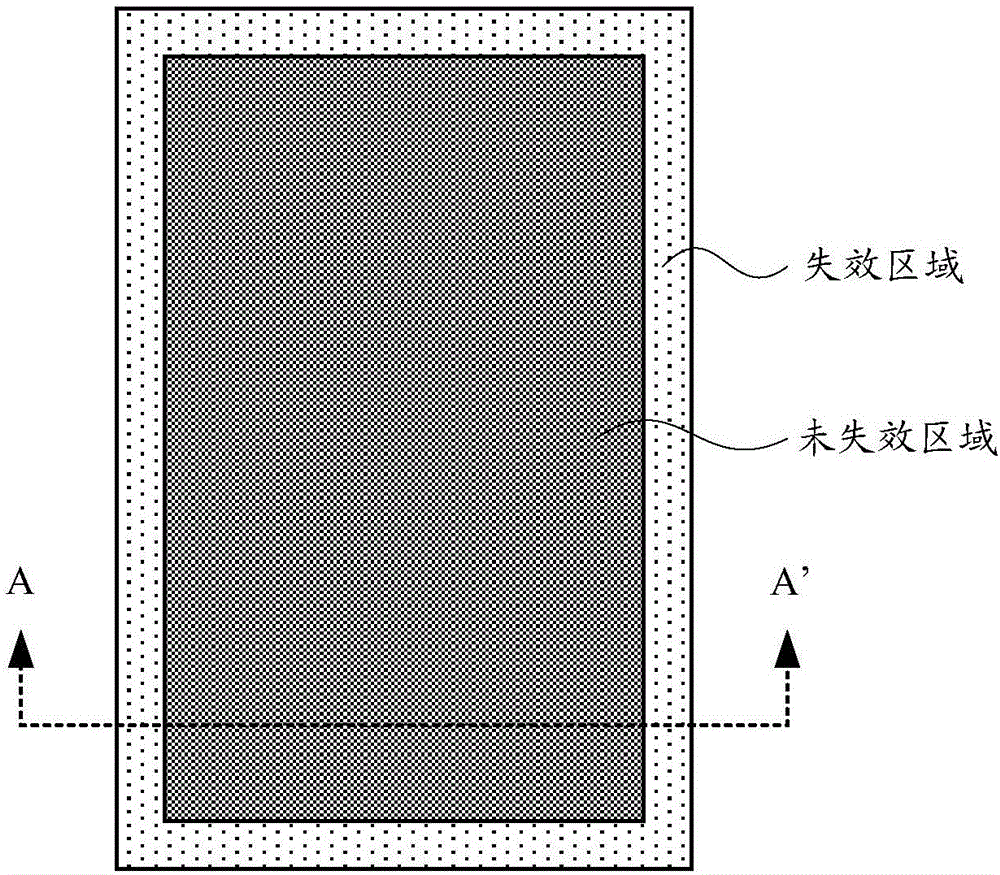

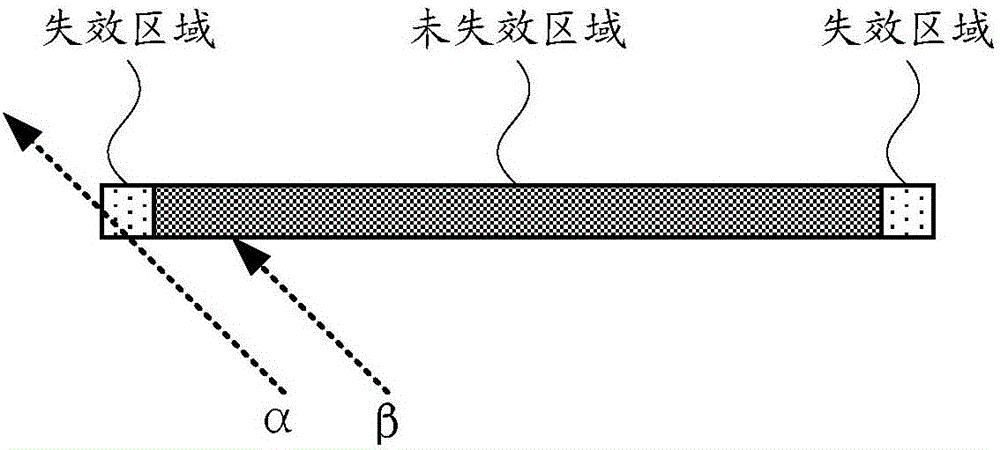

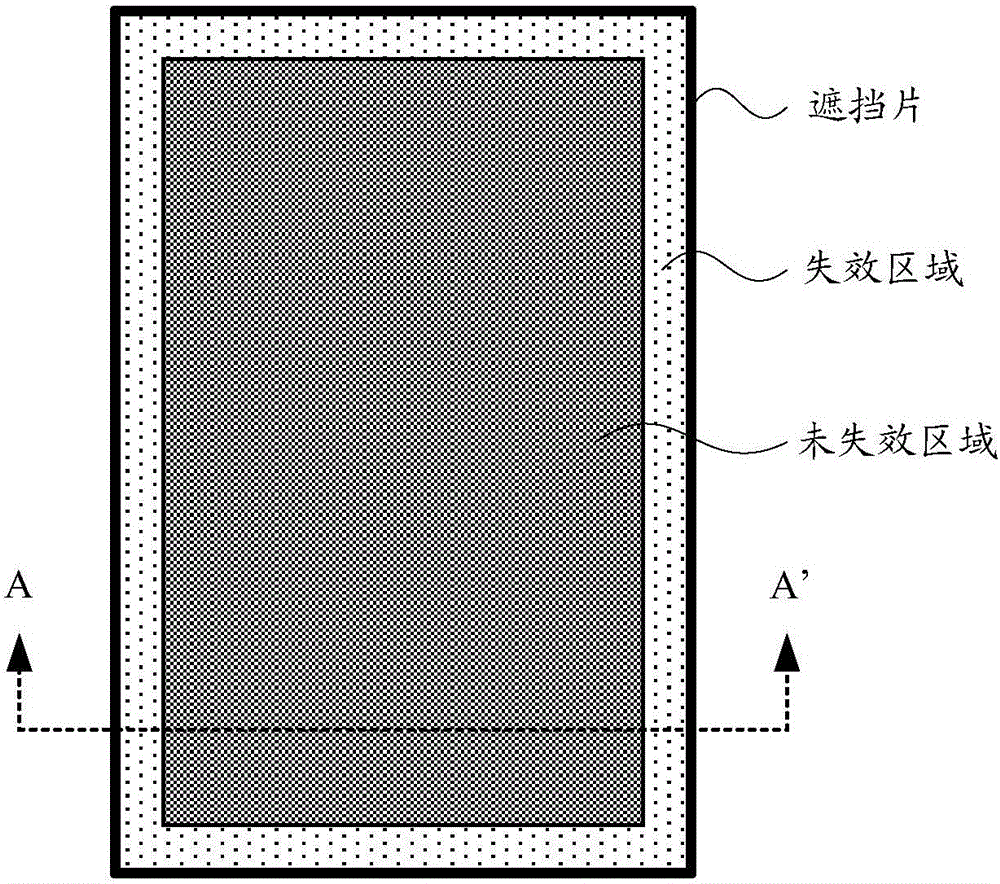

Quantum dot thin film, manufacturing method thereof, display device and electronic equipment

The invention relates to a quantum dot thin film, a manufacturing method thereof and electronic equipment. The quantum dot thin film comprises a quantum dot material layer and multiple shielding pieces which are at least arranged at the edge of the quantum dot material layer and are vertical to the quantum dot material layer. According to a technical scheme of the invention, by arranging the shielding pieces at the edge of the quantum dot material layer, light, which is obliquely irradiated into the quantum dot material layer at a larger angle, of light rays coming from light sources can be shielded by the shielding pieces when the light is irradiated to the shielding pieces, so that the light cannot be irradiated out from the edge of the quantum dot material layer; only the light which is vertically irradiated into the quantum dot material layer can be successfully irradiated out, so that the light in corresponding color with the light sources can be prevented from being leaked from the edge of the quantum dot thin film, and a good viewing effect is ensured.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

A flower sprinkler for ceremonial celebrations

The invention provides a flower strewing device for stages and celebration. The flower strewing device comprises a pedal horizontally arranged, side plates movably arranged on two sides of the pedal,a gas blow pipe which is arranged at the bottom of the pedal on one side of the inner parts of the side plates and is used for blowing flowers and plants to the other side of the pedal, a gathering mechanism which is arranged at the bottom of the pedal on the other side of the inner parts of the side plates and is used for collecting the flowers and plants, and a lifting mechanism which is connected with a straw and the gathering mechanism and used for lifting the flowers and plants to the high place, wherein a buffer assembly is arranged at the lower end of the pedal, and the lifting mechanism comprises a release mechanism for enabling the flowers and plants at the high place to spatter; and the flower strewing device also comprises a horizontal spreading mechanism which is arranged at the lower end of the releasing mechanism and is used for horizontally spreading the flowers and plants along the pedal and a vertical spreading mechanism which is arranged at the lower end of the horizontal spreading mechanism and used for enabling the flowers and plants to spread vertically along the pedal. The flower strewing device for celebration provided by the invention can enable petals for celebration to be durably, unceasingly and periodically sprayed, and cleaning the petals is also convenient.

Owner:游精学

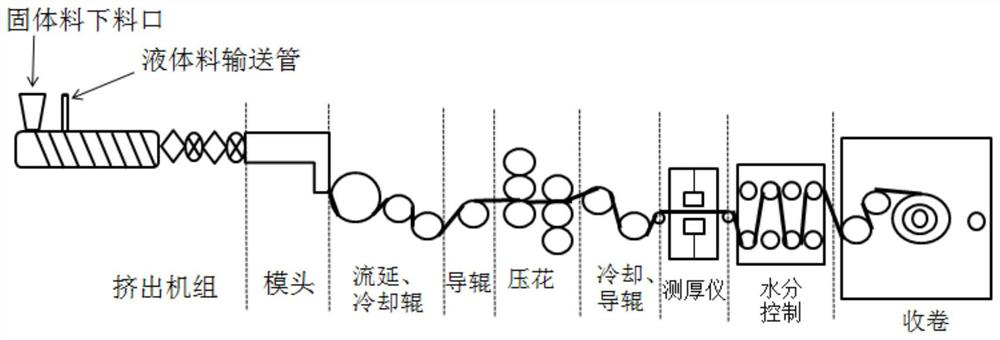

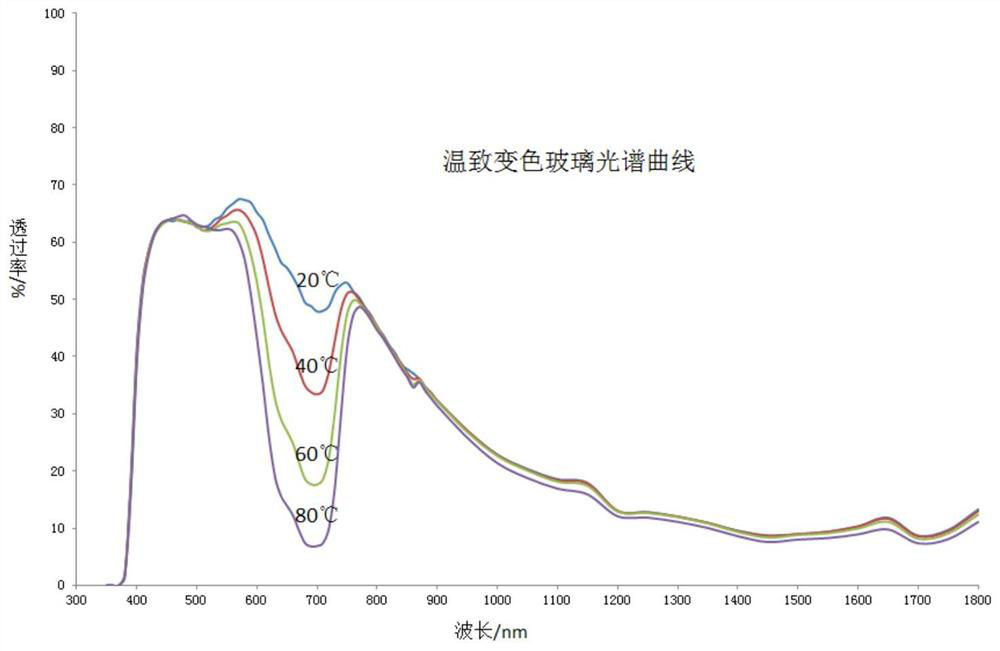

Thermochromic sheet as well as preparation process and application thereof

PendingCN114573935ADoes not affect uniformityDoes not affect permeabilityNon-macromolecular adhesive additivesSynthetic resin layered productsPlasticizerColor changes

The invention provides a thermochromic sheet as well as a preparation process and application thereof, and relates to the technical field of laminated glass, the thermochromic sheet is prepared from the following components in parts by weight: 47-81.45 parts of resin powder, 10-25 parts of a color-changing auxiliary agent, 8-25 parts of a low-polarity plasticizer, 0.2-1.0 part of a nano dispersion liquid, 0.1-1.0 part of an antioxidant and 0.25-1.0 part of a light stabilizer, the components are blended and extruded to obtain the thermochromic sheet, and the thermochromic sheet is prepared from the thermochromic sheet. The method can be applied to manufacturing laminated glass. The thermochromic sheet provided by the invention is transparent in the color changing process, can improve the visible light transmittance of thermochromic glass, and has a good visual effect.

Owner:青岛至慧新材料科技有限公司

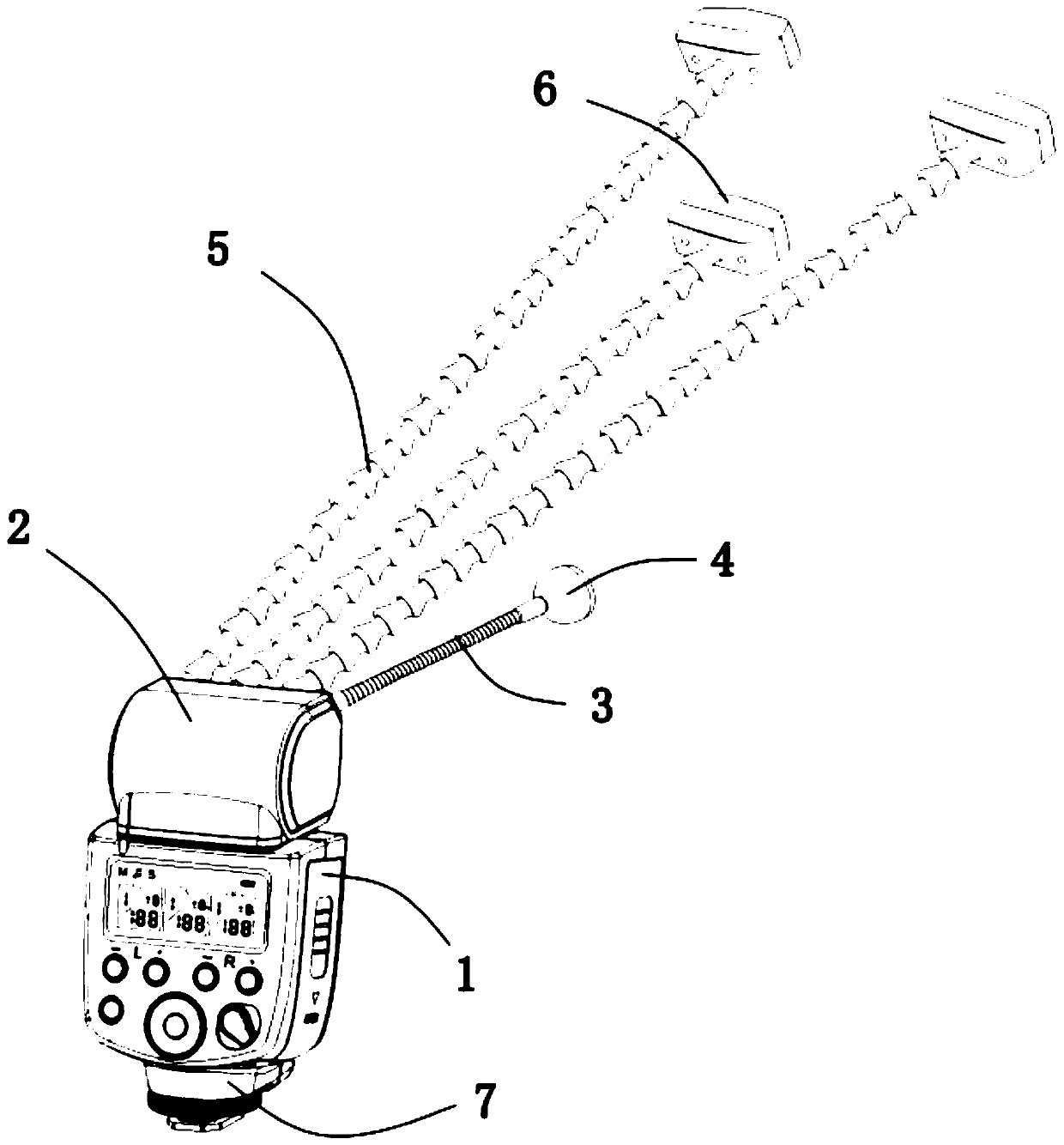

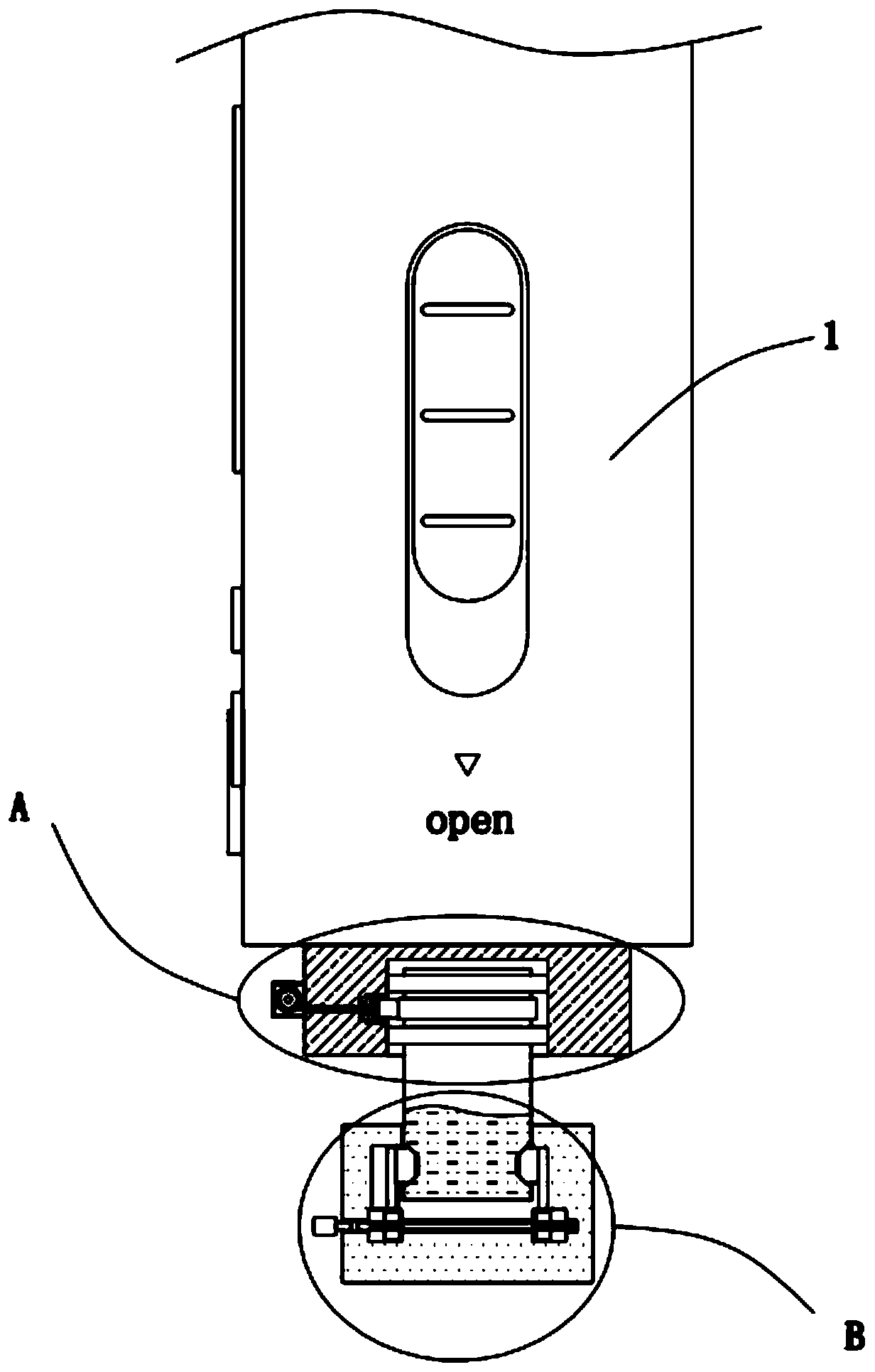

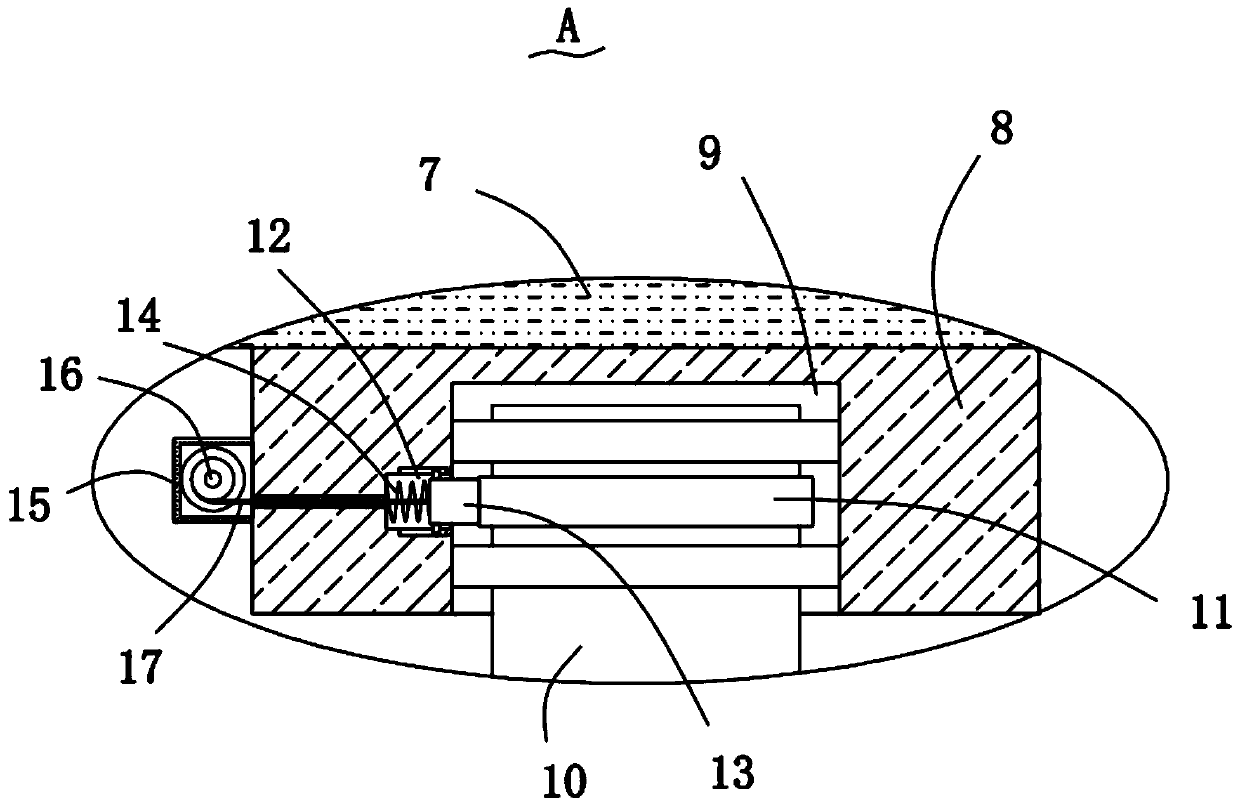

Multi-head lithium battery micro-distance flash lamp

The invention provides a multi-head lithium battery micro-distance flash lamp. The flash lamp comprises a lamp holder, wherein the two ends of the lamp holder are respectively arranged on a connector and a connecting base; a plurality of flash lamp assemblies, wherein each flash lamp assembly comprises a flash lamp head and a first connecting part, and the first connecting part is used for connecting the flash lamp head with the connecting head; an LED focusing lamp which is connected with the connector through a second connecting part. The flash lamp provided by the invention has the advantages of convenience in use, durability, easiness in disassembly and assembly, good light supplementing effect and capability of quickly adjusting the LED focusing lamp.

Owner:张柳洪

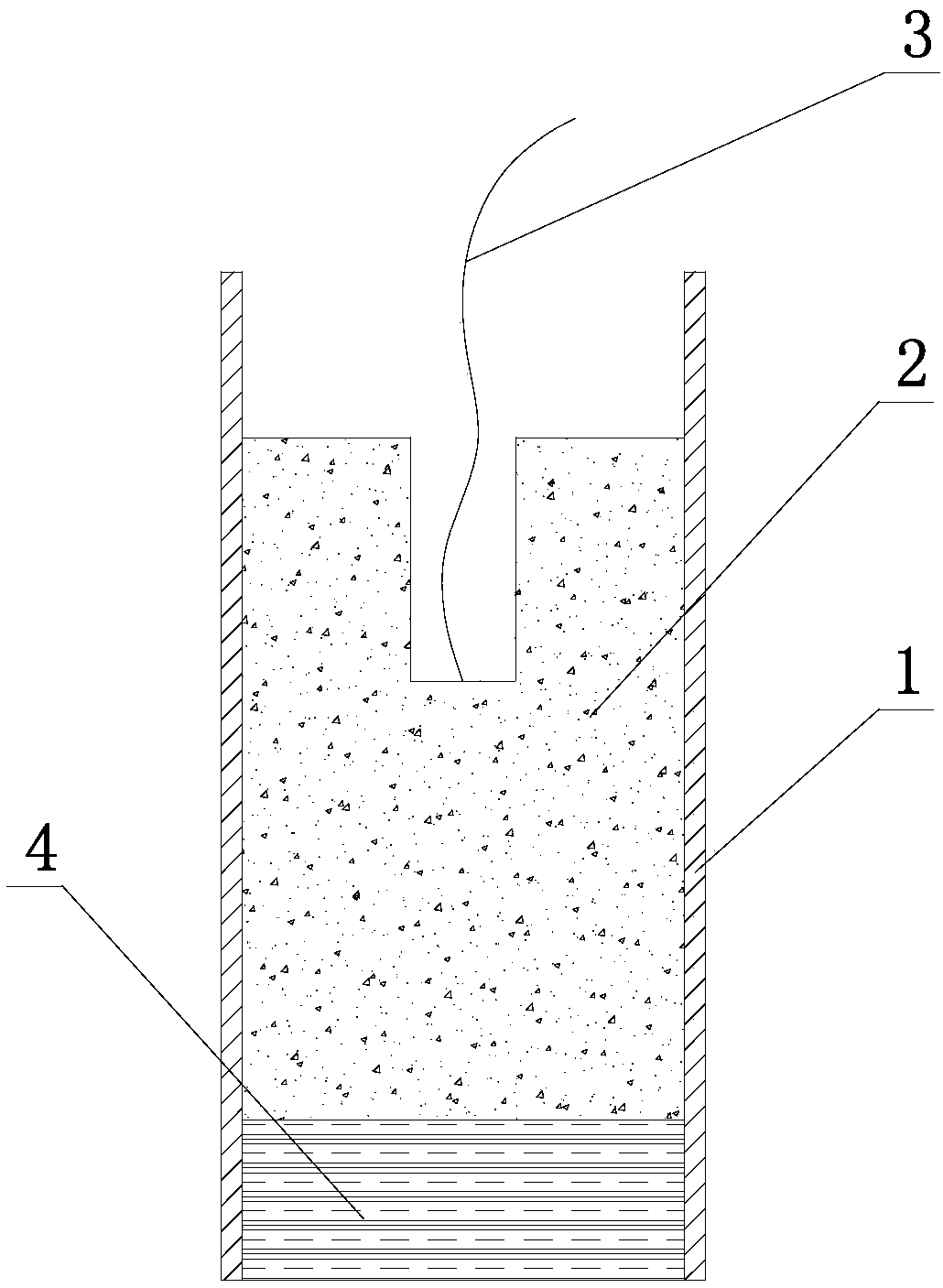

Spray flower firework

The invention discloses a spray flower firework. The firework is characterized by comprising a cylinder body (1) and a mud bottom (4) and an effect medicine column (2) respectively loaded in an innercavity of the cylinder body, the cylinder body is a structure with an opened upper end, the effect medicine column (2) is of a solid medicine column structure, an internally concave and opened chamberis formed in the middle of the upper end, and a lead wire (3) is connected with the bottom end of the internally concave chamber of the effect medicine column. The firework has the advantages of faster injection speed, larger injection force, higher injection height, improved igniting effect, reduced production cost and the like.

Owner:罗友明

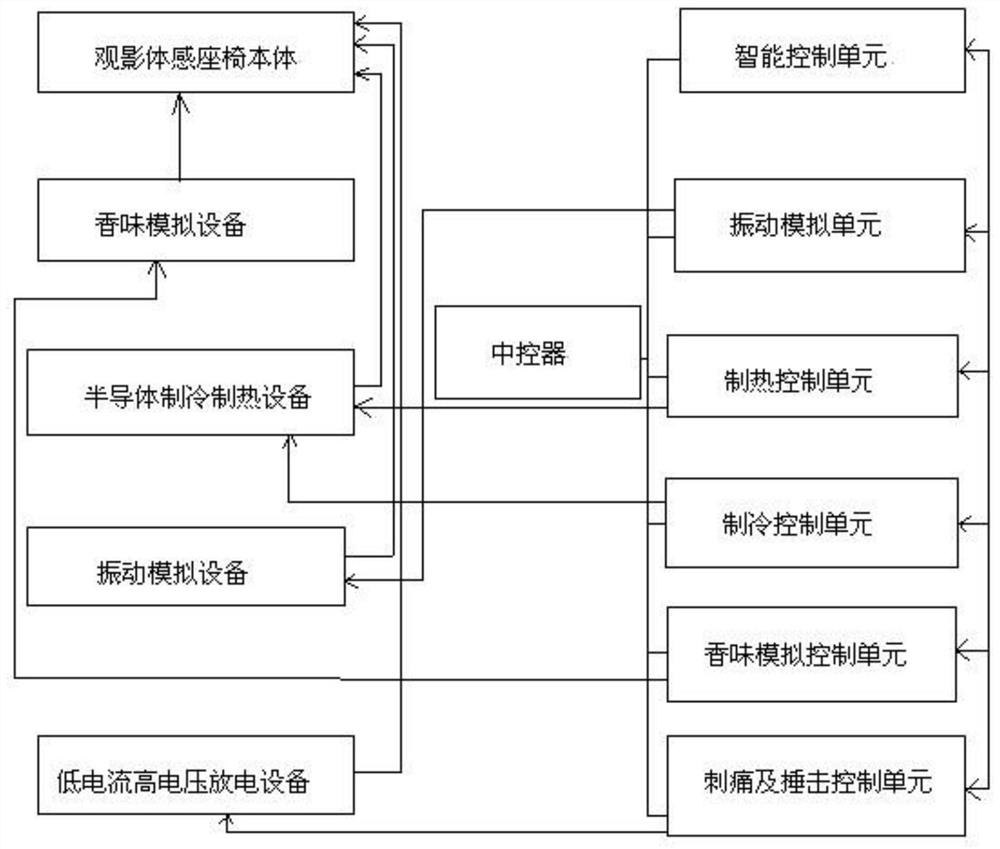

Moving-felt platform sensory simulation device

PendingCN112657215AImprove the sense of bodyGood viewing effectCinema apparatusApplication softwareAnalog control

The invention relates to a moving-felt platform sensory simulation device. The device comprises a viewing somatosensory seat body, a fragrance simulation device, a vibration simulation device, a semiconductor refrigeration and heating device and a low-current high-voltage discharge device. The device further comprises a central controller, a fragrance simulation control unit, a vibration simulation unit, an intelligent control unit, a heating control unit, a refrigeration control unit and a stabbing pain and hammering control unit. The fragrance simulation device, the vibration simulation device, the semiconductor refrigeration and heating device and the low-current high-voltage discharge device are installed on the seat body; the fragrance simulation control unit, the vibration simulation unit, the intelligent control unit, the heating control unit, the refrigeration control unit and the stabbing pain and hammering control unit are application software installed in the central controller. According to the device, an audience sitting on the somatosensory seat body can visually feel the fragrance, the vibration sense, the cold and hot temperature and the stabbing and hammering feelings like movie plots in real time, so that the somatosensory feeling of the audience during movie watching is improved, and a better movie watching effect can be achieved.

Owner:上海赛因斯文化科技集团有限公司

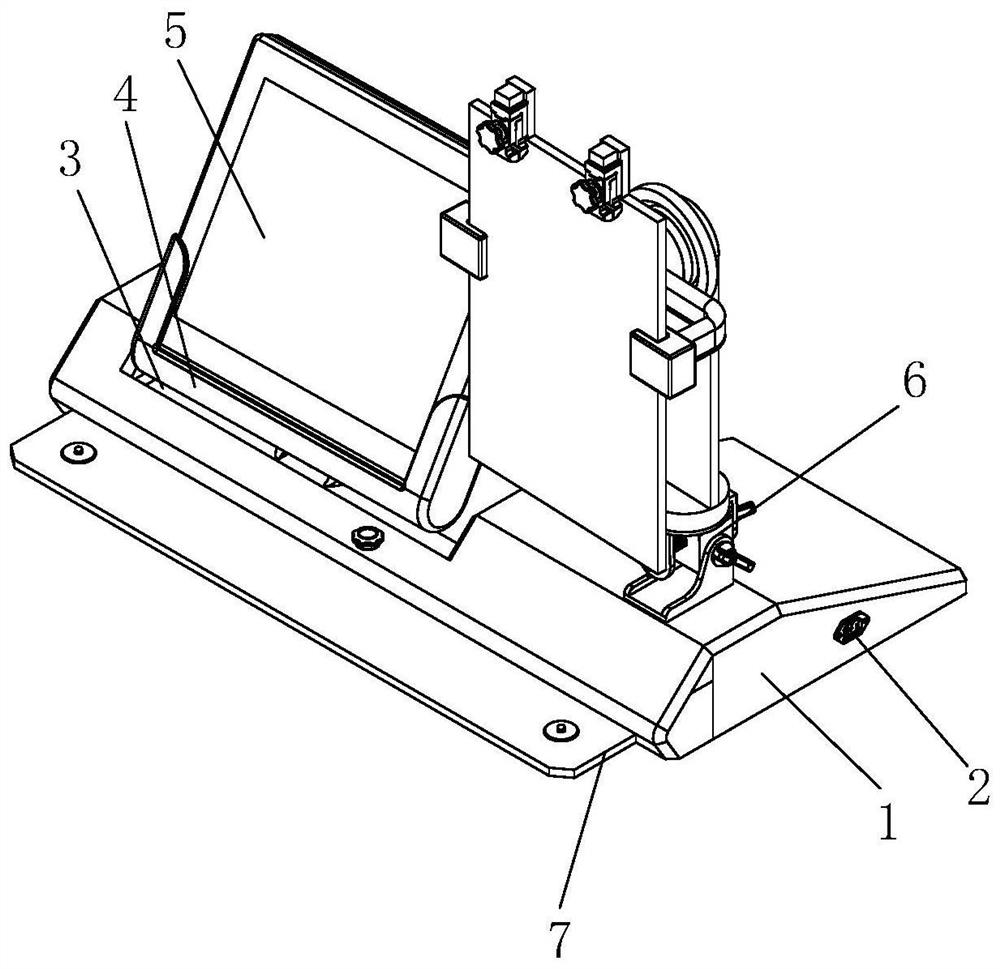

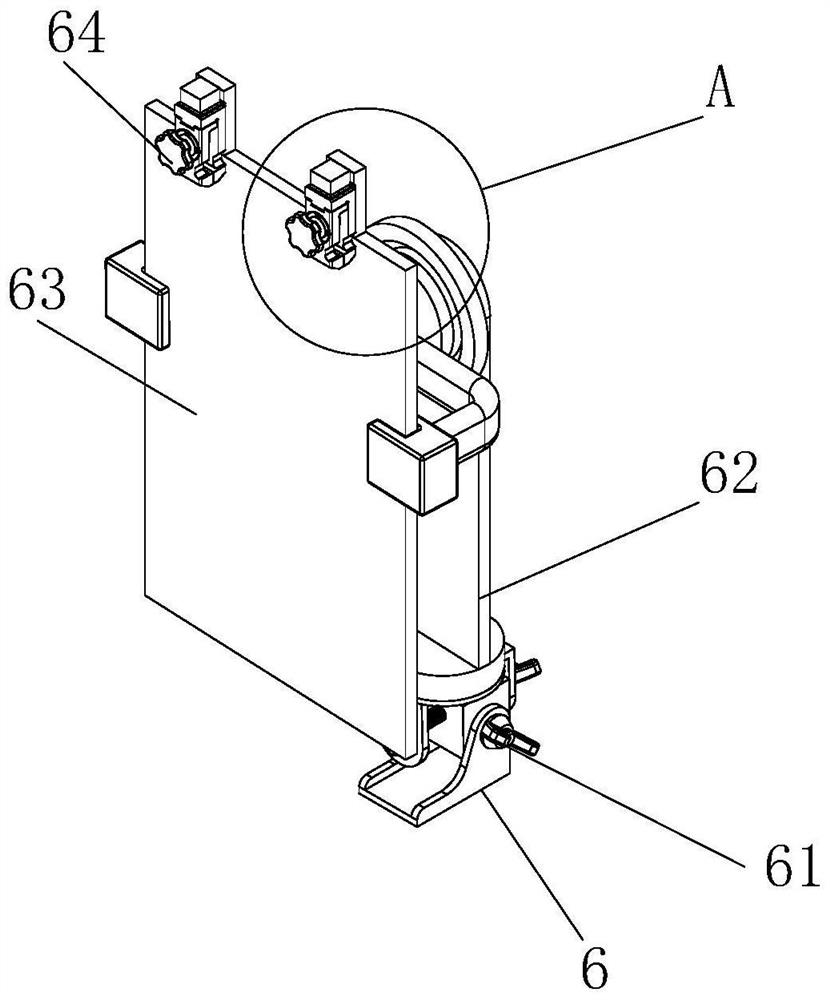

Artificial intelligence English learning device convenient to operate

The invention discloses an artificial intelligence English learning device convenient to operate. The learning device comprises a base, a power interface, a placement groove, a mounting piece, a learning device main body, an auxiliary learning device and a bearing device, the auxiliary learning device is mounted at the right end of the top of the base; the auxiliary learning device is internally provided with a fixing plate, the fixing plate is provided with a fixing mechanism, the fixing mechanism can fix some paper or some reference materials, a user can write and record conveniently, teaching assistance is effectively carried out in the English learning process, and the learning efficiency is improved; a bearing device is mounted at the front end in the base; a bottom pad can be pulledout of the bearing device; the bottom pad can support the hands of a user, comfort is provided for the user when the user records and uses the learning device, and a stabilizing mechanism is installedin the bottom pad and can be tightly fixed to a table top, so that the overall stability of the device is improved, and English learning of the user is effectively assisted.

Owner:福建九州宇圣科技有限公司

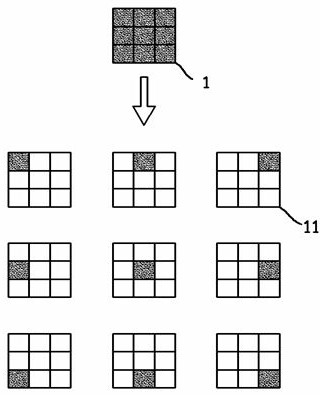

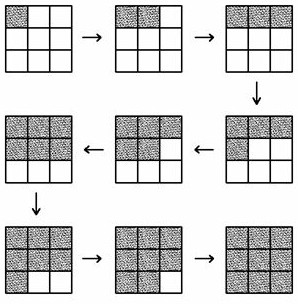

Anti-jamming video transmission and reception method

The present invention provides an anti-jamming video transmission and reception method, including a server-side transmission method: dividing each frame of a video program into a series of tile units that are tiled into the frame, and each tile unit is M*N the pixel matrix of each block unit; the pixels in each position in each block unit are sequenced to form MN pixels; the pixels with the same sequence number are extracted in each block unit to form a sub-picture of a frame corresponding to the block unit, A total of MN sub-pictures of the frame picture are obtained; the server side sends the sub-pictures of each frame picture to the client in turn, and the time interval between two adjacent frames in the video program is T. If the total transmission time of the sub-pictures of a certain frame picture reaches T, ignore the remaining sub-pictures of the frame, and directly transmit the sub-pictures of the next frame; Watch the picture effect in the best resolution.

Owner:深圳市通立威科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com